FR-XLPE/PVC Shielded-LCT · Shielded (LCT Shield) FR-XLPE / PVC Number of Conductors Conductor Size...

Transcript of FR-XLPE/PVC Shielded-LCT · Shielded (LCT Shield) FR-XLPE / PVC Number of Conductors Conductor Size...

32

FR-XLPE/PVCShielded-LCTAPPLICATIONS

• Predominantly used in utility substations

• Can be installed indoors or outdoors, in cable

trays, conduit, underground duct, or direct

buried in wet or dry locations

• Conductor operating temperatures are not to

exceed 90°C wet or dry

• Rated 600 Volts

CONSTRUCTION DETAILS

• Conductors

• 14 AWG thru 10 AWG Annealed Class B

Copper Unilay Compressed Stranded

• Insulation

• Flame Retardant Cross-Linked

Polyethylene (FR-XLPE)

• Color Coded per preferred method in

ICEA S-73-532 standard

• Assembly

• Cabled with non-hygroscopic polyethylene

fillers in order to give the cable a circular

cross-section, when needed

• Wrapped with a Mylar binder

• Shield

• Longitudinally corrugated 5 mil annealed

copper tape

• Overall Jacket

• Heat, Moisture, and Sunlight Resistant Black

Polyvinyl Chloride (PVC)

• SOUTHWIRE XXAWG XX/C FR-XLPE (XHHW-2)

CDS 90C PVC JKT SHIELDED TYPE TC 600V

SUN. RES. DIRECT BURIAL YEAR SEQUENTIAL

FOOTAGE MARKS

SPECIFICATIONS

Southwire’s Type TC Substation Control Cable

meets or exceeds:

• All applicable ASTM Standards

• ANSI/ICEA S-73-532

• UL 44 Type XHHW-2 rated VW-1

• UL 1277

• UL 1581

• IEEE 1202

• ICEA T-29-520

• RoHS Compliant

OPTIONS

Strand:

• Stranding Classes – C, K

• Tin Coated Copper

Color Coding Methods:

• Color Coding per ICEA S-73-532

• Method 1, Table E1

• Method 1, Table E2

• Method 4

• Custom, available upon request

Insulation:

• PE/PVC

• PE

• FR-XLPE

• THHN

Binder Tape:

• Flame Retardant

Shielded Constructions:

• CU LCT

• CU Helical Tape

• AL Helical Tape

• AL Longitudinal

• With drain wire

Jacket:

• PVC

• LSZH-TP

• LSZH-TS

• CPE-TP

• CPE-TS

Other:

• Rip cord

• 1000 Volt rated

• Custom print

Additional constructions available upon request

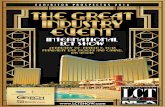

SUBSTATION CONTROL CABLE | Shielded (LCT Shield)

CONDUCTOR TYPE14 – 10 AWG COPPER

INSULATION TYPE FR-XLPE

SHIELD TYPE LONGITUDINAL

CORRUGATED

COPPER TAPE

JACKET TYPEPVC

CONSTRUCTIONAT A GLANCE

1

1

2

2

4

4

3

3

33

SU

BS

TA

TIO

N C

ON

TR

OL

CA

BL

E |

Sh

ield

ed

(LC

T S

hie

ld)

FR

-XL

PE

/P

VC

Number of Conductors

Conductor Size

(AWG)

LCT Copper Tape Shield Thickness(inches)

Nominal Jacket Thickness (inches)

Nominal Overall Diameter Approximate Weight

(inches) (mm) (lbs/1000 ft) (kg/km)

Shielded AWG 14 (7 strands)

2 14 0.005 0.045 0.363 9.2 97 144

3 14 0.005 0.045 0.384 9.8 120 178

4 14 0.005 0.045 0.417 10.6 146 217

5 14 0.005 0.045 0.454 11.5 172 256

6 14 0.005 0.045 0.493 12.5 199 296

7 14 0.005 0.045 0.493 12.5 217 323

8 14 0.005 0.060 0.563 14.3 260 386

9 14 0.005 0.060 0.6018 15.3 288 428

10 14 0.005 0.060 0.652 16.6 319 474

12 14 0.005 0.060 0.673 17.1 360 536

Shielded AWG 12 (7 strands)

2 12 0.005 0.045 0.398 10.1 122 181

3 12 0.005 0.045 0.422 10.7 154 229

4 12 0.005 0.045 0.459 11.7 189 282

5 12 0.005 0.045 0.502 12.7 225 335

6 12 0.005 0.060 0.576 14.6 278 413

7 12 0.005 0.060 0.576 14.6 305 453

8 12 0.005 0.060 0.621 15.8 343 510

9 12 0.005 0.060 0.666 16.9 381 567

10 12 0.005 0.060 0.723 18.4 422 628

12 12 0.005 0.060 0.746 19.0 482 717

Shielded AWG 10 (7 strands)

2 10 0.005 0.045 0.446 11.3 159 237

3 10 0.005 0.045 0.4728 12.0 206 306

4 10 0.005 0.060 0.546 13.9 271 403

5 10 0.005 0.060 0.595 15.1 323 481

6 10 0.005 0.060 0.646 16.4 376 560

7 10 0.005 0.060 0.646 16.4 417 620

8 10 0.005 0.060 0.699 17.8 471 700

9 10 0.005 0.060 0.750 19.1 524 779

10 10 0.005 0.060 0.817 20.8 581 864

12 10 0.005 0.080 0.884 22.5 700 1042

Dimensions and weights shown above are nominal and subject to industry tolerances.

Se

ctio

n A