Fouling and cleaning in food processing 2010

Click here to load reader

-

Upload

ian-wilson -

Category

Documents

-

view

217 -

download

2

Transcript of Fouling and cleaning in food processing 2010

E

F

ID

HifoocTspu

orenbice

aCCsndngasfwifai

t

0d

food and bioproducts processing 8 8 ( 2 0 1 0 ) 333–334

Contents lists available at ScienceDirect

Food and Bioproducts Processing

journa l homepage: www.e lsev ier .com/ locate / fbp

ditorial

ouling and cleaning in food processing 2010

an Wilson ∗, John Chewepartment of Chemical Engineering, University of Cambridge, Pembroke Street, Cambridge CB2 3RA, United Kingdom

ingham, and show how AFM can be used for understanding

andling information is a major challenge for engineers work-ng in the food sector. Data can involve length scales rangingrom the micron to the kilometre, timescales from fractionsf seconds in processing units to months for shelf lives, allriginating from very different sources – biological sciences,hemistry, physics, economics, animal and human behaviour.he ability to process this information in order to identifyolutions to processing problems and to develop process androduct opportunities is not getting any easier as the dataniverse continues to expand at a staggering rate.

The topics of fouling and cleaning are a prime examplef a field where workers have to handle data from a wideange of sources and to juggle conflicting constraints. The fieldmbodies many aspects of the ‘discipline’ of food process engi-eering, not only in the breadth of sciences that it draws onut also the symbiotic nature of the two core processes: foul-

ng and cleaning are intimately linked and one always has toonsider the impact of an action or engineering solution onach phase of operation.

This special issue of Food and Bioproducts Processing presentsselection of papers from the conference on Fouling and

leaning in Food Processing 2010 held earlier this year inambridge, England. It continues the series of meetingstarted in Lund in 1981, aiming to provide a focused tech-ical forum for workers active in the field to learn of newevelopments, to hear industrial case studies, to developetworks and to train younger researchers. Over 60 dele-ates attended from Europe, North America and Australasia:quarter were drawn from industry and half were research

tudents. The presentations and papers were of a uni-ormly high quality and those appearing in this issue of FBPere selected by the technical committee on the basis of

mpact and innovation. Further information about the con-erence, including how to obtain copies of the proceedings arevailable at www.ceb.cam.ac.uk/pages/fouling-and-cleaning-n-food-processing-2010.html.

One may ask why there is still a need for conferences onhese topics after 30 years of meetings? Has not everything

∗ Corresponding author. Tel.: +44 1223 334 777; fax: +44 1223 334 796.E-mail address: ian [email protected] (I. Wilson).

960-3085/$ – see front matter © 2010 The Institution of Chemical Engioi:10.1016/j.fbp.2010.11.011

been solved? As with all practical activity, the devil is in thedetail and in the food sector there is plenty of detail. More-over, there are factors – particularly economic ones – whichpreclude the use of the best available technology to tackle anindividual problem. When one is dealing with multi-productplant, with units processing materials only remotely related tothose they were originally designed for, and hygiene the onefactor that cannot be compromised, one ends up with verydifferent solutions to those which would be found in ‘normal’chemical plants. The papers here demonstrate that there isplenty of ongoing creative activity, particularly in the use ofnew tools and technologies, to help tackle fouling and clean-ing.

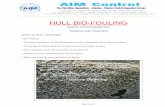

The first three papers address issues of surfaces, theuniversal feature of fouling and cleaning problems. Theattachment of micro-organisms to food processing surfacesmay not give rise to fouling in terms of engineering perfor-mance (e.g. heat transfer and pressure drop) until sufficientnumbers are present to generate biofilms, but food engineershave to define ‘clean’ in terms of hygiene. Most sensors do notwork at this level or are not robust enough to handle process-ing and cleaning environments so one has to employ invasivemicrobiological testing. The paper by Verran and co-workersprovide some salutary lessons on tests for micro-organismson surfaces which process engineers, who may be temptedto think of such tests as routine, would be well advised toconsider.

Fouling layers build up when the foulant can attach to thesurface, and a number of tools have become available to con-sider attachment at the finest of length scales. Atomic forcemicroscopy (AFM) is an exciting scientific tool but the engi-neering question is how to relate the information it generatesto the pilot and process scale. Akhtar et al. compare resultsfor various real food deposits obtained using AFM and the‘millimetre’ scale micromanipulation tool developed at Birm-

fouling and cleaning. The attraction of obtaining quantita-tive indicators of performance without the need for large

neers. Published by Elsevier B.V. All rights reserved.

cessi

334 food and bioproducts proscale trials is obvious! Developing surface treatments to inhibitattachment, i.e. antifouling coatings, has been pursued forseveral years now: Bani-Kananeh et al. present results fornanotechnology-derived coatings tested at both the lab andindustrial pilot plant scale. Examples of the latter are rare andthis is a welcome addition to the literature.

The rest of the special issue concentrates on aspects ofcleaning. This reflects industrial practice, where depositionis often accepted and the emphasis lies on removing foulinglayers. The saying in parts of northern England that ‘Wherethere’s muck there’s brass’ may be true, but to a food companyfouling research is about saving money rather than makingit. Understanding how fouling layers are removed is key toselecting and optimising cleaning protocols.

The complex rheology of foulants in the fast movingconsumer goods (FMCG) sector means that this is a phe-nomenologically rich area. Goode et al. and Cole et al. presentresults for yeast slurries and toothpaste, respectively, thathighlight the range of cleaning behaviours reported in thecleaning map by Fryer and Asteriadou (2009). Cleaning agentsare designed to transform the fouling layer into a more readilyremovable form and the group at Cambridge have developedtheir fluid dynamic gauging (FDG) technique to allow thedynamics of soft layer swelling and removal to be studiedin situ. Gordon et al. report a new form of this probe, whichcan scan across a surface, while Saikhwan et al. report swellingand dissolution behaviour of milk protein gels that completethe elucidation of the cleaning behaviour of milk proteindeposits reported by Bird and Fryer (1991). The interaction with

flow is also important, and Augustin et al. demonstrate howflow pulsing can be exploited to enhance cleaning in complexgeometries.ng 8 8 ( 2 0 1 0 ) 333–334

Whereas heat exchangers promote fouling by differencesin temperature at the wall, membranes promote deposi-tion by concentrating rejected components at the surface.Two papers describe new techniques for studying mem-brane fouling and cleaning. Creber et al. combine advancedmethods in magnetic resonance imaging (MRI) and numer-ical modelling to study and simulate the development ofbiofilms in water purification: there are obvious opportu-nities for using these techniques with food systems. Joneset al. report the use of the FDG technique to study micro-filtration membrane fouling, and demonstrate a mode thatallows it to be used at industrial transmembrane pres-sures. The final pair of papers highlight an importantdifference between hard surface and membrane cleaning,namely the tendency of cleaning agents to damage themembrane and change its performance. Both consider theimpact of hypochlorite, a standard disinfectant, on polyether-sulfone (PES) ultrafiltration membranes. Yadav and Morisonelucidate the mechanism of degradation while Rabiller-Baudry et al. show that cleaning should be completedbefore hypochlorite is applied in the disinfection step. Onreflection, we seem to have come quite a long way in 30years. . .

References

Bird, M.R., Fryer, P.J., 1991. An experimental study of the cleaningof surfaces fouled by whey proteins. Food Bioprod. Proc. 69,13–21.

Fryer, P.J., Asteriadou, K., 2009. A prototype cleaning map: aclassification of industrial cleaning processes. Trends FoodSci. Technol. 20, 255–262.