Florida · 3000psi - Powers Steel & Wire · 2017-10-18 · from top of all lintel designs and in...

Transcript of Florida · 3000psi - Powers Steel & Wire · 2017-10-18 · from top of all lintel designs and in...

888.525.0108 • www.PowersSteel.com/Lintels

L2 Lintel EngineeringPS8 • 16ga.

October 2017

Florida · 3000psi

888.525.0108 • www.PowersSteel.com/Lintels

By:

sw

sP

S8

Lint

els

WIT

HO

UT

STI

RR

UP

S (

L2)

Dat

e:

10/2

017

8" in

ch b

lock

wid

thch

k:

gcs

LIN

TEL

LOA

D T

AB

LE (I

N P

OU

ND

S P

ER

LIN

EA

L FO

OT)

Gra

vity

Loa

d Ta

ble

3000

psi g

rout

--- A

LL L

OA

DS

AR

E SU

PER

IMPO

SED

---

SPA

NPS

8-8"

PS8-

8"PS

8-12

"PS

8-12

"PS

8-16

"PS

8-16

"PS

8-20

"PS

8-20

"PS

8-24

"PS

8-24

"PS

8-32

"PS

8-32

"PS

8-40

"PS

8-40

"PS

8-48

"P

S8-

48"

SPA

N(ft

)#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t(ft

)

1'-6

"89

4589

4510

746

1074

61'

-6"

2'-2

"61

7461

7474

1274

1286

5086

502'

-2"

2'-8

"50

0550

0560

0560

0570

0670

0680

0780

072'

-8"

3'-2

"42

0542

0550

4350

4358

8158

8167

2067

2075

5875

5892

3592

353'

-2"

4'-0

"33

1633

1639

7439

7446

3246

3252

9052

9059

4759

4772

6372

634'

-0"

4'-6

"29

4129

4135

2235

2241

0441

0446

8646

8652

6752

6764

3164

314'

-6"

5'-2

"25

5325

5330

5630

5635

5935

5940

6240

6245

6545

6555

7155

715'

-2"

6'-2

"19

5719

5725

4625

4629

6329

6333

8033

8037

9737

9746

3146

3154

6454

646'

-2"

7'-0

"15

0515

0522

3222

3225

9625

9629

6029

6033

2433

2440

5240

5247

8047

807'

-0"

8'-0

"11

3811

3819

4219

4222

5722

5725

7225

7228

8728

8735

1735

1741

4741

4747

7747

778'

-0"

9'-2

"77

777

716

7016

8319

5519

5522

2622

2624

9724

9730

4030

4035

8335

8341

2541

259'

-2"

10'-0

"59

959

913

8914

2417

8217

8220

2820

2822

7522

7527

6727

6732

6032

6037

5337

5310

'-0"

11'-2

"43

043

010

1610

1615

5015

8418

0118

0120

1920

1924

5424

5428

9028

9033

2533

2511

'-2"

12'-0

"34

634

681

981

913

2614

6516

6616

6618

6718

6722

6822

6826

6926

6930

7030

7012

'-0"

12'-8

"29

529

569

669

611

7813

8215

2515

7117

5917

5921

3621

3625

1425

1428

9128

9112

'-8"

13'-4

"25

325

359

759

710

5213

0713

6214

8516

6316

6320

1820

1823

7423

7427

2927

2913

'-4"

14'-0

"21

821

851

651

694

311

7912

2214

0715

0015

7519

1119

1122

4722

4725

8325

8314

'-0"

16'-0

"34

534

569

587

590

111

5711

0813

5715

2116

4419

3019

3022

1722

1716

'-0"

18'-0

"24

324

352

466

768

188

483

911

0011

5414

3514

6916

8417

8319

3318

'-0"

18'-8

"47

961

262

381

176

810

1110

5713

7613

4616

1416

3418

5218

'-8"

20'-8

"36

947

848

263

559

479

382

011

0810

4514

2312

7016

4020

'-8"

22'-8

"28

737

737

650

346

563

064

388

282

111

3599

813

8822

'-8"

24'-0

"24

833

832

456

340

170

555

399

170

612

7785

913

6424

'-0"

26'-0

"25

545

831

657

543

881

155

910

4668

112

3326

'-0"

Not

e: A

ll lin

tels

gre

ater

than

22'

-8" i

n le

ngth

will

requ

ire (2

)-#5

bar

s to

p or

(2)-

#5 b

ars

top&

bott.

0" -

22'-8

">

22'-8

"

888.525.0108 • www.PowersSteel.com/Lintels

By:

sw

sP

S8

Lint

els

WIT

HO

UT

STI

RR

UP

S (

L2)

Dat

e:

10/2

017

8" in

ch b

lock

wid

thch

k:

gcs

LIN

TEL

LOA

D T

AB

LE (I

N P

OU

ND

S P

ER

LIN

EA

L FO

OT)

Gra

vity

Loa

d Ta

ble

3000

psi g

rout

--- A

LL L

OA

DS

AR

E SU

PER

IMPO

SED

---

SPA

NPS

8-8"

PS8-

8"PS

8-12

"PS

8-12

"PS

8-16

"PS

8-16

"PS

8-20

"PS

8-20

"PS

8-24

"PS

8-24

"PS

8-32

"PS

8-32

"PS

8-40

"PS

8-40

"PS

8-48

"PS

8-48

"S

PAN

(ft)

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

(ft)

lson

6428

'-0"

200

375

248

472

346

667

443

863

540

1058

28'-0

"30

'-0"

155

308

194

389

271

552

349

715

426

877

30'-0

"32

'-0"

211

457

272

594

333

730

32'-0

"

34'-0

"20

849

325

660

834

'-0"

36'-0

"19

250

536

'-0"

38'-0

"38

'-0"

40'-0

"40

'-0"

Not

e: A

ll lin

tels

gre

ater

than

22'

-8" i

n le

ngth

will

requ

ire (2

)-#5

bar

s to

p or

(2)-

#5 b

ars

top&

bott.

888.525.0108 • www.PowersSteel.com/Lintels

888.525.0108 • www.PowersSteel.com/Lintels

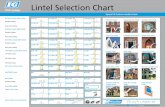

NOTES: PS8(L-2) Gravity – 16 Gage 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13.

PRODUCT NAME (PATENT NO. 5465538); PREFORMED POWERS STEEL LINTEL SHALL BE GALVANIZED COIL STEEL AS MANUFACTURED BY POWERS STEEL AND WIRE PRODUCTS, INC. STEEL GRADE SHALL BE ASTM A570 GRADE C (FY = 40 ksi). SHORE LINTELS AS REQUIRED TO COMPENSATE FOR DEAD LOAD DEFLECTION ON NON-CURED MASONRY GROUT. ALL LINTELS GREATER THAN 18'-0" ARE BUILT WITH 1/2" CAMBER. LINTEL TO BE USED WITH BRICK OR CONCRETE MASONRY UNITS HAVING MINIMUM f’m AS SHOWN. STEEL SURFACES IN CONTACT WITH GROUT AND/OR MORTAR SHALL BE UNPAINTED AND FREE OF MATERIAL THAT MIGHT INHIBIT BOND. BEARING EACH END SHALL BE 3" +/- 1/2". BEARING SHALL BE ON A MINIMUM 8" DEEP GROUTED CELL PER THE STANDARD BUILDING CODE. f’m = 1500 psi. MASONRY UNITS SHALL CONFORM TO ASTM C90, GRADE N. GROUT = 3,000 psi. SLUMP RANGE: 8" TO 11". ROD OR VIBRATE GROUT ADEQUATELY TO ENSURE CONSOLIDATION OF GROUT (NO AIR POCKETS). GROUT SHALL COMPLY WITH ASTM C476-83 AND BE EITHER COARSE OR FINE GROUT. MORTAR: TYPE “S” OR TYPE “M” 1800 psi. TOP REINFORCING OR TOP OF WALL REINFORCING, IS REQUIRED BY CODES TO PROVIDE A CONTINUOUS TIE AROUND A STRUCTURE AND TO PROVIDE FOR UPLIFT RESISTANCE AT LINTELS. ATTACHMENTS TO TOP OF WALL PER ARCHITECTURAL AND/OR ENGINEERING DRAWINGS. LIMITATIONS: THE LINTELS SHALL NOT EXCEED THE ALLOWABLE DESIGN LOADS AND SPANS SHOWN IN THIS REPORT. THE LINTELS SHALL NOT BE USED IN A FIRE RESISTANCE RATED ASSEMBLY UNLESS A TEST REPORT DOCUMENTING FIRE RESISTANCE IS SUBMITTED TO THE BUILDING OFFICIAL. A PROPER BARRIER IS REQUIRED WHEN USING CORROSIVE LUMBER PRODUCTS IN CONTACT WITH THE STEEL LINTELS. A PROPER BARRIER WOULD BE A POLYETHYLENE BARRIER WITH A 10 MIL THICKNESS OR TO MAINTAIN A MIN. 1/4" SPACING BETWEEN THE CORROSIVE LUMBER AND STEEL LINTEL. NOT FOR USE IN THE HVHZ IN MIAMI OR BROWARD COUNTIES AT THIS TIME. MIAMI DADE COMPLIANCE IS BEING SOUGHT. DEFLECTION LIMITS ARE SET TO L/600 FOR ALL LOADS SHOWN ABOVE THE DARKENED SOLID LINE. DEFLECTION LIMITS ARE SET TO L/360 [LIVE LOAD] AND L/240 [DEAD + LIVE LOAD] FOR ALL LOADS SHOWN BELOW DARKENED SOLID LINE, EXCEPT 8" COMPOSITE LINTELS WHICH ARE SET TO L/240 [LIVE LOAD] AND L/180 [DEAD + LIVE LOAD]. ALL LOADS SHOWN IN TABLES ARE SUPERIMPOSED LOADS. TABLES ARE DATED 10/2017 AND CLEARLY INDICATE SUPERIMPOSED LOADS

14. 15. 16. 17. 18.

A #5 REINFORCING BAR(S) GRADE 40 IS TO SET APPROX. 1-1/2" FROM TOP OF ALL LINTEL DESIGNS AND IN SOME CASES ON THE BOTTOM OF LINTEL AS SHOWN ON LOAD TABLES. TOP HORIZONTAL REINFORCEMENT IS TO BE A CONTINUOUS TIE AS NOTED IN NOTE #9. IN THE CASE THAT THE LINTEL IS NOT WITHIN A COMPOSITE BOND BEAM SYSTEM, TOP HORIZONTAL REINFORCEMENT IS TO EXTEND 2'-0" PAST INSIDE OF JAMBS. MANUFACTURER: POWERS STEEL

4118 E. ELWOOD PHOENIX, AZ 85040 PH# (602) 437-1160 FAX# (602) 437-5409

TECHNICAL DATA AND ENGINEERING POWERS LINTELS HAVE BEEN DESIGNED IN ACCORDANCE WITH THE FOLLOWING:

+ FLORIDA BUILDING CODE – 2017 (SIXTH EDITION) + NASPEC / AISI LIGHT GAGE COLD FORMED STEEL DESIGN - 2012 + ACI 530-13/ASCE 5-13/TMS 402-13

TECHNICAL ASSISTANCE IS AVAILABLE FROM THE MANUFACTURER ON SPECIAL DESIGN CONCERNS OR LINTEL DEPTHS DIFFERENT THAN THOSE SHOWN IN THE LOAD TABLES. STRUCTURAL ENGINEER FOR THESE LINTELS IS: S.E. CONSULTANTS, INC. 5800 E. THOMAS RD. SUITE 104 SCOTTSDALE, AZ 85251 PHONE (480) 946-2010 FAX (480) 946-1909 IF AN INSPECTOR, CONTRACTOR, SUBCONTRACTOR, OR PLANS EXAMINER HAS ANY TECHNICAL QUESTIONS PLEASE CALL. INSTALLATION: POWERS LINTELS ARE TO BE INSTALLED IN ACCORDANCE WITH STANDARD CONSTRUCTION PRACTICES, SET TO PROPER LINE AND LEVEL, PLUMB AND TRUE, AND IN CORRECT RELATION TO OTHER WORK.

PS8(L-2) STEEL LINTELS

NOTE: NO SCALE 16 GAGE IS .060 INCHES THICK.

888.525.0108 • www.PowersSteel.com/Lintels

By:

sw

sP

S8

Lint

els

WIT

HO

UT

STI

RR

UP

S

(L2)

Dat

e:

10/2

017

8" in

ch b

lock

wid

thch

k:

gcs

LIN

TEL

LOA

D T

AB

LE (I

N P

OU

ND

S P

ER

LIN

EA

L FO

OT)

Late

ral L

oad

Tabl

e30

00ps

i gro

ut---

ALL

LO

AD

S A

RE

SUPE

RIM

POSE

D --

-S

PAN

PS8-

8"PS

8-8"

PS8-

12"

PS8-

12"

PS8-

16"

PS8-

16"

PS8-

20"

PS8-

20"

PS8-

24"

PS8-

24"

PS8-

32"

PS8-

32"

PS8-

40"

PS8-

40"

PS8-

48"

PS

8-48

"S

PAN

(ft)

w/ #

5w

/ #5

w/ #

5w

/ #5

w/ #

5w

/ #5

w/ #

5w

/ #5

(ft)

1'-6

"90

0890

0898

5098

5010

716

1071

61'

-6"

2'-2

"57

6357

6368

1968

1974

1874

1880

2980

2986

4986

4999

0899

082'

-2"

2'-8

"38

0438

0446

2847

3053

7855

2760

7262

7070

2770

2779

1382

5489

9690

8999

9710

140

2'-8

"

3'-2

"26

9826

9832

8233

5438

1439

2043

0644

4647

6649

4056

1158

5363

8066

8870

9074

613'

-2"

4'-0

"16

9117

1620

5721

0223

9024

5726

9927

8629

8730

9635

1736

6939

9841

9144

4346

764'

-0"

4'-6

"13

3613

5616

2516

6118

8919

4121

3222

0223

6024

4627

7928

9931

5933

1235

1136

954'

-6"

5'-2

"10

1310

2912

3312

6014

3314

7216

1816

7017

9018

5621

0821

9923

9725

1226

6328

035'

-2"

6'-2

"71

172

286

588

410

0610

3411

3511

7212

5713

0314

8015

4416

8217

6318

6919

676'

-2"

7'-0

"55

256

067

268

678

180

288

191

097

510

1111

4811

9813

0613

6914

5115

277'

-0"

8'-0

"42

342

951

452

659

861

467

569

774

777

487

991

710

0010

4811

1111

698'

-0"

9'-2

"32

232

739

240

045

546

851

453

156

959

067

069

976

179

884

689

09'

-2"

10'-0

"27

127

532

933

638

239

343

244

647

849

556

358

764

067

171

174

810

'-0"

11'-2

"21

722

026

427

030

731

534

635

838

339

745

147

151

353

857

060

011

'-2"

12'-0

"18

819

122

923

426

627

330

031

033

234

439

140

844

446

649

452

012

'-0"

12'-8

"16

917

120

521

023

824

526

927

829

830

935

136

639

941

844

346

612

'-8"

13'-4

"15

215

418

518

921

522

124

325

126

927

931

733

036

037

740

042

113

'-4"

14'-0

"13

814

016

817

219

520

122

022

724

425

328

729

932

634

236

338

214

'-0"

16'-0

"12

913

114

915

416

917

418

719

422

022

925

026

227

829

216

'-0"

18'-0

"10

210

411

812

113

313

814

815

317

418

119

720

721

923

118

'-0"

18'-8

"11

011

312

412

813

714

216

116

818

419

220

421

518

'-8"

20'-8

"90

9210

110

411

211

613

213

715

015

716

617

520

'-8"

22'-8

"74

7784

8793

9611

011

412

513

113

814

622

'-8"

24'-0

"68

7177

8186

9010

210

811

612

413

014

024

'-0"

26'-0

"66

6973

7787

9299

106

111

119

26'-0

"N

ote:

Abo

ve lo

ads

incl

ude

1/3

incr

ease

for w

ind.

All

linte

ls g

reat

er th

an 2

2'-8

" in

leng

th w

ill re

quire

(2)-

#5 b

ars

top

or (2

)-#5

bar

s to

p&bo

tt.

888.525.0108 • www.PowersSteel.com/Lintels

By:

sw

sP

S8

Lint

els

WIT

HO

UT

STI

RR

UP

S

(L2)

Dat

e:

10/2

017

8" in

ch b

lock

wid

thch

k:

gcs

LIN

TEL

LOA

D T

AB

LE (I

N P

OU

ND

S P

ER

LIN

EA

L FO

OT)

Late

ral L

oad

Tabl

e30

00ps

i gro

ut---

ALL

LO

AD

S A

RE

SUPE

RIM

POSE

D --

-S

PAN

PS8-

8"PS

8-8"

PS8-

12"

PS8-

12"

PS8-

16"

PS8-

16"

PS8-

20"

PS8-

20"

PS8-

24"

PS8-

24"

PS8-

32"

PS8-

32"

PS8-

40"

PS8-

40"

PS8-

48"

PS8-

48"

SPA

N(ft

)w

/ #5

w/ #

5w

/ #5

w/ #

5w

/ #5

w/ #

5w

/ #5

w/ #

5(ft

)

28'-0

"57

5963

6675

7986

9195

103

28'-0

"30

'-0"

5052

5558

6569

7580

8389

30'-0

"32

'-0"

5761

6570

7379

32'-0

"

34'-0

"58

6265

7034

'-0"

36'-0

"58

6236

'-0"

38'-0

"38

'-0"

40'-0

"40

'-0"

Not

e:A

bove

load

s in

clud

e 1/

3 in

crea

se fo

r win

d.A

ll lin

tels

gre

ater

than

22'

-8" i

n le

ngth

will

requ

ire (2

)-#5

bar

s to

p or

(2)-

#5 b

ars

top&

bott.

0" -

22'-8

">

22'-8

"

888.525.0108 • www.PowersSteel.com/Lintels

888.525.0108 • www.PowersSteel.com/Lintels

NOTES: PS8(L-2) Lateral/Uplift – 16 Gage 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13.

PRODUCT NAME (PATENT NO. 5465538); PREFORMED POWERS STEEL LINTEL SHALL BE GALVANIZED COIL STEEL AS MANUFACTURED BY POWERS STEEL AND WIRE PRODUCTS, INC. STEEL GRADE SHALL BE ASTM A570 GRADE C (FY = 40 ksi). SHORE LINTELS AS REQUIRED TO COMPENSATE FOR DEAD LOAD DEFLECTION ON NON-CURED MASONRY GROUT. ALL LINTELS GREATER THAN 18'-0" ARE BUILT WITH 1/2" CAMBER. LINTEL TO BE USED WITH BRICK OR CONCRETE MASONRY UNITS HAVING MINIMUM f’m AS SHOWN. STEEL SURFACES IN CONTACT WITH GROUT AND/OR MORTAR SHALL BE UNPAINTED AND FREE OF MATERIAL THAT MIGHT INHIBIT BOND. BEARING EACH END SHALL BE 3" +/- 1/2". BEARING SHALL BE ON A MINIMUM 8" DEEP GROUTED CELL PER THE STANDARD BUILDING CODE. f’m = 1500 psi. MASONRY UNITS SHALL CONFORM TO ASTM C90, GRADE N. GROUT = 3,000 psi. SLUMP RANGE: 8" TO 11". ROD OR VIBRATE GROUT ADEQUATELY TO ENSURE CONSOLIDATION OF GROUT (NO AIR POCKETS). GROUT SHALL COMPLY WITH ASTM C476-83 AND BE EITHER COARSE OR FINE GROUT. MORTAR: TYPE “S” OR TYPE “M” 1800 psi. TOP REINFORCING OR TOP OF WALL REINFORCING, IS REQUIRED BY CODES TO PROVIDE A CONTINUOUS TIE AROUND A STRUCTURE AND TO PROVIDE FOR UPLIFT RESISTANCE AT LINTELS. ATTACHMENTS TO TOP OF WALL PER ARCHITECTURAL AND/OR ENGINEERING DRAWINGS. LIMITATIONS: THE LINTELS SHALL NOT EXCEED THE ALLOWABLE DESIGN LOADS AND SPANS SHOWN IN THIS REPORT. THE LINTELS SHALL NOT BE USED IN A FIRE RESISTANCE RATED ASSEMBLY UNLESS A TEST REPORT DOCUMENTING FIRE RESISTANCE IS SUBMITTED TO THE BUILDING OFFICIAL. A PROPER BARRIER IS REQUIRED WHEN USING CORROSIVE LUMBER PRODUCTS IN CONTACT WITH THE STEEL LINTELS. A PROPER BARRIER WOULD BE A POLYETHYLENE BARRIER WITH A 10 MIL THICKNESS OR TO MAINTAIN A MIN. 1/4" SPACING BETWEEN THE CORROSIVE LUMBER AND STEEL LINTEL. NOT FOR USE IN THE HVHZ IN MIAMI OR BROWARD COUNTIES AT THIS TIME. MIAMI DADE COMPLIANCE IS BEING SOUGHT. ALLOWABLE LOADS SHOWN IN THE TABLES FOR UPLIFT AND LATERAL LOAD CAPACITY INCLUDE A 1/3 INCREASE FOR WIND OR SEISMIC LOADING WITH NO FURTHER INCREASE ALLOWED. IF COMBINED LOADING CONDITIONS ARE APPLIED TO THE LINTELS FOR SIMULTANEOUS LOADING DIRECTIONS, THE ALLOWABLE LOADS SHOWN IN THE TABLES MUST BE ADJUSTED USING A UNITY EQUATION. ALL LOADS SHOWN IN TABLES ARE SUPERIMPOSED LOADS. TABLES ARE DATED 10/2017 AND CLEARLY INDICATE SUPERIMPOSED LOADS

14. 15. 16. 17. 18.

A #5 REINFORCING BAR(S) GRADE 40 IS TO SET APPROX. 1-1/2" FROM TOP OF ALL LINTEL DESIGNS AND IN SOME CASES ON THE BOTTOM OF LINTEL AS SHOWN ON LOAD TABLES. TOP HORIZONTAL REINFORCEMENT IS TO BE A CONTINUOUS TIE AS NOTED IN NOTE #9. IN THE CASE THAT THE LINTEL IS NOT WITHIN A COMPOSITE BOND BEAM SYSTEM, TOP HORIZONTAL REINFORCEMENT IS TO EXTEND 2'-0" PAST INSIDE OF JAMBS. MANUFACTURER: POWERS STEEL

4118 E. ELWOOD PHOENIX, AZ 85040 PH# (602) 437-1160 FAX# (602) 437-5409

TECHNICAL DATA AND ENGINEERING POWERS LINTELS HAVE BEEN DESIGNED IN ACCORDANCE WITH THE FOLLOWING:

+ FLORIDA BUILDING CODE – 2017 (SIXTH EDITION) + NASPEC / AISI LIGHT GAGE COLD FORMED STEEL DESIGN - 2012 + ACI 530-13/ASCE 5-13/TMS 402-13

TECHNICAL ASSISTANCE IS AVAILABLE FROM THE MANUFACTURER ON SPECIAL DESIGN CONCERNS OR LINTEL DEPTHS DIFFERENT THAN THOSE SHOWN IN THE LOAD TABLES. STRUCTURAL ENGINEER FOR THESE LINTELS IS: S.E. CONSULTANTS, INC. 5800 E. THOMAS RD. SUITE 104 SCOTTSDALE, AZ 85251 PHONE (480) 946-2010 FAX (480) 946-1909 IF AN INSPECTOR, CONTRACTOR, SUBCONTRACTOR, OR PLANS EXAMINER HAS ANY TECHNICAL QUESTIONS PLEASE CALL. INSTALLATION: POWERS LINTELS ARE TO BE INSTALLED IN ACCORDANCE WITH STANDARD CONSTRUCTION PRACTICES, SET TO PROPER LINE AND LEVEL, PLUMB AND TRUE, AND IN CORRECT RELATION TO OTHER WORK.

PS8(L-2) STEEL LINTELS

NOTE: NO SCALE 16 GAGE IS .060 INCHES THICK.

888.525.0108 • www.PowersSteel.com/Lintels

By:

sw

sP

S8

Lint

els

WIT

HO

UT

STI

RR

UP

S

(L2)

Dat

e:

10/2

017

8" in

ch b

lock

wid

thch

k:

gcs

LIN

TEL

LOA

D T

AB

LE (I

N P

OU

ND

S P

ER

LIN

EA

L FO

OT)

Upl

ift L

oad

Tabl

e30

00ps

i gro

ut---

ALL

LO

AD

S A

RE

SUPE

RIM

POSE

D --

-S

PAN

PS8-

8"PS

8-8"

PS8-

12"

PS8-

12"

PS8-

16"

PS8-

16"

PS8-

20"

PS8-

20"

PS8-

24"

PS8-

24"

PS8-

32"

PS8-

32"

PS8-

40"

PS8-

40"

PS8-

48"

PS

8-48

"S

PAN

(ft)

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

#5 to

p#5

top&

bot

(ft)

1'-6

"10

411

1041

112

358

1235

814

334

1433

41'

-6"

2'-2

"72

1872

1885

7185

7199

4599

4511

330

1133

012

724

1272

42'

-2"

2'-8

"48

3548

3569

7469

7480

9380

9392

2292

2210

358

1035

812

644

1264

42'

-8"

3'-2

"34

3934

3958

8158

8168

2668

2677

7977

7987

3887

3810

669

1066

912

611

1261

114

561

1456

13'

-2"

4'-0

"21

6921

6937

4237

4250

4450

4461

7761

7769

3969

3984

7584

7510

019

1001

911

570

1157

04'

-0"

4'-6

"17

2117

2129

6729

6740

0040

0050

4150

4160

8960

8975

4875

4889

2589

2510

307

1030

74'

-6"

5'-2

"13

1413

1422

6422

6430

5130

5138

4538

4546

4446

4462

5362

5377

9577

9590

0390

035'

-2"

6'-2

"93

393

316

0516

0521

6221

6227

2527

2532

9132

9144

3044

3055

7555

7567

2667

266'

-2"

7'-0

"73

273

212

5712

5716

9416

9421

3421

3425

7725

7734

6834

6843

6543

6552

6552

657'

-0"

8'-0

"56

956

997

597

513

1313

1316

5416

5419

9719

9726

8726

8733

8233

8240

7940

798'

-0"

9'-2

"44

244

275

575

510

1610

1612

8012

8015

4615

4620

7920

7926

1626

1631

5531

559'

-2"

10'-0

"37

737

764

364

386

586

510

8910

8913

1513

1517

6917

6922

2622

2626

8426

8410

'-0"

11'-2

"30

930

952

652

670

770

789

189

110

7510

7514

4614

4618

1818

1821

9321

9311

'-2"

12'-0

"27

327

346

246

262

262

278

378

394

594

512

7012

7015

9715

9719

2619

2612

'-0"

12'-8

"24

824

842

042

056

556

571

171

185

885

811

5411

5414

5114

5117

4917

4912

'-8"

13'-4

"22

822

838

438

451

751

765

065

078

578

510

5510

5513

2613

2615

9915

9913

'-4"

14'-0

"21

021

035

435

447

547

559

859

872

172

196

996

912

1912

1914

6914

6914

'-0"

16'-0

"28

328

338

038

047

847

857

657

677

477

497

397

311

7211

7216

'-0"

18'-0

"23

523

531

531

539

639

647

747

764

064

080

480

496

996

918

'-0"

18'-8

"29

829

837

437

445

145

160

560

576

076

091

591

518

'-8"

20'-8

"25

625

632

132

138

738

751

951

965

165

178

478

420

'-8"

22'-8

"22

422

428

128

133

933

945

445

457

057

068

668

622

'-8"

24'-0

"30

130

141

041

049

749

767

467

485

285

210

3110

3124

'-0"

26'-0

"36

236

243

943

959

559

575

175

190

890

826

'-0"

Not

e:A

bove

load

s in

clud

e 1/

3 in

crea

se fo

r win

d.A

ll lin

tels

gre

ater

than

22'

-8" i

n le

ngth

will

requ

ire (2

)-#5

bar

s to

p or

(2)-

#5 b

ars

top&

bott.

> 22

'-8"

0" -

22'-8

"

888.525.0108 • www.PowersSteel.com/Lintels

By:

sw

sP

S8

Lint

els

WIT

HO

UT

STI

RR

UP

S

(L2)

Dat

e:

10/2

017

8" in

ch b

lock

wid

thch

k:

gcs

LIN

TEL

LOA

D T

AB

LE (I

N P

OU

ND

S P

ER

LIN

EA

L FO

OT)

Upl

ift L

oad

Tabl

e30

00ps

i gro

ut---

ALL

LO

AD

S A

RE

SUPE

RIM

POSE

D --

-S

PAN

PS8-

8"PS

8-8"

PS8-

12"

PS8-

12"

PS8-

16"

PS8-

16"

PS8-

20"

PS8-

20"

PS8-

24"

PS8-

24"

PS8-

32"

PS8-

32"

PS8-

40"

PS8-

40"

PS8-

48"

PS8-

48"

SPA

N(ft

)#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t#5

top

#5 to

p&bo

t(ft

)

28'-0

"32

432

439

339

353

153

167

167

181

181

128

'-0"

30'-0

"29

329

335

535

548

048

060

660

673

373

330

'-0"

32'-0

"43

943

955

455

466

966

932

'-0"

34'-0

"51

051

061

661

634

'-0"

36'-0

"57

157

136

'-0"

38'-0

"38

'-0"

40'-0

"40

'-0"

Not

e:A

bove

load

s in

clud

e 1/

3 in

crea

se fo

r win

d.A

ll lin

tels

gre

ater

than

22'

-8" i

n le

ngth

will

requ

ire (2

)-#5

bar

s to

p or

(2)-

#5 b

ars

top&

bott.

888.525.0108 • www.PowersSteel.com/Lintels

888.525.0108 • www.PowersSteel.com/Lintels

NOTES: PS8(L-2) Lateral/Uplift – 16 Gage 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13.

PRODUCT NAME (PATENT NO. 5465538); PREFORMED POWERS STEEL LINTEL SHALL BE GALVANIZED COIL STEEL AS MANUFACTURED BY POWERS STEEL AND WIRE PRODUCTS, INC. STEEL GRADE SHALL BE ASTM A570 GRADE C (FY = 40 ksi). SHORE LINTELS AS REQUIRED TO COMPENSATE FOR DEAD LOAD DEFLECTION ON NON-CURED MASONRY GROUT. ALL LINTELS GREATER THAN 18'-0" ARE BUILT WITH 1/2" CAMBER. LINTEL TO BE USED WITH BRICK OR CONCRETE MASONRY UNITS HAVING MINIMUM f’m AS SHOWN. STEEL SURFACES IN CONTACT WITH GROUT AND/OR MORTAR SHALL BE UNPAINTED AND FREE OF MATERIAL THAT MIGHT INHIBIT BOND. BEARING EACH END SHALL BE 3" +/- 1/2". BEARING SHALL BE ON A MINIMUM 8" DEEP GROUTED CELL PER THE STANDARD BUILDING CODE. f’m = 1500 psi. MASONRY UNITS SHALL CONFORM TO ASTM C90, GRADE N. GROUT = 3,000 psi. SLUMP RANGE: 8" TO 11". ROD OR VIBRATE GROUT ADEQUATELY TO ENSURE CONSOLIDATION OF GROUT (NO AIR POCKETS). GROUT SHALL COMPLY WITH ASTM C476-83 AND BE EITHER COARSE OR FINE GROUT. MORTAR: TYPE “S” OR TYPE “M” 1800 psi. TOP REINFORCING OR TOP OF WALL REINFORCING, IS REQUIRED BY CODES TO PROVIDE A CONTINUOUS TIE AROUND A STRUCTURE AND TO PROVIDE FOR UPLIFT RESISTANCE AT LINTELS. ATTACHMENTS TO TOP OF WALL PER ARCHITECTURAL AND/OR ENGINEERING DRAWINGS. LIMITATIONS: THE LINTELS SHALL NOT EXCEED THE ALLOWABLE DESIGN LOADS AND SPANS SHOWN IN THIS REPORT. THE LINTELS SHALL NOT BE USED IN A FIRE RESISTANCE RATED ASSEMBLY UNLESS A TEST REPORT DOCUMENTING FIRE RESISTANCE IS SUBMITTED TO THE BUILDING OFFICIAL. A PROPER BARRIER IS REQUIRED WHEN USING CORROSIVE LUMBER PRODUCTS IN CONTACT WITH THE STEEL LINTELS. A PROPER BARRIER WOULD BE A POLYETHYLENE BARRIER WITH A 10 MIL THICKNESS OR TO MAINTAIN A MIN. 1/4" SPACING BETWEEN THE CORROSIVE LUMBER AND STEEL LINTEL. NOT FOR USE IN THE HVHZ IN MIAMI OR BROWARD COUNTIES AT THIS TIME. MIAMI DADE COMPLIANCE IS BEING SOUGHT. ALLOWABLE LOADS SHOWN IN THE TABLES FOR UPLIFT AND LATERAL LOAD CAPACITY INCLUDE A 1/3 INCREASE FOR WIND OR SEISMIC LOADING WITH NO FURTHER INCREASE ALLOWED. IF COMBINED LOADING CONDITIONS ARE APPLIED TO THE LINTELS FOR SIMULTANEOUS LOADING DIRECTIONS, THE ALLOWABLE LOADS SHOWN IN THE TABLES MUST BE ADJUSTED USING A UNITY EQUATION. ALL LOADS SHOWN IN TABLES ARE SUPERIMPOSED LOADS. TABLES ARE DATED 10/2017 AND CLEARLY INDICATE SUPERIMPOSED LOADS

14. 15. 16. 17. 18.

A #5 REINFORCING BAR(S) GRADE 40 IS TO SET APPROX. 1-1/2" FROM TOP OF ALL LINTEL DESIGNS AND IN SOME CASES ON THE BOTTOM OF LINTEL AS SHOWN ON LOAD TABLES. TOP HORIZONTAL REINFORCEMENT IS TO BE A CONTINUOUS TIE AS NOTED IN NOTE #9. IN THE CASE THAT THE LINTEL IS NOT WITHIN A COMPOSITE BOND BEAM SYSTEM, TOP HORIZONTAL REINFORCEMENT IS TO EXTEND 2'-0" PAST INSIDE OF JAMBS. MANUFACTURER: POWERS STEEL

4118 E. ELWOOD PHOENIX, AZ 85040 PH# (602) 437-1160 FAX# (602) 437-5409

TECHNICAL DATA AND ENGINEERING POWERS LINTELS HAVE BEEN DESIGNED IN ACCORDANCE WITH THE FOLLOWING:

+ FLORIDA BUILDING CODE – 2017 (SIXTH EDITION) + NASPEC / AISI LIGHT GAGE COLD FORMED STEEL DESIGN - 2012 + ACI 530-13/ASCE 5-13/TMS 402-13

TECHNICAL ASSISTANCE IS AVAILABLE FROM THE MANUFACTURER ON SPECIAL DESIGN CONCERNS OR LINTEL DEPTHS DIFFERENT THAN THOSE SHOWN IN THE LOAD TABLES. STRUCTURAL ENGINEER FOR THESE LINTELS IS: S.E. CONSULTANTS, INC. 5800 E. THOMAS RD. SUITE 104 SCOTTSDALE, AZ 85251 PHONE (480) 946-2010 FAX (480) 946-1909 IF AN INSPECTOR, CONTRACTOR, SUBCONTRACTOR, OR PLANS EXAMINER HAS ANY TECHNICAL QUESTIONS PLEASE CALL. INSTALLATION: POWERS LINTELS ARE TO BE INSTALLED IN ACCORDANCE WITH STANDARD CONSTRUCTION PRACTICES, SET TO PROPER LINE AND LEVEL, PLUMB AND TRUE, AND IN CORRECT RELATION TO OTHER WORK.

PS8(L-2) STEEL LINTELS

NOTE: NO SCALE 16 GAGE IS .060 INCHES THICK.

888.525.0108 • www.PowersSteel.com/Lintels

(602) 437-1160

POWERS STEEL & WIRESTEEL

P O W E R S

FAX 437-5409

GR

AV

ITY

LO

AD

S

8" (7

5/8

" AC

TUAL

)

(5)

HEI

GH

T O

F C

OM

POSI

TELI

NTE

L VA

RIE

S - S

EEPL

AN A

ND

SC

HED

ULE

S

(9)

HEI

GH

T O

F SO

LID

(13)

(10)

(9)

(1)

(7)

(2)ST

EEL

LIN

TEL

GR

OU

T VA

RIE

S-SE

E SC

HED

ULE

(13)

(1)

(2)

G:\CAD_Drawings\Powers\_East Coast Lintels\1-2015 lintels\AutoCAD Sheets\L-2\PS8 LINTEL GRAVITY.dwg, Model, 9/9/2015 3:45:39 PM, rjg, Adobe PDF.pc3, ARCH full bleed D (24.00 x 36.00 Inches), 1:12.057

888.525.0108 • www.PowersSteel.com/Lintels

(602)

437-1

160

PO

WE

RS

ST

EE

L &

WIR

ES

TE

EL

P O

W E

R S

FA

X 4

37-5

409

GRAVITY LOADS

8" (7 5/8" ACTUAL)

(5)

HEIGHT OF COMPOSITELINTEL VARIES - SEEPLAN AND SCHEDULES

(9)

HEIGHT OF SOLID

(13)(10)

(9)

(1)

(7)

(2)

STEEL LINTEL

GROUT VARIES-SEE SCHEDULE

(13)

(1)

(2)

G:\C

AD_D

raw

ings

\Pow

ers\

_Eas

t Coa

st L

inte

ls\1

-201

5 lin

tels

\Aut

oCAD

She

ets\

L-2\

PS8

LIN

TEL

GR

AVIT

Y.dw

g, M

odel

, 9/9

/201

5 3:

45:3

9 PM

, rjg

, Ado

be P

DF.

pc3,

AR

CH

full

blee

d D

(24.

00 x

36.

00 In

ches

), 1:

12.0

57

(602)

437-1

160

PO

WE

RS

ST

EE

L &

WIR

ES

TE

EL

P O

W E

R S

FA

X 4

37-5

409

GRAVITY LOADS

8" (7 5/8" ACTUAL)

(5)

HEIGHT OF COMPOSITELINTEL VARIES - SEEPLAN AND SCHEDULES

(9)

HEIGHT OF SOLID

(13)(10)

(9)

(1)

(7)

(2)

STEEL LINTEL

GROUT VARIES-SEE SCHEDULE

(13)

(1)

(2)

G:\C

AD_D

raw

ings

\Pow

ers\

_Eas

t Coa

st L

inte

ls\1

-201

5 lin

tels

\Aut

oCAD

She

ets\

L-2\

PS8

LIN

TEL

GR

AVIT

Y.dw

g, M

odel

, 9/9

/201

5 3:

45:3

9 PM

, rjg

, Ado

be P

DF.

pc3,

AR

CH

full

blee

d D

(24.

00 x

36.

00 In

ches

), 1:

12.0

57

888.525.0108 • www.PowersSteel.com/Lintels

0" – 22'-8" > 22'-8"

L2 Steel Lintel Cross Sections

Shoring Detail

16' - 0" Span

Block Shore

Wood ShoreNote: Make sure shoring supports the entire width of the bottom of the Lintel.

Approx. 5' - 4"Spacing

Lay one block at each end prior to

shoring and laying first course.

888.525.0108 • www.PowersSteel.com/Lintels

L2 Steel Lintel Installation Instructions

1. Lay wall to required height and opening.

2. Set Lintel on block with 3" ± 1/2" of bearing.

3. Place Lintel on block level and square. Lay bond beam block upside down on Lintel at each end.

4. Shore Lintel as required to compensate for dead load deflection on non cured Masonry and grout. Shore lintel prior to laying block and grouting.

5. It is recommended to shore lintel in the middle of spans greater than 8'-0" and less than 15'-0". On spans greater than 16'-0" use 2 shores spaced equal distance apart at approximately 5'-4" spacing. On spans greater than 16'-0" place shoring at 6'-0" centers. Make sure shoring is square to Lintel and secure. Make sure shoring supports the entire width of the bottom of the Lintel.

6. Proceed to lay first lay first and second courses of block for 16" deep lintels and so on for lintels with greater depths.

7. Rod grout adequately to ensure consolidation of grout (no air pockets)

8. Place top #5 rebar grade 40 Set 1.5" from top of all Lintel designs and in some cases in the bottom of the Lintel as shown on Load Tables. (see detail next page)

Powers Steel, Inc.4118 East Elwood StreetPhoenix, Arizona 85040phone: (602) 437-1160

(602) 454-8828

888.525.0108 • www.PowersSteel.com/Lintels