FILING - South Carolina

Transcript of FILING - South Carolina

I I() I (1:Ill) s)f'I'(.'I. sllitc ')fl(l

('n)mi)I)i:&. s(: 2')s() I

July 30, 2015

VIA ELECTRONIC FILING

Jocelyn G. Boyd, EsquireChief Clerk & AdministratorPublic Service Commission of South Carolina101 Executive Center Drive, Suite 100Columbia, South Carolina 29210

Re: Application of South Carolina Electric & Gas Company for Approval to Revise Ratesunder the Base Load Review ActDocket No. 2015-160-E

Dear Ms. Boyd:

The South Carolina Offrce of Regulatory Staff hereby encloses our report on SouthCarolina Electric & Gas Company's Annual Request for Revised Rates.

Sincerely,

3 ~~&. H~~Shannon Bowyer Hudson

Enclosure

cc: K. Chad Burgess, EsquireMatthew W. Gissendanner, EsquireJoseph Melchers, Esquire

South Carolina Office of Regulatory Staff

Report on Sout a Carolina Electric 5 Gas Company'sAnnual Request for Revised Rates

Docket No. 2015-260-F

jiggly 30, ZOl5

Table of Contents

Introduction and Background

Revised Rates Background

CWIP Review (3)

Summary of Expenditure Examination Procedures (4)

Detail of ORS Appendix A

Capital Structure

Rate Design and Allocation ofAdditional Revenue (8)

Revenue Verification (8)

ORS's Review of SCE&G's Quarterly Reports

Approved Schedule and Budget Review

(9)

(9)

Conclusions (10)

Appendices

Appendix A: CWlP through June 30, 2015

Appendix B: Capitalization Ratios and Cost ofCapital

Appendix C: Revenue Requirement

Appendix D: ORS's Review ofSCAG's Quarterly Reports

Introduction and Background

Pursuant to the Base Load Review Act ("BLRA"), South Carolina Electric & Gas Company("SCE&G" or "Company") may request to revise rates no earlier than one year after the requestof a Base Load Review Order or any prior revised rates request. In Docket No. 2015-160-E,SCE&G filed its Annual Request for Revised Rates ("Request") with the Public ServiceCommission of South Carolina ("Commission") on May 29, 2015, with an effective date of May30, 2015. The Company states that as of June 30, 2015, it will have invested $596,541,000 inincremental Construction Work in Progress ("CWIP") related to its construction of V.C. SummerNuclear Station Units 2&3 (the "Units" or "Project") that is not reflected in current rates and isrequesting additional retail revenues of $69,648,000 to recover associated financing costs forthe Units.

In accordance with the BLRA, the South Carolina Office of Regulatory Staff ("ORS") hastwo months to review SCE&G's Request and file a report with the Commission indicating theresults of its examination. ORS's review of SCE&G's Request focuses on the Company's abilityto adhere to the requirements of the BLRA and applicable Commission Orders. This reportdetails the results of ORS's examination.

On March 2, 2009, the Cominission approved SCE&G's request for the construction ofthe Units under the Engineering, Procurement and Construction ("EPC") Contract withWestinghouse Electric Company and CB&I Stone & Webster, Inc. (collectively "theConsortium"). The Commission's approval of the Units can be found in the Base Load ReviewOrder No. 2009-104(A) filed in Docket No. 2008-196-E.

Subsequent to the Base Load Review Order, the Commission has held three (3) hearingsregarding the Units and issued the following Orders:

: Issued on January 21, 2010 and filed in Docket No. 2009-293-E.The Commission approved the Coinpany's request to update milestones and capital costschedules.

: Issued on May 16, 2011 and filed in Docket No. 2010-376-E. TheCommission approved SCE&G's petition for updates and revisions to schedules relatedto the construction of the Units which included an increase to the base project cost ofapproximately $174 million.

d : Issued on November 15, 2012 and filed in Docket No. 2012-203-E. The Coinmission approved SCE&G's petition for updates and revisions to schedulesrelated to the construction of the Units which included an increase to the base projectcost of approximately $278 million.

Revised Rates Review 2015 Pagel1

The anticipated dependable capacity from the Units is approximately 2,234 megawatts("MW"J, of which 55% (1,228 MWJ will be available to serve SCE&G custoiners. South CarolinaPublic Service Authority ("Santee Cooper") is currently contracted to receive the remaining45% (1,006 MWJ of the electric output when the Units are in operation and is paying 45% ofthe costs of the construction of the Units. In October 2011, SCE&G and Santee Cooper executedthe permanent construction and operating agreements for the Units. The agreements grantSCE&G primary responsibility for oversight of the construction process and operation of theUnits as they come online. On March 30, 2012, the Nuclear Regulatory Commission voted toissue SCE&G a Combined Construction and Operating License ("COL") for the construction andoperation of the Units.

In 2010, SCE&G reported that Santee Cooper began reviewing its level of ownershipparticipation in the Units. Since then, Santee Cooper has sought partners in its 45% ownership.Santee Cooper signed a Letter of Intent with Duke Energy Carolinas, LLC in 2011. On January28, 2014, Duke Energy Carolinas, LLC filed a report with the Commission stating that itconcluded its negotiations with Santee Cooper which resulted in no change in ownership of theUnits. On the day before, January 27, 2014, SCE&G announced that it had an agreement toacquire from Santee Cooper an additional 5% (110 MWs) ownership in the Units. Theagreement is contingent upon the Commercial Operation Date of Unit 2. Ultimately, under thenew agreement, SCE&G would own 60% and Santee Cooper would own 40% of the Units. Thenew agreement and the specific terms are subject to Commission approval. The Units continueto be governed by the ownership responsibilities as established in the EPC Contract.

Revised Rates Background

Pursuant to the BLRA, until a nuclear plant commences commercial operation, the rateadjustments related to the Units include recovery only of the weighted average cost of capitalapplied to the outstanding balance of CWIP, and shall not include depreciation or other itemsconstituting a return of capital to the utility.

The BLRA allows SCE&G to choose the date on which to calculate the outstandingbalance of CWIP. SCE&G utilized the CWIP balance forecasted as of June 30, 2015. Exhibit C ofthe Request sets forth the capital structure and weighted average cost of capital. Exhibit D ofthe Request sets forth an increase in retail rates totaling $69,648,000. It also shows theincremental CWIP balance for the Units, as of June 30, 2015 — which is not reflected in currentretail rates — of $596,541,000. The Company's Request shows the total CWIP for the Unitsforecasted, as of June 30, 2015, to be approximately $3.267 billion.

Revised Rates Review 2015 Page l2

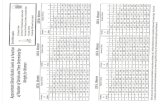

Table 1 shows the requested and approved increases from all prior Revised Rate Filingsfor the Units with the Commission.

Table 1:

SCE&G Revised Rates History

I)() ckctN().

() I'(lcr

N()

kc(locate(lI 11 c I

' ' s c

S ()RS 0I: X '1111111 'I I I () )I

Al)pl'()vc(l

Il)cl c;IscltCtl) i I

lllcl'C IsC

it() tcsI;Iieet lvc

2008-196-E 2009-104(A) $8,986,000 ($ 1,183,509) $7,802,491 0.43%

2009-211-8 2009-696 $22,533,000 $0 $22,533,000 1.100%%d

2010-157-E 2010-625 $54,561,000 ($ 7,260,000) $47,301,000 2.310%%d

4/1/2009

10/30/2009

10/30/2010

2011-207-E 2011-738 $58,537,000

2012-186-E 2012-761 $56,747,000

($5,753,658) $52,783,342 2.430%%d 10/30/2011

($4,598,087) $52,148,913 2.33%0 10/30/2012

2013 150 E 2013 680(A) $69 671 000 ($2 430 768) $67 240 232 2 870AI 10/30/2013

2014-187-E 2014-785 $70,038,000 ($3,800,000) 66,238,000 2.82% 10/30/2014

2015-160-E TBD $69,648,000 ($5,122,719) TBD TBD 10/30/2015

CWIP Review

ORS's examination was limited to the actual CWIP reported for the review period of July1, 2014, through June 30, 2015 ("Review Period") together with the associated revenuerequirement and Allowance for Funds Used During Construction ("AFUDC") calculations. As

agreed to by the Company and ORS, the June 2015 CWIP activity presented for recovery, andreviewed by ORS, was limited to accrued charges under the EPC contract. Likewise, no AFUDC

charges for June were presented or reviewed. The ORS Audit Department reviewed only actualcosts and did not examine or otherwise test any of the Company's projected results. The resultsof ORS's examination of the Request and the underlying financial records through June 30, 2015,are contained in Appendix A.

Revised Rates Review 2015 Page l3

The purpose of the ORS Audit Department's examination was to verify that:

~ The actual capital expenditures reflected in the Company's tiling were complete, accurate,and supported by the books and records of the Company;

~ The actual costs incurred were properly allocated between SCE&G and its co-owner,Santee Cooper, and accurately assigned to the cost categories set forth in the Request;

~ The Company's gross cost of capital as of June 30, 2015 was calculated accurately andsupported by the books and records of the Company; and

~ The Company's calculations of the AFUDC were accurate and properly reflected in theCWIP balance at May 31, 2015.

Su ary of Expenditure Examination Procedures

The key audit steps performed are summarized below:

~ Interviewed key accounting personnel within SCE&G New Nuclear Deployment, andreviewed the audit work papers from the prior request to examine existing processes,and gain an understanding of any changes in the accounting team or new processesbeing performed.

~ Toured the construction facility periodically during the Review Period to provide ORS

with a visual frame of reference in conducting its examination.

~ Obtained invoice-level listings of all charges to CWIP through May 31, 2015 of theReview Period, and of EPC accrued charges for June 2015.

~ Selected samples of invoice and journal entry items to test in detail, including inter-departmental cross-charges. Verified the mathematical accuracy of sampled invoicesand related support, and verified that each was incurred during the Review Period.

~ Ensured that the nature of each sample expenditure appeared to relate to the Project,and that the amounts in question appeared reasonable.

~ Analyzed the gross cost of capital rate.

Revised Rates Review 2015 Page I4

~ Scrutinized the CWIP expenses under the EPC contract ("EPC Items") to ensure thecharges were approved by Company management prior to booking, and were codedinto the appropriate construction cost categories as set forth in the Request. Basecharges invoiced by the EPC vendors were verified against the EPC contract, andescalation amounts were recalculated for accuracy using the appropriate inflationindices.

~ Obtained from the Company certain roll-forward and trend schedules; tested them toensure the ending CWIP balance from June 30, 2014, together with incremental costsincurred during the Review Period, supported the reported balance at June 30, 2015, intotal and by cost category.

~ Verified that invoice items were accrued in the month incurred.

~ Determined that the ending CWIP totals for each month reconciled properly to generalledger detail. For the quarter-end balances, ensured they agreed with the Company'spublished Schedules 10-Q, as filed with the United States Securities g. ExchangeCoinmission ("SEC") and with Form 1, as filed with the Federal Energy RegulatoryCommission.

~ Verified a sample of items from each month to ensure that payment had actually beenmade to the vendor by examining bank drafts and wire transfer acknowledgements.

~ Traced each invoice item to the PeopleSofto payment vouchers, ensuring that requiredapprovals were present. Also traced the EPC Items to internal approval sheets signedby construction management.

~ Performed a test of payroll costs charged to the Project, noting that einployees'rosspay was supported by the payroll department records, that their time appeared to beproperly allocated to the Project, and that charges reconciled to the general ledgerdetaiL

~ Recalculated the AFUDC for the test year using actual CWIP expenditures in lieu of theprojected amounts reflected in the Request. Total AFUDC of $24,246,000 wascalculated for the period under examination.

Revised Rates Review 2015 page j5

Detail of ORS Appendix A

Revenue Requirement and CWIP through June 30, 2015

Appendix A shows the CWIP included in rates as of June 30, 2014, incremental additionsto CWIP and AFUDC for the Review Period, and total CWIP as of June 30, 2015. Appendix A isdesigned to reflect "Revised Rates Filing" projected CWIP as coinpared to both the "Actual"

CWIP per book atnount, and the maximum "Allowable" CWIP. All amounts presented onAppendix A reflect the Company's portion after applying the allocation to Santee Cooper.

Colutnn (A) reflects Revised Rates Filing CWIP through June 30, 2015, of$ 3,267,493,000 and an adjusted net incremental CWIP for the Review Period of $596,541,000.Utilizing the resulting increase in the CWIP balance and the projected gross cost of capital,SCE&G's projected incremental revenue requiretnent per the Request was $ 72,002,000 in total,or $69,648,000 after applying the retail allocation factor of 96.73%.

Column (8) presents Actual CWIP through June 30, 2015, as verified by ORS

examination, totaling $3,218,588,000. Incremental Actual CWIP for the Review Period was$ 551,745,000 before removing deferrals of $ 52,000 related to the COL Delay Study, and$4,468,000 related to Costs Pending Approval in Docket No. 2015-103-E. Total adjustedincremental CWIP for the Review Period is $547,225,000.

Column (C) reflects the Allowable CWIP through June 30, 2015, computed as$3,218,587,000 which includes removal of non-allowable expenditures. Incremental AllowableCWIP for the Review Period was $ 547,224,000 net of previously discussed deferrals. Utilizingthe resulting increase in the CWIP balance and the gross cost of capital, the incremental,allowable revenue requirement is $66,707,000 in total, or $64,526,000 after applying the retailallocation factor of 96.73%.

Column (D) calculates the differences between Columns (A) and (B). The difference inincremental CWIP shown in the Revised Rates Filing figures versus the Actual column was$49,316,000 indicating that the actual, audited CWIP, per the Company books, was less than theprojected CWIP by that amount.

Column (E) reflects no costs to be carried over to the next Reporting Period.

Appendix A was prepared in accordance with recognized regulatory accountingpractices and conforms to prior orders of the Commission.

Revised Rates Review 2015 Page l6

Capital Structure

Section 58-33-280(B) of the BLRA states, "a utility must be allowed to recover throughrevised rates its weighted average cost of capital...cakulated as of a date specified in the filing."

Exhibit C of SCE&G's Request shows the capital structure for the Company as of March 31, 2015adjusted for equity transfers and debt issuances planned through June 30, 2015.

The filed capital structure reflects two adjustments to the per-books amounts. An

adjustment of $200,000,000 to Common Equity included in Exhibit C of the Company's filingreflects the projected transfer of additional equity by June 30, 2015 from the parent company,SCANA, to SCEgtG. This transfer occurred. The second adjustment, to Long-Term Debt, reflectsthe issuance of $500,000,000 in bonds anticipated at the time of the tiling that has nowoccurred.

Three subsequent adjustments were not indicated in the filing. First, the embeddedcost of Long-Term Debt changed from 5.63e/e to 5.86e/e due to the effect of the losses oninterest-rate swaps. The second adjustment came from the addition of $39,455,301 inRetained Earnings. A third very small adjustment of $50,768 came from the amortization ofAccumulated Other Comprehensive Income. As a result of the second and third adjustmentsafter the filing, Common Equity rose from $4,886,596,404 to $4,926,102,473.

Appendix B of this report shows the capital structure as filed for March 31, 2015,updated to June 30, 2015 for changes in Long-Term Debt and Common Equity. With CoinmonEquity amounts and Embedded and Average Costs of Long-Term Debt updated, the TotalCapitalization is now $9,354,972,473, the Common Equity Ratio is 52.66e/e, its WeightedAverage Cost is 5.79e/o and its Gross-of-Tax cost is 9.42'/o. The Embedded and WeightedAverage Cost of Long-Term Debt reflect the increase in the cost-rate discussed above. As aresult, the Net of Tax Return on Total Capitalization is 8.57e/o, as opposed to the 8.45'/e that wasfiled, because the Embedded Cost of Debt and the Ratio of Common Equity were higher thanfiled. The Cost of Capital Gross of Tax is 12.19/o, twelve basis points higher than in the filing.As in the 2011, 2012, 2013, and 2014 Requests, the capital structure includes $ 100,000 inPreferred Stock, as SCEIkG filed its capital structure. This is a token amount with a zero costrate, held by SCANA, but with no return, for the purposes of maintaining certain reportingrequirements to the SEC. The Ratios of Long-Term Debt and Common Equity are proportionsof the Total Capitalization, less the $ 100,000 in Preferred Stock.

Revised Rates Review 2015 Page I7

Rate Design and Allocation of Additional Revenue

Section 58-33-270(D) of the BLRA states, "In establishing revised rates, all factors,allocations, and rate designs shall be as determined in the utility's last rate order..." ORS

examined the Company's proposed rate schedules in its Request and found the rate designswere consistent with those approved in the Company's last rate order, which is CommissionOrder No. 2012-951 found in Docket No. 2012-218-E.

Section 58-33-270(D) of the BLRA also requires "... that the additional revenuerequirement to be collected through revised rates shall be allocated among customer classesbased on the utility's South Carolina firm peak demand data from the prior year." ORS verifiedthat the Coinpany used the summer firm peak demand day of August 22, 2014, along with thecoincident class firm peaks, to determine the appropriate percentages upon which to allocatethe additional revenue requirements. The firm peak demand was based on the approved four-hour coincident peak allocation methodology. The appropriate South Carolina retail firmdemand allocation of the system total is 96.73% as shown on Exhibit B of SCE&G's Request.

Revenue Verification

ORS verified that the corresponding approved base rates for 2015 reflect actualrevenues generated in the test year of 2014. ORS then utilized the most recent approved ratesin effect at the time the Company filed its Request to obtain the most current annualized raterevenues. That is, ORS utilized SCE&G's rate schedules effective in May 2015.

Additionally, ORS verified that the proposed revised tariffs in Exhibit F of SCE&G's

Request generate additional revenues totaling $69,647,053, which is shown in Exhibit E of theCompany's Request.t ORS's review determined the appropriate retail revenue target increaseto be $64,525,281 instead of $69,648,000 as proposed by the Company and shown in Exhibit D

of its Request. The results of ORS's exainination are shown in Appendix A. ORS's reviewreduced the Company's Request by $ 5,122,719 or 7.36%. The total additional revenues of$64,525,281 allocated by class are shown in Appendix C. Appendix C also includes the annualrevenues generated under the currently approved rates and the incremental change bycustomer class. Since the general lighting schedules do not contribute to SCE&G's firm peakdemand, those schedules of rates were not affected by the revised rates filing and received noincrease in charges.

'Exhibit G of the Company's Request provides general information based on internal financial reports estimating future revenuerequirements and rate increases. It does not contain information necessary to evaluate the revenue increase being considered in thisfilin . Therefore,ORSdoesnotutilize Exhibitc ofthe Cpm an 'sRe uestinits anal sis and review.

Revised Rates Review 2015 Page I8

It should be noted that it is difficult to set rates to produce precise dollar amounts dueto the general complexity of rate designs of the various tariffs, their interdependentrelationships, and the large number of billing determinants associated with these calculations.The commonly accepted practice is to adjust rates while inaintaining the appropriate ratedesign and generate revenues close to the desired level without exceeding the targetedamount.

Based on ORS's review and a reduction of $ 5,122,719 to the Company's Request, theresulting overall increase to the retail class (excluding lighting) is 2.57%. Residentialcustomers using 1,000 kWhs would see an increase of approximately $3.78 in their averagemonthly bill. If the Commission approves the findings of ORS's examination, the Companywould then apply the reduced revenue amount in like proportion to the Company's Requestusing the above criteria. ORS will then verify that these new rates generate the approvedrevenue increase.

ORS's Review of SCE8cG's Quarterly Reports

As required by the BLRA, SCE&G must include its most recent quarterly report on thestatus of construction of the Units. Accordingly, SCE&G included its 2015 1" Quarter Report("Report"j which was filed on May 15, 2015. The Report is in Commission Docket No. 2008-196-E and covers the quarter ending March 31, 2015. Subsequently, ORS completed andproduced a document describing its review of the Report. ORS's review of the Report isattached as Appendix D. ORS also included in Appendix D its prior reviews of SCE&G's

quarterly reports since the last revised rates request.

With reference to Section 58-33-275(A) of the BLRA, ORS's review of the Company'squarterly reports focuses on SCE&G's ability to adhere to (1) the approved constructionschedule and (2) the approved capital cost schedules. The following information summarizesORS's review of SCE&G's Report:

A ro e Sche 1 andBud R

During the 1" quarter 2015, the project continued to make progress toward thecompletion of several major construction milestones. However, the project continues toexperience delays due to design and delivery issues. The critical path work is centered on Unit2 Nuclear Island work necessary to allow additional concrete pours inside the ContainmentVessel and within the Auxiliary Building perimeter walls. ORS continues to monitor this workclosely.

Revised Rates Review 2015 Page l9

On March 12, 2015, SCE&G filed with the Cominission in Docket No. 2015-103-E aPetition seeking approval to update the construction milestone schedule as well as the capitalcost schedule for the Units. In its Petition, SCE&G is requesting the Commission to modify theconstruction schedule to reflect new substantial coinpletion dates of June 19, 2019 and June 16,2020 for Unit 2 and Unit 3, respectively. SCE&G reports to ORS that the Consortium continuesto experience delays in fabrication and delivery of sub-modules for the Units and that thesedelays are the primary purpose for issuing a Revised Schedule.

This Petition includes incremental capital costs that total approximately $698 million(SCE&G's portion in 2007 dollars); of which $539 million are associated with these delays andother contested costs. The total project capital cost is now estimated at approximately $ 5.2billion (SCE&G's portion in 2007 dollars) or $6.8 billion including escalation and allowance forfunds used during construction (SCE&G's portion in future dollars). The cumulative projectcash flow amount projected to be spent on the Units by December 31, 2015 is $3.7 billion.

The construction schedule and budget presented in SCE&G's Quarterly Report is basedon SCE&G's Petition. Therefore, until the Commission issues an order in response to SCE&G's

Petition, ORS will not have the ability to provide complete updates on the status of theapproved schedule or approved budget.

On June 29, 2015, SCE&G, ORS and the South Carolina Energy Users Committee enteredinto a Settleinent Agreement ("Agreement") related to the Company's Petition. In theAgreement, the parties agree that beginning with any revised rates filing made on or afterJanuary 1, 2016, and prospectively thereafter until such time as the Units are completed,SCE&G will develop and calculate its revised rates filings using 10.5% as the return on commonequity rather than the approved return on common equity of 11%. With the reduction of thereturn on equity from 11% to 10.5%, the total impact is estimated to be approximately $ 15million in savings to ratepayers. The Agreement is filed in Docket No. 2015-103-E and subjectto approval by the Commission.

Conclusions

The purpose of the BLRA is to provide for recovery of financing costs associated withprudently incurred costs of new base load plants when constructed by investor-ownedelectrical utilities, while at the same time protecting customers of investor-owned electricalutilities from responsibility for imprudent financial obligations or costs. ORS reviewedSCE&G's Request, conducted an on-site examination of the Company's books and recordsregarding the Company's capital expenditures, and found the expenditures to be prudentlyincurred.

Revised Rates Review 2015 Page j10

Based on the information reviewed, the additional revenue requested by SCE&G shouldbe reduced by $5,122,719 to reflect actual CWIP through June 30, 2015; and, the appropriaterevenue increase is $64,525,281.

Revised Rates Review 2015 Page l11

South Carolina Office of Regulatory StaffSCERG - 2015 Revised Rates Filing

Construction Work ln Progress (CWIP) through June 30, 2015Docket No. 201 5-160-E

(5 ln lllousonds)

ORS Examination

Cost Ciitcgorics SCE&0 Revised Ciirrv Over toActuiil Allow;ible Diffcrcnceltlitcs Filing

(A) (8) (C) (D) (8)(A-8)

CWIP in Rates as oFJune 30, 2014~$ 2.666,843) ' '

2,666,843 $ 2,666,843 $ - $Per Commission Order Na 2014-785~

547,225 $ 547,224 $

Incremental Actual Additions to CWIP through March 31, 2015 $ 413,264 $ 413,264 $ 413,264 $ - $

Incremental APUDC through March 31, 2015 I $ 20.500 I $ 20,500]I

$ 20,500$ S - $ia.

Incremental Additions to CWIP April 1 through June 30, 2015 163.172 $ 114,235 $ 114,234 $ 48,937

Incremental AFUDC April 1 through June 30, 2015 IS 3,714 jib 3,746/[5 3,746]IS (32)I

5

CWIP as of June 30, 2015 3,267,493 $ 3,218,588 $ 3,218,587 S 48,905

Incremental CWIp before Adjustment I $ 600,650]I

S 551,74JSJ $ 551,744]I

$ 48,905~ I IDeferral of 2/2 of Change Order No. 11(COL Delay Study Costs) (52) $

annnart(F

Removal ofCosts Pending Approval in Docket No. 2015-103-8 I 5 (4057)J

5 (4468) [$ ':,'4468) l 5 x-- 411 lt 5

Incremental CWIP, as adjusted $ 596,541 $ 49,316 $

Cross Cost ofCapital 12.07% 12.19%

Incremental Revenue Requirement 72,002 66,707

Allocation Factor For Retail Operation Nla 96.7395 96.73%

Anocated Retail Revenue Requirement $ 69,648 $ 64,526

'CWIp railccis oas's removal of non-sflowahlc expenditures.

SCEAC's May 30, 2015 Request unlizad projected incremental CWIp amounts. Oas's examination reflects actual incremental CWIp amounts through May 31, 2015, and EpC charges only for June 2015.pending costs include ApunC.

Appendix B

South Carolina Office of Regulatory StaffSCE&G - 2015 Revised Rates Filing

Capitalization Ratios and Cost of CapitalAs of June 30, 2015*Docket No. 2015-160-E

Captial Cost Category A In 0 ti I1 i RatioElnbedded

Cost

~ Weighted ~

Average Cost ofCapital

Gross ofTax

Long-Term Debt $4,428,770,000 47.34%; 5.86% 2.77% 2.77%

Preferred Stock t ~ $100,000 L0.00%, ~ 0.00% 0.00%, 0.00%

Common Equity ~ ~9Z6~02 73 ~66e 11.00%~ 5299n

~Total Capitalization ~Lill~e

* Reflects $500,000,000 Long-Term Debt issuance included in filing and issued on May 15, 2015, anticipated Equity transfers in tiling, nowrealized, in the amount of $200,000,000, and updated Debt Cost and Equity Dollars.

i The Preferred Stock amount is nominal in that it is used for Total Capitalization but not for the calculation of the Ratio Column because ofPreferred Stock's 0.00% Embedded Cost

Appendix C

South Carolina Office of Regulatory StaffSCE&G - 2015 Revised Rates Filing

Revenue RequirementDocket No. 2015-160-E

Rate Class

Residential

Small General Service

Medium General Service 'argeGeneral Service

Retail Total (Excluding Lighting)

Approved Annual ORS ExaminationRevenue Annual Revenue

(A)

$ 1,169,954,845 i $

$ 453,290,834 $

7

l$ 244,548,778 . $

$ 639,309,746 $

) $ 2,507,104,203 ) ) $

654,518,355 $ 15,208,609 2.38%

64,525,2811 0 2.57%2,571,629,484

loci enlcntal lncl'cnlcntalChange Change I

S

(c) (0)(B-A) (C /A)

- "'-'- I '-" 8465,440,944 $ 12,150,110 2.68%

~%1i)Niii)~251,556.195 $ 6.807.417 2.78%

South Carolina Office of Regulatory Staff

Review of South Carolina Electric R. Gas Company's2015 1" Quarter Report on

L

V. C. Summer Units 2 R. 3

Status of Construction

July 30, 2015

Executive SummaryApproved Schedule and Budget Review

(iii)

(iv)

Introduction and Background

Approved Schedule ReviewMilestone ScheduleMajor Structural Modules ("Big Six"j

Specijic Construction ActivitiesNND Training ActivitiesTransmission

(3)(3)(3)(6)(8)(9)

Licensing and Inspection ActivitiesFederal ActivitiesState Activities

(11)(11)(11)

Approved Budget ReviewCapital Costs and Petition Docket No. 2015-103-EAnnual Requestfor Revised Rates

(12)(12)(12)

Additional ORS Monitoring ActivitiesMilestone Invoices

Offsite Visits

(14)

(14)

(14)

Construction ChallengesRevised ScheduleStructural ModulesShield Building PanelsPlant Reference Simulator Software TestingFirst-of a-Kind TestingManufacturing ofMajor EquipmentMain Switchyard Capacitor IssuesLicense Amendment Reviews

Cyber SecurityConstruction Productivity

(15)(15)(15)(16)(16)(16)(17)(17)(17)(17)(17)

Notable Activities Occurring after March 31, 2015NRC Notice of ViolationNRC Special Instructions ResultsPetition SettlementAgreementVVeldable Coupling IssueUnit 3 Completed Milestones

(18)(18)(18)(18)(18)(19)

Appendix A: Big Six Structural Modules

Appendix B: Construction Site Photographs

Appendix C: License Amendment Requests

Appendix D: Change Orders and Amendments

Appendix E: NRC Letter Referencing Notice ofViolations to CB&I

Appendix F: NRC Letter Referencing Special Inspection

Appendix G: SCE&G SettlementAgreement Announcement

Appendix H: Unit 3 Completed Milestones

Appendix l: Acronyms

On May 15, 2015, SCE&G submitted its 2015 1" Quarter Report related to constructionof V.C. Suminer Units 2 & 3 in Jenkinsville, SC. The Quarterly Report is filed in CommissionDocket No. 2008-196-E and covers the quarter ending March 31, 2015. With reference to theBase Load Review Act, ORS's review of SCE&G's Quarterly Report focuses on SCE&G's ability toadhere to the approved schedule and approved budget.

A roe h i evie

On March 12, 2015, SCE&G filed with the Commission in Docket No. 2015-103-E aPetition seeking approval to update the construction milestone schedule as well as the capitalcost schedule for the Units. In its Petition, SCE&G is requesting the Commission to modify theconstruction schedule to reflect new substantial completion dates of June 19, 2019 and June 16,2020 for Unit 2 and Unit 3, respectively. SCE&G reports to ORS that the Consortium continuesto experience delays in fabrication and delivery of sub-modules for the Units and that thesedelays are the primary purpose for issuing a Revised Schedule.

On June 29, 2015 SCE&G, ORS and the South Carolina Energy Users Committee enteredinto a Settlement Agreement related to the Petition. For additional details, see "NotableActivities Occurring after March 31, 2015," on page 18 of this report.

During the 1" quarter 2015, the project continued to make progress toward thecompletion of several major construction milestones. However, the project continues toexperience delays due to design and delivery issues. The critical path work continues to becentered on Unit 2 Nuclear Island work necessary to allow additional concrete pours inside theContainment Vessel and within the Auxiliary Building perimeter walls. ORS continues tomonitor this work closely.

This Petition includes incremental capital costs that total approximately $698 million(SCE&G's portion in 2007 dollars); of which $539 million are associated with these delays andother contested costs. The total project capital cost is now estiinated at approximately $5.2billion (SCE&G's portion in 2007 dollars) or $6.8 billion including escalation and allowance forfunds used during construction (SCE&G's portion in future dollarsj. The cumulative amountprojected to be spent on the Units by December 31, 2015 is $3.7 billion.

The construction schedule and budget presented in SCE&G's Quarterly Report is basedon SCE&G's Petition. Therefore, until the Commission issues an order in response to SCE&G's

Petition, ORS will not have the ability to provide complete updates on the status of theapproved schedule or approved budget.

Introduction and Background

On March 2, 2009, the Public Service Commission of South Carolina ("Commission")approved South Carolina Electric & Gas Company's ("SCE&G" or the "Company") request for theconstruction of V.C. Summer Nuclear Station AP1000 Units 2 & 3 (the "Units" or "Project") inJenkinsville, SC and the Engineering, Procurement and Construction ("EPC") Contract withWestinghouse Electric Company ("WEC") and CB&I Stone & Webster, Inc. ("CB&1") (collectively"the Consortium"). The Commission's approval of the Units can be found in the Base LoadReview Order No. 2009-104(A) filed in Docket No. 2008-196-E.

Subsequent to the Base Load Review Order, the Commission has held three (3) hearingsregarding the Units and issued the following Orders:

: Issued on January 21, 2010 and filed in Docket No. 2009-293-E. The Commission approved SCE&G's request to update milestones andcapital cost schedules.

: Issued on May 16,2011 and filed in Docket No. 2010-376-E. The Commission approved SCE&G's petition for updates and revisions toschedules which included an increase to the base project cost of approximately$ 174 million.

: Issued on November 15, 2012 and filed in Docket No.

2012-203-E. The Commission approved SCE&G's petition for updates andrevisions to schedules which included an increase to the base project cost ofapproximately $278 million.

The anticipated dependable capacity from the Units is approximately 2,234 megawatts("MW"), of which SS% (1,228 MWJ will be available to serve SCE&G customers. South CarolinaPublic Service Authority ("Santee Cooper") is currently contracted to receive the remaining45% (1,006 MW) of the electric output when the Units are in operation and is paying 45% ofthe costs of the construction of the Units. In October 2011, SCE&G and Santee Cooper executedthe permanent construction and operating agreements for the Project. The agreements grantSCE&G primary responsibility for oversight of the construction process and operation of theUnits as they come online. On March 30, 2012, the Nuclear Regulatory Commission ("NRC")

voted to issue SCE&G a Combined Construction and Operating License ("COL") for theconstruction and operation of the Units.

Q1-15 Review Page l1

In 2010, SCE&G reported that Santee Cooper began reviewing its level of ownershipparticipation in the Units. Since then, Santee Cooper sought partners in its 45% ownership.Santee Cooper signed a Letter of Intent with Duke Energy Carolinas, LLC in 2011. On January28, 2014, Duke Energy Carolinas, LLC filed a report with the Commission stating that itconcluded its negotiations with Santee Cooper which resulted in no change in ownership of theUnits. On the day before, January 27, 2014, SCE&G announced that it had an agreement toacquire from Santee Cooper an additional 5% (110 MWs) ownership in the Units. Theagreement is contingent upon the Commercial Operation Date of Unit 2. Ultimately, under thenew agreement, SCE&G would own 60% and Santee Cooper would own 40% of the Units. Thenew agreement and the specific terms are subject to Commission approval and have yet to bepresented to the Commission. The Project continues to be governed by the ownershipresponsibilities as established in the EPC Contract.

On May 15, 2015, SCE&G submitted its 2015 1" Quarter Report ("Quarterly Report")related to construction of the Units. The Quarterly Report is filed in Commission Docket No.2008-196-E and covers the quarter ending March 31, 2015 ("Review Period"). The Company'sQuarterly Report is submitted pursuant to S.C. Code Ann. 5 58-33-277 (Supp. 2014) of the BaseLoad Review Act ("BLRA"), which requires the Quarterly Report to include the followinginformation:

1. Progress of construction of the plant;2. Updated construction schedules;3. Schedules of the capital costs incurred including updates to the information

required in Section 58-33-270(B)(5);4. Updated schedules of the anticipated capital costs; and5. Other information as the Office of Regulatory Staff may require.

With reference to Section 58-33-275(A) of the BLRA, the review by the Office ofRegulatory Staff ("ORS") of the Company's Quarterly Report focuses on SCE&G's ability toadhere to the approved construction schedule and the approved capital cost schedule.

Ql-15 Review Page (2

Approved Schedule Review

On March 12, 2015, SCE&G filed with the Commission, in Docket No. 2015-103-E, apetition seeking approval to update the construction milestone schedule as well as the capitalcost schedule for the Units ("Petition"). In its Petition, SCE&G is requesting the Commission toapprove the revised construction schedule ("Revised Schedule"j which reflects new substantialcompletion dates ("SCDs") of June 19, 2019 and June 16, 2020 for Unit 2 and Unit 3,respectively. SCE&G reports to ORS that the Consortium continues to experience delays infabrication and delivery of submodules for the Units and that these delays are the primarypurpose for issuing a Revised Schedule.

The construction schedule presented in SCE&G's Quarterly Report is based on SCE&G's

Petition. Therefore, until the Commission issues an order in response to SCE&G's Petition, ORSwill not have the ability to provide complete updates on the status of the approved schedule.

or r M 1

The Big Six modules for the Units are CA01 through CA05 and CA20. (See Appendix Afor illustrations). The supply of these modules is specifically identifled in the Fixed/Firm costcategory of the EPC Contract and key components to WEC's modular design of the Units. Table1 and Table 2 provide a summary of the status of the Big Six modules as of the end of thereview period:

Q1-15 Review Page l3

i2B'

Unit 2

Module ¹ ~

CA01

Description

Houses SteamGenerator/

Pressurizer andRefueling Canal

Vendor

CB&l-Lake

Charles, LA

~

SubmodulesReceived

47 of 47

CertificationPa erwork

47 of 47 on Siteand Under

Review

Status

Assemblycomplete

waiting forscheduled on

Hook Date

CA02

CA03

In-ContainmentRefueling Water

Tank Wall and HeatExchanger Wall

ModuleIn-ContainmentRefueling Water

Storage Tank WallModule

CB&I-Lake

Charles

SMCI inLakeland, FL

5of5

1 of 17

PendingBeing

Assembled in

MAB

1 of 17 Pending

CA04

CAOS

CAZO

Reactor VesselCavity

Containment VesselPassive CoolingSystem Tunnel

WallsAuxiliary Buildingand Fuel Handling

Area

CB&I-Power(On-Site)

CB&l-LakeCharles, LA

CB&I-LakeCharles, LA

SofS

Bof8

72 of 72

Complete

Complete

Complete

Set in Placeon 10/21/13

Set in Placeon 12/6/14

Set in Placeon 5/9/14

Ql-15 Review Page l4

ixM es

Unit 3Description

Module ¹Submodulesg

VendorReceived

CertificationPaperwork

Status

CA01

Houses SteamGenerator/Pressurizer andRefueling Canal

Toshiba/IHIYokohama,

Japan2of47 2 of 47 Pending

CA02

CA03

In-ContainmentRefueling WaterTank Wall andHeat Exchanger

Wall ModuleIn-ContainmentRefueling Water

Storage TankWall Module

CB&l-Lake

Charles, LA

SMCI inLakeland, FL

Oof5

0 of 17 Pending Pending

Pending Pending

Reactor VesselCavity

SMCI inLakeland, FL

Sof5 CompleteSet in placeon 6/29/15

CAOS

ContainmentVessel PassiveCooling SystemTunnel Walls

CB&l-Lake

Charles, LA0 of 8 Pending Pending

AuxiliaryBuilding and

Fuel HandlingArea

Oregon IronWorks

Portland, OR

16of72 16 of 72 Pending

Ql ~ 15 Review Page IS

0

Approximately 4000 workers are currently on-site, 3500 Consortiuin (includingsubcontractors) and 500 SCE&G. Major construction activities during the review period arediscussed below by Unit:

The Company reported that the critical path for Unit 2 remains the fabrication of theShield Building ("SB") panels supplied by Newport News Industries ("NNI"). Through the end ofthe 1" quarter, 57 of 167 Unit 2 panels have been received. The secondary critical pathcontinues to be the assembly of module CA01 and construction of the Annex Building. All CA01submodules have been delivered to the site and assembly is underway in the Module AssemblyBuilding ("MAB"). Unit 2 work continued in the Containment Vessel ("CV") with the installationof rebar, embedment plates and electrical conduit in preparation for the placing of layer 3 and4 in the CV base. However, this work is being delayed due to resolution of the weldablecoupling licensing basis code compliance issues that are further discussed in the "NotableActivities Occurring after March 31, 2015," on page 18 of this report.

Work continued on securing CA20 in place with three-quarters of the needed anchorblocks in place. It was noted that the north wall on CA20 needed realignment. This wall wasremoved and was in the process of being realigned.

Module CA05, which forms the chemical and volume control system tunnel and passivecore cooling system walls within the CV was completed and set in place inside the CV.

Assembly of CA22 module, which houses filters for the Reactor Cooling Water System wascompleted and is ready to be set inside the CV.

Work on Unit 2 Nuclear Island ("NI") Auxiliary Building ("AB") continued with theforming of walls to support level 2 and level 3 of the AB. The exterior walls needed to supportbackfilling to begin the erection of the Unit 2 Annex Building were completed and backfillingbegan.

Turbine Building ("TB") work continued with the installation of structural steel andwork on the turbine pedestal. Condenser water boxes and the first section of permanentstairwell were installed. Work continued on installing the Service Water System, CondenserTube Cleaning System, Condensate Draining System, and Condensate Polishing System.

Welding on the CV Ring 1 to the Containment Vessel Bottom Head ("CVBH") continues.The welding of attachment plates and ventilation fittings continued on CV Ring 2. Welding ofthe 3rd and final course of plates for CV Ring 3 has been completed. Assembly began on theplates that will be welded together to form the CV Top Head, which forms the crown on the CV.

Q1-15 Review Page l6

Cooling Tower ("CT") 2A is substantially complete. The installation of rebar andplacement of concrete for the walls of CT 2B continues, with the basin and foundation workcompleted and turned over to the contractor for CT erection. The Pump Basin is ready forinstallation of pumps.

Concrete foundations and walls for the Transformers in the High-Side Switchyardcontinued to be installed. The Company has experienced capacitor failures in the Switchyardand an investigation is underway to determine the cause (under warranty).

The Company reported that the Unit 2 Steam Generators A lk B and the Pressurizerwere received on site. Approximately 85% of the major equipment for Unit 2 has beendelivered. Major equipment is considered as any equipment with a cost of $ 10 million orgreater. Also, the Unit 2 PRHR heat exchanger was returned to the equipment manufacturer toinstall a Supplemental Restraint Bar that was a result of a design enhancement. The SquibValves were redesigned and successfully passed the submergence qualification testing.Additional full flow and functional testing of other components are continuing.

The Company reported the critical path for Unit 3 remains the fabrication of the SB

panels supplied by NNI and continues to run through successful fabrication and setting of CA20followed by the installation and completion of CA01, CA03 and the SB.

~ Rebar work continues in support of the first layer of concrete to be placed above theUnit 3 Nl basemat to form the AB Walls which are in turn the SB foundation. Four of 167SB panels have been delivered to the site from NNI.

~ Four submodules forming CA04 were upended and fit issues are being corrected.~ The installation of rebar and placement of concrete continued for sections of the AB,

and backfill work continued around the exterior of the Nl.~ The first layer of concrete inside the CV is in place.~ Work continued on the assembly of CV Ring 1 and welding of the vertical seams of the

first 3 courses of CV Ring 2 was completed.~ CT 3A is essentially complete. Structural work for 3B CT is approximately two-thirds

complete. Workis underwayfor the Pump Basin for the CTs.~ Placement of fill concrete continued beneath the TB. Rebar, piping and other

embedments were installed in the TB mudmat in preparation for pouring the TBhasemat.

~ The Company reported that the Core Makeup Tanks 1 and 2 were delivered to the siteand that approximately 30% of the Unit 3 major equipment has been delivered to thesite.

Q1-15 Review Page (7

The Company reported that several Information Technology Systems were continuingto progress. The site fiber optic cable system back bone for the Units is complete. TheConfiguration Management Information System ("CMIS") completed two demonstration runs totest CMIS workflow routing. Work Management System is expected to begin module testing inthe second quarter of 2015.

Photographs of construction activities during the review period are shown inAppendix B.

The Company and Contractor conducted Integrated Systems Validation ("ISV") testingin support of developing the Plant Reference Simulator ("PRS"). This testing is required by theNRC to validate the siinulator for use in the Operator Licensing Program. The Company isworking with the NRC to certify their simulator as a Commission-Approved Simulator, ("CAS"),

which will allow the early use of the simulator in the upcoming initial NRC OperatorExaminations. When achieved, the CAS wifl be used to support the licensing of the firstoperator training class scheduled for later in the year.

Q1-15 Review Page l8

J~ggg1~1S 0 1

In 2011, SCE&G entered into a contract with Pike Electric, LLC for the permitting,engineering and design, procurement of material, and construction of multiple transmissionlines and associated facilities related to the Units.

Map 1 shows the new transmission lines and facilities supporting the Units. Thetransmission lines are represented by the corresponding line color indicated below:

Green3i110:VCS1-Killian Line is complete and energized.

EulLinc:VCS2- Lake Murray Line No. 2 is complete and energized.VCSZ-St George Line No. 1 will be energized when the remaining St. George segment(Purple Line) is complete.

P~leliue:VCS2-St. George Lines Nos. 1 and 2 are currently under construction between LakeMurray and St. George. This work will progress through the build out of the SaludaRiver Substation which is scheduled to be completed in August 2015. The remainingsegment will travel from the Saluda River Substation to the St. George switching station,which is scheduled to be complete in June 2016.

Xgllem3~The portion of the VCS2-St. George Line No. 2 segment between VCS2 and the LakeMurray substation is complete.

Blm~g:VCNS Lines to connect Unit 1 Switchyard with Units 2 and 3 Switchyard are completeand energized.

Q1-15 Review Page (9

New SCE&G Transmission Lines and FacilitiesSupporting V.C. Summer Units 2 & 3

Innsboro

vcs2 ~ sL scots e ttee Na 2

L

In M/IIctt t I u ~u oku~Nt'u

~ tts//ISOVSdo d i'' wsusuwttocoeaed I scson eruotttU ItlSWnkyetdautu Itt i

2O Szadu:ky R $ onusy.u rliciti

ususad/d/MM 3 -.

Vcs It/uses ~

Ws1 ~ SIIII U ~

//Iwo obt~

n/Itskvs kueu

/

/Kcrshntv

p/

VCS? - Lake Muney Uoe Na 2e ISCstotzeU/t N Ir

knludn

otnaoat

lakettoeey

/oleNuteySSO/I 15Ieluutk

n Ioytratk»

V Islwn3Je/US kysuleot/I I

Caluwbla.

O Us/I I S IV

S ktott

litchland

~reeds/n

(:nlhuun

1 1ttlon

vcsz.st.a nnunetuut naNo.z I

Or//CKchurb

Ownasbura

VC. Summer Nuclear Station Units 2 & 3r/Nnstnlwlan une Roon lacanans

~ Vest-tOIUNNLtne

M VCS2-tahe Murray Line No. 2 andVCSZ-St. Geotge Une No. 1

VCS2-St. George Lines Nos. 1 and 2 . VCS2-St. George Line No. 2~ VCSNS Lines to Connect Unit 1 Switchyardwith Units 2 and 3 Switchyard

iuwhrrg

r n~st~e.,~tlo kvsead toast

Coiirtwt

D nchoslot

Ql-15 Review Page )10

Licensing and Inspection Activities

SCE&G has identified the need to submit numerous License Amendment Requests("LARs"j to the NRC. A LAR is the process by which a licensee requests changes to the COL

issued by the NRC. The licensee may seek a Preliminary Amendment Request ("PAR") toaccompany a LAR. PARs allow the licensee to continue with construction at its own risk whileawaiting final dispensation of the LAR. The Company filed two new LARs with the NRC and twowere approved. A table of LARs submitted to the NRC, and accompanying PARs, if alsosubmitted, is attached as Appendix C.

Status of LARs

Total45

A roved28

Under Review17

The NRC conducts routine site inspections to monitor construction progress.The NRC issued its 4e'uarter Integrated Inspection Report. Two Green Non-CitedViolations were documented. A Green finding is the least significant in the NRC

Construction Reactor Oversight Process. Both findings were related to Design Controlissues. The NRC also sent a three-member NRC Special inspection team to review theevents of a coring operation that resulted in minor damage to the Unit 2 CV. Results oftheir investigations are provided in the "Notable Activities Occurring after March 31,2015," on page 18 of this report

There were no state licensing activities during the review period.

Q1-15 Review Page ~11

Approved Budget Review

ORS's budget review includes an analysis of the 1" quarter 2015 capital costs, projectcash flow, escalation and Allowance for Funds Used During Construction ("AFUDC").

Caui~lC its

To determine how consistently the Company adheres to the budget approved by theCommission in Order No. 2012-884, ORS evaluates 9 major cost categories for variances. Thesecost categories are:

1. Fixed with No Adjustinent2. Firm with Fixed Adjustment A

3. Firm with Fixed Adjustment 84. Firm with Indexed Adjustment5. Actual Craft Wages6. Non-Labor Cost7. Time & Materials8. Owners Costs9. Transmission Projects

On March 12, 2015, SCE&G filed a Petition with the Commission in Docket No. 2015-103-E seeking approval to update the construction milestone schedule as well as the capitalcost schedule for the Units. This Petition includes incremental capital costs that totalapproximately $698 million (SCE&G's portion in 2007 dollars); of which $539 million areassociated with these delays and other contested costs. The total project capital cost is nowestimated at approximately $5.2 billion (SCE&G's portion in 2007 dollars) or $6.8 billionincluding escalation and AFUDC (SCE&G's portion in future dollars). The cumulative projectcash flow amount projected to be spent on the Units by December 31, 2015 is $3.7 billion.

The capital cost estimates presented in SCE&G's Quarterly Report are based on SCE&G's

Petition. Therefore, until the Commission issues an order in response to SCE&G's Petition, ORSwill not have the ability to provide complete updates on the status of the approved budget.

n sfr R

Pursuant to the BLRA, SCE&G may request revised rates no earlier than one year afterthe request of a Base Load Review Order or any prior revised rates request. On May 29, 2015,SCE&G filed its Annual Request for Revised Rates (Docket 2015-160-E) with the Commissionrequesting a retail revenue increase of approximately $70 million (or approximately 2.789'e).

Ql-15 Review Page l12

Table 4 shows a summary of SCE8(G's Revised Rate Filings with the Commission.

Table 4:

SCE&G Revised Rate FilingsD()Ckct

No.

0 I'0 C

I'().

Rc(I(lcstc(Iil)CI'C(1!iC

ORS

I'ilnllllil tl() ll

A i) i) I'() V C (i

In el'c IscRct;Iil ~

i llcl'C'ISC

2008-196-E 2009-104(A) $8,986,000 ($ 1,183,509) $7,802,491 0.43%

2009-211-E 2009-696 $22,533,000 $0 $22,533,000 1.10%

2011-207-E 2011-738 $58,537,000 ($5,753,658) $52,783,342

2012-186-E 2012-761 $56,747,000 ($4,598,087) $ 52,148,913

2010-157-E 2010-625 $54,561,000 ($ 7,260,000) $47,301,000 2.31%

2.43%

2.33%

2013-150-E 2013-680(A) $69,671,000 ($2,430,768) $67,240,232 2.87%

2014-187-E 2014-785 $70,038,000 ($3,800,000) $66,238,000 2.82%

2015- 160-E Pending $69,648,000 Pending Pending Pending

Q1-15 Review Page [13

Additional ORS Monitoring Activities

ORS continually performs the following activities, as well as other monitoring activitiesas deemed necessary:

~ Audits capital cost expenditures and resulting AFUDC in Construction Work inProgress

~ Reviews invoices associated with the Milestone Schedule

~ Performs weekly on-site review of construction documents

~ Attends on-site Plan of the Day meetings with Project Managers

~ Attends on-site planning and scheduling meetings with Area Managers

~ Participates in monthly on-site observations of construction activities andprogress

~ Holds monthly update meetings with SCE&G

~ Meets quarterly with representatives of the Consortium

~ Attends NRC Public Meetings regarding SCE&G COL and other constructionactivities

~ Visits vendor fabrication facilities

The following milestones invoices were reviewed for completeness.

~ Milestone 102, Unit 2 Steam Generator at Port of Entry,

~ Milestone 104, Unit 3 Pressurizer Hydro Test,

~ Milestone 119, Unit 3 Main Transformers Fabricator Issued Purchase Order formaterial

ORS visited the CB&I Laurens Manufacturing Facility ("CBI-Laurens"), in Laurens, SouthCarolina which fabricates piping and mechanical equipment to be installed in Unit 2 and Unit 3.

Company personnel were in attendance and an overview of the CBI-Laurens Quality andProduction processes was provided. The briefing was followed by a factory tour, where weobserved several components being completed and a number of units loaded and ready fordelivery to the site.

Q1-15 Review Page i14

Construction Challenges

Based upon the information provided by the Company in its Quarterly Report, as well asinformation obtained via additional monitoring activities, ORS identifies several ongoingconstruction concerns that create risk to the on-time completion of the Units. ORS continues tomonitor these areas closely.

The Units are proceeding based on the revised SCDs for Unit 2 of June 19, 2019 and Unit 3

of June 16, 2020, although SCE&G has not formally accepted these dates and will continue toexplore mitigation and further negotiations. ORS repeats its concern that it is important to thesuccessful completion of the Project that the schedule and cost estimates be formally finalized andfully implemented. Continued negotiations over these issues may divert management attentionaway from concentrating on the successful completion of the Project This is borne out by SCE&G's

statement in their Quarterly Report that the Consortium has already advised the Company thatthe SCDs have changed to August 10, 2019 for Unit 2 and May 28, 2020 for Unit 3.

As identified in previous ORS reviews, one of the most signiTicant issues related to theconstruction of the Units remains the continued inability of Chicago Bridge & Iron - Lake Charles("CB&l-LC") and the other sub-contracted module fabricators to reliably and predictably meet thequality and schedule requirements for fabricating and delivering the submodules, including theassociated quality-related documentation. However, signiTicant progress was made in this area.

Welding on the Unit 2 CA01 module was nearing completion in the MAB and the moduleshould be ready for setting in the CV. However, delays in pouring of concrete for Layer 3 inside theCV due to issues relating to the licensing basis code compliance of weldable couplings, as furtherdiscussed in the "Notable Activities Occurring after March 31, 2015," on page 18 of this report,may further delay the setting of CA01. Unit 2 module CA05 was set in the CV and work continueson its final aligninent and installation. In addition, all sub-modules of Unit 2 CA02 are on-site andare now under assembly in the MAB with 5 of the 5 upended and ready for welding.

Metal-Tek SMCI in Lakeland, FL continued fabrication of the Unit 2 CA03 sub-modules andUnit 3 CA03 and CA04 sub-modules, and had their first delivery to the site. One of the seventeensub-modules for Unit 2 CA03 and four of the five sub-modules for Unit 3 CA04 have beendelivered to the site, along with their associated Certificates of Conformance. Work was underwayto assemble and align the Unit 3 CA04 module. However, due to poor quality and scheduleperformance, the fabrication of Unit 3 CA03 sub-modules has been transferred from SMCI back toCB&I-LC.

Ql-15 Review Page ~15

Work appears to be progressing well at Toshiba/IHI on the fabrication of the Unit 3 CA01sub-modules with 2 of 47 delivered to the site. Oregon Iron Works has now delivered 16 of 72sub-modules for Unit 3 CA20. In addition, all sub-modules for Unit 2 CA22 from Greenberry inOregon were delivered to the site and the floor module is fully assembled and ready for set.

Work continued on the installation of the anchor blocks for Unit 2 module CA20 in the ABwith approximately three quarters of them installed. However, the north wall of the alreadyinstalled module had to be removed and realigned due to concerns about the tolerances of theexisting installation exceeding allowable limits. The issue dealing with the capacity of the HeavyLift Derrick identiTied in ORS's 4th Quarter 2014 Report regarding the handling of the Unit 3

module CA01 has been resolved and will not impact the construction.

Although the fabrication, delivery, erection and installation still remain a critical issue onboth units, progress is slowly being made, but is outside the bounds of the schedule. ORS remainsconcerned about this issue.

The critical path of both units is now identiTied as the fabrication and delivery of the SB

panels. NNI's performance continues to show improvement with 57 of the 167 Unit 2 panels and 4of the 167 Unit 3 panels delivered to the site. The first course of Unit 2 panels have been fitted-upand aligned on the special assembly pad and detailed measurements made in preparation for theirinstallation on the top of the AB walls. The second course has also been fitted on the assembly padin preparation for welding two panel pairs together before installation on top of the first course SB

panels. The delay in installation of the SB panels is also associated with resolution of the weldablecoupling issue identified in the Structural Module section above. It is very important to the Projectthat installation of the SB panels begins soon if the Revised Schedule is to be met.

P1 ren e e nSCE&G has advised that the ISV testing has been completed on similar software and

hardware to that of the PRS, but that certification by the NRC was not expected until the end of2015 and this does not support the Company's operator training schedule. Therefore, SCE&G isseeking the approval of a CAS as an alternative in order to proceed with operator training andlicensing. The Company expects to have NRC approval by Q3 2015.

SCE&G has identified in its Quarterly Report that some ilrst-of-a-kind equipment andsystems testing that were to be performed on the China AP1000 new nuclear units are notacceptable to the NRC, and that additional testing will be required on the Units. This issue mayimpact the overall costs and schedule. No definitive information has yet been provided in this area,and ORS will continue to monitor progress.

Ql-15 Review Page l16

M f

The Reactor Coolant Pumps 500 hour endurance test was underway with the modifiedthrust bearing design and was expected to be completed in June 2015. The Squib Valves with themodified seal design successfully completed their submergence qualiTication testing, and areundergoing the final environmental qualification tests which are also to be completed by June2015. However, equipment storage and proper maintenance of stored and installed equipmentcontinue to be a concern, especially for those items that have been on-site for an extended periodof time.

pris e

Several mitigating approaches to resolve the capacitor failures and overheating issueshave been identified and are being actively pursued, including additional testing by themanufacturer. Although it does not appear that this issue will challenge the plant schedule oradversely impact the overall budget, the plan for resolution needs to be schedules and expedited.

R e s

Numerous LARs will be required to be approved by the NRC. There have been 45 filedwith the NRC thus far with 28 approved and 17 pending review. Several are approaching therequired approval date which could delay construction if they are not approved by the NRC. ORS

will continue to monitor LAR status and progress.

The continuing issues with cyber security compliance are a source of concern for theProject and for ORS. Phase H of this program has now been well defined and an estimate of $18.8million has been submitted by SCE&G as part of its filing to the Commission. However, this cost is

contingent on sharing the cost with the Vogtle plants, and an agreement with Southern NuclearCompany has not yet been reached. In addition, the potentially significant issue of vendorcompliance with cyber security requirements (now identiTied as Phase III) has not yet beenadequately addressed and the concern is that there may be hardware or soibvare modifications toequipment already on-site and that this may adversely impact the plant start-up schedule. Fullresolution of this issue will be monitored by the ORS.

Cns 'nP i

SCEIkG has identified in its Petition that the low productivity of the construction workforce has increased the cost of the Project. Corrective measures have been identified to improvethis productivity, but the impact of these corrective measures is not yet lmown. ORS has beenconcerned with this issue for some time, but it was not definitively apparent until the revisedbudgets were formulated. Low productivity could also affect schedule performance.

Q1-15 Review Page l17

Notable Activities Occurring after March 31, 2015

The BLRA allows SCE&G 45 days from the end of the current quarter to file its QuarterlyReport Items of importance that occurred subsequent to the Review Period are reported below.

N

On April 20, 2015, the NRC issued a letter (EA-14-085) to CB&l with a Notice of Violationand proposed imposition of a civil penalty of $ 11,200 as a result of NRC Investigation Report No.

2-2013-024. A copy of the cover letter may be found in Appendix E.

eel ll s e o l

The NRC followed-up with the results of its investigation of the February 9ie event where,CB&I workers were core drilling the concrete floor inside the Unit 2 CVBH. In the process, CB&l

cut some safety-related rebar and damaged the Unit 2 CVBH. The dainage was confirmed onFebruary 12ih when the hole was examined using a borescope. The NRC concluded the inspectionwith no cited violations, but indicated the potential for two Green Non-Cited Violations related toreporting and review and verification of field configuration for design control processes. Theminor damage was repaired and the additional dowels that were required were properly installedto the correct depth and configuration. On June 10, 2015, the NRC issued its final reportconcerning the CVBH damage incident to the Company. The NRC Letter referencing the reportmay be found in Appendix F.

Pe i io ttle r

On June 29, 2015, a Settlement Agreement was provided to the Commission under DocketNO. 2015-103-E, representing an agreement between SCE&G, ORS and the South Carolina EnergyUsers Committee concerning SCE&G's Petition. The SCE&G Settlement Agreement announcementmay be found in Appendix G of this report, and is subject to approval by the Commission under thereferenced docket

ble Co li s e

Issues regarding the licensing basis code compliance of weldable couplers have beenidentified and are delaying the concrete pour of Layer 3 and 4 in the CV until they can be resolvedwith the NRC. The licensing basis was established using the 1992 AWS Code; however, theConsortium applied AWS D1.1-2000 criterial for structural welds. A difference exists betweenthese two welding codes, and SCE&G has advised that resolution will require a LAR submittal anda PAR from the NRC in order to reduce further delays to construction. This approval is beingpursued with the NRC.

Q1-15 Review Page i18

3C

On July 7, 2015, SCEij.G announced the completion of two major milestones on Unit 3:

the setting of CA04 (Reactor Vessel Structural Module) and the delivery of the Unit 3 ReactorVessel to the site. The announcement may be found in Appendix H of this report.

01-15 Review Page j19

f21-15 License Amendment Requests Appendix C

Nli(:I,A Ii No.

tiiiiiiii'ii'I'«litSu Imi i I I a I

~ l)«te~I.A)i X)eius

I«i)i X I'AltAppruv il Vubmiu il

I) iii: 1).iicI'AN X)«)uv

I'i) Ii

Appl Ilv.lll)«io ~

12-01

12-02

13-01

13-02

13-03

Stud Spacing around Electrical Penetrations

Deg nit) on o( Wall Thickness In Table 3 3 1

Basemat Shear Reinforcement Design Spacing

Basemat Shear Reinforcement Desfgn Detegs

Turbine Building Eccentric and Concentric 8 racing

8/29/2012 Approved 7/1/2013

1/15/2013 Approved 2/26/2013 1/24/2013 Approved

1/18/2013 Approved 3/1/2013 1/22/2013 Approved

2/7/2013 Approved 7/1/2013

9/26/2012 Approved 5/30/2013 12/6/2012 Approved 1/16/2013

I/29/2013

1/29/2013

13.04 Reconcglatlon ofTier 1 Value Differences 2/7/2013 UnderReview

13-05

13-D6

13-07

13-08

13-09

13-10

13-11

13.12

13-13

Structural Module Shear Stud Site and Spacing

Primary Sampgng System Changes

Changes to Chemical and Volume Control System

Module Dbstructlons and DetagsIAR 13.20

Annex/Radwaste Bugdlng Layout Changes

Human Factors Englneerfng Integrated Plan

Nuclear Island Walls Reinforcement Criteria

Fire Area Boundary Changes

Turbine Building Layout Changes

2/14/2013 Approved 5/23/2013

2/7/2013 Approved 8/22/2013

3/13/2013 Approved 2/24/2014

2/28/2013 Withdrawn

2/27/2014 UnderReview

3/13/2013 Approved 7/31/2014

3/26/2013 Approved 6/6/2013 4/2/2013

7/17/2013 Approved 9/9/2014

7/30/2013 Approved 5/12/2014

Approved 4/10/2013

13.14 Turbine Bugdlng Battery Room Electrical Changes 10/2/2013 Approved 10/24/2014

13-15 Dperator Break Room ConfigurationLAR not required Withdrawn

Changed to sNon-LAR

13-16

13-17

13-18

13-19

, 13-20

Revision to Human Pactors EngineeringVerigcatlon Plan

Revision to Human Factors EngineeringTask VeriBcanon Plan

Revision to Human Factors EngineeringIssue Resolutfon Plan

Revise to Human Factors Engineering Plan

Module/Stud Channel Obstmctlons Revisions

9/25/2013 Approved 7/31/2014

9/25/2013 Approved 7/31/2014

10/3/2013 Approved '7/31/2014

10/3/2013 Approved 7/31/2014

7/17/2013 Approved 11/19/2013

13-21

13-22

CA03 Module Design Differences

Annex Bundlng Structure and Layout Changes

2/2/2014

12/4/2014

UnderReview

UnderReview

13-23 Reinforced Concrete (RC) to Steel Plate Composite,Construction Connections 7/11/2014 Approved 12/16/2014

13-25 Tler15dltorlalandConsfstencyChanges,.ec 7/2/2013 APProved 7/31/2014

13-26

13.27

13-28

Emergency Plan Rule Changes

Control Rod Drive Mechanism latching Relays

Piping Line Number Additions, Deletions, andFunctional

10/30/2014

12/18/2014

UnderReview

UnderReview

12/17/2013 Approved 6/20/2014

13-29 Class 1E DC and Unlnterruptlble power Supply Sysmm17 19 2014Removal of Termlnatfon Boxes

UnderReview

13-32 Liquid Waste System Changes 8/30/2013 Approved 1/8/Z014

'umbering may not be In sequenceTier 2's a NRC term to denote ))er 2 Design Control-Document information that is subjea to the change process in Section Vgl 8 6. of Appendix D of Part 52 Design-Ceit)fication Rule for the AP1XO Design.

Qt-15 License Amendment Requests Appendix C

Nn(:I.All Nu.

hunlulul 7

I.AltSu)un ) I t a I

I )u t u

IAR S)eiusI.AR — I'AR

Appruval Submittall)ute ~ l),uo

I'AltPAR St.uu) Appr w.d

Dale

13.33 passive Core CooUng System (pXSj Condensate Return 7/8/2014UnderReview

13-34Clarlficatlon ofTier 2'aterial In Human Factors

Documents 3/19/2014 Approved 10/0/2014

13.36 CIM/DAS Diversity Clarification 9/11/2014 UnderReview

13-37

13-38

13-41

13-42

14-01

VCSNS Units 2!13 Tech Spec Upgrade

ACI Code CompUance With Critical Sections HigherElevatlons - L4R net

Coating Thermal Conductivity- Revise DCD Tier 2Document

Tier 1 Editorial and Consistency Changes «2

Auxfilary Bufidlng Roof and Floor DetaBs

12/4/2013 Approved 11//12/14

11/7/2013 Withdrawn

11/26/2013

5/20/2014

UnderReview

UnderReview

3/10/2015

4/3/1014 Approved 7/10/2014 4/9/2014 Approved 4/15/2014

14-03 Tier 2'ditorial and Clarification Changes 6/12/2014 UnderReview

14-05 Conte)nment Internal Suucmral Module Design Detafis 7/17/2014 UnderReview

3/12/2015

14-06 Enclosures for Class 15 Electrlcal PenetratlonsinMiddle Annulus

6/20/2014 Approved 12/30/2014

14-07 CA04 Structural Module ITAAC Dimensions Change 9/25/2014 UnderReview

14.00 Integrated Test Program (I7Pj 10/23/2014 UnderReview

14-09

14-15

14-19

Turbine Building Swltchgear Room and Dffice Layout9 ig 2014

Compressed and lnstrumentAlr Supply Modlficatlon 10/30/2014

HFE OSA Task Update and Removal of WCAP-15847 1/27/2015

UnderReview

UnderReview

UnderReview

'umbering mar not be in sequenceTier 2's a NRC term to denote Tier 2 Design-Control-Document Information that is subject to the change process in Section Vfi).8.6, of Appendix D of Part 52 Design-Certification Rule for the AP100D Design.

Appendix D

Chan e Orders and A end entsNo. Summary Cost Categories

InvolvedType ofCI1'111 e

Dtt toAp roved Status

Operator training for WEC1; Reactor Vessel Systems andSimulator

2 Limited Scope Simulator

3 Repair of Parr Road .

Transfer of Erection of CA20Module from WEC to Shaw

'Supplements Change Order No.

1'ncreasedtraining by two (2)weeks

Fixed Price with 09kescalation

'irm

Price

Time and Materials

Target Price workshifting to Firm Price

Fixed Price with 09kescalation

OwnerDirected

OwnerDirected

OwnerDirected

ContractorConvenience

OwnerDirected

7/22/2009

9/11/2009

1/21/2010

N/A

5/4/2010

Approved

Approved

Approved

Superseded byChange Order

No. 8

Approved

6 Hydraulic Nuts

7 St. George Lines ¹1 & 2

8 Target to Firm/Fixed Shift

Fixed Price

Firm and Target PriceCategories

Target, Firm and FixedPrice es

OwnerDirected 7/13/2010

OwnerDirected 4/19/2011

Entitlement 7/13/2010

Approved

Approved

Approved

Switchyard Lines

10 Primavera

11 COL Delay Study

Firm and Target Price

Fixed Price with OeA

escalationFixed Price, but would

be applied to T&MWork Allowances

OwnerDirected

OwnerDirected

OwnerDirected

12/16/2010 Approved

2/24/2011 Approved

11/30/2010 Approved

12 2010 Health Care Act Costs Firm Entitlement 11/14/2011 Approved

13 Ovation Workstations No CostOwner

Directed 3/12/2012 Approved

14 Cyber Security Phase 1

Liquid Waste System

Firm Price andT&M Price

Firm Price OwnerDirected 3/15/2012

Entitlement 3/15/2012 Approved

Approved

Delay in COL, Shield BuildingUnit 2 Rock, etc.

17 Commercial Issues

Perch Guards on TransmissionStructures

Target Price and FirmPrice

Under Review

Firm Price

Entitlement

UnderReview

OwnerDirected

TBD

TBD

10/7/2014

Under Review

Under Review

Approved

'Fixed price with 0% escalation, but would be applied to Time and Materials Work Allowances by adding a new categoryfor Simulator instructor training and reducing Startup Support by a commensurate amount.

Appendix D

Chan e Orders and A end entsNo. Summary

PRS Hardware and Softwaree

Cost Categoriesinvolved

Firm Price

Type ofCllail e

OwnerDirected

DateA roved Status

10/14/2014 Approved

WEC Costs Related to HealthCare Act of 2010 Firm Price 1/7/2015

Approved

21 ITAAC Maintenance T&M Price Entitlement 3/5/2015 Approved

A list of definitions for each type of Change Order is found below:

~ Contractor Convenience: These changes are requested by the contractor.They are undertaken at the contractor's own expense, and are both generallyconsistent with the contract and reasonably necessary to meet the terms of thecontract.

~ Entitlement: The contractor is entitled to a Change Order in the event certainactions occur, including changes in law, uncontrollable circumstances, and otheractions as defined in the contract.

~ Owner Directed: These changes are requested by the Company.

April 20, 2015

EA-14-065

Mr. Luke Scorsone, Executive Vice President,Group President Fabrication ServicesChicago Bridge and Iron Company4171 Essen LaneBaton Rouge, LA 70609

SUBJECT: NOTICE OF VIOLATION AND PROPOSED IMPOSITION OF CIVIL PENALTY-$ 11,200, NRC INVESTIGATION REPORT NO. 2-2013-024

Dear Mr. Scorsone:

This refers to the investigation conducted by the U.S. Nuclear Regulatory Commission (NRC)Office of Investigations (Ol) between April 13, 2013, and May 9, 2014, of activities at ChicagoBridge and Iron Company's, Lake Charles, Louisiana, facility (CB8I-LC), formerly known asShaw Modular Solutions. The investigation was conducted to determine: (1) whether aproduction manager, rigging manager, and safety representative directed CB&l-LC personnel tofalsify statements, and thus create a false quality record associated with a sub-module destinedfor the Virgil C. Summer Nuclear Station (V. C. Summer) site; and (2) whether CB8 I-LC willfullyfailed to correct a condition adverse to quality by creating an inaccurate condition report. Theresults of the investigation were described in the NRC's letter transmitting the factual summaryof the Ol report dated December 15, 2014 (Agencywide Documents Access and ManagementSystem (ADAMS) Accession Number ML14296A036).

A Predecisional Enforcement Conference (PEC) was conducted at NRC headquarters onJanuary 22, 2015, with members of your staff to discuss the apparent violations, theirsignificance, their root causes, and your corrective actions. The conference was closed topublic observation because we discussed the findings of an Ol report that has not been publiclydisclosed.

Based on the information developed during the investigation and the information that youprovided during the conference, the NRC has determined that violations of NRC requirementsoccurred. These violations are cited in the enclosed Notice of Violation (Notice) and thecircumstances surrounding them were described in the NRC letter transmitting the factualsummary of the Ol report, dated December 15, 2014.

The violations occurred in March 2013, when two CB&l-LC officials deliberately instructedsubordinate CB&l-LC employees to knowingly omit from an Incident Investigation Report that:(1) the V. C. Summer CA-01-20 sub-module had dropped approximately 3.5 feet; (2) improperrigging equipment (nylon slings) had been used and had broken; and (3) the sub-module hadsustained damage. In addition, the CB81-LC officials deliberately failed to promptly identify thata condition adverse to quality occurred regarding the incident and resultant damage to thesub-module. When CB8 I-LC subsequently opened a corrective action report, CB&l-LC officials

L. Scorsone