Formule Verte - N°11 October 2012

-

Upload

infopro-digital -

Category

Documents

-

view

217 -

download

0

description

Transcript of Formule Verte - N°11 October 2012

11 OCTOBER 2012N°

PIERRE POTIER PRIZE 2012

Three awards for bio-based chemistry

« Our investments may increase, dependingon demand of furfural »

BETAINE

DuPont opens a production line in France

ALDERYS

Synthetic biologysubstitutes oil

A workin progress

Special reportECO-DESIGN

PENNAKEM

ww

w.form

ule

-vert

e.c

om

3FormuleVerte - N°11 -October 2012

Editorial

3

Sylvie LatieuleChief [email protected]

BiomimeticsPicardy is at the forefrontonce again

ith the increasing awareness that fossil resources will only be a distant memory in the

history of mankind, man is naturally turning to Mother Nature. Already, around the

world plans to substitute fossil carbon by carbon plants are multiplying. And for the

last decade, an American scientist, Janine Benyus, has proposed going further by bringing the

idea of biomimetics up to date. This discipline is not limited to the mere imitation of life, such as

the reproduction of shark skin to make wetsuits or the small hooks on burdock plants to make

Velcro. More broadly, she also recommends inspiration from the organisation strategies seen in

nature which are constantly adapted and improved. In France, many laboratories are conducting

research in this area, but often on the margins of their main work.

Therefore knowhow is geographically dispersed throughout the country and there is no real

emulation based around this emerging discipline.

However, thanks to the town of Senlis, that situation is about to change. In fact, the city in Picardy

has taken the initiative by creating the first European biomimetics centre. It will open in 2014 and

will house a campus, research and higher education institutions, innovative

start-ups, SMEs and VSEs and even large industrial groups. “The goal of this

centre for excellence dedicated to biomimetics is to develop and mutualise

exchange and collaboration spaces between all of the public and private actors

based around innovative collaborative projects which can generate growth,”

says Francis Pruche, a researcher and alderman of Senlis, describing a veritable

platform for open innovation.

The idea of this centre is very recent, one a half years ago, with the arrival of a

new team in the Senlis town hall. After the departure of a military battalion in

September 2009, leaving behind 10 hectares of disused barracks, a first tranche of land had been

dedicated to the creation of a new residential area. But the new team did not approve it. “Our idea

is to revitalise Senlis, combining economic activity with housing, with the aim of rebuilding

employment,” explains Pascale Loiseleur, the new mayor of Senlis.

In terms of funding, the State will participate to the tune of 1.5 million euros as part of a local

revitalisation plan (PLR) signed on July 13th, 2012. Also, the project team will have to find

additional funding of 12 million euros to implement the first phase of the project. But Pascale

Loiseleur remains confident because she has already managed to bring on board several partners,

such as the Regional Council of Picardy, the IAR cluster, the State via the PLR and the Cleantuesday

association. And then, by combining biomimetics and open innovation, this new centre aims to

create a culture of breakthrough innovation. Many manufacturers will be more than a little

interested in the latter.

W

The town of Senlishas createdthe first Europeancentre for biomimetics.

Baby eats organic ...plastic■ “Save the earth!” “Preserve thefuture!” This is the motto of Mother’sCorn. This brand which offers dishes forbabies has developed its products usingPLA. Their range of plates, glasses, andcutlery is made from bio-plastic. Theresearch teams at Mother’s Corn havealso managed to make products whichare resistant to heat so that they can beused in the microwave. Themanufacturer uses certified non-toxicinks. Mother’s Corn obtained acertification for container safety fromthe Technical and Test Institute in

Prague forConstruction inPrague.

■ The world of luxury has adoptedrenewable materials. This summer theGuccibrand has marketed shoes using bio-plastics. The luxury brand has adoptedecological soles for two models. The insolesare made of bio-plastic which isbiodegradable into compost. For men, theluxury brand offers their California Greensneakers with ecological Gucci soles,vegetable tanned lambskin, organically

certified laces and metal details. Forwomen, the Marola Green shoes aredesigned entirely in bio-plastic.

6 FormuleVerte - N°11 - October 2012

GreenBiomass is being used in many everyday products, even in thefaçades of houses.

showcase

Coffee and tea in cardboard■ Coffee capsules are booming with consumers, but using capsule coffee is not veryenvironmentally friendly. Tirouvady Mouttyhas worked for five years on creating a capsulewhich is biodegradable and environmentally friendly. The Moutty capsule is made ofcardboard with a biodegradable film derived from corn starch which serves as a natural barrieragent. Finally, the capsule can contain coffee or tea and can be recycled into compost within 45days. The company also highlights the benefits of the properties of coffee grounds in compostfor agriculture. Moutty has also developed a machine for using these capsules.

The boomerang effect for PLA■ It’s not just boomerangs that return.Recycled PLA can now be used. Thecompany Futuramat offers itsBiofibra range composed ofrecycled PLA loaded with wood fibreand containing plant-based additives. It isa range which attracted WallabyBoomerangs for their boomerangs whichare manufactured and painted entirely byhand. Their inks and varnishes are alsowater-based. The Biofibra range fromFuturamat comes in various formulations

whose compositionsare adjusted accordingto the final applicationand transformation method(thermoforming, injection,calendering etc.)

Walking on bio-plastics

© Wallaby Boomerangs

© Tirouvady Moutty

© Gucci

© Mother’s Corn

7FormuleVerte - N°11 - October 2012

■ Keeping products separate fromcomponents which are synthetic orpetrochemical is the goal of NatureCoswith their cosmetics brand CouleurCaramel. The brand uses ever moreingredients from organic agriculture. AsNatureCos points out: “Our range containsless than 1% synthetic ingredients, exceptfor the nail polish.” For its eye shadow, thecompany offers a micronized powderwith active ingredients such as olive oilderived from red tea extract. And there isno question of using plastic packagingderived from petrochemicals; the brandhas turned to kraft paper for that.

■ How do we educate the youngergenerations about gestures to help theplanet?The Dutch government intends to do so

while they are playing. Inside the pavilion“My green world” in Venlo, a playgroundnamed Kidshouse was built from naturalmaterials. The company Puracnotably

participated in thisproject initiated byBE-Basic, a public-private partnership.For the playground,the waterproofingthe roof is providedby materials madefrom vegetable oils.Coconut and hempfibre panels are usedfor the interior walls.Bio-plastics madefrom potato peelingare used for electricaloutlets.

■ While the microalgae industry grows,the question of finding areas to cultivatethem in arises. The agency X-TUArchitects, the engineering-environmental–food laboratory of theUniversity of Nantes along with theconsortium SymBio2 are proposing to usethe façades of buildings to growmicroalgae. The first prototypes have beencarried out. Flat and thin intensifiedphoto-bioreactors are integrated onto the

rear panel of a curtain wall. Thermalregulation of algal cultures on the front(between 18 and 25 °C) reduces theoverheating effect of large glass surfaces.In addition, such a facility would allow areduction of more than 40 % in theoperating costs for algal culturescompared to cultures in horizontalglasshouses.

A playground for “organic” children

Kraftpaper wrapsup organic cosmetics

Microalgaeclimb the façades of buildings

© X-TU Achitects

© BE-Basic

© Natu

reCos

Z O O MA natural fibre insula-ting reinforcement forPVC workEcoRenfort is an isola-ting reinforcementcombining naturalfibre insulationunmatched in its ther-mal performancewhilst providing thenecessary rigidity forPVC profile work. It islightweight and madein its majority fromplant fibres. By simplyreplacing steel reinforcements,EcoRenfort significantly improves theperformance of PVC work as well as theircarbon footprint. EcoRenfort is a productfrom the company Innobat, a member ofthe IAR cluster.

© In

nob

at

Information selected by the sitewww.agrobiobase.com

8

Created to reward innovations in sustainablechemistry, this award annually honours projects inplant-based chemistry.

PIERRE POTIER PRIZE 2012

tical group Sanofi for the development of aninnovative industrial process for manufac-turing artemisinin, the main active ingre-dient of an anti-malaria drug. Rather thanextracting the active ingredient from theArtemisia plant, whose cultivation is longand expensive, the process combines abacterial culture step with a photochemi-cal step. The bacterium was obtained bysynthetic biology and feeds agriculturalcarbon sources. “With this new innovativeprocess, production time has been reduced bya factor of three to just four months. We arevery pleased to announce the launch of thisnew production as of this month,” says Fran-cis Carré, vice president of Chemistry &Biotechnologies at Sanofi. This large-scaleproduction required an investment of 15million euros. For Francis Carré, this jointproduction project also represents a model

lant-based chemistry wasshowcased on September12th on the occasion of the

presentation of the seventh Pierre PotierPrize by Arnaud Montebourg, Minister forIndustrial Recovery. This award was createdin 2006 by the Ministry of Economy,Finance and Industry in partnership withthe French Federation for ChemistrySciences (FFC) and the Union of ChemicalIndustries (UIC) with the aim of rewar-ding initiatives in sustainable develop-ment. For this seventh edition, 29applications were submitted, with six ofthem directly related to biobased products.“It has been a good year. We received 29quality applications and we ended up awar-ding three trophies instead of two,” saysMaurice Leroy, president of the FFC.Among the winners was the pharmaceu-

Three awards for bio-based chemistry

P

FormuleVerte - N°11 - October 2012

for the future which he wants to apply inparticular to the production of corticoste-roids. These products are now seeing strongcompetition from Asian production, butthe discovery of a cheaper synthetic path-way could help stabilise production onFrench territory.A trophy was also awarded to the companyFermentalg. Created in 2009 by PierreCalleja, it has developed a method for theindustrial exploitation of microalgae. Thealgae are grown in fermenters from orga-nic substrates (glycerol, whey, cellulose,and vinasse) and are able to producevarious molecules (omega 3, colorants,antioxidants, and hydrocarbons). “We ente-red the arena of the exploitation of microal-gae in competition with Asia and America.But with our 15 patents, we are a globalleader. Moreover, our company is experien-cing strong growth. At the time of filing ourcandidature for the Pierre Potier Prize, wehad 22 employees. Fermentalg now has 38employees,” says Pierre Calleja.The company Wheatoleo received a medalfor the development of innovative agro-

surfactants (APP and lipid sopho-roses) from agriculturalco-products. Wheatoleo has usedARD patents since 1996, butcontinues to file them. “Thisaward is a mark of recognition ofthe research work by the agricul-tural sector which has takenresponsibility for research andwhich remains committed toindustrialisation on our territory,”says Yvon Le Hénaff, president ofARD.*Alongside this prize, the plat-form Chemstart’up awarded aprize for a young and innova-tive company with a value ofup to 150,000 euros, if industrialdevelopment is relocated to Lacq.This year Ecoat, a start-up crea-ted in Grasse in 2011, was awar-Awards presented by the Minister for Industrial Recovery, Arnaud Montebourg.

© M

inis

tère

du

red

ress

emen

t p

rodu

ctif

InIn light [DISTINCTION]

9

ded for the development of new bio-basedpolymers for the paint industry. For this, thecompany has developed and patented anew reaction mechanism based aroundplant-based synthons which are applicableto numerous polymers. This mechanism isactivated at the time of paint application,and substitutes oxidative drying paintwhich is usually catalysed by Cobalt salts.

Forward-looking chemistry

In his closing speech, the minister ArnaudMontebourg recalled that chemistry is atthe heart of all science and technology:materials, biotechnology, nanotechnology,electronics. “Long perceived by the publicas a source of pollution, the chemical indus-try is today showing that it is able to providetechnical solutions that are able to meet themajor challenges of sustainable develop-ment, while increasing the use of renewablesources raw materials (green chemistry),” hesaid. He also referred to existing programsfor supporting innovation. “We want thering-fence the Research Tax Credit because it

* Two other winners were awarded, but theirprojects did not concern plant-based rawmaterials. These were the group Arkema for theirnanostructured Altuglas ShieldUp acrylic glassand BASF with an industrial process for theproduction of MOFs (Metal Organic Frameworks)in aqueous media.

is an investment in intelligence. We want toextend innovation within the framework ofthe 2013 Finance Act,” said the Minister.He showed the same determination inregards to future investments and clus-ters. “These are tools which strengthen andreinforce.” In addition, the minister referredto the planned Public Investment Bank forthe financial support of SMEs and MSEs.“This bank will slow the pace of return oninvestment,” he said. Obviously being veryattached to the notion of industry, theminister indicated that in the near futurehe would meet with the strategic commit-tee on Chemistry and Materials. ■

SYLVIE LATIEULE

By rewarding Fermentalg, the jury has confir-med interest in the industrial exploitation ofmicroalgae.

©Fe

rmen

talg

InIn light[DISTINCTION]

10

addition, by starting from highly oxygena-ted raw materials, unlike fossil raw mate-rials, they should be able to access moreinnovative products: new solvents whichare less harmful to humans and the envi-ronment, as well as highly oxygenatedmolecules. “Oil will become scarce andexpensive, resulting in soaring prices forfossil-based chemistry. Plant chemistryopens up new perspectives,” says VincentTouraille.Like PCAS, Isochem is also aiming to lookinto these new markets for plant chemis-try. “One of our axes for strategic develop-ment is focussed on diversifying intonon-pharma, while retaining our customsupplier model”, says Xavier Jeanjean,commercial director at Isochem. Already,the company has made its first steps in thefield of plant chemistry. In this emergingfield, biotechnology is well established,but Xavier Jeanjean considers that itcannot do everything. It is sometimeseasier to make one or two conventionalchemical reactions in order to functiona-lise a molecule. “These two technologiesare complementary. Also, we can play therole of the missing link in the field ofgreen chemistry”, he says. Isochem alreadyhas projects at the pilot stage with part-ners who have found new specialty mole-cules and need the involvement of achemist with a green approach. “This areais more sensitive than pharmacy in termsof the environmental impacts of processes,which is an interesting challenge for us interms of innovation,” adds Xavier Jeanjean.

FormuleVerte - N°11 - Octobre 2012

To capture these new markets, Isochemimplemented a marketing strategyapproach over a year ago and hired a dedi-cated business manager. “At first we werenot sure about the result, but now wehave already achieved some initial successand we are even a little ahead of our busi-ness plan,” he says. For Isochem, this newbusiness focused on plant chemistry couldrepresent 10% of the company’s turnoverin the medium term, while its competitorPCAS does not rule out the possibility ofcreating a new division dedicated to thisactivity. ■

SYLVIE LATIEULE

As producers of pharmaceutical active ingredients andspeciality molecules, French fine chemicals producerssee opportunities in plant-based chemistry.

FINE CHEMICALS

Diversification into plant-based is being studied

The view of ProfessorDaniel Thomas

“OXYGENATEDMOLECULES AREAN ASSET FORFINE CHEMISTRY”

* Johan Sanders, Elinor Scott, Ruud Weusthuis,Hans Mooibroek, Macromolecular Bioscience2007, 7, 105–117

© Novasep

rench fine chemistry is aprofession which generatesa turnover of between 1.5 to

3 billion euros in revenue and accounts for10,000 to 12,000 employees in the country.About 60% of them work for large pharma-ceutical companies producing active ingre-dients. The remaining 40% are employedby subcontractors or CMO’s, such as Nova-sep, Isochem, PCAS and Axyntis. They arespread over three businesses - productionof generics, custom manufacturing andspecialty fine chemistry – this professionis currently eyeing development opportu-nities in plant chemistry, particularly tooffset the decrease in exclusive pharma-ceutical synthesis. “France has the goodfortune of being a large agricultural coun-try which has the resources and the abilityto recover a great deal of plant residueswhich can be recovered and transformedinto plant based carbon,” says VincentTouraille, President of Sicos and CEO ofPCAS. Certainly, chemicals actors are notintending to position themselves in thetransformation of agricultural matter.However, they do think they can gravitateto biorefineries and extract carbon chainswhich they will then be able to trans-form. The Pivert project, supported by theSofiprotéol group, which should soon leadto the establishment of a “biorefinery” inPicardy is a proof of concept, says VincentTouraille. His company is also one of theproject partners with expertise in bothchemical and enzymatic synthesis whichis provided by their subsidiary, Proteus. In

F

InIn light [SECTOR]

12

gaining importance with polymerists. Ourgoal is to develop furan monomers which canbe substituted for petrochemical monomers.In the fields of polymers and solvents, thefuran nucleus could be an alternative topetrochemical products in high volume appli-cations. Our size will not allow us to be themain player in this market, but we want toshowcase our expertise..

What areas of development are being

envisaged?

N.P.: We are part of the Minafin group andthe goal is to develop synergies within thegroup, especially with Minasolve whichis also in the growth phase and has no realproduction tools. This leads us to look atwhat is possible in the field of cosmetics.

Pennakem was created following the

acquisition of Penn Specialty Chemicals

by Minafin. What is your assessment of

the first year?

Norbert Patouillard: When we createdPennakem in 2008, we were not startingfrom scratch. We received a business withmore than sixty years of expertise in furfu-ral. However, the activity of Penn SpecialtyChemicals underwent stagnation. Between2000 and 2005, annual turnover totalled anaverage of 15 million dollars annually overthat period. Since then sales have grown toapproximately 50 million dollars projectedfor 2012. Our goal is to reach 75 milliondollars in sales in the next two to threeyears. We have not attained this progressvia simple maintenance activity. In recentyears, Pennakem teamshave been working ondeveloping new productlines based aroundbiomass.

Which markets are

Pennakem active in?

N.P.: We specialise infuran. We are mainlypresent in two segments:solvents and interme-diates. And anecdotally,we are developing a thirdsegment, monomers. Weare in the project anddevelopment phase inthat segment. Renewa-ble monomers are

FormuleVerte - N°11 - October 2012

We are also working on building upon ourgreen solvents for new applications as wellas developing new solvents. Our third areafor development is the synthesis of inter-mediates and active ingredients for theagrochemical industry. We want to bemore active there. In parallel to these axes,we are developing new uses for biomass inorder to expand our product range. Todaywe are buying furfural derived from corncobs and sugarcane bagasse. We are lookingat other sources of biomass and we areopen to the use of other building blocks.However, we are not starting from zero. Weare analysing a combination of our techno-logical tools and the use of certain biomass.Our strength lies in our expertise in hete-rogeneous catalysis, notably in catalytic

hydrogenation, reduc-tive amination and inthe thermolytic trans-formation cycle,coupled with a strongcapacity for distilla-tion in our solventactivity.

The mothballed green THF unit atthe Memphis site.

Norbert Patouillard, sales director for Europe and South America atPennakem Europa SAS since October 2011, details the strategy ofthe Minafin subsidiary, specialising in the use of furfural in the sectorsof solvents and intermediates.

FURFURAL

“Our investments may increase,depending on demand”

© Pennakem

Europas SAS

© Pennakem

Europe SA

S

InIn light [STRATEGY]

13FormuleVerte - N°11 - October 2012

You have a production site in Memphis

(Tennessee). Do you have other site pro-

jects in the world?

N.P.: Currently we are expanding ourpresence in Europe and Asia. In 2012, of theapproximately 50 million dollars in projectedsales, 28 million dollars has been made in theUnited States, 16 million dollars in Europeand 6 million dollars in Asia. However, wehave no plans for new sites. The Memphissite offers us many opportunities to increaseproduction capacity. For example, in thesolvent segment, we produce 5000 to 6000tonnes per year of specialty solvents. Wehave the ability to produce THF at a rate of30,000 tonnes per year. In fact, this productwas manufactured at the site until it washalted due to competition from petrochemi-cal THF and Asia. The production tool wasstopped and kept mothballed. The samegoes for intermediates. We have a multiser-vice site which is currently running at 100%.There is an investment program underwayto the tune of several million dollars toexpand production lines and refurbish buil-dings that are no longer used. Over the pasttwo years, we have invested between 2.5 and4 million dollars. And these investmentscould increase depending on demand; wehave unused capacity. Our policy is to useexisting facilities and refurbish them formulti-product use or, as appropriate, to installnew technological tools in parallel. ■

INTERVIEW BY AURÉLIE DUREUIL

PENNAKEM EUROPA SASIN BRIEF

InIn light

14

The American chemical company has opened abetaine unit in Origny-Sainte-Benoîte (Aisne) to supplythe animal feed and cosmetics markets.

BETAINE

evaporation and membrane filtration.“This unit is a way of utilising the co-productsof sugar beet distillery. The vinasse, once thebetaine is removed, is recovered by Tereos tobe used in spreading on agricultural land,”says Yves Belegaud. “Our capacity for inno-vation and scientific research and our colla-borative approach allow us to meet marketneeds whilst generating new opportunities,”says James C. Collins, president of DuPontIndustrial Biosciences.The betaine produced can be used foranimal feed (a product improving theintestinal health of livestock), as well ascosmetics and personal hygiene (moistu-risers). It also has more industrial applica-tions, such as in de-icing products usedmainly for airport runways. DuPont, which

he American companyDuPont has opened itsbetaine production plant

located in Origny-Sainte-Benoîte in theAisne region. With an investment of “sometens of millions of euros”, the unit has aproduction capacity of about 8000 tonnesper year. “This production line is located onthe site of the largest Tereos sugar beet distil-lery, which produces over 100,000 tons ofvinasse per year,” says Yves Belegaud, CEOof Tereos France, adding that “the twocompanies have signed a collaborationagreement for a minimum of 15 years.”Betaine is produced from beet vinasse, a coproduct of the distillation of beet intoethanol, via a process involving a chroma-tographic technology involving steps of

DuPont opens a production line in France

T

FormuleVerte - N°11 - October 2012

owns other betaine units around theworld, is currently the world’s largestsupplier of this product for applications infood, animal nutrition and industrial appli-cations.

The legacy of Danisco

The production line at Origny-Sainte-Benoîte is “the largest production unit in theworld for natural betaine produced frombeet vinasse,” which, according to bothpartners, will employ 20 permanentTereos staff, as well as an employee fromDuPont. In production since April 17th, theproduction site works 235 days a year,24 hours per day. The commissioning ofthe new unit is part of the overall strategyof the U.S. chemical group, which isseeking to benefit from three megatrends:food (animal and human), energy, andenvironmental and population protec-tion. “One of our strategic priorities, withabout 60% of our research budget, is theagri-food sector,” says James Laughton,executive vice president of Bioactives, oneof the activities of the Industrial Bios-ciences division. Construction on thebetaine unit project was initiated byDanisco in 2010, prior to its acquisition byDuPont Group, finalised in May 2011.Since then, the activities of the Danishcompany were incorporated into theIndustrial Biosciences division of the U.S.chemical group, which had a turnoverof 705 million dollars (€ 574 million) in 2011. ■

ORIGNY-SAINTE-BENOÎTE, DINHILL ONThe plant was inaugurated in the presence of elected officials and executives from Tereos andDuPont.

© T

ereo

s

N+

CH3

CH2

CH3

H3C CO

O-

Chemical structure of natural betaine (or tri-methyl-glycine).

InIn light [REPORT]

16FormuleVerte - N°11 - October 2012

ALDERYS

Synthetic biology substitutes oil

Dominique Thomas, founder of Alderys.

ALDERYS IN FIGURES AND DATES● 22 employees

● 2011 turnover:

1.3 million euros

● Laboratory space: 1000 m2

● Investment in materials

and equipment:

2.5 million euros

● July 2010: founded

●August 2010: signing of

first industrial partnership

in animal nutrition

●Nov. 2011: signing of a

second industrial

partnership

●December 2011: first

fundraising, with 2 million

euros from the venture

capital company Emertec

The young company Alderys produces key chemicalcomponents thanks to technology from syntheticbiology. It targets the sectors of animal and humannutrition, and intermediates for the synthesis ofmolecules of interest.

[A YOUNG AND INNOVATIVE COMPANY]& ResearchDevelopment

estled among trees, Alderyshas taken up residence inOrsay. The colour green suits

it well, as the fledgling company is deve-loping new processes for industry frombiomass.“10% of world oil is not converted intofuels,” said Emmanuel de Maistre, headcharge of business development at Alde-rys. A portion of this 10% is used toproduce food and industrial compounds,such as methionine, an essential aminoacid in animal nutrition. Alderys’ niche isto produce these chemicals, not frompetroleum, but thanks to microorganisms.The company is aiming at the industry foranimal and human nutrition, as well asthat of synthons, the building blocks forconstructing more complex molecules. Inorder to achieve this, the company usessynthetic biology. First emerging in the2000’s, synthetic biology allows for theconstruction of new metabolic pathwaysand the development of new enzymecatalysts. This science aims to createmicroorganisms designed to producemolecules of interest. The Alderys storybegan a little over two years ago withDominique Thomas, a former director of

research at CNRS and specialist in yeastmetabolism. After founding a drugresearch company in 2000, he took thehelm of Incuballiance in 2007, a techno-logy incubator on the campus of Paris-Saclay-Ile-de-France. “I closely followedwork in metabolic engineering. I felt therewas an opportunity to create a company,”he says. At his side, Philippe Marlière, asynthetic biologist and designer ofprocesses for the chemical industry, tookcharge of scientific consulting at the

company. Today the company has morethan twenty employees.Alderys draws its expertise from so-calleddisruptive technologies. There are three ofthem: metabolic design, acceleratedDarwinism and massive genome modifi-cations. They were developed within ayear, with the overall aim of transformingmethods of synthesising compounds ofinterest in optimised microorganisms.Synthetic biology can apply rational engi-neering methods to biology.The technology of metabolic design aimsto fully redesign metabolic pathways inmicroorganisms. The objective is toincrease fermentation yields and consumeless energy.Alderys is working on the design andselection of yeasts, whose metabolism isrectified in order to produce a high yield.The technology consists of implanting (orremove) new genes into yeast strains toproduce new enzymes. The activity ofthese enzymes is then tested and valida-ted. Finally, the production of metabolitesof interest follows fermentation trials. Theprocess, which is highly iterative, continuesuntil satisfactory results are obtained. Thegenetically modified microorganisms thusproduced do not leave the fermenters,and are destroyed after production phases.Finally, thanks to robotic manipulation,Alderys has created hundreds of variantsby directed robotic evolution. It is accele-rated Darwinism. Robots evolve thou-sands of yeast strains in parallel byapplying selection pressures. More effi-cient modified enzymes are thus selec-ted. Directed evolution optimises either aspecific reaction (selection of more effec-tive modified enzymes) or an entire yeast(improved fitness of a production strain).“The protocols are specific to our company,”says Dominique Thomas, co-founder ofAlderys.And to exploit these technologies, Alderysuses three platforms: genome enginee-

N © A

lder

ys

17

[A YOUNG AND INNOVATIVE COMPANY] &ResearchDevelopment

ring for the construction of geneticallymodified strains, biological chemistry forthe analysis of metabolites, and roboticsfor the evolution of strains. Their equip-ment is situated in 1000 square meters ofAlderys laboratories.Yeast is at the heart of all of the technolo-gies used by Alderys. Why this choice,rather than bacteria, for example? Yeast iseasier to work with from a genetic point ofview, has no antibiotic resistance cassettes,and does not have virus issues... In addition,yeast growth is possible in an acidicmedium, which simplifies the purifica-tion process. This sexed organism allowsfor the combinatorial recombination ofgenetic traits, and as it has extra chromo-somes, new features can be introducedmassively. Finally, production yields fromthis robust body can be retained duringramping up to industrial scale.In addition to its technology, Alderys hasadopted a strategy of flexible develop-ment, allowing its partners to be involvedat several stages. Depending on the clientand the molecules in question, thecompany may be involved from designto production technology including scalingup, in partnership with industry in orderto respond to a specific request. Businessdevelopment agreements can be establi-shed at an early stage or after pre-indus-trial scale-up. Alderys also plans to developits own capabilities for piloting and

produced from petroleum, its synthesisinvolves constraining regulations at Sevesoplants. An alternative biobased methodwould be a considerable advantage for acompetitor. Four programs are underway,including two conducted with heavyweightindustrial partners. Other very promisingpartnerships are on the horizon for Alderys.“Our ambition is to become the French leaderin green-tech industry,” says Emmanuel deMaistre, enthusiastically.■

RAPHAËLLE MARUCHITCH

production. “This third strategy is plannedfor the coming three to five years,” saysEmmanuel de Maistre. “We have alreadyidentified the relevant markets in which wewill develop.”Market potential is promising. To return tothe example of methionine,“800,000 tonnes are produced annuallyworldwide, of which 80% are for breedingchickens. And every day, mankind consumes100 million chickens,” says Emmanuel deMaistre. Besides the fact that methionine is

Alderys set up its laboratories in Orsay.

© A

lder

ys

n a context where environmen-tal issues are increasingly impor-tant, renewable resources havethe wind in their sails. In parti-cular, biomass (derived from agri-

cultural, forestry and microalgaeproduction) which is incorporating evermore bio-products such as fuels, sol-vents, materials, lubricants, plastics,etc. These biobased products can in par-ticular contribute towards meeting thechallenge of the increasing scarcity of

18FormuleVerte - N°11 - October 2012

fossil resources in economic terms.Although some biobased products arean alternative to fossil fuel products,environmental benefits remain diffi-cult to assess. However, the benefits ofbio-products have yet to be evaluatedin a very accurate and reliable man-ner. Better assessment and understan-ding of positive and negative impactsrelated to the production of biobasedproducts will allow for better environ-mental protection and resource mana-gement.Reducing the impact of products onthe environment can be achievedthrough a process termed eco-design.It consists of integrating the environ-mental dimension at the product des-ign stage, and combining differentelements in order to reduce its impacton the environment at different stagesof the life cycle of a product. For exam-ple, these choices may involve the useof recyclable raw materials, the use ofless energy or processes consumingless water or toxic reagents. AtRoquette, eco-design focuses on opti-mising the production process. “Thereare two possible approaches. On the onehand, we can optimise the efficiency ofthe use of raw materials by improvingtheir use and reducing waste via therecovery of all fractions of the material.On the other hand, we can reduce theconsumption of energy and water andencourage recycling,” says Camille

I

ECO-DESIGN A work in progress

Burel, head of business innovation atRoquette and co-leader of the group ofexperts on LCA at the Association in ofPlant Chemistry (ACDV). At DRT, effortsin eco-design follow two axes, asexplained by Eric Moussu, sales andmarketing director of DRT, specializedin the production of rosin and terpenederivatives: “On one hand, our workfocuses on the use of raw materialswhich are less harmful towards the envi-ronment. For example, we recently laun-ched our Pithys range where wesubstituted a fossil-based componentby an equivalent made from sugar cane.On the other hand, we are seeking toreduce the impact of the manufactu-ring processes for our products, by tryingto limit our consumption of energy,water and waste.” In terms of raw mate-rials, it is necessary to analyse allimpacts, as Eric Moussu says: “It issometimes better to opt for a fossil-based product, rather than choosing abiobased one. Indeed, the use of plant-based raw materials can lead to worseenvironmental impacts than the fossil-based option.”

LCA analysis in 4 steps

In order to help manufacturers esta-blish their eco-design strategy, there isa tool called Life Cycle Analysis (LCA).First appearing in the 1970’s, thismethodology allows companies to eva-luate the environmental impacts ofproducts, from raw material extractionright up to their end of life, includingtheir manufacture, distribution anduse. “This is a very comprehensive ana-lysis tool, but is very heavy in terms ofdata,” says Camille Burel. “LCA is alsoa way of giving customers a scientificassessment of the environmentalimpact,” adds Eric Moussu. LCA consistsof four main steps. The first is to define

Manufacturers in plant chemistry want to move towardsproducts which are more eco-designed. However, environ-mental impact assessment and life cycle analysis of pro-ducts is still complex. Therefore one of the challenges foreco-design is to communicate in a manner which is clear,simple and scientifically relevant to consumers.

PINE RESIN ISUSED TO MANU-FACTURE MOST OFTHE PRODUCTSFROM DRT.

© DRT

Special report

FormuleVerte - N°11 - October 2012

the purpose and scope of the study,which identifies the data needed toquantify environmental impacts. Thesecond step, which is highly complexand detailed, aims to identify all of theconsumption of resources and emis-sions at each stage of a product’s lifecycle. Then comes the step of evalua-ting impact, where the collected datahas to be converted into environmen-tal indicators according to the impactof the study (see table). For example,relevant indicators for assessing poten-tial for climate change are calculatedfrom emissions of greenhouse gases(CO2, methane, nitrous oxide, etc.).Finally, the last step of LCA is to inter-pret the life cycle, i.e. analyse and com-ment upon the environmental impactsobtained in order to draw conclusions,explain limitations and provide recom-mendations in terms of the objectivesand scope of the study. Although thetool is standardised via a series of ISO

19

standards (ISO 14041-14044), it has itslimitations: in fact, two analyses of thesame product may differ dependingon the objectives, assumptions,methodological choices andquality of the data collected.Despite this drawback, LCA is the mostsuccessful and suitable tool for asses-sing the environmental impacts of pro-ducts, and therefore even if they arewholly or partially biobased. Indeed,its complexity can take into accountall steps related to the existence of abio-product, and even more so duringthe production phase, where it is pos-sible to identify all energy flows, inputsand reagents in the agricul-tural and industrialphase. “The advantageof biomass products inLCA studies is that they areable to fix CO2 during theproduction of the biomasswhich is the raw mate-

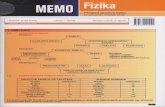

Examples of impacts and environmental indicators

Category Impact Impact Significance of indicator Unitindicator

Consumption Depletion of Potential depletion Quantifies the extraction of non renewable Kg of Sbof resources non-renewable of abiotic natural resources, consumed at a rate (antimony)

resources resources greater than the time requiredtheir natural production.

Consumption of Potential for Includes all non-renewable primary energy Mega joule (MJ)non-renewable consumption non sources extracted from natural reserves primary energy renewable primary (coal, natural gas, oil and uranium)..

energy

Water consumption potential depletion Potential depletion of water resources m3

of water resources

Climate Greenhouse effect Potential Identifies increase in the average Kg of CO2Change global concentration of anthropogenic substances

warming (CO2, CH4, N20, etc.)

Air Pollution Air pollution Potential acidification Identifies the amount of acidic substances Kg of S02in the lower atmosphere

(SO2, NOx, NH3, HCl, HF, etc.).

Photochemical Potential for creation Identifies impacts due to organic Kg of C2H4

oxidation photochemical ozone substances involved in the formation of (ethylene)tropospheric ozone..

Depletion of Potential depletion Caused by reactions between stratospheric Kg of CFC-11the ozone layer of the ozone layer ozone and compounds such

as CFCs.

Water Pollution Eutrophisation Potential for The introduction of nitrogen or phosphorus Kg of PO43-

eutrophisation nutrients promotes the proliferation of (phosphate)certain species (algae, plankton)

into aquatic systems.

Source : Valbiom

>

© D.R.

Special report[ECO-DESIGN]

20FormuleVerte - N°11 - October 2012

this elemental analysis, coupled withthe measurement of biobased carbonwould allow us to verify informationfrom manufacturers about bio-pro-ducts,” explains Camille Burel. The asso-ciation is also working on thestandardisation of this indicator atEuropean level.

Guidelines on end of life

LCA thus helps to quantify the impacton the environment at every stage ofthe life of a product, to identify the ele-ments with the greatest impact, andthus serve as a basis for an overall assess-ment of environmental integration. LCAallows the best possible managementof waste at the end of product life to be

determined, notably in terms of recy-cling. “Even if eco-friendly designed bio-products are designed to be recyclable orbiodegradable, there is still the problemof the separation of similar products atend of their life for effective recycling.This is very expensive today becausevolumes remain low,” says Camille Burel(Roquette). “Existing recycling processesfor petrol-based materials might workfor biobased materials” says SylvainCaillol. He adds: “But before talkingabout recycling, it’s necessary to imple-ment a sorting process to captureresources.” It is an opinion shared byCamille Burel: “The hardest part is cor-rectly collecting, separating and trea-ting waste. It has a veritable process logicto it and the challenge is to organise itin a viable manner.”The complexity of LCA limits its imple-mentation for each individual product,and many manufacturers use theirown variant of the methodology forthe eco-design of products. For exam-ple, the sustainable development stra-tegy at Roquette includes systematicmeasures necessary for carrying outLCA in order to make data collectionand the calculation of impacts automa-tic. “Impact monitoring allows us to setgoals for improvement and integrate

rial, as compared to a product derivedfrom petroleum,” says Camille Burel(Roquette). She continues: “However,as this is a living material, its environ-mental impact will not be the same,depending on cultures, location, etc,which makes collection of data on theproduction phase difficult.” In addition,the LCA methodologies used have tobe adapted, in particular taking intoaccount the management of agricul-tural by-products, changes in land usefor crops, and the reactions in the trans-formation processes. Indeed, little LCAdata for biobased products is available,as confirmed by Camille Burel(Roquette): “In the field of plant che-mistry, processes for conversion of bio-mass and the innovative technologieson which they are based are evolving atsuch a rate that LCA results should bereviewed regularly and due to this thereis little communicated.” It is a view sha-red by Eric Moussu (DRT): “With regardto specialty chemicals, we have very lit-tle feedback in terms of LCA for bioba-sed products.” Currently, the mostcommonly used indicator to assess theenvironmental impact is carbon-14content. “This indicator is relevant butis not sufficient because plants are notentirely made of carbon,” says EricMoussu. And to overcome this lack ofinformation, the ACDV is currentlyworking on a complementary indica-tor for specific products made from bio-mass, reflecting the vegetable contentof products. “The ACDV has establisheda certification based on an analysis ofproduct components (carbon, nitrogen,oxygen, etc.), which would be performedby an independent laboratory. Thus,

>

RECOMMENDATIONS BY THE ADEME FOR SIMPLIFIED LCAIn December 2009, the ADEME carried out a

study on LCA and made a number of recom-

mendations for simplifying the process.

Firstly, the study recommends the examina-

tion of three essential points: the purpose of

the LCA, the scope of the study, and the choice

of indicators. In order to make the evaluation

of the environmental impact of the agricultu-

ral phase easier (which is highly dependent on

criteria such as the type of culture, the cli-

mate, soil, use of fertilizers or pesticides, etc. ),

the ADEME recommends using data aggrega-

ted by country and not by plot of land. In addi-

tion, it recommends the use of a credit logic

for carbon storage of biogenic origin.

Finally, the study indicates that an LCA must

include end of life scenarios (recycling, incine-

ration or landfill).

The life cycle of a product

Extraction and processing of

non-renewable resources

Agricultural production andpre-treatment

of biomass

Management of co-products and

waste management

Production of bio-products

Use phase which is

often overlooked

End of Life

Cradle to grave

Cradle to factory gate

Source : Ademe

Special report[ECO-DESIGN]

21FormuleVerte - N°11 - October 2012

ign approaches, the ADEME advocatespromoting a better understanding ofthe subject via the establishment of aninformation portal and approaches toencourage professionals. Although thetrend is toward greater transparencyin terms of the environmental assess-ment of bio-products, there is still pro-

© M

olydal

© DR

©DR

these parameters in our decisionmaking,” says Camille Burel. For DRT,an internal project which ran fromDecember 2009 until mid-2011 allo-wed them to develop an LCA tool withthe help of the company BioIntelligenceServices. “We have computer softwarecoupled with a database to evaluate ourproducts from raw materials right upuntil they leave the plant,” explains EricMoussu. Thus, on request, the companyis able to provide a dossier of environ-mental data when required by the clad-ding and construction sector. “Clientsusing our products have an exclusivecontract, allowing them, if need be, touse the information for their own envi-ronmental assessment,” says EricMoussu. According to a study by theADEME (the French Environment andEnergy Management Association) oneco-design completed in 2010, thisupsurge in individual initiatives isexplained by “a strong heterogeneityin the needs and expectations of busi-nesses, related to their level of maturityvis-à-vis the subject.” The studies showthat the absence of the application ofa global framework of reference encou-rages the proliferation of ad hocmethods and tools. In order to helpcompanies implement their eco-des-

AT THEIR LESTREMSITE, ROQUETTESYSTEMATISESMEASUREMENTOF THEENVIRONMENTALIMPACTS OF ITSPRODUCTS.

ROQUETTE USESBIOMASS FROMMAIZE FOR ITSBIO-PRODUCTS.

© Roquette

gress to be made in France. “France islagging behind in terms of eco-designand LCA, and research projects on sus-tainable development have just begun.With the little money that is being allo-cated to R&D, LCA is not yet a priorityarea,” says Sylvain Caillol (ChemSud). ■

DINHILL ON

Special report[ECO-DESIGN]

22

not imagine each member country beingrepresented by one or two structures of thiskind? As far as we are concerned, they act ashighly efficient relays and remove many of

the constraints that we, asindustrialists, are subject to,"states Jean-François Rous, Direc-tor of Innovation, SofiproteolGroup, in an indirect referenceto the success of the PIVERTproject. "Being a part of the crea-tion of this structure is anopportunity open to everyone.Getting on board now alsomeans enjoying a strategicadvantage," claims CamilleBurel, Manager for InnovationAffairs, Roquette Group. France

has a strong agro-food industry, a strongchemicals industry and very high levels ofresearch. "Setting up this PPP is also impor-tant as a source of solutions for the growthof agriculture and for maintaining a strongrural society and the jobs to go with it," sheadds. Everyone has come away from thediscussions surrounding the PPP with asense of confidence, everyone shares in thechallenges, and quality and pragmatismwill be the order of the day in the represen-tation and organisation of the partnership.

Biobased for growth, an opportunity for all

While all private sector members arewelcome to join the PPP between now and2014, the first members to sign up to theproject will be central to future roadmaps.The partnership remains open, however,and the terms on which private sector firmsand research institutes not involved from theoutset will be admitted to membership arecurrently under consideration as part offuture calls for projects. The intention is in noway to create a private club, but to ensureevery chance of success for the project andgive as many members as possible a chanceto be involved. "This PPP offers a real oppor-tunity to create even stronger links betweencompanies collectively involved in the futuresuccessful marketing of biobased products,"says Christophe Luguel, Head of Internatio-nal Affairs at the IAR cluster. "Currently, the

Publi-information

FormuleVerte - N°11 - October 2012

This future PPP is a perfect illustration of a new investment dynamic shared by both publicand private sector to promote innovative businesses and their future economic outlets.Europe faces a major new challenge: becoming one of the leaders in the new globalbiobased economy.

: the three letters stand forPublic-Private Partnership, afinancing tool introduced in

2008 and which has already resulted in fiveoperational programmes. The healthcare,aeronautics and transport sectors are alreadyreaping the benefits, with hundreds of newprojects and applications already creatingvalue and jobs. PPPs give industry a rolealongside government in defining Euro-pean innovation strategies and more directinvolvement in calls for innovation-basedprojects. PPPs also provide a response to thechallenges of fierce global competition byattracting high-growth sectors and the jobsthey generate. Europe is already gearing upto become a pacesetter in one of the neweconomies of tomorrow: the biobasedeconomy.

A new PPP announcedfor 2014

"Biobased for Growth " is intended to kick-start radical innovation and the emergenceand reinforcement of competitive and inno-vative biobased sectors, by injecting fundingprecisely where it is most needed in Europe:demonstration and flagship plants.The PPP is also committed to developingsolutions to the major challenges facingmodern society, such as the growing pres-sure on fossil fuel reserves and the issue ofgreenhouse gas emissions. Its members arefocusing on generating new momentumfor the agriculture and forestry sectors thatwill eventually help to revitalise rural areasand develop a circular economy based onsustainably managed renewable resources.The PPP will play a key role in the shapingand development of this new economy,whose potential other parts of the worldhave been quick to grasp (Brazil, Asia and theUSA, to name but three). The stakes arehigh, not only in terms of joint public-privatesteering but also in terms of giving industrya chance to make its mark on the worldstage. At the outset, i.e. from the beginningof 2014 and running through to 2020, itwill involve investment of some €2 billion,half from industry and the other half fromthe European Commission. The industrialpartners will be responsible for designing

programmes to tackle the key challenges ofindustrial growth, while the Commissionwill analyse and validate the programmesfor the benefits and social spinoffs they areexpected to provide. It is herethat the partnership comesinto its own: it will be basedon dialogue and a sharedvision over the seven years ofits existence. Not forgetting,of course, the necessaryeconomic balances, startingwith the basis on which thefuture structure will operate."We are in the process ofscaling up, with less fragmen-tation in terms of fundingand greater concentration onlarge-scale projects; this is a unique opportu-nity to catch up on ground lost to the UnitedStates, which drew up its roadmap some timeago and has massive funding available,"remarks Jean-Marie Chauvet, Head of theBiorefinery Research & Innovation platform.In short, this is an opportunity for Europe toestablish its visibility and its credibility in thebiobased economy on the global stage.Following the clear statement of intent fromthe private and public sector partners, all thatremains is to finalise the European part-nership and turns this powerful lever into astrike force for French and European firmsspearheading innovation, and just waitingfor a chance to position themselves.

Strong commitment fromFrench firms and agencies

"This PPP is an opportunity for groups ofstakeholders representing sector interests –agriculture and agro-industries, the forestrysector, the pulp and paper industries, chemi-cals – to organise and start working togetherto form new value chains from which allwill benefit," adds Jean-Marie Chauvet. Struc-tures such as ACDV, the IAR cluster or ARD,already perform this representative role intwo areas in which France is particularlystrong: agriculture and agro-industry. The involvement of the competitivenessclusters, with the organisation and thesupport they provide, can help reinforce thecommitment of French stakeholders. "Why

Jean-Marie Chauvet,Head of the BiorefineryResearch & Innovationplatform

© D

.R

"Biobased for Growth", pursuing Europeanleadership in the biobased economy

PPP

23FormuleVerte - N°11 - October 2012

What decided the

IAR cluster to get

involved in the PPP?

We have, in fact, been

part of the process

since 2009, when the Star-COLIBRI project was

launched. The aim of the project was to unify

the visions and roadmaps of the different

industrial sectors of the bioeconomy and thus

prove to the Commission that our industry

was ready to move on to the next stage. We

were in the right place at the right time and

now we are able to capitalise on that expe-

rience.

© D

R

outsourcing these calls for projectswill cost Europe less, it will costindustry more to finance themsuccessfully". Hence the perfectlyunderstandable call for a financialcommitment from as many part-ners as possible.

The importance of balanced, simplified and strict governance

"It mustn't turn into a hotchpotch,though," warns Jean-FrançoisRous. "The success of the PPP willbe largely determined by the

quality of its governance." Quality of organi-sation, first and foremost, andthe number and commit-ment of members. "The objec-tive is to find the right balancebetween the representativenature of the member firmsat the European level and thecapacity for each member tobe really involved on a day-to-day basis." The message isclear: it would be a pity tofail to make the most of thisnew financing tool by impo-sing an organisation that istoo restrictive or time-consu-ming.Administrative processes will also have to bekept as simple as possible in order to be"appealing", the term used by Camille Burel,who shares the views of Jean-François Rousand adds, "To avoid the risk of slipping intoan organisation that is too complex for firms,the PPP's governance must match the attrac-tiveness of the project as a whole". Thatattractiveness will be based on the drive to

How is the PPP strategic for the cluster?

As you know, it is not the level of research in

France and Europe that poses a problem, but

the link between research and bringing a pro-

duct to market, what is known as the "innova-

tion valley of death". This is a real challenge for

Europe's bioeconomy and also for our mem-

bers. The PPP is specifically designed to meet

this challenge.

The cluster offers its members, particularly

SMEs, support for innovation and the PPP

marks another step: where do SMEs stand in

the PPP?

It's the ideal tool for them! The Commission

decided that industrial firms, and innovative

SMEs in particular, should have their say in

ensuring that research is applied to the mar-

kets that matter to them.

What role does the cluster play

in governance?

We are one of the three European clus-

ters involved in the founding of the

PPP, and proud of the fact. Proud on our

own behalf, and proud for our members

and for the SMEs we represent..

For anyone interested in plant-based chemistry

www.chimieduvegetal.com

forestry, agriculture, chemi-cal and agro-industrialsectors are represented. Theinvolvement of thesecomplementary sectors,alongside the EuropeanCommission, in the yearsahead will help establishsound strategy and fundingfor innovation in the bioe-conomy over the longterm," adds Camille Burel.True, the time span ismeasured in years, but thisonly underscores theimportance of maintaininghigh quality of dialogue between the privatesector and Commission members, and ensu-ring their continued involvement over time.

The challenge of SME involvement in a majorEuropean programme

Even so, the question arises of what roleSMEs will play in this new financing scheme.While the issues of SME participation arestill under discussion, one thing is clear: SMEsmust be given the chance to benefit from thisdynamic new initiative. "They have not beenforgotten," explains Jean-Marie Chauvet."Professional organisations and associationshave been and continue to be active in raisingawareness of the opportunity on offer". Inaddition, a clear definition of themes and aconcentration of new resources around astructure that will require its own specificapplications should have a beneficial knock-on effect for the SMEs involved. "Of course theissue arises, and there is no question of theirexclusion," explains Jean-François Rous, "butit's also important to remember that while

create, develop and maintain a sense ofmomentum for a partnership currently stillin the formative stages. Industry and the Commission will need tofind the right balance between everydayreality, organisational constraints and simpli-fied processes to make the launch of thisnew partnership a success.Biobased for Growth marks a new step interms of mode of governance, levels of callsfor projects and more direct involvement ofindustries with an interest in potential appli-cations. In fact, this is probably the most stri-king innovations in terms of projectfinancing policy: all the stakeholders, thefuture road maps, a novel form of gover-

nance, all the industrialmomentum - all united behindin a very real vision of appliedresearch and process demons-tration.Now is the time to movetowards a concrete projection,applied to markets wheredemand exists, all the waythrough to industrialisation inthe form of demonstrators. Acloser look reveals that this isexactly what the Commissionis considering as part of itsfuture funding plans. Thingshave changed; industry now

has a say in and control over theprogrammes that will enable it to competeon an equal footing on internationalmarkets. ■

Camille Burel, Managerfor Innovation Affairs,Roquette Group

Jean-François Rous,Director of Innovation,Sofiproteol Group

© D

.R

© D

.R

Interview with Christophe Luguel, Head of International Affairsat the IAR cluster

MEMBERS HAVE THEIR SAY

24

Index [COMPANIES]

List of advertisersADVERTISERS PAGE

3C FRANCE 9

ACDV 22-23

CRODA 11

ENDRESS+HAUSER 13

GROUPE NOVASEP 2ND COVER

ITERG 17

LEBAS TECHNOLOGIES 15

PLANT BASED 3ND COVER

POLE IAR 4ND COVER

POLE IAR 5

SIA/NOVANCE 4

VALBIOM 24

Magazine published by ETAIAntony Parc II 10, place du Général de GaulleBP 20156 - 92186 ANTONY CedexTel.: 01 77 92 92 92Web site: www.formule-verte.comTo contact your correspondents, dial 01 77 92,followed by the four figures shown after each name.To send them an email, type the first name initial,the surname then @etai.fr (eg.: [email protected])

Director of the magazine:Christophe Czajka

Director of the specialist magazine hub:Pierre-Dominique Lucas

Chief editor:Sylvie Latieule (95 87)

Copy editor:Ariane Boixière-Asseray(95 85)

Editors:Aurélie Dureuil, FlorenceMartinache (95 81), Dinhill On (95 80),JulienCottineau (95 86), Audrey Fréel (95 83)(Chimie Pharma Hebdo)

Magazine Studio Manager:ThierryMichel (96 30)with Christian Le Coz (96 31)

Design editor:ThierryMeunier (96 29)

Advertising:Sandrine Papin (advertisingdirector Industry hub - 96 43),Eric Leuenberger (director - 96 37),Assisted by Martine Szuba (technicalassistant - 96 44)

Representatives:– Rhône-Alpes: Become, Eric Bechetoille,19/21 chemin de Montauban, 69005 Lyon,Tel./Fax: 04 72 00 04 14, Mobile: 06 80 68 44 00– Germany / Switzerland / Austria: AxelleChrismann(Sales Manager) - Tel.: +33 (1) 77 92 9259 Email: [email protected] HUGUES (Advertising Manager)Tel.: +33 (1) 77 92 95 36 - Email:[email protected]

– Italy: Piero Tomassi (Sales Manager)Tel.: +33 (1) 77 92 96 90 - Email:[email protected]– USA: Trade Media International corp.,421 Seventh Avenue, New York, NY 10001-2002 USATel.: (1.212) 564-3380 - Fax: (1.212) 594-3841

Marketing, distribution, subscriptions:Director: Jean-Baptiste AllineCustomer Distribution and Marketing:Laurence Vassor - [email protected]: Isabelle de Goüyon [email protected]

To subscribe:: [email protected]: 33(1) 77 92 99 14 – Monday to Friday

(9am to 12am – 2pm to 5pm / 4pmFriday)

: 33(1) 77 92 98 15: INFOPRO Communications (GISI - ETAI) -Subscription service - Antony Parc II -BP 20156 - 92186 Antony Cedex

1 year, France: €107.64inc. VAT (VAT at 19,6%)Students, international: please contact usSales by issue n°: (back issues, almanac): www.librairie-gisi.fr : 33(1) 77 92 97 75

Legal deposit: September 2012Printed by the presses of

Corlet Imprimeur - ZI, route de VireBP 86 - 14110 Condé-sur-Noireau

ISSN 2117-4172

Simplified Joint Stock Company with capital of 47 111 184 euros

Siret: 806 420 360 00117 – APE code: 5814Z

40 conferences and round tables 100 speakers – 100 exhibitors 2.000 auditors and visitors

September 25-26, 2013 Grande Halle de la Villette - Paris - France

THE EUROPEAN CONFERENCE AND EXHIBITION

FOR BIOBASED SOLUTIONS

Speaker contact

Conference manager Gaëlle Clertan+33 (0)1 77 92 94 [email protected]

Sponsor, exhibitor contact

DirectorJean-Luc Garnier+33 (0)1 77 92 96 [email protected]

E-T-A-I, a french SAS with a capital of €47,111,184 the head office of which is located at 10 place du Général de Gaulle La Croix de Berny BP 20156 - 92 186 Antony Cedex France, registered with the Trade Register of Nanterre 806 420 360

Co-organised by:

Call for papers

SHAPING THE FUTURE WITH THE PLANT BASED CHEMISTRY

THE EUROP

REAN CONFETHE EUROP

XE AND ENCER

IONTIBIHX

FOR BIOB

D SOLEASFOR BIOB

IONSTUD SOL

September 25-26, 2013

September 25-26, 2013

40 conferences and round tables 100 speakers – 100 exhibitors 2.000 auditors and visitors

Grande Halle de la V

40 conferences and round tables 100 speakers – 100 exhibitors 2.000 auditors and visitors

- Paris - FranceilletteGrande Halle de la V

- Paris - France

[email protected]+33 (0)1 77 92 94 06Gaëlle ClertanConference manager

Speaker contact

+33 (0)1 77 92 94 06

Conference manager

Submit your paper our

to join the high level panel of more than 100 contributors. 30 chosen speakers will have the opportunityYONLLY

or paall fC

2.000 auditors and visitors

.plantbasedsummit.frto join the high level panel of more than 100 contributors.

30 chosen speakers will have the opportunity

speror pa

2.000 auditors and visitors

b f O t bd it fto join the high level panel of more than 100 contributors.

30 chosen speakers will have the opportunity

, 31st 2012

[email protected]+33 (0)1 77 92 96 86Jean-Luc GarnierDirector

, exhibitor contactSponsor

+33 (0)1 77 92 96 86

, exhibitor contact

Submit your paper our

.plantbase www w.plantbasedsummit.frSubmit your paper our

before Octoberedsummit.frr

, 31st 2012 before October

pital of a french SAS with a ca,-A-IE-T

Co-organised by:

ted a47,111,184 the head office of which is loca€pital of

APING HS

y BP 20156 - 92 186 t 10 place du Général de Gaulle La Croix de Bernted a

TH WIEURT FUTHE

istered with the regy Cedex France,Antony BP 20156 - 92 186

EAS BTAN PLTHETH

ister of Nanterre 806 420 360rade RegTTrade Registered with the

YRTMISHED CE