Finite Element Analysis using HyperWorks at PWR …...Anti-roll bar is the part of suspension...

Transcript of Finite Element Analysis using HyperWorks at PWR …...Anti-roll bar is the part of suspension...

Finite Element Analysis using HyperWorks at PWR Racing Team for RT07 car

About Team • 65 team members who are students at

Wroclaw University of Science and Technology in Poland,

• 6 departments:

Marketing&Management,

5 Engineering Departments:

• Powertrain,

• Chassis,

• Suspension,

• Electronics.

• Aerodynamic.

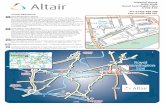

Formula Student 2016

In 2016 we were at three edditions

of Formula Student competition:

FS United Kingdom at Silverstone

FS Germany at Hockenheimring

FS Czech Republic

SILVERSTONE

HOCKENHEIMRING

AUTODROM MOST

2016 Achievements 1st place Acceleration FS Germany

1st place Skid Pad FS Czech Republic

8th place Business Presentation FS Czech

Republic

4th place Autocross FS Czech Republic

1st place Acceleration FS United Kingdom

(combustion class)

5th place Design Event FS United Kingdom

5th place Endurance FS United Kingdom

5th place overall FS United Kingdom

Specification of RT07 • RTO7 is our latest vehicle that competed during FS United Kingdom, FS Germany and FS Czech Republic in 2016

• Significant features and facts:

Weight: 198 kg

Chassis: hybrid construction,

CFRP monoque with steel frame

Engine: Honda CBR600,

Power: 85 KM,

10 inch wheels from forged aluminium alloy,

Self designed attenuator made of honeycomb.

FEA using Altair software • We utilize Altair software in the following types of structural analyses:

Structural static linear,

Structural static nonlinear,

Buckling,

Eigenvalues,

Topological optimization.

Conducted simulations

• Here we are going to show you a few exemplifications of our work using your software.

• The software helps us to get response on vital question during design process if selected element

has capable strength and durability,

• We are conscious that to obtain reliable results we need to achieve lot of knowledge

and engineering experience.

• Given examples were utilized during design FS vehicle RT07.

Rocker • Rocker is used to translate the vertical motion of the

wheel to horizontal motion of the damper and spring. The

rocker is mounted on monoque/frame by bearing (which

is the axis of rotation). Front rockers might be different

than rear.

• Structural static simulation,

• about 40 000 QUAD8 elements,

• Constrained in rotational holes through RBE2s all

DOFs.

Front Rocker

Rear Rocker

• Force coming from pushrod affects on rocker,

• Material: steel

• During simulations plenty of ’manual optimization’

were done and parallel topological optimization.

Front rocker The pictures below show the example of boundary conditions and results of simulations about final model.

Front rocker The pictures below show the results of simulations about selected models wchich were made to choose the best.

Front rocker mount Front rocker mount is made of aluminum. This element is attached to the monoque and maintains rocker

in the correct position.

Rear rocker The pictures below show the example of boundary conditions and results of simulations about final model.

Rear rocker The pictures below show the results of simulations about selected models wchich were made to choose the best.

Front dampers mount Front dampers mount is made of aluminum and attached to the monoque by two 5mm diameter bolts (similar to

front rocker mount). Discrete model is made from TETRA10 elements.

Uprights • Upright is a part that enables located inside on bearings hub to rotate

which transmit this movement on wheel. It is connected by two wishbones

to body of monoqocue and by pushrod to rocker and than CFRP body,

• All uprights are made from Aluminum 7075,

• Discrete solid model is made from 400 000 TETRA10 elements and some

HEX20 elements,

• The solid body is connected to 1D CBAR elements these reflect wishbones

and pushrod (the HyperBeam tool is used). They were constrained on their

free ends.

• There were used RBE2s and RBE3s elements as

connectors of bars and distributors of loads,

• The distributed load is applied via bearing-simulating body

with value respectively to various load conditions,

• Contact between bearing-simulating body and upright is

defined as TIE.

Uprights

Differential Mounting Body

• This part makes for one of differential supports via bearing that is installed in it. What is more it's a part of chain

gear tensioning system.

• Part was subjected to static simulation. Linear static loadstep was chosen.

• Discrete model and boundary conditions:

Discrete model is made from 2nd order tetrahedral elements for bracket and mixed quad & pyramid elements for

bearing,

Element size is 3 mm,

The model was constrained with 2 bar elements: the upper one has TX, TY, TZ, RX, RZ degrees fixed whereas the

lower one allows also movement in z axis,

The distributed load is applied via bearing-simulating body at 22 degree angle to xy plane and parallel to zx plane

(33.84 kN),

Contact between bearing-simulating body and bracket is defined as tied. Friction was ommitted,

Differential Bracket material is Aluminium 7075.

Differential Mounting Body

Discrete model and result of simulation.

Differential Mounting Body

Another side of result of simulation and displaement.

ARB arm Anti-roll bar is the part of suspension

system, which reduces the value of total roll of the sprung mass due to lateral force during cornering or driving on bumpy track. It connects two opposite wheels (there are usually two ARB for front and rear axle each) through lever arms (in our case they are connected to rockers through rods with spherical bearings), which affect the main bar by creating torque. Main bar acts as a torsion spring and by resisting torque it increases (together with force from lever arms being bended) general lateral stiffness of the suspension.

ARB arm Discrete model of ARB and results of simulation. Presented results is loaded by maximum possible force.

The used material is steel.

Mounting of ARB

• Mounting connects anti roll bar

to monocue and its role is to

stabilize vehicle against side

acceleration,

• Structural static simulation,

• Material: Aluminium 7075-T6

• 100 000 TETRA10 elements,

• Constrained on face and two holes

for mounting screw – all DOFs,

• Force in two bores distributed by

RBE2 rigid elements.

Hubs

• Hubs are the elements which connect the wheel, brake disc and upright. Hub and upright are connected

by bearing,

• Front and rear hub can be different because rear hub is driven by driveshaft,

• All hubs are made from Aluminum 7075,

• Discrete solid model is made from 181 500 TETRA10 elements,

• Contact between bearing-simulating body and bracket is defined as tied, friction was ommitted,

• Given examples show the effect of inhibition on stress and displacement

Hubs

• Below you can see the example of discrete model and result of simulation.

• The model was constrained with 2 RBE2s elements that are fixed

• It is loaded by moment

Hubs

• Displacement and another side of result.

Wishbones • Wishbone is the part which connect

wheel (by upright) and monocoque.

It allows wheel to move up and down,

• Wishbones are subjected to a

complex stress state so we need to

do a lot of simulation having regard

to all cases of force,

• Presented example of discrete

model show the lower wishbone

which is exposed to braking.

Wishbones • The result of this simulation show that the most critical places because of stress are the welding places.

Monocoque

• Monocoque is a main part of a race car. It allows to connect suspension and frame with an engine. It

also gives a space for the driver. The most important goal is to provide safety for the driver, so it must be

designed to stand high tensions. The tensions can come from the suspension (mainly during breaking - the

biggest overload) but also could be caused by the variety of impacts. The part should be not only safe but also

fulfil ergonomic features. Monocoque is a composition of carbon fiber and the core, which provides its stiffness.

It contains inserts that enable to connect the whole part with other components, not destroying monocoque at the

same time.

Monocoque • Discrete model:

- Monocoque – QUAD 4 Elements

- Suspension and frame – Bar2 Elements

- Mounts and uprights – RBE2 / RBE3

- Layup from previous year monocoque

• Presented results of simulations apply to the

tensions comes from the suspension.

Monocoque

Displacements and rotations was

compared to previous car with the same

laminate stacking and boundary

conditions to choose best concept for

further optimization.

Monocoque

Composite failure can occur

possible areas, where laminate

orientation or ply thickness

should be changed.

Monocoque Element thicknesses, ply sizes

and shuffle generated in

composite optimization process

where verified at three point

bending test to meet

Formula Student requirements.

Upcoming tasks CFRP wheel analyses,

Improving skills of meshing and topological optimization,

More analysis of assemblies

Dynamic explicit simulation

Numerical optimization of uprights and laminates

Acknowledgment

Thank you so much for your collaboration with our team and for the

whole support presented by you.

We hope we will continue our work together!