For every destination the optimum drive -...

Transcript of For every destination the optimum drive -...

siemens.com/sinamics

For every destination the optimum driveSINAMICS – the seamless and integrated drives family for every application

siemens.com/sinamics

SINAMICS – for every destination the optimum drive

Subject to change without prior notice Article No. E20001-A180-M112-V4-7600 Dispo 21500 D&M/66743 V6.MKSIDA.WES PT 03155.0 Printed in Germany © Siemens AG 2015

The information provided in this brochure contains merely general descriptions or characteristics of per-formance which in case of actual use do not always apply as described or which may change as a result of further development of the products. An obligation to provide the respective characteristics shall only exist if expressly agreed in the terms of contract.

All product designations may be trademarks or prod-uct names of Siemens AG or supplier companies whose use by third parties for their own purposes could violate the rights of the owners.

Siemens offers products and solutions with industrial security functions, which support the secure opera-tion of plants, solutions, machines, devices and/or networks. They are important components in a seam-less and integrated industrial security concept. The products and solutions from Siemens are being con-tinually developed under this particular perspective. Siemens urgently recommends that you regularly in-form yourself about product updates.

For the secure operation of products and solutions from Siemens it is necessary to take protective mea-sures (for example, cell protection concept), and to integrate every component into an integrated and seamless industrial security concept that corresponds to state-of-the-art technology. In so doing, products from other manufacturers should be taken into ac-count. You can find more detailed information about industrial security at http://www.siemens.com/industrialsecurity.

Register for our product-specific Newsletter so that you are always informed about product updates. You can find additional information on this topic at http://support.automation.siemens.com.

Siemens AG Digital Factory P.O. Box 31 80 91050 Erlangen Germany

Follow us on: www.twitter.com/siemensindustry www.youtube.com/siemens

For more information please contact: www.siemens.com/automation/partner

Industry Services: www.siemens.com/industry-services

Discover in detail how Integrated Drive Systems boost your competitive edge and improve your time to profit.

Integrated Drive Systems to go: Visit our mobile site!

Find out more:siemens.com/ids

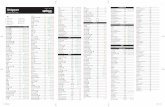

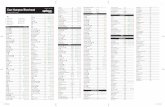

Low voltageDirect

voltageMedium voltage

V20 V90 G120C G120P / G120P Cabinet

G120 G110M G110D G120D G130 / G150 G180 S110 S120M S120 S150 DCM / DCM Cabinet

GL150 / SL150 GM150 / SM120 CM / SM150

GH150 / GH180

The cost-effective, reliable and user-

friendly converter for basic applications

The power-optimized and simple to operate

servo drive system

The compact and versatile converter

with optimum functionality

The specialist for pumps, fans and

compressors

The modular converter –

space-saving, safe, and rugged

The distributed converter integrated

in the motor

The distributed converter for

basic applications

The specialist for demanding, distributed

conveyor technology applications with

positioning capability

The universal converters for high power ratings

The specific drive solution for oil & gas,

chemical and process industries

The specialist for basic positioning tasks

The flexible, modular drive system for demanding single-axis and multi-axis applications The converter for demanding applications in

the high power range

The scalable converter for basic and demanding

applications

The SINAMICS solutions for the medium-voltage range

Current-source DC link converter/cycloconverter

3-level voltage-source DC link converter Cell-based converter

Format Blocksize unit Blocksize unit Blocksize unit Chassis units, units for wall/panel mounting

and cabinet units

Blocksize unit Integrated in the motor / close to

the motor

Separate from the motor

Separate from the motor

Chassis unit, cabinet unit

Compact unit, converter

cabinet unit

Blocksize unit Integrated in the motor Blocksize unit Chassis unit Booksize unit Chassis unit Cabinet module Converter cabinet unit

DC converter unit, converter cabinet

Converter cabinet unit

Drive type AC/AC unit ready to connect up

AC/AC unit ready to connect up

AC/AC unit ready to connect up

AC/AC unit modular,

AC/AC unit ready to connect up

AC/AC unit modular

AC/AC unit modular

AC/AC unit ready to connect up

AC/AC unit modular

AC/AC unit modular,

ready to connect up

AC/AC unit ready to connect up

AC/AC unit modular

DC/AC unit modular

AC/AC unit modular

DC/AC unit modular

AC/AC unit ready to connect up

Compact AC/DC unit AC/AC unit ready to connect up

AC/pulse width modulated DC

Degree of protection

IP20 IP20 IP20 IP20 – IP55 IP20 Up to IP66 IP65 IP65 IP00 – IP54 IP20 – IP54 IP20 IP65 IP20 IP20 IP20 IP00/IP20 IP20–IP54 IP20–IP54 IP00/IP54 IP21–IP54 IP22, IP43, optional up to IP42 and IP54

IP21, IP52

Supply voltage/input voltage: power

1AC 200–240 V 0.12–3.0 kW – – – 0.55–4 kW – – – – – 0.12–4 kW – 0.12–4 kW – – – – – – – – –

3AC 200–240 V – – – – 0.55–7.5 kW – – – – – – – 0.55–7.5 kW – – – – – – – – –

3AC 380–480 V 0.37–30 kW 0.4 – 7 kW 0.55–18.5 kW 0.37–400 kW (IP20) 0.37–90 kW (IP55) 110–400 kW (IP54)

0.55–250 kW (IP20) 0.37–4 kW 0.75–7.5 kW 0.75–7.5 kW G130: 110–560 kW, G150: 110–900 kW

2.2–4,100 kW 0.37–90 kW 0.25–1.1 kW 0.37–90 kW 110–250 kW 1.6–107 kW 110–3,040 kW 1.6–3,000 kW 110–800 kW – – – –

3AC 500–600 V – – – – – – – – G130: 110–560 kW, G150: 110–1.000 kW

2.2–5,300 kW – – – – – – – – – – – –

3AC 500–690 V – – – – 11–55 kW – – – – 2.6–6,600 kW – – – – – 75–5,700 kW 75–5,700 kW 75–1,200 kW – – – –

3AC 660–690 V – – – – – – – – G130: 75–800 kW, G150: 75–2,700 kW

7.5–6,600 kW – – – – – – – – – – – –

1AC 85 V–3AC 950 V – – – – – – – – – – – – – – – – – – 6 kW - 30 MW – – –

3AC 2.3–7.2 kV – – – – – – – – – – – – – – – – – – – 800 kW–85 MW 820 kW–31.5 MW 150 kW–14.2 MW

Energy recovery – – – – optional – – Yes – – – Yes, depending on the infeed

– – Yes, depending on the infeed Yes Yes, for the corresponding version

Yes Only SM150 –

Closed-loop control technique

V/f Servo control (speed and torque)

with encoder

V/f, vector control (without encoder)

V/f, vector control (without encoder), and torque control without encoder

V/f, vector control (with/without encoder), FCC

V/f, vector control (without encoder), FCC

V/f, FCC V/f, vector control (with/without encoder)

V/f, vector control (without encoder)

V/f control, servo control

(with/without encoder)

Servo control V/f control, vector control (with/without encoder), servo control (with/without encoder) V/f control, vector control

(with/without encoder), servo control

(with/without encoder)

Closed-loop speed/torque control

(with/without encoder)

V/f control, vector control

(with/without encoder)

Closed-loop vector control

V/f control, vector control

(with/without encoder)

Motors Induction motors Synchronous motors Induction motors Induction motors, synchronous motors¹

Induction motors Induction motors, synchronous motors (encoderless), torque motors (encoderless)

Induction motors, synchronous motors

Induction motors, synchronous motors

Synchronous motor Induction motors, synchronous motors, torque motors, linear motors Induction motors, synchronous motors

DC motors Induction motors, synchronous motors

Technological functions (selection)

Automatic restart, flying restart, energy-saving mode, keep-

running mode, blockage clearing

mode, hammer start and supplementary boost torque, tech- nology controller, motor cascading, wobble function

Auto tuning in real time, automatic suppression of

machine resonances, integrated braking resistor, integrated

positioning function, switchover of the open-loop control

mode, DI/DO parameterization

Flying restart, automatic restart, kinetic buffering, BICO technology,

technology controller, compound

braking, DC braking, dynamic braking

Automatic restart, energy-saving mode,

hibernation, flying restart, motor

cascading, 4 PID technology

controllers, logic and arithmetic functions,

essential service mode, multi-zone controller,

bypass

Flying restart, automatic restart, kinetic buffering, BICO technology,

technology controller, free function

blocks, compound braking, DC braking,

dynamic braking, basic positioner,

motor and machine encoder evaluation

Quick Stop, limit switch function, free function blocks (PLC function),

integrated braking resistor (optional),

motor holding brake, software-based braking, stand-alone converter

for installation by customer – or as complete drive unit with

SIMOGEAR geared mo- tor or SIMOTICS motor

Flying restart, automat-ic restart, positioning

down ramp, quick stop, jog mode, technology controller, control for motor holding brake and operating brake,

electronic braking (software brake and

resistor)

Flying restart, automatic restart,

kinetic buffering, BICO technology, technology controller, free function

blocks, compound braking, DC braking,

dynamic braking, basic positioner, motor and machine encoder

evaluation

Flying restart, automatic restart, kinetic buffering, BICO technology,

technology controller, free function blocks, Drive Control Chart

Flying restart, kinetic buffering, automatic restart, DC current

limiting, current and voltage control, line

synchronization, process controller,

logic functions

Basic positioner, BICO technology, technology controller, free function

blocks, DC braking, kinetic buffering

Flying restart, automatic restart, kinetic buffering, basic positioner, BICO technology, technology controller, Drive Control Chart, motion control in conjunction with SIMOTION, numeric control with SINUMERIK solution line

Flying restart, automatic restart, kinetic buffering,

technology controller, Drive Control Chart,

BICO technology

BICO technology, technology

controller, free function blocks,

automatic restart, Drive Control Chart

Flying restart, automatic restart, kinetic buffering, technology

controller, Drive Control Chart, BICO technology

Advanced cell bypass, ProTOPs, automatic restart, anti-condensation heating,

other options on request

Safety functions – STO STO – STO, SS1, SBC, SLS, SDI, SSM

STO STO STO, SS1, SLS, SDI, SSM

STO, SS1, SBC, SLS, SDI, SSM

STO STO, SOS, SBC, SS1, SS2, SLS, SSM, SDI

STO, SS1, SBC, SOS, SS2, SLS, SSM, SDI, SLP, SP, SBT – – STO (SM150) Emergency Stop Cat. 0 is defined as standard for

uncontrolled rundown (coast down)

Communication profiles

USS/Modbus RTU Pulse/direction interface, analog

interface

PROFINET, PROFIBUS DP, EtherNet/IP,

USS/Modbus RTU, CANopen

PROFINET, PROFIBUS DP, EtherNet/IP,

USS/Modbus RTU, BACnet MS/TP,

CANopen

PROFINET, PROFIBUS DP, EtherNet/IP,

USS/Modbus RTU, BACnet MS/TP,

CANopen

PROFINET, PROFIBUS DP, EtherNet/IP,

USS/Modbus RTU

AS-Interface PROFINET, PROFIBUS DP,

EtherNet/IP

PROFINET, PROFIBUS DP,

EtherNet/IP, USS, CANopen

PROFIBUS DP, EtherNet/IP,

Modbus TCP/IP, Modbus RTU,

CANopen, on request: PROFINET

PROFINET, PROFIBUS DP,

USS, CANopen, pulse/direction interface

PROFINET, PROFIBUS DP, EtherNet/IP ², USS, CANopen PROFINET, PROFIBUS DP, EtherNet/IP,

USS, CANopen

PROFINET, PROFIBUS DP, EtherNet/IP,

USS

PROFINET, PROFIBUS DP, EtherNet/IP,

USS

PROFINET, PROFIBUS DP, EtherNet/IP,

other profiles on request

Modbus Plus, Modbus RTU, Modbus Ethernet, DeviceNet,

Control Net, PROFIBUS DP

Additional energy- saving functions

Yes – Yes Yes Yes Yes Energy usage display Yes Yes Yes – Yes Yes Yes Yes Yes Yes Yes Yes, application-specific

PROFIenergy – – Yes Yes Yes Yes – Yes Yes – Yes Yes Yes Yes Yes Yes Yes Yes – Yes Yes –

PROFIsafe – – Yes – Yes Yes – Yes Yes – Yes Yes Yes Yes Yes Yes Yes Yes – Yes Yes –

PROFIdrive – – Yes Yes Yes Yes – Yes Yes – Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes –

Tools DT Configurator SINAMICS V-ASSISTANT, DT Configurator

STARTER, SINAMICS Startdrive, SIZER, DT Configurator STARTER, SIZER, DT Configurator

STARTER, SINAMICS Startdrive, SIZER, DT Configurator

STARTER, SIZER, DT Configurator

IMS (Inverter Management

Software), SIZER, DT Configurator

STARTER, SIZER, DT Configurator SIZER WEB ENGINEERING,

DT Configurator

Typical applications

Basic applications, e.g. pumps, fans, com-

pressors, conveyors, mixers, kneaders, agitators, mills,

spinning and textile machines

Handling machines, e.g. automatic equipping machines, packaging

machines, e.g. labeling machines, automatic assembly machines,

metal-forming machines, printing

machines, e.g. screen printing machines,

winders and unwinders

Conveyor belts, mixers, extruders,

pumps, fans, compressors

and basic handling machines

Pumps, fans, compressors, particu-larly for e.g. building

technology, water supply and process

industry, HVAC

Universal converters in machinery construc-

tion, e.g. positioning, pumps, fans, compres-

sors, conveyor belts, extruders, mixers,

crushers, auxiliary and main production machines drives

Conveyor technology, industrial applications,

pumps, fans and compressors

Standard V/f applications

for conveyor tech- nology, distribution

logistics, airport, basic, high-performance applications in the

automotive industry, food and beverage,

packaging

Electric monorails, conveyor belts, storage and retrieval machines,

hoisting gear, servo-controlled positioning

of individual drives

Pumps, fans, compres-sors, conveyor belts,

extruders, mixers, mills

Pumps, fans, blowers, compressors,

conveyor belts, extruders, mixers,

crushers, kneaders, centrifuges, separators

High-performance single-axis drives High-performance multi-axis drives Test stands, cross-cutters,

centrifuges, conveyor belts, presses

Rolling mill drives, wire-drawing

machines, extruders and kneaders, cable

railways and lifts, test stand drives,

mine hoists

Pumps, fans, compressors, ship drives, extruders, blast furnace blowers,

rolling mills, mine hoists, mining

conveyor systems, crushers, excavators

Pumps, fans, compressors, mills, crushers, conveyor

belts, ship drives, test stands,

rolling mill drives, etc.

Pumps, fans, compressors, mills, crushers,

conveyor systems, retrofit projects, etc.

Servo-controlled positioning of single-

axis drives with synchronous/induction

motors, e.g. in production machines

Servo-controlled positioning applications in production machines,

(packaging, printing, woodworking, glass,

converting) and machine tools

Continuous motion control/positioning tasks in production machines, e.g. packaging, textile, printing, paper and plastics machines, plants and process lines, presses, converting applications, numeric control applications in machine tools,

test stands and marine applications

Catalog V20 brochure, distribution catalog

V90 brochure D31, distribution catalog

D35 D31, distribution catalog

D31 D31 D31 D11 D 18.1 PM22 / D31 Siemens Mall and SIOS PM21 / D31 PM21, D21.3 PM21 PM21, D21.3 D21.3 D21.3 D23.1, D23.2 EM3.5/1.2 D12 (GM150/SM150) D15.2/16.2

STO: Safe Torque Off SOS: Safe Operating Stop SBC: Safe Brake Control SS1: Safe Stop 1 (safe stopping process, Cat. 1) SS2: Safe Stop 2 (safe stopping process, Cat. 2) SLS: Safely Limited Speed SSM: Safe Speed Monitor ¹ on request ² only DC/AC units

We reserve the right to make changes. Updated 03/2015, Article No.: E20001-A180-M112-V4-7600