Finite Element Thermomechanical Analysis of an Exhaust Manifold System of a Diesel Engine for...

-

Upload

altair-engineering -

Category

Technology

-

view

1.641 -

download

7

Transcript of Finite Element Thermomechanical Analysis of an Exhaust Manifold System of a Diesel Engine for...

Finite Element Thermomechanical Analysis

of an Exhaust Manifold System of an

Engine for Automotive Applications

Matteo Giacopini, Roberto Rosi, Simone Sissa

Outline

• Aim and scope of the activity

• Modeling strategy, based on thermal and structural decoupled simulations

• Thermal analysis: gas/solid heat transfer

• Mechanical analysis: thermostructural loading FEM analysis

• Fatigue analysis: energy based LCF criterion

• Conclusions

Aim and scope

The present activity take its bases from some crack propagations that actually have

been observed during engine bench tests. In particular, cracks have been detected in

the region of the manifold bellows:

This activity aims at evaluating the mechanical behaviour of the exhaust manifold

system and at investigating if low cycles fatigue phenomena could be identified as the

reason behind these crack propagations.

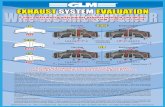

Modeling strategy

Non-linear Finite Element models have been employed to mimic the manifold system

behaviour when subjected to the exhaust gases thermal loading.

Engine Head Interfaces

The modeling strategy developed in this study consists in separated thermal and

mechanical simulations, performed using the commercial Finite Element software

Altair HyperMesh and RADIOSS (Bulk Data Format) solver v12.0.

Engine Block Interfaces

Turbine

Flange Exhaust Manifold

Bellows

Modeling strategy

A model of the bellows alone is then employed to better investigate the mechanical

behaviour of the bellows in the crack regions.

Double layer bellows

Modeling strategy

Particular care has been devoted to the mesh generation process. A uniform

thickness boundary layer has been created on the manifold surface.

Advantage:

1. Better contact detection

2. Optimal surface resolution in stress and strain calculation

Thermal analysis

The thermal analysis is based on a previous CFD 1D-3D coupled simulation of a

whole engine cycle.

Due to high thermal inertia of metals, the instantaneous gas temperatures and heat

transfer coefficients have been cycle-averaged and they have been mapped on the

exhaust system FEM model with an ad-hoc developed fortran routine.

HTC [W/mm2/K]

External surfaces h = 5∙10-5 [W/mm2/K]

T = 60 [°C]

Engine Head T = 170 [°C]

Thermal analysis

Exhaust gases h = mapped from previous CFD simulations

T = 820 [°C]

Thermal boundary conditions:

• Heat transfer coefficient and reference temperatures on external surfaces and

internal surfaces touched by exhaust gases.

• Fixed temperature on the engine head interfaces.

Thermal analysis

Thermal contacts are modeled with CGAP elements and the contact thermal

resistance for closed gap imposed in PGAPHT card is estimated with the Yovanovic

expression for thermal resistance of conforming rough contacts as follow:

where:

𝑘𝑠: thermal conductivity [W/m/K]

𝑚: mean absolute surface slope

𝜎: rms surface roughness [μm]

𝑃: pressure [Pa]

𝐻𝑚𝑖𝑐: microhardness of the softer material in contact [GPa]

𝐴: contact area [m]

𝑛_𝐶𝐺𝐴𝑃 : number of CGAP element involved in contact surface

ℎ𝑠 = 1.25𝑘𝑠

𝑚

𝜎

𝑃

𝐻𝑚𝑖𝑐

0.95

𝐾𝐴𝐻𝑇 =ℎ𝑠𝐴

𝑛_𝐶𝐺𝐴𝑃

Thermal analysis results

Nodal Temperatures

Bellows T = 365 [°C]

Exhaust manifold T = 765 [°C]

Inner tube T = 770 [°C]

Mechanical analysis

The mechanical model consists in a subsequent applying and removal of the

temperature distribution. The aim is to evaluate if some point eventually undergoes a

plastic hysteresis cycle.

Bolt Tightening 1 I Warming 2

I Cooling 3

II Warming 4 II Cooling 5

Mechanical analysis

Bolt tightening F = 22000 [N]

Engine head/block interfaces dof1 = 0 dof2 = 0 dof3 = 0

Engine head/block interfaces dof1 ≠ 0 dof2 ≠ 0 dof3 ≠ 0

Mechanical boundary conditions:

• Fixed zero displacements are applied on the engine head and engine block

interfaces during bolt tightening.

• Displacements evaluated with a previous engine head/block thermomechanical

FEM analysis are superimposed to the model during warming/cooling loadings.

Mechanical analysis

The non-linear temperature-dependent mechanical behaviour of all the materials

involved in the analysis has been considered to carry out plastic strain by simulations.

Mechanical analysis

Due to the high temperatures and to the particular bellows geometry, thermal low

cycle fatigue phenomena could be considered as a possible reason of crack initiation.

The employed approach consists in the computation of the plastic energy dissipated

per cycle at a certain location, whose value can be directly correlated to the low cycle

fatigue life of the component.

Thermal Load History

Plastic Strain/Stress

Hysteresis Cycle

Low Cycle Fatigue

-300

-200

-100

0

100

200

300

-0.08 -0.06 -0.04 -0.02 0 0.02 0.04 0.06 0.08

str

ess [

MP

a]

plastic strain

strass - plastic strain curves

20 °C

250 °C

Mechanical analysis results

403 [MPa]

Displacements

Tmax

377 [MPa]

323 [MPa]

von Mises Stress

Mechanical analysis results

0.01394

0.01449

Plastic strain

Tmax

Tmin

Mechanical analysis results

Plastic strain

0.01113

0.01184

Tmax

Tmin

Mechanical analysis results

Displacements

Mechanical analysis results

Results obtained by the previous whole model analysis show two critical areas

located at the bellows extremities. Therefore, a model of the bellows alone has been

created to better evaluate stress and strain in these regions.

Mechanical analysis results

Displacements previously evaluated on the welded joints at the both sides of the

bellows have been applied to the corresponding nodes of the bellows alone model.

REB2 used to impose global displacements

Mechanical analysis results

Plastic strain-stress curves

Mechanical analysis results

Plastic strain-stress curves

Conclusions

• A thermomechanical analysis has been performed in order to evaluate the

thermomechanical behaviour of an exhaust system;

• First, decoupled thermal and mechanical FEM models have been developed of the

whole exhaust system. Secondly, a mechanical model of the bellows alone has been

introduced to better compute stress and strain in this critical region;

• An energetic LCF criterion based on the plastic dissipated energy per cycle has

been employed in order to rationalise some crack propagations observed in the

bellows during engine bench tests;

• The methodology has been shown to be able to correctly locate the most critical

areas in terms of Low Cycle Fatigue life and it constitutes a valid instrument for future

design optimizations of the bellows geometry.

Thank you for your attention!