Forming Proses

-

Upload

ulana-masitoh -

Category

Documents

-

view

39 -

download

3

Transcript of Forming Proses

Bulk Deformation Forming - Rough Shapes

Overview of Lecture 3• Definitions• General characteristics of forming processes • Individual Bulk Deformation Processes

– Rolling– Extrusion– Forging

• Open Die• Closed Die• Other• Die Design• Forging machines• Forging economics• Comparison of Forging and Casting

Overview - Shaping and Forming F

inishing

Ingotcasting

MoltenMaterial

Powders

CastingShapes

RollingForging/

Press forming

Stamping

Pressing

Sheet metalforming

ContinuousCasting/Rolling

InjectionMolding

Mac

hini

ng

Raw

Mat

eria

l

Special

Extruding

Single crystalpulling

Firing/Sintering

SLS

Increasing level of detail

Blowmolding

Definitions of Shaping and Forming• Forming - changing the shape of an existing solid

body or workpiece, stock or blank by applied forces to cause plastic flow– Usually involves minimal scrap (flashing)– Low buy to fly ratio

• Shaping - usually means removal of material– Milling, drilling, turning, carving, etc.– Lots of scrap– High buy to fly ratio

• Kalpakjian Definition of Shaping– molding or casting

Bulk Deformation Processes• Start with a cast ingot in a particular shape• Process in a machine which causes gross or bulk

deformation to provide a new shape• Can only use these processes when the material

has a plastic regime in its stress strain behavior.– Most metals– Most plastics

• Some materials must be formed hot to obtain plastic behavior– Some metals– Some plastics– Inorganic glasses above their transition range

Bulk Deformation Processes• The resultant shape is usually further worked or

shaped.• Total deformations can be very large

– Foil 5000– Canstock 1400– Typical sheet 400 – Typical Plate 3– Extrusions 8

• Deformation = initial dimension/final dimension

Bulk Deformation Processes• Rolling typically starts with a rectangular ingot and

results in rectangular – Plates(t>6mm)– Rolls of thin sheet (t<6mm)– Rods– Bars– Structural shapes (I-Beams)– Rails

• Typically, material must be further shaped or formed to be useful

Bulk Deformation Processes• Extrusion starts with typically cylindrical cast

ingots and results in a multitude of shapes usually with constant cross section close to final form

• Less subsequent work is required to make products useful then rolled sheet or plate

Bulk Deformation Processes• Forging starts with a sawn off section of a cast

or extruded ingot and ends up with a multitude of shapes close to final form

• Least work required to make product useful

Characteristics of Products Formed by Rolling

• Flat – Produces coils of sheet and foil, rectangular flat plate; – Excellent properties; Good surface finish; High capital

investment; low labor costs; Skilled labor required to operate mill

• Shape– Produces shapes of diverse cross section; – Excellent properties along the rolling direction: Good

surface finish; Expensive specially shaped rolls; Low labor costs; Relatively low labor skill required to operate mill

Characteristics of Products Formed by Extrusion

• Extrusion – Produces long lengths of solid and hollow shapes with

usually constant cross section; – Product may be cut to form discrete products; – Excellent surface finish, Excellent properties; Moderate

to high equipment cost (dies are expensive); Low to moderate labor costs; Low to moderate operator skill

Characteristics of Products Formed by Drawing

• Drawing – Produces long lengths of solid rod or wires of

constant cross section; – Smaller cross sections than typical extrusion; Good

surface finish; Low to moderate equipment and labor costs; Low to moderate operator Skill

Characteristics of Products Formed by Forging

• Forging – Produces discrete parts with a variety of unlimited

shapes; Typical properties better than extrusions;– Surface finish fair to good; High die and equipment

costs; Moderate to high labor costs; Moderate to high operator skill

Overview of Lecture 3• General characteristics of forming processes

(metals only)• General

– Bulk deformation processes• Rolling

ROLLING

Use of front and back tension to reduce friction in rolling

Friction Hill in rolling

2121

21

h

b

h

rYp

Mean rolling pressure:

Strip rolling in four stand continuous mill

Backing rolls

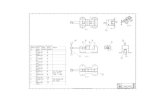

Rolling Process

Rotating rolls reduce the thickness of the incoming ingot

Vo Vf

Width of Strip is wfWidth of Strip is w0

Vf = Vo (ho/hf)

ho hf

F

F

N

Overall Process for Sheet and Plate• Cast ingot• Scalp (not always)• Reheat and homogenize• Hot roll in reversing mill to ~1-2 in thick• Cut off ends (alligators)• Warm roll to 0.1-2 in thick• Heat treat to recrystallize (sometimes)• Cool• Cold roll to finish thickness• Heat treat (where appropriate)• Results in material which must be further worked

Schematic of various rolling processes

Kalpakjian p 358

Rolling definitions and forces

Average Force

Angularrotation,

N

RollContactLength

L

Approximate Rolling EquationsSpeed of exiting strip: Vf= Vo (ho /hf) (m/s)Maximum Draft: ho - hf = 2R (mm)

Roll Force: avg F = LwY (N)Power: P = 2FLN/60,000 (kW)

Roll Strip Contact Length L = R 1/2(ho -hf)1/2 (mm)

Examples– Copper strip, 9 in wide, 1 in thick, reduced to 0.9 in. Roll

radius is 12 in, rotates at 100 rpm

– L = (12(1-0.9))0.5 = 1.55 in = 0.13 ft = ln (1/0.9) = 0.223; Average true stress is 26,000 psi

– F = (21.55)(9)(26000) = 363,000 lb = 165 ton

– P = 2(363000)(.13)(100)/33000 = 898 HP = 670 kW per roll

– Total power = 1796 HP = 1340 kW

True Strain E = ln (ho/hf)

Hot Rolling• Advantages– Stresses lower– Forces smaller– Power requirements less– No work hardening– Large deformations possible– Breaks up the cast structure into preferable forms– Closes porosity– Sometimes the only way to create sheet

• Disadvantages– Higher friction– Rolls need to be cooled– Material handling difficult– Personnel must be protected from heat

Hot Rolling and Microstructure Development

Kalpakjian p 364

Cold Rolling• Advantages

– Deformations of ~ 50 to 80%– Work hardening increases strength– Excellent surface finish– Excellent tolerance on thickness and shape

• Disadvantages– High forces– Small reductions give rise to surface stresses and non-

uniform stress distributions– ?

Effect of Roll Forces

• The forces result from the resistance of the material to deformation and cause – Roll bending

• Non flat material– Cambered sheet– Buckling

– Roll flattening• Poor tolerances• Increased forces (larger contact area)

avg F = LwY (N)

L = R 1/2(ho -hf)1/2 (mm)

Roll Force Compensation – Can decrease Roll Forces by:

• Reducing friction - Lubricants• Using smaller diameter rolls (Sendzimir mill)• Smaller reductions per pass (Residual stresses)• Increasing temperature (Hot rolling)• Front or back tension (important for high strength metals)• Provide backup rolls (four high)• Camber rolls to compensate• Bend rolls back

Control of Overall Properties• Thickness– Roll gap which impacts roll force and hence the

dimensions of the mill frame• Width (due to spreading of slab)

– Edge rollers (push material back)– Edge shears (cut material off)

• Length– End shears

• Mechanical Properties– Controlled by the microstructures which is controlled

by the rolling parameters (reduction, temperature, etc)

Control of Overall Properties• Tolerance

– Thickness• Operator skill/automation

– Gauges measure thickness of input and output

– Computers control roll gap

– Camber• Roll bending/automation

– Special segmented tensionmeters measure "shape"

– Computers bend the rolls

• Surface finish– Roll finish

Bearing reaction forces

Applied forces

Product Quality Issues• Non-flat material (p366 in Kalpakjian)

– Thermal camber– Wavy edges (caused by roll bending) – Zipper and edge cracks (poor ductility)

• "Alligatoring" (non-uniform deformation) typically in nose and tail of slab or plate

• Residual stresses– Small deformations cause surface deformation

• Flaws in the surface– Roll finish perfection

See Kalpakjian p 366 for examples

A rolling mill for hot flat rolling. The steel plate is seen as the glowing strip in lower left corner (photo courtesy of Bethlehem Steel).

Rolling Mills

• Equipment is massive and expensive• Rolling mill configurations:

– Two-high – two opposing rolls– Three-high – work passes through rolls in both

directions– Four-high – backing rolls support smaller work rolls– Cluster mill – multiple backing rolls on smaller rolls – Tandem rolling mill – sequence of two-high mills

Figure 19.5 Various configurations of rolling mills: (a) 2 high rolling ‑mill.

Two-High Rolling Mill

Figure 19.5 Various configurations of rolling mills: (b) 3 high rolling ‑mill.

Three-High Rolling Mill

Figure 19.5 Various configurations of rolling mills: (c) four high rolling ‑mill.

Four-High Rolling Mill

Multiple backing rolls allow even smaller roll diameters

Figure 19.5 Various configurations of rolling mills: (d) cluster mill

Cluster Mill

A series of rolling stands in sequence

Figure 19.5 Various configurations of rolling mills: (e) tandem rolling mill.

Tandem Rolling Mill

Thread RollingBulk deformation process used to form

threads on cylindrical parts by rolling them between two dies

• Important commercial process for mass producing bolts and screws

• Performed by cold working in thread rolling machines

• Advantages over thread cutting (machining):– Higher production rates– Better material utilization– Stronger threads and better fatigue resistance

due to work hardening

Figure 19.6 Thread rolling with flat dies:

Thread Rolling

(1) start of cycle (2) end of cycle

Work Rest

Rolls

Work piece

Machined thread Rolled thread

Thread Rolling

Rolling Mill Design• Most commercial mills are 4 high, reversible

– Small rolls in contact– F L R0.5

– Large back up rolls provide stiffness• p 363

Cold Rolling Mill Design• Input and output coils with tensioning control• Shape meters consisting of segmented coils

measuring force• Tandem mills allow multiple reductions in one

operation• Laser inspection systems for surface finish

inspection becoming popular (especially for canstock)

• Surface condition of rolls critical to maintain surface finish

• Roll bending almost essential to provide crown control

Sendzimir Mill Design

Hot Rolling Mill Design • Basically the same as cold mills, but designed

for higher temperatures and are reversible• Typically have edging rolls to control thickness• Often have a warm mill at the end

Slab

Hot mill

Roller table

Warm millTake-up roll

Hot Rolling Process Example• Start with 12in. thick slab, 20 feet long • Hot mill converts to 2 in thick slab, 120 feet

long with 11 passes (six forward and 5 reverse)

• Front end sheared off to eliminate alligatoring• Warm mill converts this to roll of sheet 0.25 in

thick, 960 feet long• Rolls more easily handled by overhead cranes

to transport it to cold mills than 1000 ft long slabs

Typical Uses of Sheet and Plate• Sheet and plate are everywhere after further

processing• Automotive bodies (steel and aluminum)• Appliances• Aircraft skins (fuselage and wings)• Electronic assemblies• Steel studs for construction• Tanks• Ships• Beverage cans• Containers of all sorts

• Because they are:• Inexpensive• High quality• Strong

Shape Rolling

Work is deformed into a contoured cross section rather than flat (rectangular)

• Accomplished by passing work through rolls that have the reverse of desired shape

• Products include: – Construction shapes such as I beams, L beams, ‑ ‑

and U channels‑– Rails for railroad tracks– Round and square bars and rods

Shape Rolling• Non-flat shapes can be produced by having rolls

with shape– I-Beams– H-sections– Rails (trains)– Angle iron

• Design of shaped rolls to provide the right amount of non-uniform deformation is critical

Figure 19.2 Some of the steel products made in a rolling mill.

Rolled Products Made of Steel

Shape Rolling• Ring Rolling

– Thick ring small diameter transformed into thin ring, large diameter

– Used in Jet Engines, large ring gears– Advantages

• Circular shapes with no joins can be made with a variety of cross sections

• Thread rolling– Creates thread on screws, bolts etc.– Advantages

• No loss of material• Good surface finish• Increased strength through cold working a favorable grain

flow

Overview of Lecture 3• General characteristics of forming processes

(metals only)– General

• Bulk deformation processes– Rolling– Extrusion

Extrusion process• Push through an orifice with the desired shape• Like toothpaste out of the tube• Both hot and cold extrusion are possible• Depends on the material

Material Flow in Extrusion

Kalpakjian p 422

Extrusion Processes• Direct or forward extrusion

– Billet pushed through die from behind

• Indirect– Die pushed into billet

• Hydrostatic– Ram compresses fluid surrounding billet which is

pushed out through the die• Lateral

– Like direct, but material comes out of the die at right angles to the direction in which the billet is pushed

Kalpakjian p 419

Comments on Direct Extrusion • Also called forward extrusion • As ram approaches die opening, a small portion

of billet remains that cannot be forced through die opening

• This extra portion, called the butt, must be separated from extrudate by cutting it just beyond the die exit

• Starting billet cross section usually round• Final shape of extrudate is determined by die

opening

Figure 19.31 (a) Direct extrusion to produce a hollow or semi hollow cross ‑sections; (b) hollow and (c) semi hollow cross sections. ‑

Hollow and Semi-Hollow Shapes

Figure 19.32 Indirect extrusion to produce (a) a solid cross section and (b) a hollow cross section.

Indirect Extrusion

Comments on Indirect Extrusion

• Also called backward extrusion and reverse extrusion

• Limitations of indirect extrusion are imposed by – Lower rigidity of hollow ram – Difficulty in supporting extruded product as it exits

die

Extrusion Variables • Die angle• Extrusion ratio (ratio of input to output cross-

sectional areas• Circumscribing circle diameter• Shape factor

– Ratio of perimeter of shape to cross-sectional area – a circular shape has the minimum– A measure of the complexity of the extrusion

• Temperature of billet• Ram speed• Lubricant

Extrusion Force

F = k Aoln(Ao/Af)

Where– k is the extrusion constant

– related to stress strain behavior– Page 421 in Kalpakjian

– A0 and Af are the initial and final cross-sectional areas

– A0/Af is the extrusion ratio

– ln rx = ln (Ao/Af)– P = Yf ln rx

– Yf = K εn / 1+n– K = konstanta ekstrusi (stress koefisien)

εx = a + b ln rx

a dan b = konstanta empirik

• Ekstrusi langsung

P = Yf (ε + 2L/Do) Yf = stress sebenarnyaε = estimasi strainL = panjang billetDo = diameter billet

• Ekstrusi tidak langsung(Johnson’s extrusion strain formula)p = Yf ε

F = p Ao

contoh

• billet panjang 75mm dan diameternya 25mm. Billet ini akan dilakukan proses ekstrusi secara langsung. Dengan rasio ekstrusi 4,0. Sudut die 90o. Streng koefisien(K) 415 Mpa. Strain hardening (n) 0,18. estimasi strain ekstreusi a= 0,8 dan b= 1,5.

• Tentukan besar presure yang diberikan oleh ram kepada billet tersebut.

• ε = a + b ln r = 0,8 + 1,5 ln 4 = 2,9• Yf = K εn / 1+n = 415. 2,90,18 / 1,18 = ….• P = Yf (ε + 2L/Do) = ….

Material Flow• Easy to extrude metals and alloys

– Aluminum– Copper– Magnesium– Steels– Stainless steels

• Difficult to extrude metals and alloys– Titanium– Refractory metals

Extrusion Practice• Ratios

– Typically 10 to 100– Must be at least 4 to deform the bulk of the material– Can be as high as 400

• Circumscribing Circle Diameter– Typically 6 mm to 250 mm– Can be as high as 1000 mm– Steel usually restricted to <150 mm

Extrusion Practice • Ram speeds

– Up to 0.5 m/s– Slower for aluminum, magnesium and copper– Higher for steels, titanium and refractory alloys

• Length– Typically less than 7.5 m (heat treat ovens limiting)

Extrusion Practice• Straightening by stretching or rolling (simple cross-

sections)• Coaxial extrusion

– Two metals with similar properties can be coextruded• Stepped extrusion

– Start with small die– Switch to larger X-section die– Use in Aerospace industry to minimize machining scrap

Advantages of Extrusion• Variety of shapes possible, especially in

hot extrusion – Limitation: part cross section must be

uniform throughout length • Grain structure and strength enhanced in

cold and warm extrusion • Close tolerances possible, especially in

cold extrusion • In some operations, little or no waste of

material

Hot vs. Cold Extrusion

• Hot extrusion - prior heating of billet to above its recrystallization temperature – Reduces strength and increases ductility of the

metal, permitting more size reductions and more complex shapes

• Cold extrusion - generally used to produce discrete parts – The term impact extrusion is used to indicate high

speed cold extrusion

Hot Extrusion• Advantages

– Lower stresses– Sometimes the only way to extrude certain metals

• e.g. Titanium, refractory alloys, high strength alloys• Disadvantages

– Higher die wear– Oxide film buildup results in non-uniform flow,

inclusions and poor surface finish– Cooling of billet in container results in non-

uniform flow– Distorted parts

Hot Extrusion

Process temperature ranges

Material TempRange (oC)

Lead 200-250

Aluminum and alloys 375-475

Copper and alloys 650-975

Steels 875-1300

Refractory alloys 975-2200

Hot Extrusion Die Design• Difficult and requires a lot of experience• Square dies (die angle = 90o) give rise to dead

metal zones around the die• Dead metal zones give bright finishes to aluminum

alloys (no surface exposed to air)• Spider dies produce hollow shapes (page 424-425

– How is the cross section completed?

Die Angle

Dead Metal Zone

Die

Hot Extrusion Lubrication• Molten glass supplied as a coating of glass frit• Lower melting alloys as a can• Also

– reduces sticking to container walls– prevents contamination

Cold Extrusion• More recent development (1940's)• Includes some operations similar to forging• Advantages

– improved mechanical properties– work hardening– Good control of tolerances– Improved surface finish– Elimination of heating costs– High production rates

• Disadvantages– Higher stresses require more expensive tooling and die

material– Difficult die design essential to success– Lubrication critical

Impact Extrusion• Similar to indirect extrusion• Can be considered a subset of cold extrusion• Tends to look very similar to forging Used to make

short parts with thin walls• See page 428-429 for examples

Hydrostatic Extrusion• Even more recent development (1950's)• Advantages

– No friction at walls– Can successful extrude brittle materials– Yield stress reduced by hydrostatic pressure– Room temperature operation

• Disadvantages– Limited industrial applications– Complex tooling– High pressure experience required

Ideal Work of Deformation: Uideal

Redundant work: Uredundant

+

+Work of Friction: Ufriction

Tool – Workpiece Interaction:

* Friction

* Acting Loads

f

dU ideal

0

.

redundant work in extruding sheet material through a die

Total WORK of DEFORMATION

Utotal = Uideal + Ufriction + Uredundant

total

ideal

U

UProcess Efficiency:

c

U

c

UT idealtotal

...max Temperature Increase:

RISK !!

Hot Shortness

Hot shortness in Al alloy extrusions

Extrusion Ratio

Also called the reduction ratio, it is defined as

where rx = extrusion ratio; Ao = cross-sectional area of the starting billet; and Af = final cross-sectional area of the extruded section

• Applies to both direct and indirect extrusion

f

ox A

Ar

Figure 19.35 (a) Definition of die angle in direct extrusion; (b) effect of die angle on ram force.

Extrusion Die Features

Comments on Die Angle

• Low die angle - surface area is large, which increases friction at die billet interface ‑– Higher friction results in larger ram force

• Large die angle - more turbulence in metal flow during reduction– Turbulence increases ram force required

• Optimum angle depends on work material, billet temperature, and lubrication

Orifice Shape of Extrusion Die

• Simplest cross section shape is circular die orifice

• Shape of die orifice affects ram pressure • As cross section becomes more complex,

higher pressure and greater force are required • Effect of cross-sectional shape on pressure

can be assessed by means the die shape factor Kx

Figure 19.36 A complex extruded cross section for a heat sink (photo courtesy of Aluminum Company of America)

Complex Cross Section

Extrusion Cross Sections

Product Quality Issues• Surface cracking (tearing, fir-tree cracking, speed

cracking, bamboo defects)– Caused by

• high temperature• high speed• high friction

• Surface appearance– Oxides, scratches, discolorations

Product Quality Issues• Pipes (tailpipe, fishtailing)

– Caused by surface oxides and defects being piped to the middle by the flow pattern

– Results in significant lengths being scrapped– Can be minimized by machining billet surface first,

making the flow pattern more uniform• Internal Cracking

– Caused by a state of hydrostatic stress at the center of the extrusion which results from poor die design

Typical uses of extrusions• Windows and doors (aluminum)• Aircraft components

– stringers, ribs• Tubing

– copper and plastic for plumbing, aluminum, steel for– lawn furniture

• Discrete parts (sawn off)

Drawing Process• Like extrusion but material pulled out the

orifice of the required shape instead of being pushed in.

• Although drawing applies tensile stress, compression also plays a significant role since metal is squeezed as it passes through die opening

• Resulting shape variety is more limited than extrusion– Rod (larger cross sections)– Wire (smaller cross sections)

Figure 19.40 Drawing of bar, rod, or wire.

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Wire and Bar Drawing

Drawing • Advantages

– Very long product with non-flat cross-section than extrusion - wire, rod (total length can exceed miles)

– Non circular cross sections can be produced• Disadvantages

– Higher forces required– If exceed tensile strength further deformation can

be non-uniform– Limited size reduction per pass (Maximum 63%)– Need multiple dies and take up rolls

Area Reduction in Drawing

Change in size of work is usually given by area reduction:

where r = area reduction in drawing; Ao = original area of work; and Ar = final work

o

fo

AAA

r

Wire Drawing vs. Bar Drawing

• Difference between bar drawing and wire drawing is stock size – Bar drawing - large diameter bar and rod stock– Wire drawing - small diameter stock - wire sizes

down to 0.03 mm (0.001 in.) are possible

• Although the mechanics are the same, the methods, equipment, and even terminology are different

Drawing Practice and Products

• Drawing practice:– Usually performed as cold working– Most frequently used for round cross sections

• Products:– Wire: electrical wire; wire stock for fences, coat

hangers, and shopping carts – Rod stock for nails, screws, rivets, and springs – Bar stock: metal bars for machining, forging, and

other processes

Bar Drawing

• Accomplished as a single draft‑ operation the ‑stock is pulled through one die opening

• Beginning stock has large diameter and is a straight cylinder

• Requires a batch type operation

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007

Figure 19.41 Hydraulically operated draw bench for drawing metal bars.

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Bar Drawing Bench

Wire Drawing

• Continuous drawing machines consisting of multiple draw dies (typically 4 to 12) separated by accumulating drums – Each drum (capstan) provides proper force to

draw wire stock through upstream die – Each die provides a small reduction, so desired

total reduction is achieved by the series – Annealing sometimes required between dies to

relieve work hardening

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007

Figure 19.42 Continuous drawing of wire.

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Continuous Wire Drawing

Features of a Draw Die

• Entry region - funnels lubricant into the die to prevent scoring of work and die

• Approach - cone shaped region where ‑drawing occurs

• Bearing surface - determines final stock size • Back relief - exit zone - provided with a back

relief angle (half angle) of about 30‑ • Die materials: tool steels or cemented

carbides

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007

Figure 19.43 Draw die for drawing of round rod or wire.

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Draw Die Details

Preparation of Work for Drawing

• Annealing – to increase ductility of stock• Cleaning - to prevent damage to work surface

and draw die• Pointing – to reduce diameter of starting end

to allow insertion through draw die

Product Quality Issues• Similar to those in extrusion, especially center

cracking– Additionally, seams appear as folds in the surface– Residual stresses can cause problems in

subsequent shaping processes

Overview of Lecture 3• General characteristics of forming processes

(metals only)• General• Bulk deformation processes• Rolling• Extrusion• Forging

– Open Die– Closed Die– Other

ForgingDeformation process in which work is

compressed between two dies(The forming of workpieces through the

successive tools and dies)• Oldest of the metal forming operations,

dating from about 5000 B C • Components: engine crankshafts,

connecting rods, gears, aircraft structural components, jet engine turbine parts

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007

Forging Process

• Also, basic metals industries use forging to establish basic form of large parts that are subsequently machined to final shape and size

• Initially just a hammer on an anvil (jewelry, horse shoes, sword making)

• Used to improved properties as well as form a shape

• Produces discrete parts

Forging Process History• Molds of stone helped initial forming efforts• Now forces are

– Mechanical (hammer presses)– Hydraulic

• Dies are tool steel• Near net shape forming

Forging Practice• Prepare raw material including cleaning• Heat workpiece (for hot forging)• Descale if necessary• Preheat and lubricate dies ( hot forging)• Forge in appropriate dies and in correct

sequence• Remove excess material ( flashing)• Clean• Check dimensions• Machine to final dimensions• Straighten if necessary• Heat treat if necessary• Inspect

Forging Process Capabilities

• Tolerances of 0.5% to 1% can be achieved• Material properties can be tailored by appropriate

die design• Directed material flow

Forging Processes• Advantages

– Metal flow and grain structure can be controlled– Results in good strength and toughness– Near net shape (low buy to fly ratio)– Parts of reasonable complexity can be created

• Landing gear• Connecting rods• Complex shafts

• Disadvantages– Dies are expensive, particularly for hot forging– Highly skilled labor required

Classification of Forging Operations• Cold vs. hot forging:

– Hot or warm forging – most common, due to the significant deformation and the need to reduce strength and increase ductility of work metal

– Cold forging – advantage: increased strength that results from strain hardening

• Impact vs. press forging:– Forge hammer - applies an impact load – Forge press - applies gradual pressure

Types of Forging Dies

• Open die forging - work is ‑compressed between two flat dies, allowing metal to flow laterally with minimum constraint

• Impression die forging - die contains ‑cavity or impression that is imparted to workpart– Metal flow is constrained so that flash is

created • Flashless forging - workpart is

completely constrained in die– No excess flash is created

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007

Forging Process Categories

HotWarm

Isothermal

SlugPreform

Billet

Heading, Coining,Cogging, Fullering,

Gathering, Hubbing,Piercing, Roll Forging,

Skew Rolling

Open die, Impression Die,

Closed Die, Precision,

Orbital, Swaging

Trimming,Machining,Cleaning

HeatTreating

Preparation ForgingSubsequent Operations

Kalpakjian p 382

PRODUK FORGING

Shaft Parts

Gears

Open Die Forging and Cogging• Simplest and cheapest• Also called upsetting or flat-die forging• Deformation operation reduces height and increases

diameter of work • Advantages– Cheap– Can form a wide variety of simple shapes with the same

dies• Squares, cylindrical

– Useful for preparing material for other forms of forging or machining

– Can handle large items (35 tons)• Disadvantages– Barreling of shape due to high friction

Figure 19.9 Three types of forging: (a) open die forging. ‑

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Open-Die Forging

Figure 19.10 Homogeneous deformation of a cylindrical workpart under ideal conditions in an open die forging operation: (1) start of process ‑with workpiece at its original length and diameter, (2) partial compression, and (3) final size.

Open-Die Forging with No Friction

Open-Die Forging with Friction

• Friction between work and die surfaces constrains lateral flow of work, resulting in barreling effect

• In hot open-die forging, effect is even more pronounced due to heat transfer at and near die surfaces, which cools the metal and increases its resistance to deformation

Figure 19.11 Actual deformation of a cylindrical workpart in open die ‑forging, showing pronounced barreling: (1) start of process, (2) partial deformation, and (3) final shape.

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Open-Die Forging with Friction

Distribution of tooling pressure in plane strain forging: the friction hill

PLANE STRAIN FORGING

)(

2exp)( ax

hYxpxy

From Equilibrium + Tresca (low friction):

h

aYxp

2exp0

Maximum tooling pressure:

h

aYp

1

Mean tooling pressure:

h

awaYwapF

1).2().2(

Tooling load:

Friction in close die forging

h

arYF

3

21 2

For a cylindrical workpiece:

Open Die Forging ForceF = Yf r2 (1 + 2r/3h)

where Yf is the flow stress of the material

is the coefficient of friction

r is the radius

h is the height of the workpiece

Examples– Stainless steel workpiece, 150 mm diameter, 100 mm

high reduced with flat dies to 50% of original height.Coefficient of friction is 0.2

– Force is 5000 tons

Kalpakjian p 385

Impression and Closed Die Forging• Use dies with the approximate end shape• Usually requires more than one die to complete

process• Fullering and Edging dies prepare material to take

up die shape– Fullering moves material away from center– Edging moves material away from edges

• Flashing produced from excess material• Often used to ensure good die filling

(b) impression die forging. ‑

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Impression-Die Forging

Figure 19.14 Sequence in impression die forging: (1) just prior to ‑initial contact with raw workpiece, (2) partial compression, and (3) final die closure, causing flash to form in gap between die plates.

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Impression-Die Forging

Impression Die Forging Practice‑

• Several forming steps often required, with separate die cavities for each step – Beginning steps redistribute metal for more

uniform deformation and desired metallurgical structure in subsequent steps

– Final steps bring the part to final geometry

• Impression-die forging is often performed manually by skilled operator under adverse conditions

Advantages and Limitations• Advantages of impression-die forging

compared to machining from solid stock:– Higher production rates– Less waste of metal– Greater strength– Favorable grain orientation in the metal

• Limitations:– Not capable of close tolerances– Machining often required to achieve

accuracies and features needed

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007

Precision Forging• A further development of closed die forging• Close calculation of material required to fill die

minimizes scrap and flashing• Dies have more detail minimizing subsequent shaping

operations• Advantages

– Little subsequent shaping– Good to excellent properties

• Disadvantages– Expensive– Difficult to control

Impression and Closed Die Forging

Forging A Connecting Rod

FIGURE 6.26 Stages in forging a connecting rod for an internal combustion engine. Note the amount of flash that is necessary to fill the die cavities properly.

Flashless Forging (Precision Forging)Compression of work in punch and die

tooling whose cavity does not allow for flash

• Starting workpart volume must equal die cavity volume within very close tolerance

• Process control more demanding than impression die forging ‑

• Best suited to part geometries that are simple and symmetrical

• Often classified as a precision forging process

Closed Die Forging ForceF = k Yf A

where Yf is the flow stress

A is the area and

k is a factor given below

Shapes k

Simple, no flashing 3-5

simple, with flashing 5-8

Complex, with flashing 8-12

Kalpakjian p 389

Figure 19.17 Flashless forging: (1) just before initial contact with workpiece, (2) partial compression, and (3) final punch and die closure.

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Flashless Forging

Forging Presses

• Apply gradual pressure to accomplish compression operation

• Types:– Mechanical press - converts rotation of drive

motor into linear motion of ram – Hydraulic press - hydraulic piston actuates ram – Screw press - screw mechanism drives ram

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007

Upsetting and Heading

Forging process used to form heads on nails, bolts, and similar hardware products

• More parts produced by upsetting than any other forging operation

• Performed cold, warm, or hot on machines called headers or formers

• Wire or bar stock is fed into machine, end is headed, then piece is cut to length

• For bolts and screws, thread rolling is then used to form threads

Figure 19.22 An upset forging operation to form a head on a bolt or similar hardware item The cycle consists of: (1) wire stock is fed to the stop, (2) gripping dies close on the stock and the stop is retracted, (3)

punch moves forward, (4) bottoms to form the head.

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Upset Forging

Figure 19.23 Examples of heading (upset forging) operations: (a) heading a nail using open dies, (b) round head formed by punch, (c) and (d) two common head styles for screws formed by die, (e) carriage bolt head formed by punch and die.

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Heading (Upset Forging)

Figure 19.29 Trimming operation (shearing process) to remove the flash after impression die ‑

forging.

Trimming After Impression-Die Forging

Related Processes• Coining

– Similar to precision forging but much older– Die cavity completely closed– Very high pressures involved– Used in coin making

• Heading– Used mostly for bolts

Related Processes• Piercing

– Exactly as it sounds– Makes holes– Used in conjunction with closed die forging

• Hubbing– Like piercing but for making cavities, not complete

penetrations larger areas• Roll Forging

– Uses rolls to shape parts (ball bearings)– Similar to shape rolling but makes discrete parts

Related Processes• Orbital Forging

– Forms the part incrementally– Small forging forces because the die contact is– concentrated on a small part of the workpiece at anyone

time (Kalpakjian p 394)– Applicable to mostly cylindrical shapes

• Incremental forging– Blank formed in several small steps like orbital– non-rotational parts can be made

Related Processes• Isothermal forging

– Dies at same temperature of workpiece– No workpiece cooling– Low flow stresses– Better material flow– More close tolerances and finer details can be

achieved• Swaging

– Cylindrical parts subjected to radial impact forces by reciprocating dies

– Used to reduce tube diameter and introduce rifling into gun barrels

Die Design p 398• Requires knowledge of

– Material strength– Sensitivity of these to deformation rate and

temperature– Friction and its control– Shape and complexity of workpiece– How the metal will flow to fill the die cavity– Great skill and expertise– Multiple dies to move the material in the right

direction

Forgeability• Defined as the capability of a material to undergo

deformation without cracking• Common test is the upset test

– Upset cylindrical specimen to fixed, large deformation– Examine barrel surfaces for cracks

• Another is the hot torsion test– Twist long cylindrical specimen around its axis– No of twists to failure is forgeability– Also used for rolling and extrusion deformation

capabilities

Hot forging TemperaturesMaterial Temperature

Range (oC)

Aluminum alloys 400-550

Magnesium alloys 250-35-

Copper alloys 600-900

Carbon and low alloy steels 850-1150

Stainless steels 1100-1250

Titanium alloys 700-950

Iron based superalloys 1050-1180

Tungsten alloys 1200-1300

Forging ferrous alloys

• Baja karbon dan paduannya :• Perlu seleksi temperatur based on Kandungan karbon Komposisi paduan Range temperatur deformasi optimum % reduksi

Temperatur forging baja karbon

• AISI %C Temp.max forging (oC)

C1010 0.1 1315 C1030 0.3 1290 C1050 0.5 1260 C1080 0.8 1200 C1095 1.0 1180

Product Quality Issues

• Surface cracks (forgeability limitation)• Buckling• Laps• Internal cracks

Forging Machines• Mechanical Presses

– Hydraulic– Mechanical– Screw– Hammers– Gravity Drop– Power Drop– Counterblow– High Energy Rate

Forging Machines

FIGURE 6.28 Schematic illustration of various types of presses used in metalworking. The choice of the press is an important factor in the overall operation.

Hydraulic Presses

• Constant speed• Load limited• Compared to mechanical

– Typically slower– Higher initial cost– Less maintenance

Mechanical Presses• Crank or eccentric types• Stroke limited• Energy dependent on that stored in flywheel• Very large forces can be generated at bottom dead

center• Hence must be careful in die design and placement

to avoid die fracture

Screw Presses

• Derive energy from flywheel like mechanical presses

• Flywheel drives a screw, not a ram• Energy limited• Process stops when flywheel energy exhausted

Hammers• Ram is raised by some mechanism and let fall onto

workpiece• Derives energy from potential energy of the

hammer• They are energy limited• High speeds• Minimal cooling• Different types

– Gravity drop– Power drop– Counterblow– High energy rate machines

Forging Hammers (Drop Hammers)

Apply impact load against workpart • Two types:

– Gravity drop hammers - impact energy from falling weight of a heavy ram

– Power drop hammers - accelerate the ram by pressurized air or steam

• Disadvantage: impact energy transmitted through anvil into floor of building

• Commonly used for impression-die forging

Figure 19.19 Drop forging hammer, fed by conveyor and heating units at the right of the scene (photo courtesy of Chambersburg Engineering Company).

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007

Figure 19.20 Diagram showing details of a drop hammer for impression die forging. ‑

©2007 John Wiley & Sons, Inc. Adapted from M P Groover, Fundamentals of Modern Manufacturing 3/e D Holland 2007 Drop Hammer Details

Characteristics of Forging ProcessesProcess Advantages Limitations

Open die Cheap dies limited to simple shapesSmall quantities Poor tolerancesWide range of sizes Low production ratesGood strengths high skill required

Closed Die Good utilization of material High die costsBetter properties Machining necessaryGood tolerances and accuracyHigh ratesGood reproducibility

Precision Close tolerances Machining necessaryMachining unnecessary High forcesExcellent material utilization Intricate diesThin webs and flanges Need way of removing part

Forging Economics• Setup and tooling costs are high initially• Good for large production quantities• Material costs as a fraction of total costs vary with

material– High percentage for stainless steels (70-85%)

Comparison of Forging and Casting• See page 412 for comparison of forging. Investment

casting, sand casting, permanent mold cast, and die casting costs

• Both require dies and have parting lines• Difficult to differentiate a casting from a forging• Casting gives lower strength material than forging but

more shape complexity• Forging allows better control of the material

microstructure (controlling material flow)• Costs comparable: Which is cheaper depends on

volume, page 412)– Low percentage for carbon steel (25-45%)

Summary• General characteristics of forming processes

(metals only)• General• Bulk deformation processes

– Rolling– Extrusion– Forging

• Open Die• Closed Die• Other

• Summary

Summary of Metal Forming Processes

• They rely on plastic flow of the bulk of the material

• Forces causing the plastic flow are the result of different kinds of machines

• Result in products which typically require subsequent processing to make useful products

• Products from these processes are ubiquitous