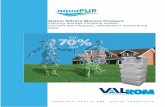

Sistem Filtrare Stocare Pompare Filtering Storage Pumping ...

FRL - Ultrafilterultrafilter.ro/wp-content/uploads/2017/04/Filtrare... · 2018. 4. 5. · FRL units...

Transcript of FRL - Ultrafilterultrafilter.ro/wp-content/uploads/2017/04/Filtrare... · 2018. 4. 5. · FRL units...

-

AG Büssingstraße 1 · D-42781 Haan · Telefon ++49/2129/569-0 · Telefax ++49/2129/569-100

Technical alterations reserved (Date 03/03)

The quality demands on compressed airpurity are set by the individual compo-nents. With a centralized purification theentire compressed air generated has to bepurified to meet the quality requirementsof the most sensitive application. Localcompressed air treatment with ultrafilterFRL units supplies each individual appli-cation exactly with air quality required andtherefore avoids costly superqualificationof compressed air for low demand purpo-ses.

Decentralized compressed air purificationcan decrease operation costs, especiallyin the case, where only a few applicationsrequire higher qualities.

Step by step – the purification process

The distinctive advantage of the ultrafilterFRL is the various combinations whichoffer individual solutions for every applica-tion.

FRLModular compressed air purification.

The ultrafilter purification chain starts witha Filter/Water separator. It retains bulkparticle contamination by a sieve effectand contains a cyclone separator to remo-ve water and oil droplets from the com-pressed air.

The filter/water separator prevents the fol-lowing high efficiency filter from bulk con-tami-nants, and therefore avoids pollutionrelated problems like short overall lifetimeor high differential pressures.

The next important step on your way tocompressed air purified exactly to the indi-vidual requirement is filtration.Dependingon inlet as well as outlet parameters filtra-tion can be designed purely as a one stageFRL component but also up to a several-stage maximum retention device.

ultrafilter offers the proven submicrofilterSMF with patented binder free filtermedium ultrair, already in the standard ver-

sion. High volume flows, low differentialpressure and high dirt retention capacitiesallow these filters to fulfil all requirementsconcerning highest operation scurity andoptimzed economy.

-

AG Büssingstraße 1 · D-42781 Haan · Telefon ++49/2129/569-0 · Telefax ++49/2129/569-100

Technical alterations reserved (Date 03/03)

The Plus from ultrafilter – dry compressedair

Leaving the last filtration stage the com-pressed air is free of particles, oil andwater but far from being dry. ultrafilter hastherefore integrated their proven membra-ne dryer in the FRL system.Air coming from the filters enters the inte-grated dryer and is led through the centreof a bundle of hollow fibres. Moisture dif-fuses across the semi-permeable mem-branes as air moves through the centre ofthe hollow fibre bundle. A small portion ofthe dried compressed air is led back overthe outside of the fibre bundle and ventedto atmosphere via outlets. The dry air pro-duced leaves the system in order to drivethe application or to enter the next purifi-cation step.

Always the right pressure.Different pneumatic components usuallyrequire different operation pressures. Thepurified compressed air comes with an

operating pressure generated in a centralcompressor station. The operating pressu-re has to become adjusted to the individu-al pneumatic components. An implemen-ted regulator ensures that the maximumpressure for the pneu-matic componentwill not be exceeded and eliminates thetransmission of pressure shock waves.

No bitter aftertaste. After filtration and drying the purified com-pressed air still contains oil and wateraerosols and odour. If the following pneu-matic components requires absolutely oil-free compressed air, e.g. in food industry,these aerosols must be eliminated by anactivated carbon filter.

ultrafilter Oil Mist Lubricator – and every-thing will work out fine.Usually pneumatic cylinders and actuatorsdepend on a constant amount of lubrica-ted compressed air in order to do their jobwith the required precision and repeatingaccuracy. These pneumatic components

therefore depend on a certain amount ofoil only a lubricator can ensure. The ultra-filter mist lubricator ensures function ofpneumatic components and improves ope-ration time.

1 Filter-Water-Separator with cyclone system and filter element, filterelement available in different poresizes

2 Submicrofilter equipped with ultrafilterfilter element ultrair® SMF

3 VarioDry FRL with integrated purge airnozzle and internal regeneration air duct

4 Pressure Regulating Valve and PressureGauge for outlet pressure visualisation,handwheel lockable

5 Activated Carbon Filter equipped withultrafilter filter element ultrac® AK

Modular Compressed Air Purification with integrated Dryer:VarioDry FRL

� � � � �

-

Technical data

AG Büssingstraße 1 · D-42781 Haan · Telefon ++49/2129/569-0 · Telefax ++49/2129/569-100

Technical alterations reserved (Date 03/03)

Type

FRL

capacity connection

G”m3/h1) m3/h1) l/min1)

weight

kgSF 0002SF 0005SF 0010SF 0015SF 0020SF 0025SF 0035SF 0050SF 0065SF 0080SF 0100SF 0125SF 0150

2,551015202535506580

100125150

0,040,080,170,250,330,420,580,831,081,331,672,082,5

4283

16725033341758383310831333166720802500

1/4”1/4”1/2”1/2”1/2”1/2”1/2”1/2”1”1”1”1”1”

2,12,53,23,43,63,86,16,712,215,819,52222

325495540540540540540540720720720720720

8585

110110110110127127305395485575575

50506363636363639292929292

dimensions in mm

H W

operating pressure pg barcorrective factor fpü

5 6 7 8 9 10 11 12 13 14 15 160,57 0,78 1,00 1,21 1,42 1,64 1,85 2,06 2,28 2,49 2,70 2,92

··

Vnom.Vcorr = ––––fpg

* Dimensions for Membrane Dryer only.

1) volume flow refers to compressor inlet(20°C, 1 bar),Ambient temperature 25°C.Operating pressure 7 bar g.Inlet temperature 35°C according to DIN ISO7183.Performance date given refer to a PDP reductionof 20°C and a regeneration air flow of 10 %.Min. ambient temperature: 2°C;max. ambient temperature: 60°C.

Filter 0002 to 0050 with polycarbonat-housing.Filter 0065 to 0150 with metal housing.

operatingparameter

Membranedryer

othercomponents

Optional:other components

min. max. min. max. min. max.operating pressureInlet Temperature

5 bar2oC

16 bar60oC

0,5 bar2oC

10 bar50oC

0,5 bar2oC

16 bar80oC

W W DD

D

-

AG Büssingstraße 1 · D-42781 Haan · Telefon ++49/2129/569-0 · Telefax ++49/2129/569-100

Technical alterations reserved (Date 03/03)

ultrafilter FRLPrefilter PEHousing with filter element PEcyclone separator and drain

Technical data

nominal2) m3/hmaximal3) m3/h

min. °Cmax. °Cmin. °Cmax. °Cmin. barmax. bar30 µm5 µm15) µmin %6)

manualsemi-automatical7)

automaticalpolycarbonat

Metall with sight glassmetal

Descriptionmodel1)

connectioninstallation

volume flow

inlet temperature4)

ambient temperature4)

operating pressure

pore size

retention rate

condensate drain

bowl material

PE 1/4-51/4”

vertical33860

50°C at 10 bar0

50°C at 10 bar016

optionstandardoption95 %

standardoption

-standardoptionoption

PE 1/2-5A1/2”

vertical1143000

50°C at 10 bar0

50°C at 10 bar016

optionstandardoption95 %optionoption

standardstandardoptionoption

PE 1-51”

vertical3008400

50°C at 10 bar0

50°C at 10 bar0

10option

standardoption96 %optionoption

standardn.a.

standardn.a.

1) Typing for standard execution only – options come with different typing.2) at an operating pressure of 6 bar and 25 m/s3) at an operating pressure of 6,3 bar and a p of 1 bar4) different temperatures upon request5) as dust filter without cyclone separator and drain. Housing in special finish, therefore not suiting filter

housings of standard or superplus version.6) refered to nominal volume flow7) at pressure relief

-

AG Büssingstraße 1 · D-42781 Haan · Telefon ++49/2129/569-0 · Telefax ++49/2129/569-100

Technical alterations reserved (Date 03/03)

ultrafilter FRLSubmicrofilter SMFHousing with depth filter SMF andcondensate drain

Technical data

Depth filter SMF with threedimensional,binderfree filter fleece ultrair, made ofbinderfree borosilicat. Secure retention ofparticles and liquids is achieved by gravity,sieve effect and diffusion.

nominal m3/h3)

min. °Cmax. °Cmin. °Cmax. °Cmin. barmax. bar

in barin %5)

ppm 6)

manualautomaticalpolycarbonat

metal with sight glassmetal

descriptionmodel1)

connectioninstallationvolume flow

inlet temperature4)

ambient temperature4)

operating pressure

differential pressure ( new )retention rate

residual oil content

condensate drain

housing

SMF 1/4-51/4”

vertical120

50°C at 10 bar0

50°C at 10 bar0

160,1

99,99999

-

AG Büssingstraße 1 · D-42781 Haan · Telefon ++49/2129/569-0 · Telefax ++49/2129/569-100

Technical alterations reserved (Date 03/03)

ultrafilter FRLPostfilter AKHousing with activated carbon filter AK

Technical data

The adsorption filter AK offers doublesecurity. Adsorption of steam and gaseouscarbons and odours effects by a two-stageactivated carbon filter media.The adsorption by two stages offers ahigher adsorption surface, extended oper-ation time and higher efficiency. A stain-less steel support mesh and the filtermedium fix the activated carbon andensure that no carbon can leave the filter.

nominal m3/h2)

min. °Cmax. °Cmin. °Cmax. °Cmin. barmax. bar

in barppm 4)

polycarbonatmetal with sight glass

metal

descriptionmodel1)

connectioninstallationvolume flow

inlet temperature3)

ambient temperature3)

operating pressure

differential pressure (new)residual oil content

housing material

AK 1/4-51/4”

vertical120

40°C at 10 bar0

40°C at 10 bar0

160,1

0,003standardoptionoption

AK 1/2-5A1/2”

vertical360

40°C at 10 bar0

40°C at 10 bar0160,1

0,003standardoptionoption

AK 1-51”

vertical1850

450°C at 10 bar0

40°C at 10 bar0

100,1

0,003n.a.

standardn.a.

1) Typing for standard execution only – options will come with different typingIn order to prevent the AK filter element, we recommend a SMF-prefiltration.

2) operating pressure of 6 bar3) other temperatures upon request4) in combination with a SMF-depth filter

-

AG Büssingstraße 1 · D-42781 Haan · Telefon ++49/2129/569-0 · Telefax ++49/2129/569-100

Technical alterations reserved (Date 03/03)

ultrafilter FRLOil mist lubricator OLwith volume compensation(drop quantity per minute almost constant)

Technical data

nominal m3/h3)

maximal m3/h4)

min. m3/hmax. m3/h

min. °Cmax. °Cmin. °Cmax. °Cmin. barmax. barmax cm2

manual7)

automaticpolycarbonat

metal with sight glassmetal

descriptionmodel2)

connectioninstallation

volume flow

volume flow optimum

inlet temperature5)

ambient temperature5)

operating pressure

Oil-level quantity6)

Oil re-filling

housing material

OL 1/4-51/4”

vertical331100,230-20

50°C at 10 bar-20

50°C at 10 bar0

1645

standardn.a.

standardoptionoption

OL 1/2-5A1/2”

vertical1143182

1200

50°C at 10 bar0

50°C at 10 bar0

16112

standardn.a.

standardoptionoption

OL 1-51”

vertical3001080

050°C at 10 bar

050°C at 10 bar

010

500standard

n.a.n.a.

standardn.a.

1) Quantity of oil drops per minute almost constant – mixture relation Oil/Air degressive2) Typing for standard execution only – options will come with different typing3) at an operating pressure of 6 bar and 25 m/s4) at an operating pressure of 6,3 bar and Dp = 1 bar5) other temperatures upon request6) only for use of recommended oils of viscosity class VG 32 according to ISO 34487) also during operation possible

Oil Mist Lubricator with volume flow compensation 1)

-

AG Büssingstraße 1 · D-42781 Haan · Telefon ++49/2129/569-0 · Telefax ++49/2129/569-100

Technical alterations reserved (Date 03/03)

ultrafilter FRLPressure regulator PRMembrane-pressure valve(spring controlled) with secondary relief andvolume flow compensation,hand wheel fixable

Technical data

nominal m3/h2)

max. m3/h3)

min. °Cmax. °Cmin. °Cmax. °Cmin. barmax. barmin. barmax. barmin. barmax. bar

min. bar

5) barbar

descriptionmodel1)

connectioninstallation

volume flow

inlet temperature 4)

ambient temperature4)

operating pressure inlet

operating pressure outlet standard

operating pressure outlet optional

achievable differential pressure(inlet / outlet )

Hysterese

PR 1/4-81/4”any33630600600160,58415

0,2

0,50,46)

PR 1/2-81/2”any1143420600600160,58410

0,2

0,90,77)

PR 1-101”any3008400

600

600

160,51016

0,2

0,60,27)

1) Typing for standard execution only – options come with different typingDelivery effects incl. manometer

2) at an operation pressure of 6 bar and 25 m/s3) at an operation pressure inlet of 10 bar, outlet 6,3 bar and Dp = 1 bar4) other temperatures upon request5) at an inlet operation pressure of 10 bar, outlet 0 bar6) at an inlet operation pressure of 10 bar, outlet 8 bar7) at an inlet operation pressure of 10 bar, outlet 10 bar