Flotation plant

Click here to load reader

-

Upload

henan-hongxing-mining-machinery-co-ltd -

Category

Marketing

-

view

30 -

download

3

description

Transcript of Flotation plant

China Mining Machinery Production and Export Base Address: No.8 Tanxiang Road, Zhengzhou, Henan, China

Tel: +86-371-67833161 / 67833171E-mail: [email protected] [email protected]: [email protected]: http://www.hxjqchina.com

FOB Price: US $9,600 - 78,300 / SetPort: Qingdao,Tianjin,Shanghai or other port

requestedMinimum OrderQuantity:

1 Set

Supply Ability: 100 Sets per monthPayment Terms: L/C, D/A, D/P, T/T,Western Union

Condition: New Place ofOrigin:

Henan,China

Brand Name: Hongxing

Model Number: Flotationmachine

Voltage: 380 Power(W): As requested

Dimension(L*W*H): As requested Weight: as requested Certification: ISO9001Warranty: 1 year After-sales

ServiceProvided:

Engineersavailable toservice

Certificate: ISO9001:2008

China Mining Machinery Production and Export Base Address: No.8 Tanxiang Road, Zhengzhou, Henan, China

Tel: +86-371-67833161 / 67833171E-mail: [email protected] [email protected]: [email protected]: http://www.hxjqchina.com

machineryoverseas

Application: Ore-dressingequipment

Training: providing Type: FlotationMachine

Application2: Mining industry

Packaging & Delivery

PackagingDetail:

Packed in bulk or in containers,bare main machine,motor and small parts are inwooden cases.

DeliveryDetail:

Within 25-30 working days after receiving the down payment.

Specifications

1.Durable ball mill2.High efficiency dryer3.Advanced flotation machine4.Large capacity

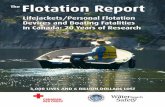

Ore Flotation Separating Process--Leading and Skilled Manufacturer

It is mainly composed of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener, drier, feeder,and conveyor, etc.

Advantages

High efficiency,low energy cost, high production capacity and economy and rationality.

Procedure of Complete Ore Flotation Beneficiation Plant

The ore is first sent to the jaw crusher for primary crushing. Then the ore with a proper size for secondary crushing willbe sent into the ball mill for fine crushing and grinding. The ore powder discharged from the ball mill will be sent to thenext procedure:

classifying. Because of the different sedimentation rate due to the varied specific gravity, spiral classifier can clean andgroup the ore mixture. The cleaned and grouped mixture is sent to magnetic separator, due to the different susceptibility,magnetic substance can be separated from the mixture under magnetic and mechanical force. Then the mixture is sent toflotation machine. According to the features of different ores, we can add different additive into the mixture to separatethe ore which we want from the mixture. After the separation from the mixture, the ore we want always contains a lot of

China Mining Machinery Production and Export Base Address: No.8 Tanxiang Road, Zhengzhou, Henan, China

Tel: +86-371-67833161 / 67833171E-mail: [email protected] [email protected]: [email protected]: http://www.hxjqchina.com

water, then we need a thickener to have it concentrated and then dried by a drier, eventually we can get dry ore.