Formulation and Controlled Release – Titania Core-shell...

Transcript of Formulation and Controlled Release – Titania Core-shell...

DepartmentofChemistryandChemicalEngineeringAppliedSurfaceChemistry CHALMERSUniversityofTechnology Gothenburg,Sweden2016

FormulationandControlledRelease–TitaniaCore-shellParticles

withBiocide

BachelorofScienceThesis

VictoriaDavidsson

Formulationandcontrolledrelease–titaniacore-shell

particleswithbiocide

Astudyofreleasepropertiesfromtitaniacore-shellparticles

VictoriaDavidsson

DepartmentofChemistryandChemicalEngineering

CHALMERSUNIVERSITYOFTECHNOLOGY

Gothenburg,Sweden2016

Formulationandcontrolledrelease–titaniacore-shellparticelswith

biocide

-Astudyofreleasepropertiesoftitaniacore-shellparticles

VICTORIADAVIDSSON

©VICTORIADAVIDSSON,2016.

DepartmentofChemistryandChemicalEngineering

ChalmersUniversityofTechnology

SE-41296Göteborg

Sweden

Telephone+46(0)31-7721000

Cover:

Titaniacore-shellparticleswithbiocidepreparedbyinterfacialcondensation

Gothenburg,Sweden2016

Abstract

Anti-growthagentslikebiocidesarecommonlyusedtoprotectpainedhousefacadesand

otherexteriorsurfacesfrombiofoulinglikemold,lichens,mossesandalgae.Thebiocidesare

normallydirectlymixedintothepaintduringformulation.Thebiocidesaresmallmolecules

withhighdiffusivitywhichleadstofastleakageofbiocideoutfromthepaintedcoating

matrix.Whentheconcentrationofthebiocideinthecoatingmatrixistoolowthereisno

protectionagainstbiofouling.Tomaintaintheconcentrationforaslongaspossible

microencapsulationhasbeenshowntobeapromisingmethodtoslowdownthediffusion

rate.Thebiocidemustthendiffusethroughtheshellofthemicrocapsulebeforediffusing

throughthecoatingmatrix.Inpreviousstudiesvarioustypesofbiocideshavebeen

encapsulatedinmicrocapsulesbasedonthepolymerpolymethylmethacrylate.Inthisstudy

atitaniacore-shellwasusedforencapsulationofthebiocideBHT(2,6-di-tert-butyl-4-

methylphenol)viaaninterfacialcondensationmethod.Thereleasefromtheprepared

microcapsuleswasstudied.Thereleasebathwas0.125MaqueoussolutionofSDS(sodium

dodecylsulphate).Themicrocapsulesdidyieldfullencapsulationofthebiocidethroughthe

purification.SamplesweretakenfromthereleasebathandanalysedwithUV/Vis-

spectroscopy.TheresultsshowanalmostimmediatereleaseofBHTfromthecore-shell

particles.

Sammanfattning

Växthämmandeagens,såsombiociderärvanligtanväntförattskyddamåladehusfasader

ochandraytorutomhusfrånmikrobiellpåväxtsommögel,larvar,mossaochalger.

Biocidernablandasnormaltdirektnerifärgenundertillverkningen.Biociderärsmå

molekylermedhögdiffusivitet,vilketledertillsnabbtläckageavbiocidenutfråndenmålade

färgmatrisen.Ärkoncentrationenavbiocidenifärgmatrisenförlåg,verkarintelängredess

skyddandeeffektmotpåväxt.Förattbehållakoncentrationenpåenlagomnivåochföratt

geettlångvarigtskyddharmikroinkapslingvisatsigvaraenlovandemetodförattsaktaner

diffusionshastigheten.Biocidenmåstedådiffunderagenomskaletpåmikrokapselninnan

denkandiffunderagenomfärgmatrisen.Itidigarestudierharolikatyperavbiocider

inkapslatsimikrokapslarbaseradepåpolymerenpolymethylmethacrylate.Idennastudie

användskärnskalskapslaravtitanförattkapslainbiocidenBHT(2,6-di-tert-butyl-4-

methylphenol)viaeninterfacialcondensationmetod.Frisättningenfråndetillverkade

kapslarnastuderades.Frisättningsbadetvar0.125MvattenlösningavSDS(sodiumdodecyl

sulphate).ProvertogsfrånfrisättningsbadetochanalyseradesmedUV/Vis-spektrometri.

ResultatenvisadepåennästanomedelbarfrisättningavBHTfrånkärnskalskapslar.

ABBREVATIONSBHT–2,6-di-tert-butyl-4-methylphenolorbutylatedhydroxytoluene

Brij®L23–Polyoxyethylene(23)monododecylether

NMR–Nuclearmagneticresonance

PEG-PPG-PEG–Poly(ethyleneglycol)-block-poly(propyleneglycol)-block-poly(ethylene

glycol)

PMMA–Poly(methylmethacrylate)

PVA–Poly(vinylalcohol)

Ti(OBu)4–titaniumtertbutoxide

Ti(OEt)4–titaniumtertethoxide

SDS–sodiumdodecylsulphate

UV/Vis–ultravioletvisible

TableofContents

1.Introduction........................................................................................................................................1

2.Purpose...............................................................................................................................................3

3.Theory.................................................................................................................................................4

3.1Surface-activesubstances.............................................................................................................4

3.1.1Surfactants.............................................................................................................................4

3.1.2Surfaceactivepolymers.........................................................................................................5

3.2Emulsions......................................................................................................................................6

3.3Suspensions...................................................................................................................................6

3.4Biocides.........................................................................................................................................6

3.5Microencapsulation.......................................................................................................................7

3.5.1.Internalphaseseparationbysolventevaporation................................................................8

3.5.2Doubleemulsion....................................................................................................................9

3.5.3Emulsionpolymerization........................................................................................................9

3.5.4Interfacialpolycondensation..................................................................................................9

3.6Releasemechanisms...................................................................................................................10

3.6.1Releasefrommicrocapsules.................................................................................................10

3.6.2Sustainedrelease.................................................................................................................11

3.7Previousstudiesaboutreleasefrommicrocapsules...................................................................11

4.MaterialsandMethods.....................................................................................................................12

4.1Pre-studies...................................................................................................................................12

4.2Formationofthemicrocapsules..................................................................................................13

4.3Constructionofstandardcurve...................................................................................................14

4.4Stabilitytests...............................................................................................................................14

4.5ReleasestudiesofBHT................................................................................................................15

4.5.1Encapsulationyield...............................................................................................................15

4.6Sizedistribution...........................................................................................................................16

5.ResultsandDiscussion......................................................................................................................17

5.1Pre-studies...................................................................................................................................17

5.2Microcapsules.............................................................................................................................17

5.3Releasestudiesandsustainability...............................................................................................18

5.5Sizedistribution...........................................................................................................................19

6.Conclusion.........................................................................................................................................20

7.Futureperspectives...........................................................................................................................21

8.Acknowledgments.............................................................................................................................22

2

9.References.........................................................................................................................................23

AppendixI:Phaseseparationfrompre-studies....................................................................................26

AppendixII:Standardcurve..................................................................................................................27

AppendixIII:Sizedistribution................................................................................................................28

AppendixIV:Stabilitytest.....................................................................................................................29

AppendixV:Emulsionwitholeylalcohol..............................................................................................32

1

1.IntroductionDifferentkindsofcoatings,likepaint,varnishandlacquersarewellusedindifferentareasin

today’ssociety.Thedifferentcoatingshavealargevarietyoffunctionsandcanbedivided

intodecorative,protectiveandfunctionalcoatings.Antifoulingandantimicrobialcoatings

areatypicalexampleoffunctionalcoatings.Functionalcoatingsalsoincludefunctionsas

self-cleaning,lubricating,self-polishingandflame-retardant[1].

Growthofmold,mosses,lichensandalgaeonexteriorsurfaceslikehousefacadesandship

hullsisacriticalproblem.Discolorationandrottingofthewall,especiallythewoodmaterial

isafewresultsofthebiofouling.Italsoresultsinsocietycostsbecauseofreparationcost

andithasbeenfoundthatthegrowthofanespeciallyfungihasaseriousimpactonthe

humanhealth.Theseimpactscanleadtorespiratorydiseaseslikeasthmaandbronchitis.

Themarinebiofoulingmayincreasethefuelconsumptionoftheshipbyasmuchas40%

becausethebiofoulingleadstoanincreasedfrictiondrag.Higherfuelconsumptionleadsto

morepollutionoftheenvironment[1,2,3,].

Topreventhigherfuelconsumptions,respiratorydiseasesandotherhealthproblems,

discolorationandpotentialdamageofthepaintedsurfaceantifoulantsareused[1].These

antifoulantspreventbiofoulingandarenormallymixeddirectlyinthepaintduring

formulation.Earliertoxicmetalbasedcompoundshavebeenusedasantifoulantsbutdueto

thenegativeimpactontheenvironmenttheyarenowprohibited[2].Nowadays,biocides,a

moreenvironmentallyfriendlysubstanceisused.Eventhoughthebiocidesarefriendlier

thanthemetalcompoundsthereisalimitonthelegalconcentrationinthepaint.Biocides

aresmallmoleculeswithahighdiffusivity[2,4,5].Thehighdiffusivityleadstopremature

lossofthebiocidesbecauseofdiffusionthroughthecoatingmatrixtothecoatingsurface,

wherethebiocideisflushedawaybytherainwater.Therebytheprotectionagainst

biofoulingislost,thatisthebiocidalactionisoverbeforethelifetimeofthecoating.

Dependingonthepaintsystemtheporosityinthedry-filmcoatingmatrixdifferandthereby

thediffusionrateofthebiocidethroughthecoatingmatrix.Thisleadstoaquicklossof

protectionandrepaintingandcleaningofthecoatingisnecessary[1,2,3].

Thebiocidesprotectionactivityisonlyeffectiveattheactionofgrowth,whichisatthe

coatingsurface.Thebiocidehasatoxicfunctionandinhibitsthecellularactivitywithinthe

2

biofoulingorganisms.Thereforetheconcentrationofthebiocideatthecoatingsurfacemust

beabovethecriticalthresholdtoprotectagainstbiofouling.Aconcentrationtoolowwillnot

giveanyprotectionandaconcentrationtoohighcaninvolveenvironmentalimpacts,

regulatoryaspectsandmaterialmodification.

Awaytoovercometheproblemofprematurebiocideleakageistoencapsulatethebiocide.

Encapsulationwillreducethereleaseratefromthecoatingsandbythatprolongthe

protection[3].

Encapsulationofspecificsubstancesisalreadyusedindifferentareaswithdifferent

applications.Foodindustry,agriculturalapplications,cosmeticandpharmaceuticalproducts

arecommonareasforapplicationofmicroencapsulation[3,6].Thereasonforencapsulating

materialsistoensurethatthesubstancereachthetargetofactionwithoutgetting

negativelyaffectedbytheenvironmentorreleasedbeforereachingthisspecifictarget[6].

Dependingontheareaofapplication,differentreleasemechanismoftheencapsulated

materialscanbeused.Thesubstancecanbereleasedbydiffusionthroughthewallofthe

capsule,dissolutionormeltingofthewallorbymechanicalrupture.Theserelease

mechanismscausedifferenttypesofreleaseandreleaseratefromthemicrocapsule.

Triggeredrelease,immediatereleaseorsustainedreleasearetomentionafew.

3

2.PurposeThepurposeofthisprojectwastogainunderstandingofthereleasepropertiesfromtitania

core-shellparticles.Thisprojectwaspartlycarriedoutincooperationwithagroupof

bachelorstudents’project,wheretheaimwastooptimizetheformulationofthetitania

core-shellparticlesandprolongtheirstability.

4

3.Theory3.1Surface-activesubstances

Surfaceactivesubstanceslikesurfactantsandsurfaceactivepolymerswillbedescribedin

thefollowingsection.Inthisprojectsurfaceactivepolymersareusedasstabilizer.

3.1.1Surfactants

Surfactantsareamphiphiliccompoundshavingapolargroupandanonpolarhydrocarbon

chain.Thepolargroupisoftenreferredastheheadandthechainasthetailofthe

surfactantmolecule.Thisamphiphilicstructuremakesitpossibleforthesurfactantto

concentrateattheinterfaceswhenitisaddedtoasolution.Thisabsorbanceattheinterface

isasignificantbehaviourforthesurfactant.Iftheconcentrationofthesurfactantinthe

solutiongetstoohigh,therewillnotbeenoughspaceforallthesurfactantmoleculesatthe

interfaces.Themoleculesinexcessareforcedtoaggregateinthesolution,whichisanother

typicalbehaviour.Theformoftheseaggregationsareusuallymicellesorotherformsof

aggregates[7,8].Thedrivingforceforthisphenomenaistominimizingthecontactbetween

thehydrocarbonchainandthesurroundingwater.Duetothisaggregationprocessthetotal

freeenergywillincrease[8].

Theconcentrationofsurfactantswhenthefirstmicellesstartstoformiscalledthecritical

micelleconcentration,oftenshortenedCMC.Ifmoresurfactantsareaddedtothesolution

moremicelleswillform.Theconcentrationoffreesurfactantmoleculesisconstantabove

CMC.ThevalueofCMCisofsignificancebecausealowvalueindicatesthatthesurfactant

ratherwillformmicellesthenbeingafreemolecule.Themicellesareformedbya

characteristicnumberofsurfactantmolecules,itisalsoknownasaggregationnumber.The

aggregationnumberdependsonthesurfactantgeometry.Thehydrophilicheadisincontact

withthesurroundingsolutionandthereforeformstheshell/outersurfaceofthemicelle.The

hydrophobictailisorientatedtothecentreofthemicelle[7].

Thehydrophilicheadcanbeclassifiedintonon-ionicandionicduetothenatureofpolar

groups.Iftheheadisclassifiedasionicitcanbeeithercationicoranionicandamphotericor

zwitterionic.Thenon-ionicsurfactantareamphiphiliccompoundsanddoesnotdissociate

intoionsandthereforehasnocharge.DependingonthepHvaluesomenon-ionicsurfactant

canacquirecharge,especiallytertiaryamineoxides.Themainpartofnon-ionicsurfactant

5

doesnothaveanychargeinthepredominantworkingrangeofpHandareclassifiedinto

alcohols,polyetherandesters[8].

Theclassificationofananionicsurfactantisanamphiphiliccompoundwithananionicgroup,

eitherattacheddirectlytothehydrocarbonchainorthroughanintermediates.Themost

characteristicpropertiesofanionicsurfactantsaredispersingability,highfoamingand

sensitivitytowaterhardnessandproteindenaturation.Whendissociatedinwaterthe

anionicsurfactantdoformsurface-activeanionsandhydratedcations.Theanionic

surfactantsarealsocalled“detergents”astheyareoftenusedincleaningproducts.Mostof

theanionicsurfactantsarebasedonsyntheticrawmaterial[8].

Cationicsurfactantdoformasurface-activecationandanormalanionthendissociatedin

water.Themaingroupsofcationicsurfactantsarealkylamines,ethoxylatedamines,alkyl

imidazolinesandquaternaries[8].

Amphotericsurfactantsareamphiphilicsurfactantandcanformabothcationicandanionic

charges.Theyarereferredtocompoundsthatshowamphotericpropertiesdependingon

thepH-value.IfthesurfactantisindependentofthepHitiscalledazwitterionicsurfactant.

Usuallythisshowbothanionicandcationicproperties,becauseofthestronglyacidicand

basicgroupsinthestructureofthesurfactant[8].

3.1.2Surfaceactivepolymers

Surfaceactivepolymersarecommonlyusedasstabilizersindispersedsystemslike

emulsionsandsuspensions.Theyareusedasadditivesinpaint,inkandinfoodbecauseof

theirabilitytoaffecttheflowpropertiesandviscosityandtherebyoptimizetherheologyof

theformulation.Hydrophobicallywatersolublepolymersareanexampleoncompounds

thatareusedforoptimizingtherheology.Theyconsistofapolymerbackbonewith

hydrophobicgroupsattachedalongthebackbonechain.Thehydrophobictailsdoassociate

witheachotherandasparenetworkiscreatedwhichincreasethesolubilityofthesolution.

Whenstirringthepaintthenetworkisbrokenandtheviscositydecreases,thisiscalledshear

thinningandisofhighimportancewhenitcomestopaint.Thenetworkisfastrecreated

whenthepaintisnolongerunderstirringconditions[7].

Isasurfaceactivepolymerandasurfactantiscombinedinasolutionsocalledmixed-

aggregationscanbeformed.Thesurfactantenhancestheinteractionbetweenthepolymer

6

chainsthatisformedbythehydrophobictails.Themixed-aggregationsstartstoformata

lowerconcentrationofthesurfactantwhenasurfaceactivepolymerispresentcomparedto

theCMC.Theconcentrationiscalledcriticalassociationconcentration,CAC.Atacertain

concentrationthesurfaceactivepolymerwillstarttointeractwiththesurfactantratherthan

beingabsorbedattheinterfacebetweenairandsolution.Thisleadstoadecreaseinthe

surfacetensionandwithinthisintervalthesurfactantcreatesaggregationwiththe

hydrophobictailsonthepolymer.Whennomoretailsarefreethesurfactantisagain

absorbedattheinterfaceandthesurfacetensionwilldecreaseevenmore[7].

3.2EmulsionsEmulsionsaredispersionsoftwoimmiscibleliquids.Oneliquidisdispersedintheother

liquid[9,10,11].Thedispersedliquidiscalledthedispersedphaseandtheotherliquidthe

continuousphase[10].Therearetwomaintypesofemulsions,oil-in-water(O/W)and

water-in-oil(W/O).Tobeabletocreateanemulsiononemustdiminishtheinterfacial

tensionbetweenthephases.Surfaceactivepolymersorsurfactantsarecomponentsthatare

usedforthepurpose,todecreasestheinterfacialtensionandtofacilitatethedecomposition

ofthesystem,toformsmalldroplets[11].Thepolymerandisoftenaddedtofacilitatethe

formationoftheemulsionorformaprotectivefilmtopreventtheemulsionfrom

fragmentation[9].Thepolymerisabsorbedonthedropletsandproducesaeither

electrostaticorstericrepulsions[10].Bytime,allemulsionswillseparateintotwophases

butthesurfaceactivepolymer(stabilizer)willstabilizestheemulsionsoitwilltakemuch

longertimebeforeseparation.

3.3SuspensionsSuspensionsareinmanycasessimilartoemulsions.Likeemulsionsoneliquidisdispersedin

anotherandhaveadispersedandacontinuousphase.Thedifferenceistheyarenot

thermodynamicallystableandthestabilityofthesuspensiondecreaseswithincreasingsize

attheparticles.Normallytheparticlesizeisaboutafewmicrometresbutthereare

suspensionswithaparticlesizeassmallasnanometres[12].

3.4BiocidesBiocidesarecommonlyusedtoprotectpaintedexteriorsurfacesagainstmicro-organic

growthsuchasmold,lichens,mossesandalgae[1].Earliermorehazardoussubstanceshas

beenused,butduetothehighimpactontheenvironmentbiocidesarenowused,butto

7

excessiveamountsofbiocidecanbeariskofimpactduetopollutionontheenvironment.

Thebiocidemaybeinconsistentwiththeusedbinder-solventsystemwhichcanleadto

technicalproblemslikemacroscopicphaseseparation[1].Theyaresmallmoleculeswitha

highdiffusivity.Thediffusiontothecoating-surfacegivesprotectionagainstthegrowth

becausethebiocideisonlyactiveattheactionofthegrowthwhichisthematerialexterior

surface.Thehighrateofdiffusionalsoleadstoleakageofthebiocide.Whenthecoatingis

rinsedbytherainthebiocideflowswiththerainwaterandthereforetheprotection

diminishbecauseoftheleakageofbiocide.Theprotectionagainstgrowthisonlyactive

aboveacertaincriticalconcentrationofthebiocideinthecoatingmatrix[1,2].

ThebiocideusedinthisprojectwasBHT(2,6-di-tert-butyl-4-methylphenolorbutylated

hydroxytoluene)andisshowninFigure1.

Figure1:ThestructureofBHT(butylatedhydroxytoluene).

3.5MicroencapsulationMicroencapsulationhasawiderangeofapplications,fromchemicalsandpharmaceuticalsto

cosmeticsandprinting[1,4,6].Microencapsulationisusedforthepurposetoshieldanactive

ingredientfromasurroundingenvironment.Theactiveingredient,whichisdissolvedinthe

corematerialcaneitherbeasolid,liquiddropletsorgasbubbles.Theactiveingredientis

embeddedinacoatingorshellmaterial.Thesizeofthemicrocapsulescandifferfrombelow

µmtoafewmm.Sometimestheycanbeassmallasafewnanometres,thencalled

nanocapsules[6,13,14].

Thereareanumerousofdifferentmethodsforencapsulatinganactivesubstance(biocide).

Dependingontheintendedreleaseprofileandthephysicochemicalpropertiesofthebiocide

likepolarity,sizeandchargedifferentmethodsareused[1].Internalphaseseparation,

8

doubleemulsion,emulsionpolymerizationandinterfacialpolycondensationareafew

commonmethodsthatareusedtoday.Allthesemethodscanbecategorizedintotwomain

categories.Thefirsttechniqueistheonesthathavemonomersorpre-polymersasastarting

material.Thistechniqueinvolveschemicalreactionsanddoformmicrospheres.Theother

techniquehavepolymersasstartingmaterialandunlikethefirstcategorythesetechniques

donotinvolvechemicalreactionsandonlyformtheshape[6].Startingmaterialand

microencapsulationmethodsaredecideddependingonthedesiredcompositionaland

morphologicalcharacteristicsatthemicrocapsules.

3.5.1.InternalphaseseparationbysolventevaporationTheinternalphaseseparationbysolventevaporationmethoddevelopedbyLoxleyand

Vincent[2,15]ismostsuitableforencapsulationofhydrophobicactivesinliquidoilcores

[1,2,16].Themethodgivesalmostfullencapsulationyieldoftheactivesubstance[17].An

o/wemulsionispreparedandformedbyhighshearstirring.Tocreatethesuspensionof

core-shellparticlestheemulsionispouredintoanaqueoussolutionwithavolatilesolvent.

Themethodisbasedoncoacervationwhichisinducedbysolventevaporationfromthe

emulsion.

Theemulsionconsistofanoil-andwaterphasewhichismixedtogether.Theoilphase

containsofashell-formingpolymer,low-boiling(volatile)solvent,ahigh-boilingpoorsolvent

forthepolymer(core-oil)andtheactivesubstance.Thevolatilesolventistoprovidethatthe

polymeriscompletelydissolved.Theaqueousphaseconsistofasuitablestabilizer,whichis

oftenawater-solubleandsurface-activepolymer[2,15].

Whenthesolventevaporatesthepolymer-richphasemigratetotheinterfaceofthe

dropletsandstartsformingtheshellwhilethecore-materialaccumulateinthecentreofthe

formingshell[1,15,17].

9

Figure2:SchematicpictureofLoxleyandVincentmethod;internalphaseseparation,for

preparingofmicrocapsules[15].

3.5.2DoubleemulsionLikethenamerevealsthedoubleemulsionroutestartswithcreatingadoubleemulsion,

oftenawater-oil-water(W1/O/W2)emulsion.Tocreatethedoubleemulsionatwo-step

homogenizationmethodisused.Apre-emulsionW1/Oisformedunderhighshearandthen

dispersedinthecontinuousW2phase.Theaqueousphaseconsistoftheactivesubstance

andtheoilphaseoftheshellformingpolymerandavolatilesolvent.Thesolventisslowly

evaporatedwhenthepre-emulsionisdispersedintheW2phaseundermoderateshearing

[1].

3.5.3EmulsionpolymerizationAnaqueouspolymerisationmediumcontainingcorematerialandanemulsifierisstirred

aroundandamonomerisdropwiseadded.Thepolymerizationbeginsandanucleiisformed

andentrapsthecorematerialastheygrowgraduallyasthepolymerizationproceeds.The

nucleiisformedbyinitiallyformedpolymermolecules.Commonmaterialsforthistechnique

islipophilicmaterials[6].

3.5.4InterfacialpolycondensationThisreactionoccursattheinterfaceofatwophasesystemandthereforthename

interfacial.Thepolycondensationisbetweentwomonomers.Thetwo-phasesystemshould

formsmalldropletsofonephaseintheotheroneandmustthereforebemixedundervery

carefullyandcontrolledconditions.Thesmalldropletsrepresentsthedispersedphaseand

theotherphaseisthecontinuousphase.Itisnecessarythatthematerialthattobe

encapsulatedcanformdropletsandthattheconcentrationofthestabilizerisnottoohigh

becauseofthehighriskofdropletcoalescenceandparticlecoagulation.Dependingofthe

solubilityofthepolycondensationthedropletsphasetwotypesofmicrocapsulescanbe

formed,monocoreandmatrix.Ifthepolymerissolubleinthedroplets,matrixmicrocapsules

areformedandifnotthemonocoremicrocapsulesareformed[6].

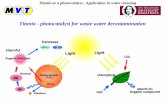

3.5.4.1Titaniacore-shellparticles

Titaniacore-shellparticleswereusedinthisprojectandtheformulationwaspriortothis

workbyagroupofbachelorstudentsbasedonanearlierstudybyCollins,Spickermannand

Mann[18].

10

Thesemicrocapsulesaremadebyanon-aqueousemulsionwiththeprecursorTi(OEt)4

(titaniumtertethoxide)andhexadecaneascore-oil.Hexadecanehasbeenusedinearlier

studiesanddosatisfytherequirementforcore-oils.Thecore-oilshouldnotreactwiththe

precursorbutdissolvetheprecursorandthebiocide[3,5,18].

3.6ReleasemechanismsEncapsulationofdifferentmaterialcanprovidecontrolled,sustainedortargetedreleaseof

anactivesubstanceandthereleasemechanismisusedinmanydifferentareas.Depending

ontheareaofuseandthedesiredrateofrelease,differentmechanismsforencapsulated

materialtobereleasedareactive.Mechanicalruptureofthecapsulewall,diffusionthrough

thewallanddissolutionormeltingofthewallareafewexamplesofreleasemechanisms

[6,17].

3.6.1ReleasefrommicrocapsulesStudiesofthereleasefrommicrocapsulestoanexternalmediumcanbeperformedinmany

differentwaysandbyusingseveraldifferentmethods.Thestudiescancoverallstepsfrom

thesetuptothetimewhenalloftheactivesubstanceisreleased.Althoughtherearethree

mainstepsthataretobeconsideredthatis;setup,analysisandevaluation.

Thesetupincludesthelaboratoryequipmentandmaterialsneededtoperformtherelease

studies.Essentiallyforthereleasestudiesistoknowthesaturationconcentrationofthe

biocideinthechosenreleasemediumandthedistributionforthebiocide.Thedistributionis

explainedbythepartitioncoefficient,K,andbythatinformationthedistributionbetweenof

thebiocideinthemicrocapsuleandthereleasingmediumisknown[17].

Thereleasestudiesinthisprojectwasperformedbydispersingthemicrocapsulesuspension

inthereleasemediumduringstirringconditions.Thereleaseoftheactivesubstancestarts

immediatelywhenthemicrocapsulesaredispersed.Smallsamplesaretakenusingasyringe

andthenfiltratedthroughasyringefilter.ThefiltrateisanalysedusingUV/Vis-

spectrophotometry.Onlytheactivesubstancethatisreleasedpassesthroughthefilter,and

sothismethodonlypermitstheconcentrationofthereleasedactivetobeanalysed.

Theanalysingpart,likethesetupstep,includealltheequipmentthatisnecessarybutinthis

casefortheanalysis,likeequipmentfordatasamplingandanalyticaltechniquetoquantify

thetime-dependentconcentrationoftheactive.

11

Lastintheevaluationstepallthecollecteddataandresultsareputintoperspectivebythe

applicationofreleasemodels[17].

3.6.2Sustainedrelease

Theuseofratedeterminingreleasesystemsincoatinghavebothshownbenefitsfroman

economicalandenvironmentalpointofview[1].Thefocusinthisprojectissustained

releasefromcore-shellparticles.

Thereleaserateoftheactivesubstanceisdeterminedbythepenetrationthoughtheshell

andthroughthecoatingmatrix.Thediffusioncoefficientandthesolubilityoftheactive

substanceinthebarrieraffectsthekineticsandthermodynamicparameters,whichare

determiningforthepenetrationoftheactivesubstance[1,16,17].Thepartitioncoefficient,

K,describespartitionoftheactivebetweenthecoreandshellorbetweenthemicrocapsule

andreleasemedium.Itisaffectedbythesolubilityoftheactivesubstanceinandthe

interactionwiththecoreandshellmaterials[16].

𝐾" = %&'

%(' (1)

Ki–partitioncoefficientforactivei

CAi–equilibriumconcentrationofactiveIinphaseA

CBi–equilibriumconcentrationofactiveIinphaseB[1]

3.7PreviousstudiesaboutreleasefrommicrocapsulesInpreviouslaboratorystudiesaboutmicroencapsulatedbiocides,severalbiocideshavebeen

studiedandtheirreleasefromPMMA-capsules.Theaimofonestudywastoevaluatethe

releaseofOITfrommicrocapsulesdispersedinanaqueoussolution.Thereleasemedium,6-

wt%Brij®L23,wasusedandthecontentofincreasestheaqueoussolubilityofOIT.The

microcapsuleswerepreparedbyinternalphaseseparation[2.16].AlsoreleaseofBHThave

beenstudiedfrommicrocapsulesbasedonPMMAusingasolidandliquidcore.Thecore-

shellparticleswerepreparedwithinternalphaseseparationwithPMMAasshell-material

anddodecane(liquid)oroctadecane(solid)ascore-oil[19].TheBHTusedwaslabelledwith14Csotheradioactivitycouldbemeasured.

Attimezero10mlofthesuspensionwithmicrocapsuleswasaddedtoabeakercontaining

190mlof0.125MSDSsolution.Thereleasebathwaskeptatroomtemperatureunder

12

continuousstirring.Atspecifictimessamplesof5mlwasremovedusingasyringeand

immediatelypressedthroughasyringefilter.3mlofthefiltratewasthenmixedwith18ml

UltimaGoldTMandtheradioactivityofthesampleswasrecorded[19].

4.MaterialsandMethods

Inthissectionthematerialsandmethodsusedwillbedescribed.Whenoptimizingthe

formulationoftitaniacore-shellparticlesnobiocidewasaddedandthefirstverification

beforecreatingthemicrocapsuleswastocheckthatthebiocideistotallydissolvedinthe

core-oilandthataphaseseparationstilloccurbetweenthecore-oilandtheshellmaterial.

Aftertheverification,abatchwithmicrocapsulescontainingthebiocidewasmadeandthe

stability,structureandthemicrocapsulesabilitytomaintainallthebiocidewithintheshell.

4.1Pre-studies

Asmentionedinsection3.5.1.1anecessityforcreatingcore-shellparticlesisthattheoil

phasedonotreactwiththeprecursorbutstilldissolvetheprecursorandthebiocide.

Phaseseparationbetweenthecore-oilandshellmaterialisalsoanecessityforcreatingthe

emulsion.Theadditionofbiocidetothecore-oilwasnottestedbythegroupofbachelor

students.Interestingwhenintroducingthebiocide,BHT,inthecore-shellparticlesisthe

distributionofBHTbetweenthecore-oilandsolvent.ThedistributionofBHTbetweenthe

phaseswasinvestigatedbymixingBHTwiththecore-oil,hexadecaneandwiththesolvent,

formamidewiththevolumetricratio1:1and1:5(hexadecane:formamide),seeAppendixI.

Whenthemixturesreachesequilibriumaphaseseparationoccursandatopandbottom

phaseisvisible.Samplesweretakenfromthetopphaseandthebottomphaseandanalysed

withNMR-spectroscopy.ThetopphasewouldcontainonlyBHTandhexadecaneandthe

bottomphaseonlyformamide.TheresultsfromtheNMRanalysiswereusedtocalculatethe

distributionfactororpartitioncoefficientfromequation(1)toseethatbasicallynoBHTwas

inthebottomphase.Theprecursorwasalsoaddedinaseparatestudytoseethatitdidnot

affecttheresultofdistributionofBHT.

Twoothercompounds(Ti(OBu)4andoleylalcohol)similartoTi(OEt)4andhexadecanewas

alsotestedtoseeiftheygaveasimilaroutcomeandthereforecouldbeanoptionforthe

13

formulationofcore-shellparticles.Ti(OBu)4wouldbeasubstituteforTi(OEt)4andoleyl

alcoholasubstituteforhexadecane.

4.2FormationofthemicrocapsulesThemicrocapsuleswerecreatedbytheinterfacialcondensationmethoddescribedinsection

3.5.4.Fortheformationofthemicrocapsule,titaniaandhexadecaneconstitutedtheshell

andthecoreoil.Thebiocidewasencapsulatedanddissolvedinthecoreoil.

Tocreatethemicrocapsulesacontinuousandadispersedphasewasused.Thecontinuous

phasewaspreparedwith0.625gPEG-PPG-PEGand25gformamidewhichwasleftwitha

magnetstirreruntiltotallydissolved.Thedispersedphasewasmadeof1.786ghexadecane,

0.1786gBHTand0.714gTi(OEt)4.

Thecontinuousphasewasheldinaroundbottomflaskwhichwasplacedinacool-water

bathwithastirrer,SilentCrusherM.Thestirrerwasstartedandshearedthecontinuous

phaseat5000rpmwhilethedispersedphasewasaddeddropwisefortwominutes.Thenthe

solutionwaslefttoshearfor60minutessoanoil-in-wateremulsionwasformed.Allthe

areasexposedagainstairwascoveredwithparafilmtopreventairtogetinthesystemsince

Ti(OEt)4reactsveryquicklywithwatervapourintheair.

Theemulsionwasthenpouredintoabeakerwithamagneticstirrerandawaterphasewas

addeddropwisetocreateasuspension.Thewaterphasewasmadeof6.25gmilliQ-water

and12.5gformamide.Itwasleftforafewminutesthenthesuspensionwasdividedintotwo

centrifugetubesandcentrifugedfor30minutesatmaximumeffect.Duringthe

centrifugationthemicrocapsuleswereseparatedfromtheformamideandthecapsules

createdawhitefoamontopoftheformamidewhichwaseasilyseparatedandputinanew

centrifugetubewithacontinuousphase.Thecontinuousphasewaspreparedbywaterand

afewweight-%ofasurfactant,eitherPEG-PPG-PEGorPVA.Thiswasrepeatedtwiceto

ensurethatalltheformamidewasgone.Thusthesolventwereremovedandreplacedby

anothercontinuousphase.Accordinglytothepre-studiesthemicrocapsuleshadshownto

bemorestableinacontinuousphasecontainingasurfactantcomparedtowaterphase.The

microcapsuleshadalsoprovedtobemorestableinwaterthaninformamide.Thepre-

studies,capsuleswithTi(OBu)4andoleylalcoholgavepromisingresults.TheTi(OEt)4was

14

substitutedwithTi(OBu)4inonebatchandanemulsionandawholebatchwasmadewith

oleylalcoholascore-oil.

4.3ConstructionofstandardcurveThestandardcurvewereconstructedbypreparingsampleswithknownconcentrationsof

BHTandthenanalysedwithUV/Vis.Themeasuredabsorbancewasplottedagainstthe

knownconcentrationstogetthestandardcurve,seeAppendixII.Usingthecurvethe

maximumreleaseconcentrationcouldbereadandbythatcalculationsforthereleasebath

couldbedone.

Astocksolutioncontaining250mg/lBHTin0.125MSDS-solutionwasmadeandbydiluting

thisstocksolutiontheothersamplesweremade.Theusedconcentration(mg/l)was250,

125,75,50,30,15,5and2,5.Byalinearfittothecurve,theequationwasfoundand

accordingtoLambertBeer’slaw(2)theabsorbanceisdirectlyproportionaltothe

absorbance.

LambertBeer’slaw 𝐴 = ԑ ∗ 𝑐 ∗ 𝑙 (2)

l–lengthofthecyvett

c–concentration

ԑ-molarabsorbtivity

A–measuredabsorbance

TheequationofthestandardcurveshowedtobeA=7.96*candbythisthemeasured

absorbancefromthereleasestudiescouldbecalculated.

4.4StabilitytestsToseeifthecapsulescouldbeusedinareleasestudythestabilityofthemicrocapsuleswere

examinedindifferentcontinuousphases.Theexaminedphaseswere6.25weight-%PEG-

PPG-PEG,2.5weight-%PEG-PPG-PEGand2.5weight-%PVA.Thestabilitywasanalysedusing

microscopeexaminationsrepeatedlyovertime.Theanalysisweremadeatdifferenttimes

bytakingsamplesfromthebatches.Thesampleswereanalysedbylightmicroscopyandthe

pictureswerecomparedtotheearlierones.Importantobservationswasforhowlongand

howwellthemicrocapsuleskepttheirshape,nobrokenmicrocapsulesorthatno

flocculationhasoccurred.

15

Anotherimportantaspectbeforestartingwiththereleasestudiesistoexamineifthereis

anyleakageofthebiocideoutofthemicrocapsules.Asamplewastakenfromthe

suspensionwithasyringeandthenfilteredthroughasyringefilterandanalysedwith

UV/Vis-spectroscopy.Thisshouldnotshowanyabsorbancebecauseifitgavearesultthat

wouldindicatethatthebiocidewouldhavediffusedoutofthemicrocapsulesandthatthe

shellwerenotstableenoughtomaintainallofthebiocideinside.

4.5ReleasestudiesofBHTThereleasemediumusedwas0.125MofaqueousSDS-solution.TheSDSincreasethe

solubilityofBHTinwaterfrom1ppmto500ppm.

Atreleasetimezerothe20mlofsuspensionwasaddedtothe70mlofSDS-solution,which

waskeptunderstirringconditions.Atspecifictimesamplesof5mlwastakenusinga

syringe.Immediatelythesampleswasfilteredthroughasyringefilter.Thesampleswasthen

analysedusingUV/Vis-spectrophotometryat277nm.Withaconstructedstandardcurve,the

measuredabsorbanceandLambertBeer’slaw(2)theconcentrationofBHTcouldbe

calculated.

4.5.1EncapsulationyieldTogetanideaofthereleaseratethefractionofthereleaseiscalculated.Therelease

fractiontellshowmuchofthebiocidethatisrelease.Itiscalculatedbydividingthereleased

amountofbiocidewiththeamountofbiocidethatcouldbereleased.

./0.102342"/0/5316147189"/."812/246./0.102342"/0/59"/."81

= 𝑟𝑒𝑙𝑒𝑎𝑠𝑒𝑓𝑟𝑎𝑐𝑡𝑖𝑜𝑛(3)

Theconcentrationofreleasedbiocideiscalculatedfromthemeasuredabsorbancefromthe

UV/Visanalysis.Thetotalconcentrationofbiocideisreachedwhenallthebiocideis

releasedfromthemicrocapsules.Tofindoutthetotalconcentrationofthebiocide1mlof

thesuspensionwasdilutedwithmicrocapsuleswith9mlof0.125SDS-solution.Fromthis

mixture2.5mlwasmixedwith2.5mlofmethanol.Thismixtureofsuspension,SDSand

methanolwasanalysedwithUV/Vis-spectroscopyat277nm.Whenthesuspensionisdiluted

withmethanolallofthebiocideisreleasedfromthemicrocapsulesandmeasuringthe

absorbancewhenallthebiocideisreleasedonecancomparethevaluewiththevaluesfrom

therealreleasebathandcalculatethereleasefraction.

16

4.6SizedistributionTodeterminethesizedistributionofthetitaniacore-shellparticlesanimageprocessing

program,ImageJwasused.Arepresentativepictureofthecapsulesusedfortherelease

studies(frombatch2)werechosen,seeAppendixIII.Thediameterofthecapsuleswere

measuredandahistogramoverthesizedistributionwereconstructed.

17

5.ResultsandDiscussion

Inthissectiontheresultsfromthepre-studies,preparationofmicrocapsulesandtherelease

studieswillbepresentedanddiscussedincludedthemicrocapsuleswitholeylalcohol.

5.1Pre-studiesThephaseseparationbetweenBHT,hexadecaneandformamidewasstableandsamples

showedthatthebottomphase,mostlyconsistingformamide,didcontainnegligibleamounts

ofBHT.ThisresultsspeaksforthebasicallyalloftheaddedBHTwillbeinthecore-oil,

exceptthelossduringtheformulation.

ThephaseseparationtestwithTi(OBu)4andoleylalcoholgavepromisingresultswithaclear

separationbetweenthetwophasesbutnoNMRanalysiswasmadeforthesetests.

5.2MicrocapsulesThemicrocapsuleswerethencentrifugedwithwaterandapolymericsurfactant.Batch1

wascentrifugedwith6.25weight%PEG-PPG-PEGanddidgaveapromisingresult.Aftera

fewdayssomeflocculationmadethisbatchunusableforreleasestudies,seeAppendixIV.

Batchnumber2weresplitintwowhereonehalfwascentrifugedwith2.5weight%PEG-

PPG-PEGandtheotherhalfwith2.5weight%PVA.Thesetwowerecomparedwithand

checkedregularly.Firsttherewasnomajordifferencebetweenthembutonecouldtellthat

themicrocapsulesinPVAwereabitmoreflocculatedthanthemicrocapsulesinPEG-PPG-

PEG.

Thephaseseparationtestwitholeylalcoholdidgaveapromisingresultsoanemulsionwas

madetoexaminethestabilityandstructureatthemicrocapsules.Theemulsiondropletsdid

lookverynicewithsmoothandroundshapes.Theemulsiondidnotshowanyflocculation

overtimeandthemicrocapsulescontaintheirshape,seeAppendixV.Thereforeabatchof

microcapsuleswitholeylalcoholwasmade(batch7).Thesuspensiondidlooknicebutthe

sizeofthemicrocapsulesdiddifferabitandthecentrifugationwasabitmoredifficultthan

withthecapsuleswithhexadecane.Thefoamofmicrocapsulesweremuchthinnerand

hardertoseparatefromtheformamide.

TogetherwiththebachelorstudentsabatchwithTi(OBu)4asprecursorwasmade,the

microcapsuleswereunfortunatelybrokenwhichmadeTi(OBu)4asnolongeranoptionfor

theformationofmicrocapsules.

18

5.3Releasestudiesandsustainability

Thetitaniacore-shellparticlescentrifugedwith2.5weight%PEG-PPG-PEG(batch2andbath

5)andthemicrocapsuleswitholeylalcoholascore-oil,alsocentrifugedwith2.5weight%

PEG-PPG-PEG(batch7)wereusedforthereleasestudies.

Batch2werethefirstreleasestudyperformed.Thefirstsampleweretaken30secondsafter

thesuspensionwasreleaseinthereleasebathandthelastone4daysafter.Thesamples

wereanalysedinUV/Visandshownreallyhighabsorbancealreadyafter30seconds.The

followingsamplesshowedaplateauofmaximumreleasewhichmeansthatthereleaseof

BHTfromthemicrocapsuleswasnexttoimmediate.Thereforeanewbatchwasmade

(batch5)inthesamewayasbatch2.Thesuspensionofbatch5wascheckedsotherewas

noleakageoftheBHT.Theresultsdidnotshowanyleakagesoa“quickanddirty”-testwas

made,thatmeansareleasestudywithaabout5-8timeintervals.Thistoseeiftheresults

aresimilarandtogetanideahowmuchoftheBHTthathasbeenreleased.Thisbatchalso

showanalmostimmediatereleaseoftheactivesubstance.

Sincetheresultsfromthereleasestudiesofthemicrocapsuleswithhexadecaneascore-oil

wasnotsopromisingthemicrocapsuleswitholeylalcoholwastested.Thereleasestudy

wereperformedinthesameway,withaquickanddirtytest.Thesecapsulesalsoshowedan

almostimmediaterelease.Thesuspensiondidshowaleakageofthebiocideaswellbutthe

amountofleakageonlycorrespondtoabout10%oftheaddedamountofBHTduring

formulation.Thesmallamountofleakagewasabletooverlookduringthereleasestudies

sincethereleasefromthemicrocapsulesseemedtobeimmediate.

Thereleasefractionofthemicrocapsulesfrombatch5andbatch7werecalculatedfrom

equation(3)andtheresultsisshowninfigure3below.

19

(i)(ii)

Figure3:ThereleaseofBHTfrom(i)microcapsulesfrombatch5withhexadecaneascore-oil

and(ii)microcapsulesfrombatch7witholeylalcoholascore-oil.

5.5Sizedistribution

Theresultofsizedistributionoftitaniacore-shellparticlesfrombatch2centrifugedwith

PEG-PPG-PEGispresentedinFigure4.Mostofthemicrocapsuleshaveadiameterinthe

rangeof1,5-3,5µm.Butthereisalsoafewmicrocapsuleswithadiameterbetween4-5,5

µm.Thepictureofthemicrocapsulesusedfordeterminethesizedistributionispresentedin

appendixIII.

Figure4:Sizedistributionoftitaniacore-shellparticleswithhexadecaneascore-oil.

20

6.Conclusion

Thetitaniacore-shellparticlesseemedtobeapromisingsolutionforencapsulationof

biocidessincetherewasnoleakageofthebiocideinthesuspensionandsincethe

suspensiondidshowagoodstabilityandnoflocculation.Whenitcomestotherelease

studiesthemicrocapsulesshowedanalmostimmediatereleaseofthebiocidefromthe

microcapsuleswhichisnotpromisinginthiscontent.Thestabilityoftheoleylcapsuleswere

notexaminedforaslongasthehexadecanecapsules,buttheyshowedimmediaterelease

likethehexadecanecapsules,whichalsomadethemnottobeanoptiontoapplyin

coatings.

21

7.Futureperspectives

Sincethemicrocapsuleswithhexadecaneascore-oildidshowgoodstabilityandnoleakage

ofthebiocide,theycanbepromisingforfuturestudies.Modificationoftheaddedamount

ofshellmaterialmaybeapossibilityforfuturestudies.

22

8.Acknowledgments

IwouldliketothanktheDivisionofAppliedChemistryforgivingmetheopportunityto

performthisprojectandabilitytousethematerialandequipmentandforallthehelpand

supportfromallthepeopleworkingthere.

AspecialthankstoLarsNordstiernamysupervisorandexaminerforallthehelpandsupport

duringthisproject.

AbigthankyoutoJonatanBergekforthehelpwithorderingallthespecialequipment

needed.

ThankyouMatsHulanderandSabaforthehelpwithandshowingmethemicroscope.

ThankstothebachelorstudentFridaBilén,SozanDarabi,JohannaEriksson,Sandra

Hultmark,RikardNiklassonandTobiasPerssonworkingwiththeoptimizingofthe

microcapsulesforshowingmethestepsforproducingthemicrocapsules.

23

9.References1.AnderssonTrojerM,NordstiernaL,BergekJ,BlanckH,HolmbergK,NydénM.Useof

microcapsulesascontrolledreleasedevicesforcoatings.AdvancesinColloidandInterface

Science.2015;222:18-43.

http://www.sciencedirect.com/science/article/pii/S0001868614001985

2.BerekJ,AnderssonTrojerM,MokA,NordstiernaL.Controlledreleaseof

microencapsulated2-n-octyl-4-isothiazolin-3-onefromcoatings:Effectofmicroscopicand

macroscopicpores.ColloidsandSurfacesA.2014;458:155-167.

http://www.sciencedirect.com/science/article/pii/S0927775714002143

3.Bergekj,AnderssonTrojerM,UhrH,NordstiernaL.Controlledreleaseofa

microencapsulatedarduoussemi-hydrophobicactivefromcoatings:Superhydrophilic

polyelectrolyteshellsasgloballyrate-determiningbarriers.2016;2015:31-39.

http://www.sciencedirect.com/science/article/pii/S0168365916300165

4.NordstiernaL,AbdallaAllaA,NordinM,NydénM.Comparisonofreleasebehaviousfrom

microcapsulesandmicrospheres.2010;69(1):49-51.

http://www.sciencedirect.com/science/article/pii/S0300944010001402

5.IntroductionmeetingwithLarsNordstierna.21March2016.ChalmersUniversityof

technology.

6.DubeyR,ShamiT.C,BhaskerRaoK.U.MicroencapsulationTechnologyandApplications.

DefenceScienceJournal.2009;59(1):82-95.

http://search.proquest.com/docview/1413391510?pq-origsite=summon

7.HolmbergK.Yt-ochkolloidkemi.Gothenburg:ChalmersUniversityoftechnology,2007;p.

8-23

8.PletnevMY.ChemistryofSurfactants.Russia:BelgorodStateUniversity.2007

http://ac.els-cdn.com/S1383730301800624/1-s2.0-S1383730301800624-

main.pdf?_tid=0af150da-0d39-11e6-9d44-

00000aab0f01&acdnat=1461845112_a348b39313d0abb7fc4866dfdd13d850

24

9.SchrammLL.Emulsions,Foams,SuspensionsandAerosols:MicroscienceandApplications

(2).Germany:Wiley-VCH,2014;p.6-9.

http://site.ebrary.com/lib/chalmers/reader.action?docID=10899790

10.TadrosTF.EmulsionFormationandstability(1).Germany:Wiley-VCH,2013;p.1-4.

http://site.ebrary.com/lib/chalmers/reader.action?docID=10767022

11.HolmbergK.Yt-ochkolloidkemi.Gothenburg:ChalmersUniversityoftechnology,2007;

p.24-35

12.HolmbergK.Yt-ochkolloidkemi.Gothenburg:ChalmersUniversityoftechnology,2007;

p.46-49

13.ThiesC.Microencapsulation.Kirk-OthmerofChemicalTechnology:JohanWiley&Sons,

Inc.2005;16:438-463.

http://onlinelibrary.wiley.com/doi/10.1002/0471238961.1309031820080905.a01.pub2/abst

ract

14.NordstiernaL,AbdallaAllaA,MasudaM,SkarnemarkG,NydénM.Molceularrelease

frompaintedsurfaces:Freeandencapsulatedbiocides.2010;69(1):45-48.

http://www.sciencedirect.com/science/article/pii/S0300944010001396

15.LoxelyA,VincentB.PreparationpfPoly(methylmetharylate)MicrocapsuleswithLiquid

Cores.1998;208(1):49-62.

http://www.sciencedirect.com/science/article/pii/S0021979798956983

16.AnderssonTrojerM,NordstiernaL,NordinM,NydénM,HolmbergK.encapsulationof

activesforsustainedrelease.2013;15(41):17707-18302:

http://pubs.rsc.org/en/content/articlelanding/2013/cp/c3cp52686k#!divAbstract

17.BergekJ.ExperimentalDesignandEvaluationofBiocideReleasefromMicrocapsules.

ChalmersUniversityofTechnology;2014.

18.CollinsAM,SpickermannC,MannS.Synthesisoftitaniahollowmicrospheresusingnon-

aqueousemulsions.2003;13(5):1112-1114.

25

19.MasudaM.NordstiernaL.MovahediA.NordinM.NydénM.Controlledreleasefrom

microcapsules:Liquidandsoildcoreandtheeffactonreleaserate.ChalmersUniversityof

Technology.

26

AppendixI:Phaseseparationfrompre-studies

(i)(ii)

(iii)(iv)

Figure1:(i)Core-oil,hexadecane,dissolvetheprecursor,Ti(OEt)4andthebiocide,BHT.(ii)

Phaseseparationbetweenthesolvent,formamideandtheprecursor,Ti(OBu)4.(iii)Phase

separationbetweenthecoreandshellmaterialwiththevolumetricratio1:1and(iv)

volumetricratio1:5.

27

AppendixII:Standardcurve

Figure2:Theconstructedstandardcurvewiththeequation,A=7.96*c.

28

AppendixIII:Sizedistribution

Figure3:Themicrocapsulesfrombatch2aftercentrifugationwith2,5weight-%

PEG-PPG-PEG.Thesesmicrocapsuleswithhexadecaneascore-oilwereusedfortherelease

studies.

29

AppendixIV:Stabilitytest

(i)

(ii)

Figure4:Batch1.(i)Suspensionbeforecentrifugationand(ii)suspensiondirectlyafterthe

centrifugation.Thesolventhasbeensubstitutedtoacontinuousphasecontaining6.25

weight-%.Someflocculationhasoccuredandthecapsuleshaveverydifferentsizesbuttheir

shapesareeven.

30

(i) (ii)

(iii)(iv)

Figure5:Batch2centrifugedwith2.5weight-%PEG-PPG-PEG.(i)Suspensiondirectlyafter

thecentrifugation.Picture(ii)and(iii)showsthesuspensiontworespectivelyfivedaysafter

thecentrifugation.Itisnotuntilafteroneweek(picture(iii))thatitshowssmallhintsof

flocculation.Theflocculationpartarestillsosmallthatthesuspensionstilllooksgood.

31

(i)(ii)

(iii)(iv)

Figure6:Batch2centrifugedwith2.5weight-%PVA.(i)Suspensiondirectlyafterthe

centrifugation.Picture(ii)and(iii)showsthesuspensiontworespectivelyfivedaysafterthe

centrifugation.Itisnotuntilafteroneweek(picture(iii))thatitshowssmallhintsof

flocculation.Theflocculationpartarestillsosmallthatthesuspensionstilllooksgood.

32

AppendixV:Emulsionwitholeylalcohol

(i)(ii)

(iii)

Figure7:Emulsionmadewitholeylalcoholascoreoil.(i)Emulsiondirectlyaftertheshearing,

(ii)Emulsionthreedaysafterand(iii)Emulsion18daysafter.

![SYNTHESIS AND CHARACTERIZATION OF CORE/SHELL ......Functionalized nanoparticles such as core/shell silica coated gold [2], alumina coated Titania [3], silver coated magnetite [4],](https://static.fdocuments.us/doc/165x107/60bd533bb67f6c68462c9209/synthesis-and-characterization-of-coreshell-functionalized-nanoparticles.jpg)