Forwards TJ Rausch 811002 ltr transmitting 'Evaluation of ... · ' John F. Wolf, Esq. 3409 Shephard...

Transcript of Forwards TJ Rausch 811002 ltr transmitting 'Evaluation of ... · ' John F. Wolf, Esq. 3409 Shephard...

r, -.-

_

FELATED CORRESPONDENCEI

ISHAM, LINCOLN & BEALE -

COUNSELORS AT LAW

ON E FIRE,T N ATIONAL PLAZ A FORTY-SECON D FLOORCHsCAGO,lLLINOIS 60003

TELEPHONE 3 2-558-7500 TELEX: 2-L2 8 8WASHINGTON OFFICE

1120 CONNECTICUT AVENUE. N. W.SusTE 325

WASMtNGTON,0.C 20036

202-833 9730

October 16, 1981p, y ..,

8 NDoaTTrr

UNITED STATES OF AMERICA S. U: '

4\NUCLEAR REGULATORY COMMISSION 2 OCT 19198h-

l-__

THE ATOMIC SAFETY AND LICENSING BOARD 9" Office cf Cea hemrv5 hDocketing & Smo

Brand, - ."In the Matter of )

) Docket Nos. 50-237-S * *COMMONWEALTH EDISON COMPANY ) 50-249-SP

) (Spent Fuel Pool(Dresden Station, Units 2 & 3)) Modification)

.

Dear Administrative Judges:

Please find enclosed Commonwealth Edison Company'sreport entitled " Evaluation of the Effects of PostulatedRocking of Racks on Spent Fuel Pool Structure of DresdenNuclear Station Units 2 and 3".

!

This report was prepared for Commonwealth EdisonCompany by the Quadrex Corporation in response to the NRCStaff's remaining technical questions concerning the proposedracks' behavior during a seismic event. The report concludesthat the spent fuel pool structures at Dresden Station Units2 and 3 are structurally-adequate to support the installationof the remaining prcmosed high density spent fuel storageracks.

Yours very truly,

( ,

Robert G. Fitzgibbons Jr.,One of the Attorneysfor Commonwealth Edison Company,

RGP:emc

h phEnclosures: Reportf 1Service ListIi 0

8110260134 811016 '

PDR ADOCK 05000237 .

O PM

.

.- - -. . .

.. -4,

i<

I UNITED STATES OF AMERICA; NUCLEAR REGULATORY COMMISS.'lN.|

THE ATOMIC SAFETY AND LICENSING BOARD

In the Matter of )) Docket Nos. 50-237-SP

COMMONWEALTH EDISON COMPANY ) 50-249-SP) (Spent Fuel Pool*

(Dresden Station, Units 2 & 3)) Modification)

i| SERVICE LIST

Mr. Richard Hubbard Ms. Mary Jo Murray,

MHB Technical Associates Assistant Attorney General'-

i 1723 Hamilton Avenue Environnental Control Divisioni Suite K 188 West Randalph Street '

! San Jose, California 95125 Suite 2315 .

! Chicago, Illinois 60601John F. Wolf, Esq.'

3409 Shephard Street Richard GoddardChevy Chase, Maryland 20015 Office of Executive Legal Director

U.S. Nuclear Regulatory Commission [Dr. Linda W. Little Washington, D.C. 205555000 Herraitage Drive

j Raleigh, North Carolina 27612

,' Dr. Forrest J. Remick305 East Hamilton AvenueState College, Pennsylvania 16801

.

Atomic Safety and Licensing7 Board Panel; U.S. Nuclear Regulatory Commission

Washington, D.C. 20555

Docketing and Serv. ice, '

; U.S. Nuclear Regulatory Commission'

Washington, D.C. 20555

TS

1

.

-7* -- fa --,s-_g- . - - < as y%-g m--en--.*w-- w-e e v. - r-.m--wm - - - - - - - ww- so-- , e-g , y-

.

.

Commonwealth Edison*2 *

' ~ . one First National Ptara CNcago. Hlinois f __

gj} Addr:ss R: ply ta. P:st Offico bo 157 RELA M C0 D"~P01mEyc3O a - I I

Chicago. Ilknois 60690

. _- 1. ,

s . ''

October 2, 1981G N

$ cc crit E.J,

tm.ao <g

Mr. Dennis M. Crutchfield, Ch30f --

OCL191981 >--

--

Operating Reactors Branch 5U.S. Nuclear Regulatory Commission g gjf;cecf theScretay 'dWasaington, DC 20555 D;;bting & Smico

EraatitYSubject: Dresden Station Units 2 and 3

High Density Spent Fuel &Storage Racks Seismic AnalysisNRC Docket Nos. 50-237/249

References (a): " Licensing Report Dresden Nuclear Power PlantUnits 2 and 3 Spent Fuel Rack Modification,"Rev. 5, dated January 19, 1981

(b): D.M. Crutchfield letter to J. S. Abel datedMay 13, 1981

Dear Mr. Crutchfield:

! Enclosed for your review are ten (10) copies of the report"Esaluation of the Ef fects of Postulated Rockirig of Rackt on Spent'

Fuel Pool StrJCtures of Dresden Nuclear Station Units 2 and 3".This report was prepared for Commonwealb Edison Co. by the QuadrexCorporation and the assumptions and methodology used in the analysisare consistent with those previously discussed in conference callsinvolving CECO., Quadrex, NRC SEP Branch, and NRC Operating ReactorsBranch 5.

Based on the results of this analysis, we conclude that thespent fu21 pool structures at L'"esden 2 and 3 are structurallyadequat< to support the installation of thirty-three (33) highcensity spent fuel storage racks as described in Reference (a). We

believe that this analysis provides the final response to thequestions transmitted in Reference (b) which were previouslydiscussed in meetings in the NRC offices in Bethesda, Md. on June 30

,

and July 17, 1981.

f Please address any questions concerning this matter to thisoffice.

i:

_

s *

-2-

One (1) signed original and thirty-nine (39) cGpies of *.histransmittal are provided for your use.

Very truly yours,

cT. J. RauschNuclear Licensing AdministratorBoiling Water Reactors

cc: Mr. Jolin F. Wolfe, Esq.Dr. Linda W. LittleDr. Forrest J. RemickMr. Richard Goddaro, Esq.Ms. Mary Jo Murray, Esq.

RIII I"?oector, Dresden

A t ta c hr.e r.t.

263ON

.

. .

. _ _ _ _ _ _ _ _ - _ _ _ _ _ _ _ _ - _ _ _ _ _ _ _ _ _ _!.

;. . \

.

.,_ - - .

! |! o

GUADREX

EVALUATION OF THE EFFECTS OF

POSTULATED ROCKING OF RACKS ON SPENT

FUEL POOL STRUCTURES OF DRESDEN

NUCLEAR STATION UNITS 2 & 3

i

Prepared for

- COMMONWEALTH EDISON COMPANY

Chicago, Illinois

'by|

Quadrex Corporation1700 Dell Avenue

Campbell, California 95008

),

Ogg-locA0T

- - . _.

.

o 8

QUAD-I-81-928

EVALUATION OF THE EFFECTS OF

POSTULATED ROCKING OF RACKS ON SPENT

FUEL P0OL STRUCTURES OF DRESDEN

NUCLEAR STATION UNITS 2 & 3

i

Prepared for

COMMONWEALTH EDISON COMPANYChicago, Illinois

|

by

Quadrex Corporation; 1700 Dell Avenue

Campbell, California 95008

Prepared by Reviewed by M~C. C. Tang T. L. Liu

*

Approved by 'i ,es,~ -- ,

,

Q Hbssain

Revision No. Date Released by Charge Number.

7 m'T.'c D W/ COM-02190 9/30/81~ loL

?

.

-

. ;'

,,

I

|

TABLE OF CONTENTS

PAGE

1-11.0 INTRODUCTION

2-12.0 DEVELOPMENT OF POOL FLOOR MOTION TIME-HISTORY

3-13.0 MATHEMATICAL MODEL

3-13.1 The Rack Structure 3-13.2 The Fuel Assemblies'

3-23.3 The Water Mass 3-23.4 Rack-Floor Interface 3-33.5 Damping for Rack Structure & Fuel Assemblies 3-33.6 Pool Floor Model for Determining Impact Load

4-14.0 NONLINEAR RESPONSE ANALYSIS RESULTS AND EVALUATION

4-14.1 Respon a Analysis Results 4-24.2 Evalua.non

5-1S.0 CONCLUS?0N

6-16.0 REFERENCES

.

u

.

e

|

-- .

- |

|; .*

l

1.0 INTRODUCTION;

It has been proposed that each spent fuel pool for Dresden Units 2 & 3 would|

contain 33 high-density spent fuel racks. These racks would be of free-standirg'

design with no anchor to the floor or lateral support from the walls. During a

| postulated seisniic event, the racks can potentially slide and/or rock. The pur-

pose of the present evaluation is to determine effects of such rocking of theracks on the pool floor and the walls.

The original design basis of the plant had an SSE of 0.29 at the ground level

(Reference 1). It used a Housner type response spectrum. Further rvaluation

of the plant was perfonned using the time-history record from the El-Centro,

earthquake of May 18, 1940, scaled to 0.2 . Subsequently, a site-specific9

This had a zere-ground spectrum for the Dresden site was developed by USNRC.

period SSE acceleration of 0.139 at the ground level. The response spectrwr

of the pool floor motion computed on the basis of this site-specific groundspectrum was used in an earlier analysis for evaluating the adequacy of thepool floor (Reference 2). Results of this analysis showed that, during apastulated SSE, the racks would rock with a maximum uplif t of about 0.1 inch.The pool floor was evaluated tu be structural 13 adequate to withstand the addi-tional load resulting from the impact of the racks during such rocking. How-

ever, during discussion with USNRC staff, it was decided that addicional analysiswould be necessary from the following consideration:

Reference 2 analysis used an approximate energy-balancemethod based on linear response-spectrum analysis of the

rack. Since rocking / sliding phenomena is actually nun-linear, the uncertainly associated with this analysiscannot be quantified. Hence, a nonlinear analysis of

the phenomenon would be preferable.

From the above consideration, it would have been adequate to perform a non-linear response analysis of the rack, uing the pool floor motion time-historycalculated from site-specific ground response spectrum. However, USNRC staff,

reasoned that this may not be adequate, because the site-specific spectra is

1-1

. . - . . - . _ ,.

-

, ,

2

relatively narrow-banded, and so it may not be conservative enough to acccunt j

|for the possible sensitivity of the nonlinear response to the change in theinput time-history and to the change in the friction coefficient between the'

rack and the pool f'loor. Considering the large computational cost arscciatedwith multiple time-history analyses tsing different coefficients of friction,it was decided that the adequacy of the pool structures would be evaluated

using a single nonlinear time-his+0ry analysis,and the effects of the above-mentioned uncertainties would be considered by way of selecting a wide-banded

ground response spectrum which would also have significantly higher amplificationThe wide-banded ground response spectrum of USNRC Regulatory Guide 1.60factors.

scaled to 0.29 (i.e. , 54 percent higher than site-specific value of 0.139) was.

judged to provide the basis for such an analysis and was used in the present

evaluation.

In Section 2.0, the procedural steps and assumpticns used in the development of

the pool floor motion time-history is presented. The ;nathematical model used

in the analysis is described in Section 3.0. Section 4.0 presents analysis re-

sults and the evaluation of the rack, pool floor and the walls. A discussion ofthe evaluation results and the conclusions are presented in Section 5.0.

.

8

5

m

1-2i

. - . . _- .-. .. . . .

. .- ._ --

.

s ;

i

2.0 DEVELOPMENT OF P0OL FLOOR MOTION TIME-HISTORY'

The development cf the pool floor motion time-history used in this evaluationconsisted of the following steps:

The building structural model developed by Lawrence Livermore Laboratorya.

was modified for as-built condition.b. USNRC Regulatory Guide 1.60 response spectrum scaled to 0.29 was selected

as the basis for the input motion at the ground' level. A synthetic time-

history matching this response spectrum was developed,A time-history response analysis was performed using the building modelc.(Item 'a'above) and the synthetic time-history (Item 'b' above).. A seven

'

percent building structural damping was used per USNRC Regulatory Guide

1.61. For use with such a conscrvative ground time-history, which is likelyto cause high stress in the building, the use of seven percent damping valueis conservative, especially when it is compared to the "best-estimate" oraverage damping value of 7 to 10 percent recommended in References 1 and 3.

Response spectrum at the spent fuel pool floor level was developed using ad.2 percent equipment damping. Again, the use of 2 percent damping is con-servative since Regulatory Gu de 1.61 recommends 4 percent damping, andi'

Reference . recommends 5 to 7 percent damping.

The floor response spectrum developed in Item 'd' above was smoothened ande.

peak u.oadened by 15 percent to account for building modeling and response

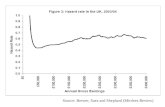

uncertainties.f. A synthetic time-history was developed (Figure 2-1) matching the peak-

broadened floor response spectrum (Item 'e' above). The comparison of

this synthetic time-history with the actually computed motion is ihownin Figure 2- 2 in terms of their response spectro. The peak acceleration

for the synthetic time-history is about 20 percent higher than the actuallycomputed peak acceleration. This provided additional cc 2rvatism :<e

input motion.

1I

.

1

2-1

-- , .- -

__ _ _ _. _.

.,

.

.

DRESDEN 2 REACTOR-TURBINE BUILDINGNRC REG. GUIDE 1.60 RESPONSE T-H (N/S)

80 '

. . . . . . . .g j

. . .. . . . . ... . . ...,

L_

-

",

- \-

.

.30 I,_

L i, i -

h f f '|Q 'wI .

-

3. i h y f! | j,5 I~

i -

hk i $ETj)!B ]i"l|j |i i F ,fliflil !) j

'

'!

1,'; r tj Eu - i.! , !o eM .

. | ,' ;s\

'

.

.3 0 ._._ __l5

-

.

" J(. -

.sO f , l,, l,,,,I l,,, l,,,,~, , , , , i , , , ,0 00 4.00 8.00 12 00 16.00 20.00 24.00

T1ME t SECONDS 1

FLOOR TIME HISTORY. ELEY. 570 FT.ITERATION = 5+S+5 DAMPlNG= 0.02FIGURE 2-1

.

. _______-_______ - ___.

. _ _ _ _ _ . _ _. _ __ _ _ _ _ _ . - _ _ ._. . __ ._ _ . .

..

..

,

.

DRESDEN 2 REACTOR-TURBINE BUILDINGNRC REG. GUIDE 1.60 RESPONSE T-H (N/S)

4.00. ii .... . . .. i,ii ,,,,,, ,, ,,,, ,,,, ,,,, , , ,,,

_ i ;

J-

l,

j_ -

L :3 00 [___

J-

g h -- a'

j~L

s L J2 00y p . .__,

,

,

O w L ;

tj L ,

E F p "

1 00

L '::= a

i- -w a

p J

b1 -!: i i

iiiil iiiiliiii! iiii!iiiiJ.

0.00 l i i i i l iiii i i ii iiii iiii

0.00 .10 20 .JO 40 50 .GO .70 80 00 1.00

PERIOD ( SECOND )-,

FIGURE 2-2 FLOOR RESPONSE SPECTRUM. ELEV. 570 FT.iTERAT10N =5+5+5. DAMPING = 0.02

_ _ _ _ .- ___

._.

~

.

. .

3.0 MATHEMATICAL MODEL

A schematic of the finite element rathematical model used in the evaluationis shown in Figure 3-1. It consists of a lumped mass stick model of a loaded

rack and a simplified mass-spring-dashpot system representing the overall be-havior of the floor as it interacts with the rocking of the rack. A nonlinear

r

rocking / sliding response analysis of this rack-floor system was performedusing the computer program ANSYS (Reference 4).

-

athematical model used in the nonlinear time-The significant features of the .

history analysis are briefly outlined in the following paragraphs:

i 3.1 The Rack Structure

The rack structure is idealized as a planar frame consisting of a beam

cantilevering from the base plate. The leg beams connect the base plate

to the floor. Elements 1, 2, and 3 represent the rack body consisting of

an array of tubes which are welded to each other and to the base plate.Elements 6 and 7 represent the rack legs. Elements 4 and 5 represent the

diaphragm behavior of the base plate in the horizontal direction, whichis essentially rigid. Elements 8 aa' 9 represent the stiffness character-

istics of.the rack in the vertical direction. The stiffness properties of

Elements I through 7 were obtained by matching the horizontal cantileverfrequency of this simplified model with that of the detailed finite-elementstatic model of the actual rack. The stiffness properties of Elements 8

and 9 were computed similarly by matching the vertical stiffness of thissimplified model with that of the' detailed mcdel.

3.2 The Fuel Assemblies

A nominal gap ci about 0.28-inch exists between a fuel assembly and the

storage tube which forms the rack body. The fuel assemblies can potentially

pivot inside the tubes and impact on the tube walls during a seismic event.To account for this nonlinear behavior, the fuel assemblies were represented

Theby beam elements 10,11, and 12, and gap-spring elements 13 through 16.stick representing the fuel assemblies (i.e., elements 10,11 and 12) wasassumed to be pinned at the bottom node (i.e., Node 8). The stiffness

properties of the beam elements (i.e., elements 10, 11, and 12) were3-1

, - ._. -- -_ _,

-

.

* *.

,

1

I

I

calculated assuming conservatively that all the fuel assemblies arechanneled, thus providing maximum stiffness to maximize impact effects.The stiffness of the gap-spring was based on local elasto-plastic deforma-tion characteristics of the tube walls impacted by fuel assembly.

A big source of conservatism has been introduced in the above modeling of

the fuel assemblies: it assumed that all of the fuel assemblies inside arack will " rattle" in-phase impacting on the rack structure simultaneously.Impacts are mor? likely to be at random, and the impact of the adjacentfuel assemblies on the common cell wall may, to some extent, cancel each

other, thereby significantly reducing the response..

3.3 The Water Mass

The horizontal hydrodynamic effects of ine water mass surrounding theracks were incorporated by considering the external water mass along with

the body mass of the rack structure. The virtual mass was computed in

accordance with Reference 5. The water mass inside the annular space be-

tween the fuel channels and the storage tube cells was represented as

coupled mass between the stick representing the rack structure (i.e.,elements 1, 2, and 3) and the stick representing the fuel assembly (i.e. ,

;

elemer.ts 10, 11, and 12). The water trapped inside the fuel assemiliesi

was considered along with the body mass of the fuel assemblies.

The hydrodynamic mass effects associated with the motion in the verticaldirection were not considered because t e rack is open in the verticaldirection and, hence, the effect is likely to be insignificant. Also,

'

the inclusion of hydroovnamic mass effect in the vertical direction would

have increased the effect,ive mass in the vertical direction and would,thereby, have reduced the uplift.

3.4 Rack-Floor Interface

Elements 17 and 18 represent the sliding / rocking interface between the

rack and the pool floor. The interface consists of two plane stainless

steel surfaces which may maintain or break physical contact in the verti-cal direction, and may also slide horizontally relative to each other.

3-2

_ _ __

.

e ;

in f.he vertical direction, the stiffness properties of these two elementsare such that no tensile force can exist in the interface. When the racklegs impact on the floor, the compressive stiffness of the element isrepresented by the local load-deformation characteristics of the poolfloor under the rack leg.

In the horizontal direction, the stiffness properties of these two elements

are based on a median coefficient-of-friction value of 0.5 (Reference 6).Since this evaluation considers the response of a large number of racks

(33 racks) involving even a larger number of leg-floor interfaces (6 times33 equals 198), the use of median coefficient of friction can be consideredas the "best-estimate" value.

3.5 Damping for Rack Structure & Fuel Assemblies

Raleigh damping (proportional to mass and stiffness) was used for the rack,

structure and fuel assemblies. The proportionality constants were deter-mined using an equivalent modal damping value not to exceed 2 percentwithin the frequency range of 1.5 cps (arbitrarily selected low-end fre-quency) to 11.5 cps (fixed-base rack fundamental frequency).

3.6 pool Floor Model for Determining Imp 3ct Load

in order to be able to determine directly the vertical response of poolfloor resulting from the rocking of the racks, it was modeled as singledegree-of-freedom mass-spring-dashpot system. The equivalent floor masscorresponding to a single rack is represented by the mass at Node 14. The

,

stiffness and damping properties are represented by the spring-dashpot

element No. 30. The stiffness of this spring was detertnined using theoverall load-deformation characteristics of the pool floor based on crackedconcrete section properties. The dashpot damping value was selected suchthat the combined effect of the Raleigh damping (corresponding to floorvertical frequency of 23 cps) and the viscous dashpot damping do not ex-ceed a conservative equivalent modal damping value of 5 percent.

.

3-3

_

-

.

.. s

I

i

@

Node No. \ |42 El. 177.00"

@ g ,0 |-@| @Element No. 2 ,

El. 135.75"'

_

415

.

@ @'

.

El. 94.50"'

5 0 6 0 --

,

Rack Assembly /@ Fuel Assembly

,

.

38

9,, @ 7, (6 El. 12.00". /g,,

,,..s

l|D ' % T @'

h@yf % El. 0.00,

;

m /4

h 3 - Horizontal Mass''

////////// 3 - Vertical Mass,

/5

f$'

i 25.2"25.2"_

_

! _

_

_

FIGURE 3-1 Non-linear Analysis Model

of Dresden Rack't . A

-- - . - - , __

- |

t ; |*

|

|

|

|

4.0 NONLINEAR RESPONSE ANALYSIS RESULTS AND EVALUATION

4.1 Response Analysis Results

A nonlinear time-history analysis of the rack-floor system was performed

using the mathematical model and the input floor motion time-history de-scribed in Sections 3 and 2, respectively. An integration time-step of

0.0025 sec. was used. Since no strong motion occurs af ter the first 14seconds of the 24-second time-history, the response was computed for thefirst 16 seconds. Results show that after the first 15 seconds, thereare no significant peaks of the responses. Other pertinent results arebriefly described in the following paragraphs:

The maximum sliding distance was about 0.03-inch, occurring at abouta.t=7.4 and t=10.6 seconds. Maximum sliding velocity was about 1.55

in/sec and occurs at about t=6.8 seconds. A portion of the slidingtime-history showing the maximum sliding is presented in Figure 4-1.

b. The maximum uplift was about 0.92-inch occurring at about t=7.05seconds. A portion of the uplift time-history showing the maximumuplift is presented in Figure 4-2. The maximum corresponding rack

impact on the pool floor interface (including dead load) is about.3450 lbs. per fuel assembly occurring at about t=7.3 seconds.

A portion of the rack leg force time-history showing this peakleg load / fuel assembly (34SO lb) is presented in Figure 4-3.

The maximum rack impact load, occurring at about t=14.8 seconds,c.'

is about 3458 lb per fuel assembly. Maximum rack leg reactions,listed in Table 4-1, are based on this value.

d. The maximum floor reaction including dead load, occurring at aboutt=7.3 seconds, is about 3350 lbs per fuel assembly. A portion ofthe pool floor reaction time history showing this is presented inFigure 4-4. The design basis pool reaction load was based on this

peak value.-

4-1

.

~

.*; ,

4.2 EVALUATION

Table 4-1 shows a comparison of the rack leg forces resulting from the

rocking effect with'those calculated earlier assuming that the racks do notslide or rock. The stresses in different components of the racks are shown

in Table 4-2. Comparison of these stresses with the allowable show that the

rack components will not be overstressed.

Pool floor and walls were evaluated for the total load, including the effectsfrom the rocking o' the racks. The total equivalent uniformly distributedload, including the impact load obtained from nonlinear response analysis ofthe rack-floor system, was computed to be 11.07 kips per sq. ft. (See 4bl+ 4-3),assuming that all of the 33 racks in each floor will impact on the floor at thesame instant. This assumption of simultaneous impact of all racks on the poolfloor is very conservative; a more realistic assumption would be to use SRSScombination of impact loads from individual racks. With such realistic assump-tion, the total equivalent uniform load on the pool floor was computed to be7.02 kips per square foot. The capacity of the pool floor slab based on diagonal

2shear is 13.04 k/f t ; flexure and shear friction capacities are much higher.Thus, the floor slab capacity is adequate to withstand the additional loads re-sulting from the proposed storage of high-density racks.

The south and the east walls were evaluated for the loads equal to the shear

capacity of the pool slab These two walls are more critical than the othertwo walls. Evaluation results, presented in Table 4-4, show that the shear

Flexural capa-capacity of the walls are much higher'than the predicted loads.city is still higher. Hence, the pool walls are structurally adequate to sup-port the total loads resulting from the proposed storage of high-density racks.

.

.

A-2

.

- .

TABLE 4-1

Maximum Rack Leg Forces Due to Rack Impact,

Vertical Seismic (SSE) and Buoyant Weight of Rack

Maximum Force (kips)

ConsiderationCorner Leg tiiddle Leg

Considering rack impactby nonlinear analysis 131.3 164.1

Original Fixed-base 179.8 208.9analysis (1) ___

NOTE:

1. For the purpose of coniparison only.

.

.

.

4-3

_- . . . .

- - .

.,.

4.

i,

4

TABLE 4-21

Stresses in Rack Components Including

The Rocking Effect of Rack

;

II) Computed (2)Rack Load Critical Allowable

Component Combination Stress Type Stress (ksi) Stress (ksi)

i _-

Tube Wall D+B+E' Membrane 33.5 16.37

fFuel Support Plate D+B+E' Membrane 33.5 13.04

__

i Filler Plate D+B+E' Membrane 33.5 13.17

Base Grid D+B+E' Membrane 33.5 2.41_

Rack Leg D+B+E' Membrane 33.5 12.14 ,

;.

Interface D+B+E' Bearing 4.76 1.24

1

i NOTES:

| 1. Using a dynamic increase factor cf 1.2i

Obtained by multiplying)the dead load stresses (from originali 2.finite element analysis with a scale factor, equal to the

| ratio of rack leg reaction considering the rack impact on poolslab over the dead load reaction of rack I g.?

|!s

; -

.

4-41!

-._ __ . _ . _ - - . . _ _ _ _ _ , , - _ ,_ _ ; _ ., .. , - _ . _ _ . . . . . , - ,

*

o

|

|l

I

TABLE 4-3

Evaluation of Pool floor Slab

(a) Capacity of pool slab based on shear failure 13.04 k/sfdue to diagonal tension

(b) Total uniform load with impact forces to 33 11.07 k/sfracks added by absolute sum method

(c) Total uniform load with impact force due to 33 7.02 k/sfracks added by SRSS method

.

4-5

,

. . _. .. . - .

~

.

.' e

.

.

4

! TABLE 4-4

II)Evaluation of Critical Pool Walls

i

k

IWall Load Combination

Allowable Computed

I4)I2) <5404North and 0+L+H+E'+1mpact 15724

South Wall

I4)3280(3) <3104East Wall D+L+H+E'+1mpact

4

NOTES: ,

1. Bending, which is less critical than shear, was nottabulated.

2. Considering the effect of vertical reinforcement inresisting diagonal tension resulting from shear.

3. Considering shear capacity due to concrete only.Value will be much higher if effect of verticalreinforcement is included.

4. These values are based on a maximum uniform loadof 13.0, k/sf, which the pool slab can resist with-out shear failure.

s

.

$

4

*

.

s

2

; 4-6

i

.- ~ - . . . . . . - . - . - ,

.~ . . . . . -

1-.

|'s .

,

e

i; .

STRO' '03E0 ,

!

!

.03:0

.

. 0 0 5 '.

N '';\ r

,..,,

0:.0 < . .

I ||h !

I

, gr i.~tJt,

.0:00 , c -

i.) 0'EO r*

i

4 | |

; 0100

0:,*,0

1

i 1%! 0040

}Ya,- |f e, ,

g

'.0!.00 - - '"-,I-~ |

. .

finei

.0040 6

5.0 55 6.0 65 7.0- 7.5 B.0 e.5 90 95 10 0

"5'8 5On t 50t N p.. uta. n 10iNG ENO RotaING ANLv5I5

i .

FIGURE 4-la Sliding (In Incl.es) of Dresden Rack

4-7.

h

.

* ' ~ ~ --= - e.w - _, ,,

.... - . = .

-

.

.

.

.

57R5'

. C S '. C

*

.

.6430

.

'0400

t

03:C,

1

.C2eC,

I !%N0!s;

i

_W.~ 1

['i

0:e'U

l N0000

._

-

; .00s;

A1 YQ g:y --R J G 1''-

; ,.

; PA. _ _ _

.0160 -"

i trtEi

f

9.6 10.8 11.2 12 0 12 6 13 6 14.4 is.: 35 0 g g, 6 17.6| .0240

|OP.[LDEN 91(13 gr,r g , egggggg, g g pgg ,

',

i

flGURE 4-lb Sliding (in inches) of Dresden Rack

4-8'

i

re w.* e + u-y- - u -- -y ,p.rgr - =wr = + ^ > m y

_ - _ - . . _ . _ . .. _ _ _ _ - _.

'

.-

.,

i

i

stKL'1 3I4

r

t

1.00-

.

j -

; :.051

i

a

I a,gg, _ _ _ _ .|

! i

.is. - -

5;

1

r-

{ .ns . _ . - -

4

i

{\ .i .'. fy4

I-

ji

bi.,3

| [\,

b^ ^ 'S)^.o;

{ |}

',---

.

fine..,5

- r>

5G 55 6.C 65 7.0 7.5 8.0 B.5 90 95 IC U

AN575 7-LREL;tN 9tl3 %C A. Ell 0ING AND R0(KlNG 4NLf 515;

!

!'

! FIGURE 4-2 Upitft (in inches) of Dresden Rack

; 4-91 .

. . - . , ., _ ~ , _ - . . , , - - , , , , - , _ ~ ~ -e+. , ,-- --- -,-. ~ . , . . . ..n- - - - - - - -

. ,

, +.

$1R$'400 .

0

. t --- - -

-4C; i ,i'

,

i 1

"'

\ i| h:'

,

]-'f ,_

-?;; .- - - .j i , .

!|ll |

-1200f

I

' -l635

-2000

-2400

P

-:SC;.

.

3

- 3;'J:s

IIMI'

'

50 55 6L 6L 7.0 75 B.O 8.5 g.0 9.5 10.0-3E03

ANLYS e*

DRE5 DEN 91]) %CM . El!OING AND ROCRING ANLYS[$

FIGURE 4-3 Rack leg Impact force (In Pounds) ofDruden Rack

4-10

.

* ..,

51R5'

3 F. 0C.

3:03

'

2500

2400

!2*** - ,

,'~

.I , |

i

! k | I I | ! l

'

f!__It Ilj_ 4r || } { jj [[. .

h_

$'y!j!{<jj])y|M{f}|$",

,

Jh|Mh?]-|||!{|%$0{<g e,c e _

i.

:

- .- -

r

120 1- -

; ,-.

i

$ 0 ",

400

0

-

, 11Mr

50 5.5 6.C 5.5 7.0 75 8.0 B5 90 9.5 1C.0'-400AN575 9

DAE50tN 9:13 st ACE . 5tt0lNC. AW9 RD(MING ANLf515

FIGURE 4-4 Pool Slab force (In Pounds) -

Due to Rack Impact

4-11

.

.. .,

.

!!

|

.5.0 CONCLUSION.

Evaluation of the effects of rocking of the racks showed that the racks, thepool floor and the pool walls are strutturally adequate to withstand the addi-tional loads that might result from racks impacting on the pool floor.

The evaluation was performed very conservatively to account for the possiblesensitivity of the nonlinear response to the change in the input time-history.The sources of conservatisms are sumnarized and discussed below:

1. The realistic ground response spectrum applicable for Dresder site is theSEP site response spectrum. The design-basis response spectrum used in

Thethe present evaluation is the USNRC Reg. Guide 1.60 response spectrumtime-history compatible with this wide-band response spectrum is much moreconservative frequency-contcot wise when compared to the site specific

spectrum. Also, the response amplification factors used in the presentanalysis were increased by 54 percert by way of using 0.2g peak groundacceleration instead of the site specific value of 0.13 ,9

2. All the fuel assemblies inside e rack were assumed to move in-phase duringa seismic event, impacting on the rack storage cells simultaneously. In

actuality, it is more likely that there assemblies would move at random,in which case the reaction load on the rack structure resulting from the2

motion of one group of assemblies may be reduced or neutralized by the re-action loads from another group of assemblies inside the same rack but

moving in the opposite direction. The factor of conservatism introduceddue to this assumption is very dif ficult to estimate; however, if theresponse was linear, and if the motion of the isseinblies could be assi"ned'

random, the factor of conservatism could be as high as 9.9.

4

1 Thirty-three high-density racks are proposed for each pool. Impact loads

resulting from the rocking of these 33 racks are likely to be somewhat atrandom because of the following:

.

5-1

,

N

c.. .e

i1

a' Oifferer ces in the inertia and stiffness characterist.cs of the 9xiland 9x13 racks. Even though the short sides of these two sizes ofracks are oriented in the same direction, their inertia and stiffnesscharacteristics are different because of hydrodynamic mass effect and

width-to-length ratio.t,) The probability that the friction coefficient between the pool floor

and different racks would vary is extremely high. This would affect

the time-phasing of the response,c) During a postulated seismic event, each rack impacts on the pool floor

several times. The resulting time history of the reaction load onthe pool floor shows a large number of load cycles (in the order ofhundreds). Of these load cycles, only a few (less than 5) have peaks

which at 1 ore than 80 percent ?f the maximum floor reaction load.Hence, it is highly improbable that these infrequent maximum floorloads from different racks would occur simultaneously.

Items 'a', 'b', and 'c' above providt justifications for using SRSS combinationof the peak floor loads resulting from the impact of each of the 33 racks. Hence,tne equivalent distributed floor load of 7.02 k/ft , computed on the ba: .,f SRSS

2combination, is more realistic than the ,alue of 11.07 k/ft , which is based onthe assumpti:n that the peak impact forces from the 33 racks would occur simulta-neously. Quantitatively, the latter assumption of simultaneous impact increasesthe floor impact load by approximately 5.7 times that obtained by SRSS method. ,

Considering the sources of conservatism discussed above, it is concluded that the2computed floor load of 11.07 k/f t has sufficient conservatism tio account for the

sensitivity of the response due to the change in the input motion time-history,since it is based on a very conservative (both frequency-content wise as well as

magnitude wise) input response spectrum. Also, it assumes in-phase motion of all

fuel assemblies inside a rack and is based on the very conservative assumption

that peak impact loods from the 33 racks would occur simultaneously. Thus, thisload approximates the upper bound load. Since even this load is significantly

2less than the floor shear capacity of 13.04 k/f t , it is concluded that the floorslab is structurally adequate to withstand the loads resulting from the storageof high-density spent fuel racks.

5-2

}"

.

. _-. ..

o .

6.0 REFERENCES*

,{

1. " Seismic Reveiw of Dresden Nuclear Power Station - Unit 2 for t!,eSystematic Evaluation Program". Prepared by Lawrence Livermore.

i

Laboratory for U.S. Nuclear Regulatory Comm1ssion, NUREG/CR-0891t

April 1980.

"Dresden Nuclear Station - Evaluation of Fully Loaded Spent Fuel| 2.-i Pool Floor", August 26, 1981.

j 3. " Development of Criteria for Seismic Review of Selected NuclearPower Plants", USNRC NUREG/CR-0098, flay 1978.4

1

4. "ANSYS User's Manual", Swanson Analysis System, Inc.

5. " Effective Mass and Damping of Submerged Structures", R.G. Dong,Lawrence Livermore Laboratory Report No. UC-80, April 1978.

.

6. " Friction Coefficients of Water Lubricated Stainless Steel for a]

Spent Fuel Rack Facility", E. Rabinovicz, Professor, Massachusetts'nstitute of Technology, November 5,1976.4

:4

!

1

IIb|

'.

1

4

4

e

e

1 8

4

s

.

:

6-1

!1

-_ #% , . -, , . . -- --- , - - - - -.