FLOORS in Africa Journal 7'2010

-

Upload

media-in-africa -

Category

Documents

-

view

269 -

download

15

description

Transcript of FLOORS in Africa Journal 7'2010

VOL 28.7 OCTOBER/NOVEMBER 2010 R38 incl. VAT

IN THIS ISSUE: Ceramic, Porcelain & Stone • Below the Surface • Luxury Flooring

Cersaie Review • Upcoming Events • Specification Considerations

Nouwens Commercial products forOffices • Executive Commercial • Churches • Shops • B&B’s

Visit our website at www.nouwens.co.za for further Nouwens Platinum Partner and Nouwens Appointed Dealer listings,

COlOurS

Colours

Nouwens easicarpet introduces a totally new quality culture in polypropylene fibre carpets. Colours was designed as a superior entry-level, commercial carpet alternative for those installations which for some reason or another do not qualify for a more costly investment.

According to the current South African grading systems, a polypropylene tufted carpet cannot achieve higher than a light commercial rating, but given the exceptional value-for-money benefits, the popularity of Colours for all kinds of commercial applications, has continued to grow since its introduction in 2006!

Track record says it all, and the super performance features of Colours once again highlight the skill of the Nouwens carpet craftsmen – they have engineered the high-twist, heat-set yarn to optimise the performance of easifibre, whilst the sophisticated multicolour effect naturally enhances serviceability. Unique Nou-wens mill-applied and heat-cured “easi-care” carpet protector also forms an invis-ible, durable shield around each fibre to help against everyday spills and soiling.

Colours comes with a Five-Year Quality Guarantee as well as a Ten-Year Wear Guarantee.

Nouwens “easi carpet” introduces Colours – a polypro-pylene fibre carpet – designed as a superior entry-level, commercial carpet alternative for those installations which do not qualify for a more costly investment.

*** Thisproducthasbeenstyledforspecificcommercialuseandwillperformthesameasorbetterthanotherlocalcommercialtuftedpolypropylenestyles.

For extra peace of mind, every easicarpet is endorsed with a 5 year quality guarantee, as well as a special 10 year wear guarantee.

usEClAss*** HeavyDomestic/lightCommercial*TYPE Cut/loopPilePIlEFIBrE 100%EAsIFIBrE–withEAsICArE soilresistantTreatmentWIDTH 3.66mAVAIlABIlITY 9standardColoursENDsper10cm ±40sTITCHrATEper10cm ±52TuFTs/looPsper100cm² ±2080PIlEFIBrEMAssgramsperm² ±1050ToTAlMAssgramsperm² ±2230PIlEHEIGHT ±6mmToTAlHEIGHT ±8mmPrIMArYBACKING WovenPolypropyleneTapesECoNDArYBACKING ActionBac

Copenhagen

Madison Square

Kirman

Contracta Spec

Twenty Ten

every Hotels • Lodges • Boutiques • General Commercial • Airports

or contact Nouwens Carpets direct at the following numbers 0117965180, 0214472856 or 0315025730.

C O V E R S T O R Y

ACCESS FlOORing & CAblE MAnAgEMEnTBates Access Flooring p62

AdhESiVES / COATingSa.b.e. Construction Chemicals p40FloorworX p97Smoothedge p27

CARpETSBelgotex Floorcoverings p2Nexus (Belgotex Floorcoverings) Front Cover, p32 - 33, p78 - 79Nouwens Carpets Inside Front CoverTuntex p89Van Dyck Carpets p6, p12 - 13

CERAMiC, pORCElAin And STOnEFerreiras Decor World Inside Back CoverKenzan Quality Tiles p9Tiletoria p91

ClEAning & MAinTEnAnCEFloorworX p45Matco Marketing p31Numatic International p15Tile & Floor Care p29

From corporate logos to tailor-made

patterns and textures, Nexus’ Custom-

X which includes sublimation print-

ing, SDX yarn technology as well as

needlepunch, offers design freedom

on any carpet tile for areas from 100m²

upwards, and this has been the pre-

ferred choice of African Bank for the

refurbishment of their premises in

Boksburg.Custom X is about working

with the Nexus design team and creat-

ing a carpet that meets the require-

ments of the client. It can be whatever the client wants – a certain

pattern, colour and/or yarn.Read the story on pages 32-33 of this

issue for details of the Nexus service that is causing architects and

designers to take another look at floor tile design.

bAnking On nExuS

Topage5

41 57 73VOLUME 28 .7 • OC TOBER NOVEMBER • 2010

G u I D E

�F L O O R S s e p t e m b e r 2 0 1 0

34

WOOd, lAMinATES & bAMbOOBarrow Flooring Back CoverBedson Flooring and Décor p77Eco-logic Bamboo Flooring p5Elastilon p36 - 37FloorworX p85Rhoms Timberworld p86 - 87Teragren p36 - 37Tiletoria p91

ACCESSORiES And OThERBelgotex Floorcovering p67Comfort Creations p88Domotex p20Frame Fibres p65, p66Genesis p30, p35Kirk Marketing p17, p19, p21, p23Pretoria Institute for Architecture p100Revestir p8The Office Plant p99Transiton Transport (Transportation) p94 - 95

Note: Editorials excluded,

listed in alphabetical order

continuedfrompage3

ExTERiOR FlOORing & pAVingBelgotex Floorcoverings p2

induSTRiAl, RESin & COnCRETE FlOORinga.b.e. Construction Chemicals p40Cemcrete p83Concrete Laser Flooring p39, p56Flowcrete SA p69

RESiliEnT FlOORingBelgotex Floorcoverings p2FloorworX p4Transit Floor Tiles p16Traviata Flooring Systems p82Wonder Flooring p25

SEAMlESS FlOORingQuartz Carpet p3

G u I D E

�F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

Roxanne Mancini

BUSINESS UNIT MANAGER

EDITorIAlCoMMENT

In line with the company’s ongoing commitment tooffer more sustainable products, Van Dyck Carpetsis proud to announce the official launch of Florpoint/ Graveltex Earth during October. Everyone in theflooring industry in South Africa knows the popular,well established Florpoint / Graveltex range, as theseproducts have been tried, tested and trusted for over15 years.

The “Earth” version of these products is a “greener”version of these two stalwarts, engineered in sucha way as to introduce recycled content without losingthe overall look and performance of the originalproducts. If anything, thanks to their intelligentdesign these products will perform even better thanthe originals. Read more about the environmentalbenefits of these new products on pages 12-13.

Another green product launched by Van Dyck Carpetsalmost a year ago is our environmentally friendlyEco-lay range of underlays. Made from 100% recycledpost-consumer rubber, Eco-lay underlays areengineered in such a way that they have an increasedlife span of 10 years (double the average life spanof most other underlays). The success of the Eco-layrange has been overwhelming and shows once againVan Dyck Carpet’s commitment to environmentallyfriendly flooring solutions. Read more about theseproducts on page 70-71.

And it won’t stop here. Keep on the look out formore product re-engineering to come as our greenjourney continues. And please remember it is notjust any green carpet ... it’s a Van Dyck Carpet.

Residential Carpets • Commercial CarpetsRugs • DIY • Sport & Leisure Grass • Underlays

TOLL FREE: 0800 CARPET (0800227738)www.vandyckcarpets.com

SA

The latest tiles from italyMedia in Africa visited the popular Cersaie exhibition in

Bologna, Italy, and brings you the latest in international

trends and technologies for Ceramics, Porcelain and

Stone.

We also take a look at the basic requirements for a

successful tile installation and highlight defects often

found in Natural Stone.

Fashion meets performance and products are manu-

factured to last. Read more about this exciting industry

from page 41.

nothing but the best!Perhaps we should have called this Luxury

Floorcoverings feature Floors for Special Buildings

because, although not all the floorcoverings are excep-

tionally luxurious, the projects on which they have

been used certainly are.

We have featured a selection of very special local and

international buildings and their flooring, including a

wood floor that is still going strong after 115 years; a

great hotel penthouse refurbishment; two 5-Star hotels

in Africa being built by a local architect; luxury khayas

at a top game reserve; South Africa’s latest airport

building; and a revelation in hospital floor design.

Read more from page 73.

below the surfaceEveryone is keen on floors that look good, but what

happens underneath is of prime importance. Get it

wrong and the floor will lose its appeal, and even

fail. In this issue we have taken a look at floor slabs,

screeds, moisture, underlays, and floor heating

Find out when to use what for the various types of

floorcovering – refer to our informative feature from

page57.

The flooring industry is alive with great product

launches and offerings! Enjoy this brilliant issue of

FLOORS!

Floorfully yours,

Roxanne Mancini

Liezel van der Merwe

EDITOR

FLOORS is about ceramics, carpets, vinyls, wood, laminates, marble, granite, cement, stone ... any floor you can think of. It is also about accessories like rugs, adhe-sives and tools. Readers are welcome to contact us for any information. FLOORS is published six weekly by Media in Africa (Pty) Ltd. The views expressed by contributors are not neces-sarily those of the editor or publisher. We accept no responsibility for information published. PUBLISHER: Media in Africa (Pty) Ltd. Contact information: Tel (012) 347 7530 Fax (012) 347 7523 International: +27e-mail: [email protected] Box 25260, Monument Park, 0105; Republic of South Africa Unit G, First Floor, Castle Walk Corporate Park, Cnr Nossob & Swakop Streets, Erasmuskloof Ext. 3, Pretoria, RSAFounder: Schalk BurgerEditor: Liezel van der Merwe Cell 082 7700 799Financial Director: Fanie VenterNews Editor: Dave Soons Tel 012 807 7012Business Unit Manager: Roxanne Mancini Cell 082 779 5751 Business Unit Co-ordinator: Madelein Smith Sales Executive: Styart HarveyCell 072 997 8940 Design and Layout: Jakolien StrydomFinancial Manager: Sietske Rossouw Proofreader: Signa Evans & Hesca JoubertREPRO & PRINTING: Business Print Centre

Liezel van der Merwe

In appreciation of the support afforded us by this sector, we would

like to invite architects and designers to participate in our magazine,

so that we can contact you for comments on certain issues. You may

even like to become contributors to FLOORS.

AninvitationtoarchitectsanddesignersFloors in Africa has attained the highest circulation

figures of any magazine in the Architectural section

of the latest Audit Bureau of Circulation (ABC) report

with a distribution of 5 722 copies of each issue.

We would also be interested in receiving details of recently complet-

ed or current projects where the flooring played an important role in

achieving the overall design concept.

Anything we write would be cleared with you before we go to print,

and full details of your practice or company given in each case. This

will provide you with the opportunity of extensive free publicity,

highlighting your creativity and architectural prowess.

Contact Roxanne Mancini on 012 347 7530 for further information,

or send us an e-mail at [email protected] with the project

details that we can start on.

Inthenextissue…

Don’tmissthenextissue!Takealookatthemainfeatureswewillbecovering:

Successful projectsLast year everyone wanted to talk about

the truly outstanding projects they

were involved in and why their prod-

ucts or systems were used, so we are

repeating it this year to give every-

body the chance to tell the world

how good they are once again! This

is your chance to be in this exciting

feature if you missed it last time!

Adhesives & installationSpecifiers cannot be expected to keep

up with all the developments within the

floorcovering industry, and yet this impor-

tant sector is one of the most hi-tech, with

fast-moving developments and improve-

ments in application and performance

characteristics a regular occurrence. We

look at the latest developments and tech-

niques to keep them up to date.

Townhouse livingAnother new feature that will look at the

flooring requirements with the current trend

of living in security complexes, upmarket

(and even golf ) estates, and everything in

between. We will talk to developers, estate

managers, architects and others to find out what

is favoured, both indoors and out.

Roxanne Mancini [email protected] Stuart harvey [email protected] Tel: +27 12 347 7530

OOP

otteryHypermarketchooses Italianclass!

“Budget price is always an issue; forgivingly based

on the quantum we required, we were able to afford

an excellent quality Italian floor tile from Kenzan

Tiles. It was essential that the tile would withstand

the high-traffic volumes which this Hypermarket

enjoys.” - Sean Hayden of KMH Architects

Fa s h i o n & D e s i g n

�F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

These are the words of Sean Hayden of KMH Architects. This

celebrated practice formed in Cape Town in 1912 is currently

handling the refurbishment of the Ottery Hypermarket, where the

new mall tiles have already been installed and are looking great,

but there are still more aesthetic changes to come.

The flooring component of the project was a challenge for the

architects. Nothing about the building at the Ottery Mall was

conventional. A typical example is the shop fronts, which are void

of any consistency and are neither aligned nor matching in height.

In order to accommodate the variation at the shop face, a perim-

eter border tile was introduced which in turn featured a piano-key

pattern in the middle.

Sean Hayden said, “We are familiar with who has what type of floor-

ing products on the market, we were specifically looking for a Grade

One tile, which was calibrated and rectified (same size and thickness)

to ensure that it would survive the foot traffic of a busy centre.”

“Kenzan were professional, there were no hiccups and

they were always at our beck and call, which we valued

throughout the project,” says Sean.

Nathalie Glenn from Kenzan provided further detail on the project.

“It was a very technical project, with a number of challenges,” she

says. “But our Italian factory gave us the backup and outstanding

service that we needed. They have extensive knowledge and experi-

ence, excellent products, are flexible, and honour all their promises.”

“It is nice to know that the new flooring can confidently take the

Ottery Mall into its next 20 years,” she concludes.

Kenzan Quality Tiles

Cape Town: 021 510 8310

Johannesburg: 011 467 8533

Port Elizabeth: 041 373 6456

Fa s h i o n & D e s i g n

When choosing floorcoverings, the options are

many and varied. Visitors to BAU 2011, which is

claimed to be the world’s leading trade fair for

architecture, materials and systems which takes

place from 17 to 22 January 2011 at the New

Munich Trade Fair Centre, will be able to review the

whole spectrum of materials, colours and designs

currently available on the world market in floorings.

Floorcoverings:Theagonyof

10

Fa s h i o n & D e s i g n

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

choice

Fa s h i o n & D e s i g n

11F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

Resilient coverings (linoleum, PVC, rubber, cork) and textile floor-

ings will be on show; laminates and parquet flooring are also

on display; and tiles and ceramics will be exhibited. Here leading

manufacturers from all over the world will be showcasing their lat-

est creations for the design of interiors and exteriors.

Architects and interior designers are increasingly discovering

floors as being an important element in the overall design. They,

their customers, and the flooring specialists that advise them and fit

the products, are confronted with a very wide choice.

The advantages of traditional coverings such as wood, stone and

tiles are their robustness and timeless quality. New formats and new

surface structures have emerged, and wooden floorboards, wood-

blocks, stone slabs and hand-painted tiles have enjoyed a renais-

sance in recent years.

Modern materials are often a mix of natural and synthetic – and

here, too, the choice is broad, from textile floorings made of natural

and man-made fibres to resilient floors of linoleum, PVC, rubber

and cork.

Colour and surface design or structure are just two of the factors

to take into account when choosing a flooring material. Others

include: What will it look like in several years time? How does it feel?

Does it smell? How do you use it, what can it withstand and what is

it meant to prevent? How long should it last, how do you clean it,

and what is the budget?

Also, it must be remembered that floorcoverings play a part in the

overall architectural design, so questions as to whether they should

harmonise or contrast with it also need to be addressed.

One important trend when it comes to sustainability is recycling,

not just in the case of resilient floorings such as PVC or linoleum,

but also carpet tiles. Some manufacturers are now taking their

products back after use and recycling them into fibres or backings.

Carpet tiles have other advantages too – they act as sound insula-

tion, are very robust even under frequent use, and can easily be

replaced as required.

In textile and resilient floorings in particular a whole host of new

products has been developed. These range from new ways with nat-

ural, renewable materials such as cork, hemp, wool and leather, and

products made from natural and synthetic base materials, such as

rubber (also called elastomeric), through to purely synthetic fibres

and plastics (vinyl floorings) and coatings of epoxy resin.

Added to this are more unusual choices such as strongly struc-

tured or even flocked textile coverings, alongside exotic options

such as those made of paper, seagrass and pineapple fibres. Visitors

can look forward to an exciting display at BAU 2011 where over 1

900 exhibitors from more than 40 countries are expected to take

part, and more than 210 000 visitors from around 150 countries.

14

P r o d u c t s & S e r v i c e s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

Customising

Delivering value to its clients forms a core part of

Numatic’s product offering. As one of the largest suppli-

ers of exceptional cleaning solutions, Numatic has identi-

fied an emerging trend in clients’ cleaning demands. In

response, the cleaning giant now customises the colour of

its products to suit the corporate identity of its customers.

–respondingtomarkettrendscorporatecolours

Janine Botha, National Sales & Marketing Manager for Numatic,

says, “Historically, cleaning equipment and the cleaning process

itself was considered to be a function completed behind closed

doors. However, as business requirements evolved a new trend has

emerged. Cleaning and the equipment used is becoming a vital part

of a corporate institution’s image.”

Most businesses, offices, banks, shopping centres and airports have

no option but to clean their premises during normal office hours,

bringing this process into the public eye.

Business owners are becoming increasingly aware of how clean-

ing equipment can be used as an opportunity to subtly portray their

corporate identity, while sending a positive and hygienic message to

the market.

Botha continues, “Providing companies with technologically

advanced cleaning equipment branded in their corporate colours

demonstrates that the company cares about the finer details and

their customers’ wellbeing.

Numatic’s process of developing branded products starts by under-

standing the client’s corporate identity. Once this has been achieved,

Numatic’s media division in the UK produces a graphic which the

client signs off before the colours are mixed and the purchase order

is put through for production. Delivery takes place within eight to 12

weeks from the date of order.

Numatic has produced branded cleaning products for a number

of respected companies in South Africa including SAFIC, Prestige

Cleaning Services, Supercare Services Group, the Red Carnation Hotel

Group and selected Holiday Inn Hotels.

For more information on Numatic’s service offering to corporate cli-

ents, visit www.numatic.co.za.

P r o d u c t s & S e r v i c e s

1�F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

GreatGolfDayforNumaticA full field of golfers enjoyed the 2010 Numatic

Golf Day held at the Eagle Canyon Country Club,

Honeydew, on 9 September which saw some great

weather, some even better golf, and a great day

had by all!

With a 4-ball alliance competition (two scores to count), the win-

ning combination was Alan Wintermeyer, Dale Cowley, Erik

Smith and Warwick Mills of Supercare. Customers from as far afield as

Botswana took part, as well as visitors from the Numatic International

Head Office in Chard, Somerset, England.

The prizes were presented by The 40 Year-old Rookie golf profes-

sional Michael Schultz, who was also the MC and guest speaker,

entertaining the guests for over an hour with golf tips and quips for

the occasion.

He also conducted an auction at the event that raised R20 000 for

Friends of Rescued Animals (FORA) which is a shelter for homeless

dogs and cats, opened in August 2003. It is a non-profit organisation

run by a dedicated team of volunteers.

The shelter, based in Luipaardsvlei, Krugersdorp, accommodates

600 dogs and 200 cats, and is a safe haven for homeless and abused

animals to live whilst awaiting adoption or, failing this, to live out the

rest of their lives in a safe environment, in keeping with FORA’s ‘No

Kill’ policy.

Now in its 16th year of operation in South Africa, Numatic

International started in southwest England, and from humble begin-

nings in 1969 has grown to be one of the foremost cleaning and

floorcare companies in the world, with subsidiary companies in France,

Germany and The Netherlands in addition to its Johannesburg office.

Numatic South Africa is serving the cleaning industry with a wide

range of quality vacuum cleaners, mopping units, janitorial and

hotel trolleys, and floor machines of all descriptions, and offers a

comprehensive sales, support and training service for its entire sales

programme.

The company is committed to support and comply with B-BBEE

standards, and feels that its success in this country is due to its

emphasis on job creation, the sharing of knowledge and expertise,

and its investment in people.

With product development and customer care high on Numatic’s

future programmes, South Africa can expect the high standards set

by the company to be maintained.

Numatic International

Tel: 0861 NUMATIC (686284)

Website: www.numatic.co.za

16

P r o d u c t s & S e r v i c e s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

6 different patterns 8 standard coloursComplete Stair SystemEnhanced abrasion resistanceSuperior chemical resistanceJumbo Tiles – a ‘look-alike’ ceramic tileConductive floor tiles for electronically sensitive areas also available

Tel (011) 397 3330 • Fax (011) 397 3810 • e-mail: [email protected] • www.transittiles.com

Elevatingthefloors!Take a look at the floor the next time you get into

a lift. If it has a raised pastille pattern the chances

are that you are being transported on a high-qual-

ity PVC studded tile floor manufactured by Transit

Floor Tiles.

You might also be admiring the quality workmanship of JD

Installations – a company in Pretoria West that specialises in

the complete refurbishment and modernisation of lifts – offering a

complete re-fitment service for every lift manufacturer, and a keen

customer of Transit for their fit-and-forget floor tiles.

Owner José Dias says he uses Transit for over 80% of the new lift

floors he provides because these can be readily installed with a

contact adhesive to steel or wood subfloor platforms, some with

Masonite sheeting over them, and he has no problems with their

quality and dimensional stability.

One of the favourite tiles in the Transit sales programme for these

applications is the 8x8 which has an improved pastille design, and

another is the New Quadra Super, which has a gloss base and the

radiused curve to the top of each pastille allowing for easier cleaning.

The 8x8 tiles are 300mm x 300mm with a base thickness of 2,20mm,

a stud height of 0,80mm, a total thickness of 3mm, and feature eight

rows of 8 round studs each 25mm in diameter.

Aesthetically Transit has the edge on many other products in these

applications as they have been in business for 25 years and, in addi-

tion to having a modern and hi-tech appearance, Transit Tiles are

extremely robust, dimensionally stable, extremely durable and ideally

suitable for elevators or other applications where a high degree of

traffic is expected.

Transit Floor Tiles

Tel: 011 397 3330 Fax: 011 397 3810

P r o d u c t s & S e r v i c e s

17F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

PVC concave edge trimAluminium Formable square edge

Brass round edge trim Stainless steel listello

GAUTENGTel: +27 11 444 1441 Fax: +27 11 444 1165

E-mail: [email protected] Website: www.kirk.co.zaCAPE TOWN

Tel: +27 21 949 2226 Fax: +27 21 949 4531KWAZULU NATAL

Tel: +27 31 564 1175 Fax: +27 31 564 1143PORT ELIZABETH

Tel: 0860 547573 Fax: 086 688 4980

Structural movement and expansion joints for floors, walls, columns, ceilings, roofs, car garages,

bridges. Fire Barriers also available.

M Trim is a brand of PVC, brass, aluminium,stainless steel and anodised profiles used for

tiles, carpets, vinyl and laminate floors.

Quality Profiles for wood and laminate floors.

Quality Tile Cleaners,Strippers and Sealants.

PVC curvable profiles for multi-shaped flooring. Commercial and domestic applications.

TrimsprovidetheperfectfloorfinishKirk Marketing is a leading Southern African supplier of trims and

top-quality accessories to the flooring industry. With a superior

range of products and branches situated throughout the region,

Kirk prides itself on its extensive experience and knowledge

gained through combined 50 years in the industry.

Stainless steel quadrant edge

Brass elite straight edge

Aluminium elite straight edge

PVC round edge

With this considerable expertise, training and product knowledge, the Kirk Marketing

design team has developed the superior and highly functional M.Trim collection, used

extensively for tile, carpet, vinyl, wood and laminate flooring.

These trims have been produced specifically for the market throughout Southern Africa

whilst being professionally designed and manufactured to international standards.

In application, trims are used for the final finishing of tiled floors and walls, with the prima-

ry elements being aesthetics (listellos, corners, edges, etc.), functionality (ramps, gap fillers,

shapes, corners, stairs, etc.) and the protection of tile edges.

The four most widely used materials for tile trims are PVC, aluminium, brass and stainless

steel, but they can also be manufactured in zinc, copper, mild steel, recycled materials and

more, depending on the requirements of the project. However, it should be noted that PVC

is not designed for floors other than its use in stair nosing applications.

Brass is a popular choice for use on floors and walls. It is a heavy-duty and resilient prod-

uct, and although tarnishing can occur in some corrosive environments, this can be easily

polished to revive the shine.

Aluminium trims is available in natural finish, anodised colours and powder-coated in any

colour, quality products such as M.Trim are recommended if the floor is to look and perform

as expected.

Stainless steel is tough, hardwearing, and suitable for all conditions depending on the

Grade used. Several grades and surface finishes are available, and trims in this material

can also be custom-designed to meet any requirement, making it a popular option with

specifiers.

For your final tile trim solution, or technical advice on any application, contact the M.Trim

experts on the following numbers.

Kirk Marketing Head Office: 011 444 1441 Helpline: 086 110 2165

Cape Town: 021 949 2226 Durban: 031 564 1175 Port Elizabeth: 0860 547 573

Email: [email protected] Website: www.kirk.co.za

WhO dO YOu Think iS ThE biggEST CERAMiC TilE MAnuFACTuRER in ThE WORld?

Sitting down? According to Ceramic World Review magazine, which

is devoted to ceramic tile and sanitaryware production technologies,

the answer is UAE-based RAK Ceramics.The Ras Al Khaimah company

dominated rankings of the top 25 ceramic tile manufacturers in 2009 with a total produc-

tion output of 115-million m² from 15 manufacturing facilities located in six countries;

and a US$1-billion global revenue with exports to over 150 countries. Two years ago RAK

Ceramics was ranked fourth with a production of 106-million m², but has expanded and

increased its production facility even during the recent economic slowdown.

FlooringsolutionsforGreenNutFarmMapei South Africa, part of the global Mapei

Group and an industry leader in the supply of

building materials, has supplied Green Nut Farm,

based in Hazyview, with epoxy flooring solutions.

Mapei South Africa supplied Mapefloor i 300 Sl, a two-com-ponent, multi-purpose, neutral-coloured epoxy floor surfac-ing treatment, for green nut Farm, based in hazyview.

Green Nut Farm, a macadamia nut grower, has had the flooring

solution applied to its packaging, production and receiving

areas, and the final floor finish has been implemented over an area

of approximately 800m2 by Maroda Concrete Preparation – a local

flooring applicator.

Mapei has supplied Mapefloor I 300 SL a two-component, multi-

purpose, neutral-coloured epoxy for industrial flooring treatment.

According to Garth Meyer, product manager (Flooring), the prod-

uct can be applied at a thickness of up to four millimetres and is

ideal for applications in environments such as the food industry,

pharmaceutical applications, shopping centres, and the chemical

and automotive industries.

“Mapefloor I 300 SL is a strong, durable product which has high

abrasion resistance and aesthetic appeal. The product can be

applied as a self-levelling system, which results in a seamless floor

surface,” he says. “This product is also available in a non-slip option.

Mapei has developed the product without using solvents or nonyl-

phenol, which makes the product ideally suitable for applications in

the food processing industry as it does not present any risk of food

contamination.”

In order to lay the new floors, Green Nut Farm’s processing equip-

ment needed to be removed from its production plant, and a contrac-

tor was hired to perform this task, but as a result of the high mass of

the processing equipment, the existing floor surface was damaged,

making it unsuitable for the application of the Mapefloor I 300 SL.

To overcome this challenge, Maroda Concrete Preparation used

Mapei Ultraplan – a cementitious, polymer-based, self-levelling sys-

tem. The product exhibits ultra-fast hardening properties and was

applied at a thickness of ten millimetres.

Once the original floor surface was repaired, Maroda Concrete

Preparation used Primer SN – an epoxy-based primer to seal the

floors and prevent any risk of delamination between the freshly

repaired floor surface and the Mapefloor I 300 SL.

Mapei has also supplied Mapefloor I 500 W, which was used for the

washbay area. This is a two-component, epoxy resin-based treatment

in water dispersion, which is permeable to vapour for industrial floors.

Meyer notes that the product is water-based, and is safe for the

environment and applications which require a vapour-permeable

floor coating. “Mapefloor I 500 W is a fantastic product, which has

been developed in Mapei’s development laboratories. Even though

the product is water-based, it is not subject to shrinkage,” he says.

“The product offers resistance to chemicals and abrasion and can

be applied to concrete after only four days of curing. After applica-

tion, the system offers a seamless, aesthetically appealing appear-

ance with high abrasion resistance.”

Feedback from the customer has been positive for the product as

well as for Maroda Concrete Preparation’s knowledge and expertise

in completion of the project.

Mapei

Tel: 011 552 8476

E-mail: [email protected]

Website: www.mapei.co.za18

P r o d u c t s & S e r v i c e s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

P r o d u c t s & S e r v i c e s

1�F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

GAUTENGTel: +27 11 444 1441 Fax: +27 11 444 1165

E-mail: [email protected] Website: www.kirk.co.za

CAPE TOWNTel: +27 21 949 2226 Fax: +27 21 949 4531

KWAZULU NATALTel: +27 31 564 1175 Fax: +27 31 564 1143

PORT ELIZABETH

Tel: 0860 547573 Fax: 086 688 4980

React 100

React 300

React 1000

Structural movement and expansion joints for floors, walls, columns, ceilings, roofs, car garages, bridges.

Fire Barriers also available.

M Trim is a brand of PVC, brass, aluminium,stainless steel and anodised profiles used for tiles,

carpets, vinyl and laminate floors.

Quality Profiles for wood and laminate floors.

Quality Tile Cleaners,Strippers and Sealants.

PVC curvable profiles for multi-shaped flooring. Commercial and domestic applications.

specifyexpansionjointswithconfidence!

Kirk Marketing is proud to be the sole South African agent for

Vexcolt Expansion Joints since 2003, and has been successful in

specifying them for numerous prestigious South African projects

by offering a wide range of options that are aesthetically pleasing

and effective.

Vexcolt is one of the world’s leading manufacturers of expansion joints, movement joints

and fire barriers. Its expansion joints are designed to accommodate the needs of the

flooring industry, regardless of the floorcoverings being used.

In South Africa the Vexcolt range has become extremely popular – with a portfolio of archi-

tectural expansion joints to meet any flooring requirement and covering joint widths ranging

from 25mm to 600mm depending on the application and the need, in addition to which

these products are all provided with the Vexcolt 10-year manufacturing guarantee.

To ensure that the designer’s problems or requirements for expansion joints are adequately

and professionally solved, Kirk Marketing is involved with the design team in selecting the

correct system to suit the building specifications, offering on-site technical advice and training.

Specifying the correct expansion joint is vital for any application, and the technical team at

Kirk Marketing is actively involved from the beginning of the project with the selection and

installation of the expansion joint systems to avoid failure of the joints, which can be costly in

terms of time and money.

Kirk Marketing has specified Vexcolt expansion joints successfully into many South African

projects nationwide, including Gold Reef City Casino (Johannesburg); the Gautrain (Gauteng);

Golden Horse Casino (Pietermaritzburg); The Grove Shopping Centre (Pretoria); Hemingways

Mall (East London); Loch Logan Shopping Centre (Bloemfontein); Palms Retail Centre (Lagos)

and University of the Western Cape, to name but a few.

Kirk Marketing Head Office: 011 444 1441 Helpline: 086 110 2165

Cape Town: 021 949 2226 Durban: 031 564 1175 Port Elizabeth: 0860 547 573

Email: [email protected] Website: www.kirk.co.za

glueless Carpet tile

Beaulieu Canada and TacFast Systems International say they have formed a partnership

to provide a totally adhesive-free, free-floating carpet installation system.

Beaulieu Canada will market and sell TacFast LocPlate products that feature a free-float-

ing substrate and carpet products with a loop fabric covering the underside. The floor-

ing surface attaches to the hook substrate by engaging the hooks and loops creating a

mechanical bond that holds the flooring surface in place securely, yet is releasable.

The LocPlate product line is a modular floor that can be installed over any subfloor, with-

out any attachment to the subfloor and supports the installation of a variety of flooring

surfaces, making it a universal subfloor system, the companies said.

“Adding a loop to the underside of our carpet broadens our product offerings as we will

offer our entire commercial broadloom line with TacFast,” said Marcel Poirier, Beaulieu

Canada’s vice-president of commercial business.

Floordaily.net

20

P r o d u c t s & S e r v i c e s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

EpoxyflooringsystemfortwonewDurbanbeachfacilitiesAn epoxy flooring system from a.b.e. Construction

Chemicals was used to provide the flooring for two

new facilities on the Durban Beach Promenade.

The company’s abescreed epoxy flooring system was used as the

flooring system for the 2010 FIFA Soccer World Cup Media Centre

on the South Beach Promenade, as well as for a new World Cup res-

taurant and its kitchen, ablutions and boat room on the North Beach

Promenade. Both have now become public entertainment facilities

on the revamped promenade.

Brad Hunt, a.b.e. Technical Sales Consultant in KwaZulu-Natal, says

abescreed was applied to a minimum thickness of 6mm over a 625m²

area at the Media Centre floors. The specialist flooring applicator was

Inter Civil Projects, and the main contractor G. Liveiro & Son. The proj-

ect/building was designed by Jay & Nel Architects.

The same thickness abescreed system was applied for the floor-

ing of the new restaurant opposite Durban’s Mini Town. “The a.b.e.-

approved applicator, Seal Con Systems, first applied a coat of a.b.e.

flooring resin and scattered a.b.e. Silica Sand number 1 coarse silica

sand, followed by 6mm thick abescreed coating, which was then

sealed with two coats of a.b.e.’s abecote PU water-based clear matt

coating,” Hunt explained.

Design Workshop were the architects appointed by the City of

Durban to handle the design and help oversee the construction of

the building.

abescreed is a four-component, solvent-free flooring system com-

prising a clear resin and activator blended with a pre-packed graded

aggregate and coloured pigment.

Hard-wearing and chemical-resistant, abescreed is a decorative

mortar that provides seamless flooring surfaces. The product is slip-

resistant and ideal for areas subjected to heavy mechanical wear. “The

flooring system is ideal for restaurants, schools, factories, laboratories,

food processing plants, supermarkets and garages,” Hunt states. “It

provides far longer life than unprotected concrete floors and requires

low maintenance.”

a.b.e. Construction Chemicals

Tel: 011 306 9000

Website: www.abe.co.za

part of the durban beach promenade facilities for which a.b.e.’s abecote flooring system was used.

P r o d u c t s & S e r v i c e s

21F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

Grout & tile cleaner Water based Tile sealant

Multi pupose cleaner Colour sheen enhancer

GAUTENGTel: +27 11 444 1441 Fax: +27 11 444 1165

E-mail: [email protected] Website: www.kirk.co.za

CAPE TOWNTel: +27 21 949 2226 Fax: +27 21 949 4531

KWAZULU NATALTel: +27 31 564 1175 Fax: +27 31 564 1143

PORT ELIZABETH

Tel: 0860 547573 Fax: 086 688 4980

GAUTENGTel: +27 11 444 1441 Fax: +27 11 444 1165

E-mail: [email protected] Website: www.kirk.co.zaCAPE TOWN

Tel: +27 21 949 2226 Fax: +27 21 949 4531KWAZULU NATAL

Tel: +27 31 564 1175 Fax: +27 31 564 1143PORT ELIZABETH

Tel: 0860 547573 Fax: 086 688 4980

Structural movement and expansion joints for floors, walls, columns, ceilings, roofs, car garages,

bridges. Fire Barriers also available.

M Trim is a brand of PVC, brass, aluminium,stainless steel and anodised profiles used for tiles,

carpets, vinyl and laminate floors.

Quality Profiles for wood and laminate floors.

Quality Tile Cleaners,Strippers and Sealants.

PVC curvable profiles for multi-shaped flooring. Commercial and domestic applications.

Qualitytilecarechemicals

Marketed in South Africa exclusively by Kirk Marketing, M-Chem

is a comprehensive range of quality tile care chemicals, devel-

oped through extensive market research and tests that allow Kirk

Marketing to introduce these unique high-quality products with

confidence for cleaning, stripping, sealing and maintaining floors,

covering almost every eventuality and tile type, and specialising in

full specifications on the entire range.

Kirk Marketing provides a comprehensive sales and delivery service, product training and

technical information that enable tile and hardware retailers to provide the best product

and advice, thus giving complete customer satisfaction. A chemical specialist within Kirk

Marketing is available for site inspections, to offer further assistance and will inform on best

product to use.

A lot of new developments are using a wide range of natural stones which have now

become available. It is imperative from an architectural viewpoint that M-Chem chemicals

are specified for these jobs, and specifications are all available on Autospec. M-Chem is

locally manufactured.

Apart from a qualified sales team, Kirk Marketing also has a national distribution network

with offices in Johannesburg, Durban, Port Elizabeth and Cape Town – each carrying stock,

enabling Kirk Marketing to provide a superior customer service. M-Chem products are all

individually colour-coded, so one can tell from a distance the product being used, thus elimi-

nating any confusion.

M-Chem is continually developing new ideas for the tiling industry, and the latest product

M-Clean is a scented lime/lemon multi-purpose cleaner and available in a 750ml spray bottle.

It is pre-diluted at 1:5 and has 1-litre concentrated refills available. All the necessary markings

are on the bottle to ensure that the end-user is able to refill and dilute to their required need.

In respect of the chemical range, Kirk also supplies a range of application tools.

Kirk Marketing Head Office: 011 444 1441 Helpline: 086 110 2165

Cape Town: 021 949 2226 Durban: 031 564 1175 Port Elizabeth: 0860 547 573

Email: [email protected] Website: www.kirk.co.za

ThE gREEkS hAd A WORd FOR iT!

Did you know that the word ceramic is derived from the

Greek word κεραμικός (keramikos)?

(and we bet you thought it was Italian!)

22

P r o d u c t s & S e r v i c e s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

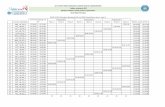

InnovativesolutionsinhealthcareIn hospital environments floors must be closely controlled as

they can transfer bacteria and transmit diseases to patients. With

over eighty years of experience, Forbo understands that hygiene

is a major concern for hospitals and has developed Sarlon Tech

Sparkling – now being marketed in South Africa by FloorworX.

STAPHYLOCOCCUSAUREUS

ESCHERICHIACOLI

PSEUDOMNASAERUGINOSA

S. AUREUSMRSA

R R R R

sArloNTECHsPArKlING 5,0 6,1 5,5 4,7

MArKETProDuCT1 0,5 -0,2 -0,9 2,1

MArKETProDuCT2 1,8 1,4 -0,6 4,1

MArKETProDuCT3 5,0 2 0,9 4,7

MArKETProDuCT4 5,0 4,8 0,5 4,7

R > 2 = Antibacterial performance is effective

R < 2 = Antibacterial performance is not effective

This innovative product offers Bacteri’Protect – the most effective antibacterial treat-

ment available for hospitals; Stain’Protect – the first treatment on the market that is

resistant to Betadine and Eosin; and the best indentation performance of acoustic certi-

fied products; in addition to being a totally eco-friendly product.

Antibacterial performance tests performed by CIBA laboratory in compliance with the JIS Z

2801 standard protocol.

In line with current sanitary requirements, Sarlon Tech Sparkling is tested by

accredited laboratories and assists in the fight against nosocomial infections, and

Bacteri’Protect is a new antibacterial treatment using silver ions, tested and approved

by the Pasteur Institute in Lille, France. It is also effective against the Pseudomonas

Aeruginosa strain.

The ion solution in the varnish and the wear layer of the floorcovering guarantees

permanent and constant action which strengthens durability over time, unlike chemi-

cal additives. It also guarantees a product that is totally innocuous for the surrounding

environment. In addition, Sarlon Tech Sparkling has the highest ranking of the VOC

Indoor Emissions standard, and is recyclable.

Finally, the Stain’Protect feature of this product provides a genuine shield against

stains, with a high resistance to standard products used in hospital environments.

It is also effective against chemical products such as ammonia, white spirit and ace-

tone and domestic products such as bleach.

In the current climate of sanitary challenges, Forbo reflects its solutions through

the development of new eco-friendly solutions by increasing both private and public

awareness and, in turn, this is replicated by the inclusion of Sarlon Tech Sparkling in the

FloorworX sales programme – which already finds favour in a myriad of South African

healthcare programmes.

FloorworX Marketing

Tel: 011 406 4146

Fax: 011 406 4205

www.floorworx.co.za

P r o d u c t s & S e r v i c e s

2�F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

GAUTENGTel: +27 11 444 1441 Fax: +27 11 444 1165

E-mail: [email protected] Website: www.kirk.co.zaCAPE TOWN

Tel: +27 21 949 2226 Fax: +27 21 949 4531KWAZULU NATAL

Tel: +27 31 564 1175 Fax: +27 31 564 1143PORT ELIZABETH

Tel: 0860 547573 Fax: 086 688 4980

Aluminium foiled Multifloor transition

Aluminium Multifloor expansion

Aluminium foiled Clipper Finish Aluminium Stepfloor

Structural movement and expansion joints for floors, walls, columns, ceilings, roofs, car garages,

bridges. Fire Barriers also available.

M Trim is a brand of PVC, brass, aluminium,stainless steel and anodised profiles used for tiles,

carpets, vinyl and laminate floors.

Quality Profiles for wood and laminate floors.

Quality Tile Cleaners,Strippers and Sealants.

PVC curvable profiles for multi-shaped flooring. Commercial and domestic applications.

Uniquelaminatefloorprofiles

Two of the major elements of the Kirk

Marketing sales programme are the Bendi

quality profiles that are ideal for curved floors,

and Dural – offering an extensive range of

profiles for wood and laminate floors.

Square end coverExpansion cover

Bendi Transition Clip

The Bendi range of curvable profiles marketed by Kirk

Marketing is extremely popular in South Africa. The Bendi

Transition clip is a curvable profile used as a transition cover

for multi-shaped floors or different levels such as laminate to

carpet, wood to laminate, and laminate or wood to tile.

Other curvable profile used are the Bendi Ramp clip, the Bendi Cover clip and the Bendi

Square clip. These curvable profiles are used as a ramp cover , an expansion cover and an

end-cover respectively for multi-shaped flooring on different height floors or on same-level

flooring or against the wall or border. All the above Bendi profiles allow for movement of

your laminate or wood flooring and the Bendi Clip system can bend on a radius of 80cm.

Laminate flooring is predominantly fitted as a floating floor and will generally experience

expansion and contraction in the South African varying climate environment, and Kirk rec-

ommends aluminium-based profiles as the most suitable for these applications.

Aluminium is the most popular, and the Dural range of profiles (manufactured in Germany)

provides solutions to accommodate expansion, transition, finish, end, step and adaptable

shapes to solve expansion and gaps against sliding doors, large floor areas, staircases, transi-

tion between different flooring types, or finishing for a laminate floor to a screed or vinyl and

curvable floor types.

Dural’s quality Multifloor range is also ideal for retrofit situations where a profile has been

forgotten, and is available in 92cm and 270cm lengths – ideal both for contracts and DIY.

Kirk Marketing offers a comprehensive sales, delivery and technical advisory service for any

flooring profile.

Kirk Marketing Head Office: 011 444 1441 Helpline: 086 110 2165

Cape Town: 021 949 2226 Durban: 031 564 1175 Port Elizabeth: 0860 547 573

Email: [email protected] Website: www.kirk.co.za

interiors 2011

This major exhibition for the construction and building industry held every year in the

UK will include a new flooring section – showcasing the latest developments, trends,

products and technologies to over 38 000 anticipated visitors.

This expo takes place at the National Exhibition Centre, Birmingham from 23 to 26

January 2011, and anyone wishing to know more should contact Sunny Patel at +44

207 921 8415 or by e-mail [email protected].

FLOORS in Africa will follow up after the event to bring you all the latest news.

NewshowroominWestlakePreviously situated in the Steenberg Village

Shopping Centre at Tokai, Gill Mackintosh

Flooring has moved into new retail premises at

the Westlake Lifestyle Centre in the southern

suburbs of Cape Town.

Established in 2003, Gill Mackintosh Flooring offers Sisal, Coir,

Hemp, Seagrass, wall-to-wall carpeting, resilient vinyl, and lami-

nate and engineered wooden flooring, together with high-quality

design, advice and personalised service, which includes an installa-

tion team offering expert installations.

All installations are fully supervised, and Gill offers complimen-

tary overlocking of off-cuts as well as ensuring that comprehensive

instruction is given to the client or staff of the installed product.

The new showroom can be found at 14A Westlake Lifestyle Centre,

Westlake Drive, Westlake, and contact can be made by telephone:

021 702 2208; Cell: 072 487 0053, or e-mail [email protected].

P r o d u c t s & S e r v i c e s

DecorativeandaffordablevinyltileoptionsWonder Flooring, the exclusive dis-

tributors of Armstrong and Wonstep

vinyl flooring ranges throughout

Southern Africa, have found unprec-

edented demand from architects,

interior designers and building and

flooring contractors for these superb-

ly versatile vinyl tile ranges.

24

P r o d u c t s & S e r v i c e s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

Apart from the favourable price, a few of the

other motivating factors towards this trend

among specifiers are as a result of the unique fea-

tures of these ranges.

These include through-grain chip construction,

which means the tiles retain a consistent appear-

ance even in areas of differential wear. Also, the

marble effect on the tile renders a quality finish

– if the grain is laid in the same direction, the tile

appears as a sheet product. This effect is obtained

through the manufacturer’s unique cutting process

P r o d u c t s & S e r v i c e s

2�F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

and the resultant squareness of the tile.

Some other features and benefits include a heavy-

duty formulation; high rolling-load integrity mak-

ing it ideal for wheeled traffic such as trolleys; easy

installation, economical options compared to other

flooring types; and textured tone-on-tone mottle

that masks traffic damage. Also, the low emissions

of Volatile Organic Compounds (VOCs) with these

ranges will inhibit ‘sick building syndrome’.

These tile ranges are available in 2mm and 2,5mm

thicknesses, and comprise exciting and varied

colourways. They have been extensively used in

retail chain stores, factories, educational institutions

and prisons.

Some of the projects that our vinyl tile ranges

have been successfully used in include Game

Stores; Checkers Hyper; Kokstad Prison; Durban

International Airport; Diepkloof Prison; and various

public and private Schools.

For further information on these exciting floor

ranges, contact Wonder Flooring at the numbers

shown below, or visit the website.

Wonder Flooring

Tel: 0860 29 80 80

E-mail: [email protected]

Website: www.wonderflooring.com

Going greenwithflooringadhesiveWith worldwide ecological and environmental

issues bearing down hard on the flooring industry,

all aspects of flooring materials in terms of manu-

facture, supply and installation now come under

close scrutiny by architects, designers, contractors

and end-users as they all seek to ‘go green’.

26

P r o d u c t s & S e r v i c e s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

In terms of installing carpet and resilient floorcoverings, perhaps

the biggest challenge has been in providing environmentally

friendly adhesives, an area that has regularly used alcohol, glycol,

methanol, ammonia (with their associated hazardous vapours) in

their manufacture.

This problem has now been solved by Smoothedge with the

introduction of its Earthbond range, comprising a revolutionary sol-

vent-free acrylic bond adhesive that contains only very low levels of

Volatile Organic Compounds (VOCs) and none of the above harmful

substances; and Earthtac PSA – a pressure-sensitive adhesive with

the same beneficial qualities.

Earthbond offers a total solution to the potential hazards com-

monly associated with traditional floorcovering adhesives; it does

not contribute to sick building syndrome and is suitable for hospi-

tals, retirement homes, hotels, office blocks and restaurants where

hazardous vapours may present potential health risks.

Local adhesives are solvent based and contain very high quantities

of Volatile organic compounds – ±140grams of VOC for solvent-

based adhesives. Earthbond is the only water-based adhesive for

carpet and vinyl installations in South Africa.

Use of this adhesive improves air quality, causes fewer health

problems (if any) and emits very little odour during installation,

becoming odourless when dry. As a water-based acrylic adhesive,

Earthbond is totally solvent-free, and provides outstanding adhe-

sion to the substrate.

Smoothedge is a member and keen supporter of the Green

Building Association and it is interesting to note that several major

banks aiming to achieve ‘Green Building’ status have specified and

used Earthbond.

To complete the range, Earthtac PSA has been developed as a

pressure-sensitive adhesive with low VOC content which is manu-

factured to the highest quality standards and enjoys all the ‘green’

features and benefits of Earthbound adhesive.

This high-quality adhesive has been used extensively in South

Africa in heavy commercial applications such as banks, furniture

stores and exhibitions centres. In use, it can be brushed or rolled on

and it remains permanently tacky after flash-off, as well as providing

an excellent hold.

Established in 1966, Smoothedge has vast experience in meeting

the needs of the flooring industry, and has gained an exemplary

reputation throughout the trade with superior products such as car-

pet grippers, aluminium edgings and flooring tools.

In 1986 Smoothedge took the decision that adhesives were an

important growth area and, having carried out extensive research

into the design and manufacture of specialised flooring adhesives,

has also developed new formulations for outdoor use with contact

adhesive including a non-flammable contact.

It is this diligent investment in development programmes aimed

at meeting the requirements of its customers and end-users that

has led Smoothedge to the provision of the Earthbound and

Earthtac PSA adhesives.

Providing a broad range of customers with solutions for all their

fitting needs is the main aim of Smoothedge, and this continued

research and development, resulting in innovative solutions to

everyday installation problems, will ensure that the company will

remain firmly established as a reputable and innovative supplier in

the forefront of the South African flooring industry.

Smoothedge

Tel: 011 555 5360

Fax: 011 555 5378

28

P r o d u c t s & S e r v i c e s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

Coolcrete concrete stain is manufactured and

marketed for the decoration of concrete floors in

South Africa by Tile & Floor Care (TFC), which is

one of South Africa’s leading floor care specialists.

The product is styled as being a (genuinely) pen-

etrating concrete stain, because the liquid pen-

etrates into the concrete and a chemical reaction

takes place that permanently changes the colour

of the concrete. It does not peel, crack or flake.

Bringingblandcementfloorstolife!The stain can be applied to old or new cement. The cement

must be unsealed, unpainted and porous, so that the stain

can penetrate and react. Once the stain is applied and penetrates

into the pores of the cement, the metallic salts in an acidic water-

based solution react with the calcium hydroxide (free lime) in the

hard cement and yield insoluble permanent colours.

Coolcrete stain is available in four colours, namely: Riverstone

(brown), Cobblestone (gold), Limestone (green), and Soapstone

(blue) and is presented in 1-litre, 5-litre and 25-litre packs.

The stain works very well as a stand-alone decorative finish or it

blends effectively with natural finishes such as sandstone, slate,

travertine and marble.

One of the many advantages of this product is that you are lim-

ited only by your artistic flair, because the colours may be used

together to create any type of pattern or shade. Your cement

floor will be seen to be beautiful, like never before.

The use of Coolcrete has clear advantages for several reasons.

For example, TFC knows and understands porous flooring sub-

strates, and thus has provided a performance-tested product.

The stain will be protected by tried-and-tested TFC sealers, thus

providing stain resistance and longevity.

The product is aimed at the DIY consumer, and thus is pro-

duced to be very user-friendly, plus the fact that it is a very

cost-effective decorative application that provides a fashionable,

natural choice of finish.

Coolcrete is available nationally through all TFC distribution

centres, which means that it is readily available anywhere. This

also means that the product is backed by the TFC support infra-

structure and experience.

Tile and Floor Care

Tel: 011 822 6901

Toll-free: 0800 00 6173

Fax: 011 822 6902

Website: www.tfc.co.za

P r o d u c t s & S e r v i c e s

2�F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

�0

P r o d u c t s & S e r v i c e s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

P r o d u c t s & S e r v i c e s

�1F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

ProtectionofyourfloorsstartsoutsideTwenty years ago, access matting options were

pretty well cut-and-dried with only a couple of

varieties to choose from. Today, improved tech-

nologies, extended durability and improved func-

tionality have been incorporated into the variety of

access matting types now available.

Traditionally, there are vast reasons why a facility manager

would consider implementing a matting system. Some might

consider it a safety factor or use mats to display logos, while others

comment that mats are a necessity that help improve cleanliness

throughout the facility. In reality, there is no one right reason why

matting is important. There are actually a variety of benefits to its

implementation.

High-performance matting systems help to stop dirt and water at

the door, minimise the tracking of soil and water into the facility, and

protect floors, as well as providing a safe surface that is slip-resistant.

Reduction of fatigue is also a factor which is often overlooked.

Picking up dirt can be a nuisance. It can also be pricey. By install-

ing a suitable matting system, the cost of manpower and need for

cleaning chemicals are reduced.

It takes just one phone call to Matco – one of South Africa’s fore-

most experts on all types of access matting – to get the informa-

tion you need on the style of matting you require – based on the

volume and type of foot traffic expected. In addition, location of

access matting plays a very important role.

The answers to these questions will determine what type of mat-

ting is required, as well as whether the matting needs fitting into a

recessed well or laying on a prepared surface. In this latter case it

is important to use bevelled edging to keep the mat in place and

reduce the risk of tripping. However, mats laid in recesses have three

times the lifespan of a loose-laying mat, and never get misplaced.

Matco is an importer and manufacturer of matting for all applica-

tions, with a knowledge of matting coupled with years of experi-

ence and an extensive sales programme that has been the core of

the company’s success in meeting any entrance matting require-

ment – selecting the right size, the correct materials, and the per-

fect installation techniques to keep the flooring looking as good as

when it was first specified.

Matco Marketing

Tel: 011 452 7961

Fax: 011 452 7965

E-mail: [email protected]/[email protected]/

Website: www.matcomarketing.co.za

Nexus (the commercial division of Belgotex

Floorcoverings) is currently supplying a total

of approximately 7 000m² of custom-made

Shadow SDX floor tiles for the refurbishment of

African Bank in Midrand.

Custom-madetilesforAfricanBank

In collaboration with the experienced Custom-X design team from

Nexus, Lily Theron of African Bank was able to create a nylon car-

pet tile that represents a significant change from the needlepunch

tiles previously used.

Emphasising the merits of Nexus Custom-X designs, marketing

services manager Helen de Villiers says, “Flooring is a fundamental

element to define your style – it communicates the company philos-

ophy and reflects the corporate identity, so it should entail collabo-

ration between client and designer to marry performance demands

with design imperatives.”

“We’ve noticed a definite move towards modular carpet tiles

where broadloom carpets once accounted for 60-70% of sales,”

noted Frank Moffat, CEO of Belgotex Floorcoverings.

“Architects, designers and consequently clients are more confident

about moving away from trusty needlepunch ranges to more excit-

ing tufted tiles,” he added.He attributes this trend to improvements

in both yarn technology and greater colour and design possibilities

Incorporating a subtle geometric square design, Shadow SDX pro-

vides an excellent choice for heavy commercial applications such

as this project, where the need to disguise soiling is essential to the

purchasing decision.�2

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

P r o j e c t s

Nexus (division of Belgotex Floorcoverings)

Tel: 033 897 7500

Fax: 033 897 7700

E-mail: [email protected]

upgrading project.”

Informed by international design trends, the plush comfort and

variety of Nexus’ stock or specially tailored carpet designs (Custom-

X) are well suited to the creation of a hushed warmer atmosphere

that will stand up to the rigours of commercial and industrial

applications.

Modular tiles from Nexus allow the replacement of worn pathways

without affecting the rest of the room. Colour-matching concerns

are a thing of the past with the development of exacting colouring

techniques and advanced SDX fibre technology that allows a fabu-

lous variety of subtle and bold patterned carpets that effectively

hide soiling.

High-traffic areas such as entrance halls or passages need durable

carpets. Nexus offers a variety of fashionable or traditional colour-

ways, patterned or plain, and textures that can be combined for

dramatic effect or matched to any corporate identity.

The SDX carpet ranges are stainproof needing only a mixture of

50% bleach and 50% water to remove the most stubborn of stains

that occur in an office environment returning them to their original

condition and with simple vacuum cleaning, it is all the mainte-

nance normally required.

Made from 100% Stainproof SDX (Solution-Dyed Nylon) fibres

which means that they are both stain-proof and UV-resistant, these

50cm x 50cm tufted level-loop-pile tiles are of Heavy Commercial

grading, and incorporate a NexBac backing system.

NexBac is a premium, multi-layered, bitumen-based backing sys-

tem developed specifically for tiles, combining superb dimensional

stability with superior lay-flat characteristics, and eliminating fray-

ing, buckling and bending in tile installations.

“We selected a durable, attractive finish in black and tan for use

throughout the building that achieves the result we were looking

for,” says the Revamp Team of African Bank, “and we are confident

that this will provide us with excellent service for at least another

seven years.”

The installation of the new floor is under the initial contract of

Linka Flooring, who also had the task of stripping out the old Berber

Point tiles previously used. “We then prepared the subfloor to

accept the Shadow SDX tiles, which are being installed using a pres-

sure-sensitive adhesive,” says Linka Flooring’s managing director,

Denis Peche.

Linka has been in operation for ten years, based in the 5-Star

Business Park in Honeydew and, although the company has worked

with Nexus before, this is its first contract for African Bank.

It was planned that the installation of new tiles throughout the

entire building should be achieved with a minimum of disruption

to the existing operation – about a third of the floor area has been

installed already, with the work still proceeding.

Mark Orton of Nexus Johannesburg says, “This installation is

going well and, as the largest carpet manufacturer in the Southern

Hemisphere – with a factory that is certified and compliant with ISO

9001 and ISO 14001 – Belgotex Floorcoverings and Nexus are proud

that African Bank has selected our product for this prestigious

P r o j e c t s

��F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

�4

P r o j e c t s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

One of the wonderful aspects of this

home is its natural character, which

is defined by the Table Mountain

Sandstone on the walls. This was

handcrafted by the original builder.

The sandstone forms a magnificent

backdrop to the living areas.

Abeautifulhome castinstone

Flow and form were extremely important

as the owner wanted to create a tranquil

space where he could come home to relax and

unwind. Quartz Carpet’s seamless, uncomplicat-

ed flow provided the perfect solution as it could

also accommodate the underfloor heating.

However, another reason for this flooring

choice was that Quartz Carpet was able to

accommodate and flow into the non-uniform

edges of the sandstone walls. As the family had

young children, the floor also needed to be

soft, stain-resistant, durable, hygienic and easy

to clean and maintain.

The original home had slate floors, but

because of the visual heaviness of the stone

walls, the flooring needed to be a lighter, more

modern and uplifting material to complement

and contrast.

Jeremy Stewart from Quartz Carpet says, “The

home has a definite Eurocentric feel, but with

a touch of Africa infused. It has a warmth that

makes you want to stay inside just that little bit

longer.”

Quartz Carpet

Tel: 086 178 2789

Fax: 021 7974743

Website: www.quartzcarpet.co.za

UniquefloorcoveringsforoysterBoxrefurbishment

Having undergone a major refurbishment that

took over two years to complete, the celebrated

Oyster Box Hotel in Umhlanga now boasts over

400m² of Synergy bamboo floor provided by

Teragren South Africa, installed with the use of

Elastilon Strong self-adhesive underlay.

Formed in 1994, Teragren is a US-based manufacturer of fine

bamboo flooring, panels and veneers, and its Synergy strand-

woven bamboo flooring with Xcora technology is manufactured

in a process that fuses bamboo fibres with an environmentally

safe adhesive under extreme pressure to form homogeneous,

high-density sheets that are sliced and milled into flooring planks.

As a result, Synergy technology is much harder than red oak,

�6

P r o j e c t s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

making it perfect for high-traffic areas in both residential and com-

mercial settings. Synergy is also FloorScore-certified, one of the most

rigorous air quality standards in the world.

Of the four distinctive blends of bamboo strands available,

Chestnut colour was used for this project.

Elastilon Strong underlay is marketed in South Africa by Suntups,

and this patented revolutionary peel-and-stick membrane has a per-

manently elastic cross-linked, closed-cell polyethylene construction

with a non-toxic, self-adhesive upper surface that bonds directly with

the hardwood, creating a solid, inseparable floor – making it ideal for

use with bamboo flooring.

While sealing the underside of the boards, Elastilon allows for

natural expansion and contraction inherent in hardwood floors with

humidity changes, which helps to eliminate cupping.

This project was completed under the control of y2k Architects in

conjunction with Giuricich Bros, the main contractor, and highlights

the successful installation of two quality branded products in a 5-Star

beachfront hotel environment, where the floor enhances the overall

ambience of the décor and caters for the high-traffic requirement.

Teragren South Africa Elastilon South Africa

Tel: 082 928 0393 Tel: 011 610 1700

P r o j e c t s

�7F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

AddinglustretoconcretefloorsAlthough Concrete Laser Flooring in Durban has

only been in existence for a little over three years, it

has already established a firm reputation for quality

workmanship and attention to detail.

These are the qualities that have already enabled CLF KZN to suc-

cessfully complete many major projects – including the exten-

sive polishing of concrete floors at Moses Mabhiba Stadium, Moses

Mabhiba People’s Park, and the Orchidea Hotel in Johannesburg.

The work carried out at the iconic Moses Mabhida Stadium – built

to accommodate 70 000 spectators at matches for the FIFA 2010

Soccer World Cup – entailed CLF KZN completing 10 000m² of con-

crete polishing in front of the retail area. Concrete polishing was also

used as the preferred method of aesthetic finish on the recent beach

front promenade upgrade including 2km of precast covers, 7000m² of

concrete bands and 1 000m² at the new restaurants.

At the adjacent Moses Mabhida People’s Park, CLF KZN were respon-

sible for placing and polishing over 24 000m² of concrete surface

beds. 12 000m² track around two football fields – a total length of 1,1

kilometres were placed to falls and densified to withstand the high

amount of foot traffic.

“By placing and polishing the concrete ourselves we eliminate split responsibilities and achieve an optimum aesthetic finish,” says CLF

KZN director Nic de Carvalho. “On these projects it also enabled us

to provide a consistent high quality and to meet the extremely tight

time constraints.”

Internal floors are placed using the laser screed method in areas

exceeding 2 000m² per day, and this wide-area pour method ensures

that far fewer construction day joints are required on any project.

The CLF KZN branch provides a professional, high-quality concrete

placing and polishing service throughout South Africa, and one of its

recent successful contracts was completed at the Orchidea Hotel in

De Korte Street, Braamfontein, Johannesburg.

As part of the ongoing Johannesburg CBD refurbishment pro-

gramme, Southpoint Properties renovated this hotel, creating 60

rooms, and renamed it The Lamunu Hotel. On this project CLF KZN

polished and dyed the floor, thus allowing the architect/designer to

add a creative touch to the polished concrete.

“In applications such as this, the concrete can either be dyed during

the polishing process or an integral colour concrete can be used as

was the case for the Moses Mabhiba commuter station, depending

on the design requirements,” says De Carvalho.

“Polished concrete is an exceptionally functional floor; it is harder

and stronger than other floor finishes, and in comparison with

unfinished concrete it has 40% more abrasion resistance, 20% better

impact resistance, and a 30% increase in ambient light reflection.”

“It also provides a more level surface, lower maintenance cost with

less wear and tear on cleaning equipment, and lower lifecycle costs

based on the cost of the initial installation,” De Carvalho concludes.

Concrete Laser Flooring (CLF) Durban

Tel: 011 323 2900 Tel: 031 705 2388

Fax: 011 823 2103 Fax: 031 705 1614

E-mail: [email protected] Email: [email protected]�8

P r o j e c t s

F L O O R S o c t o b e r N o v e m b e r 2 0 1 0

Concrete Laser Flooring was established in

Johannesburg during 2004. Following its success

in providing quality industrial flooring from its

Gauteng base, together with the acquisition of

Norton Construction products that enabled CLF to

provide an exceptional turnkey service for new or

the renovation of existing floors – it was a natural

step to offer these services in KwaZulu-Natal with

the opening of a facility in Pinetown.

Qualityconcreteflooringandpolishingthe Moses Mabhiba Stadium and the adjacent People’s Park (a total

of over 36 000m²); the successful completion of warehouse flooring

for Pepkor (22 000m²); Unilever (45 000m²), Grindrod (9 000m²); and

Heneways (9 000m²).

CLF KZN director Nic de Carvalho says, “The formation of a branch in

KwaZulu-Natal not only enables the company to provide a full service

in Durban and the coastal areas, but it adds another element to our

overall sales programme, because with the use of state-of-the-art

equipment from various international suppliers, CLF KZN can meet

the increasing demand and any requirement for high-quality polished