Flexure and Shear Design of Corbel Bracket

-

Upload

aquibzafar -

Category

Documents

-

view

234 -

download

0

Transcript of Flexure and Shear Design of Corbel Bracket

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

1/12

http://syaifulsipil96.blogspot.com/ [email protected])

11 - 1

11.1 INTRODUCTION

Corbel or bracket is a reinforced concrete member is a short-haunched cantilever used to support the

reinforced concrete beam element. Corbel is structural element to support the pre-cast structural

system such as pre-cast beam and pre-stressed beam. The corbel is cast monolithic with the column

element or wall element.

This chapter is describes the design procedure of corbel or bracket structure. Since the load from pre-

cast structural element is large then it is very important to make a good detailing in corbel.

11.2 BEHAVIOR OF CORBEL

The followings are the major items show the behavior of the reinforced concrete corbel, as follows :

The shear span/depth ratio is less than 1.0, it makes the corbel behave in two-dimensional

manner.

Shear deformation is significant is the corbel.

There is large horizontal force transmitted from the supported beam result from long-term

shrinkage and creep deformation.

Bearing failure due to large concentrated load.

The cracks are usually vertical or inclined pure shear cracks.

The mode of failure of corbel are : yielding of the tension tie, failure of the end anchorage of the

tension tie, failure of concrete by compression or shearinga and bearing failure.

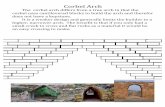

The followings figure shows the mode of failure of corbel.

CHAPTER

11THE FLEXURE AND SHEARDESIGN OF CORBELBRACKET)

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

2/12

http://syaifulsipil96.blogspot.com/ [email protected]

11 - 2

Vu Vu

Vu Vu

Nu

DIAGONAL SHEAR SHEAR FRICTION

VERTICAL SPLITINGANCHORAGE SPLITING FIGURE 11.1 MODES OF FAILURE OF CORBEL

11.3 SHEAR DESIGN OF CORBEL

11.3.1 GENERAL

Since the corbel is cast at different time with the column element then the cracks occurs in the interface

of the corbel and the column. To avoid the cracks we must provide the shear friction reinforcement

perpendicular with the cracks direction.

ACI code uses the shear friction theoryto design the interface area.

11.3.2 SHEAR FRICTION THEORY

In shear friction theory we use coefficient of friction to transform the horizontal resisting force

into vertical resisting force.

The basic design equation for shear reinforcement design is :

un VV [11.1]

where :

Vn = nominal shear strength of shear friction reinforcement

Vu = ultimate shear force

= strength reduction factor (= 0.85)

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

3/12

http://syaifulsipil96.blogspot.com/ [email protected])

11 - 3

Vu

Avf fy

Avf fy

SHEAR FRICTION REINFORCEMENT

ASSUMED CRACKf

FIGURE 11.1 SHEAR FRICTION THEORY

The nominal shear strength of shear friction reinforcement is :

TABLE 11.1 SHEAR FRICTION REINFORCEMENT STRENGTH

VERTICAL

SHEAR FRICTION

REINFORCEMENT

INCLINED

SHEAR FRICTION

REINFORCEMENT

Vn Avf Vn Avf

= yvfn fAV

=

y

nvf

f

VA

=y

u

vff

V

A

( )ffyvfn cossinfAV +=

( )ffyn

vfcossinf

VA

+=

( )ffy

u

vfcossinf

V

A+

=

where :

Vn = nominal shear strength of shear friction reinforcement

Avf = area of shear friction reinforcement

Fy = yield strength of shear friction reinforcement

= coefficient of friction

TABLE 11.2 COEFFICIENT OF FRICTION

METHODCOEFFICIENT OF FRICTION

Concrete Cast Monolithic 1.4

Concrete Placed Against Roughened

Hardened Concrete 1.0

Concrete Placed Against unroughened

Hardened Concrete0.6

Concrete Anchored to Structural Steel 0.7

The value of is :

= 1.0 normal weight concrete

= 0.85 sand light weight concrete

= 0.75 all light weight concrete

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

4/12

http://syaifulsipil96.blogspot.com/ [email protected]

11 - 4

The ultimate shear force must follows the following condiitons :

( ) db'f2.0V wcu

( ) db50.5V wu

[11.1]

where :

Vu = ultimate shear force (N)

fc = concrete cylinder strength (MPa)

bw = width of corbel section (mm)

d = effective depth of corbel (mm)

11.3.3 STEPBYSTEP PROCEDURE

The followings are the step by step procedure used in the shear design for corbel (bracket), as

follows :

Calculate the ultimate shear force Vu.

Check the ultimate shear force for the following condition, if the following condition is not achieved

then enlarge the section.

( ) db'f2.0V wcu

( ) db50.5V wu

Calculate the area of shear friction reinforcementAvf.

VERTICAL

SHEAR FRICTION

REINFORCEMENT

INCLINED

SHEAR FRICTION

REINFORCEMENT

Vn Avf Vn Avf

= yvfn fAV

=

y

nvf

f

VA

=y

u

vff

V

A

( )ffyvfn cossinfAV += ( )ffy

nvf

cossinf

VA

+=

( )ffy

u

vfcossinf

V

A+

=

The design must be follows the basic design equation as follows :

un VV

11.4 FLEXURAL DESIGN OF CORBEL

11.4.1 GENERAL

The corbel is design due to ultimate flexure moment result from the supported beam reaction Vuand

horizontal force from creep and shrinkage effect Nu.

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

5/12

http://syaifulsipil96.blogspot.com/ [email protected])

11 - 5

hd

mind/2

Nuc

Vu

a

FIGURE 11.2 DESIGN FORCE OF CORBEL

11.4.2 TENSION REINFORCEMENT

The ultimate horizontal force acts in the corbel Nucis result from the creep and shrinkage effect of the

pre-cast or pre-stressed beam supported by the corbel.

This ultimate horizontal force must be resisted by the tension reinforcement as follows :

y

ucn

f

NA

=

[11.2]

where :

An = area of tension reinforcement

Nuc = ultimate horizontal force at corbel

fy = yield strength of the tension reinforcement

= strength reduction factor (= 0.85)

Minimum value of Nucis 0.2Vuc.

The strength reduction factor is taken 0.85 because the major action in corbel is dominated by shear.

11.4.3 FLEXURAL REINFORCEMENT

dh

aNuc

Vu

Ts

Cc

a

jd

FIGURE 11.3 ULTIMATE FLEXURE MOMENT AT CORBEL

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

6/12

http://syaifulsipil96.blogspot.com/ [email protected]

11 - 6

The ultimate flexure moment Muresult from the support reactions is :

( ) ( )dhNaVM ucuu += [11.3]

where :

Mu = ultimate flexure moment

Vu = ultimate shear force

a = distance of Vufrom face of column

Nuc = ultimate horizontal force at corbel

h = height of corbel

d = effective depth of corbel

The resultant of tensile force of tension reinforcement is :

yff fAT = [11.4]

where :

Tf = tensile force resultant of flexure reinforcement

Af = area of flexure reinforcement

fy = yield strength of the flexure reinforcement

The resultant of compressive force of the concrete is :

( )= cosba'f85.0C cc [11.5]

where :

Cc = compressive force resultant of concrete

fc = concrete cylinder strength

b = width of corbel

a = depth of concrete compression zone

The horizontal equilibrium of corbel internal force is :

scTC0H

==

( ) yfc fAcosba'f85.0 =

( )=

cosb'f85.0

fAa

c

yf

[11.6]

The flexure reinforcement area is :

=

2

adf

MA

y

uf

[11.7]

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

7/12

http://syaifulsipil96.blogspot.com/ [email protected])

11 - 7

( )

=

2

cosb'f85.0

fA

df

MA

c

yf

y

uf

Cos value can be calculated based on the Tan value as follows :

a

jdTan =

[11.8]

where :

a = distance of Vufrom face of column

jd = lever arm

Based on the equation above we must trial and error to find the reinforcement areaAf.

For practical reason the equation below can be used for preliminary :

( )jdfM

Ay

uf =

( )d85.0fM

Ay

uf =

[11.9]

where :

Af = area of flexural reinforcement

Mu = ultimate flexure moment at corbel

fy = yield strength of the flexural reinforcement

= strength reduction factor (= 0.9)

d = effective depth of corbel

11.4.4 DISTRIBUTION OF CORBEL REINFORCEMENTS

a

dh

Vu

Nuc

(2/3)d

23Avf+AnAs=

Avf3

Ah= 1

FRAMINGREBAR

d(2/3)d

Ah= Af21

REBARFRAMING

aAfAs= +An

Vu

Nuc

CASE 1 CASE 2 FIGURE 11.4 DISTRIBUTION OF CORBEL REINFORCEMENTS

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

8/12

http://syaifulsipil96.blogspot.com/ [email protected]

11 - 8

From the last calculation we already find the shear friction reinforcement Avf, tension

reinforcement An and flexural reinforcement Af. We must calculate the primary tension

reinforcementAsbased on the above reinforcements.

TABLE 11.3 DISTRIBUTION OF CORBEL REINFORCEMENTS

CLOSED

STIRRUPCASE AsPRIMARY

REINFORCEMENTAh LOCATION

1 nvfs AA3

2A + nvfs AA

3

2A += vfh A

3

1A = d

3

2

2 nfs AAA + nfs AAA += fh A2

1A = d

3

2

where :

As = area of primary tension reinforcement

Avf = area of shear friction reinforcement

An = area of tension reinforcement

Af = area of flexure reinforcement

Ah = horizontal closed stirrup

d = effective depth of corbel

The reinforcements is taken which is larger, case 1 or case 2, the distribution of the reinforcements is

shown in the figure above.

11.4.5 LIMITS OF REINFORCEMENTSThe limits of primary steel reinforcement at corbel design is :

y

cs

f

'f04.0

bd

A=

[11.10]

where :

As = area of primary tension reinforcement

b = width of corbel

d = effective depth of corbel

The limits of horizontal closed stirrup reinforcement at corbel design is :

( )nsh AA5.0A [11.11]

where :

As = area of primary tension reinforcement

An = area of tension reinforcement

11.4.6 STEPBYSTEP PROCEDURE

The followings are the step by step procedure used in the flexural design for corbel (bracket), as

follows :

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

9/12

http://syaifulsipil96.blogspot.com/ [email protected])

11 - 9

Calculate ultimate flexure moment Mu.

( ) ( )dhNaVM ucuu +=

Calculate the area of tension reinforcementAn.

y

ucn

f

NA

=

Calculate the area of flexural reinforcementAf.

( )d85.0fM

Ay

uf =

Calculate the area of primary tension reinforcementAs.

CLOSED

STIRRUPCASE AsPRIMARY

REINFORCEMENTAh LOCATION

1 nvfs AA3

2A + nvfs AA

3

2A += vfh A

3

1A = d

3

2

2 nfs AAA + nfs AAA += fh A2

1A = d

3

2

Check the reinforcement for minimum reinforcement.

y

cs

f

'f04.0

bd

A=

( )nsh AA5.0A

11.5 APPLICATIONS

11.5.1 APPLICATION 01DESIGN OF CORBEL

Vu=150000 N

100Nuc

400

200

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

10/12

http://syaifulsipil96.blogspot.com/ [email protected]

11 - 10

PROBLEM

Design the flexural and shear friction reinforcement of corbel structure above.

MATERIAL

Concrete strength = K 300

Steel grade = Grade 400

Concrete cylinder strength = 9.243083.0'fc == MPa

85.01=

DIMENSION

b = 200 mm

h = 400 mm

Concrete cover = 30 mm

d = 370 mm

DESIGN FORCE

150000Vu= N

300001500002.0V2.0N uuc === N

( ) ( ) ( ) ( ) 1590000037040030000100150000dhNaVM ucuu =+=+= Nmm

LIMITATION CHECKING

( ) ( ) 3132423702009.242.085.0db'f2.0 wc == N

( ) 3459503702005.585.0db5.5 w == N

( ) ( ) 345950db5.5313242db'f2.0150000V wwcu =

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

11/12

-

8/12/2019 Flexure and Shear Design of Corbel Bracket

12/12

http://syaifulsipil96.blogspot.com/ [email protected]

11 - 12

SKETCH OF REINFORCEMENT

247

2 LEGS 10

3D16