Fibrous plastering

-

Upload

tim-weston -

Category

Education

-

view

281 -

download

1

Transcript of Fibrous plastering

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Fibrous plasterwork – overview

• Fibrous plasterwork is the ‘ornamental, decorative’ side of plastering.

• The tools are different from any of those you may have come across in other areas of plastering.

• The plaster itself is pure gypsum.

• Fibrous plasterwork is almost a trade within a trade.

• There are those who say you cannot call yourself a plasterer unless you can work in all aspects of the trade, and produce good quality work.

A reverse cornice mould with cast

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Operations of fibrous plastering

• Fibrous plaster is made in the workshop and transported to site for fixing.• The basic operations are:

– mould cutting– running– moulding– casting.

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Tools for making running moulds

• Safety edge files• Jeweller’s snips• Surform• Claw hammer• Pein hammer• Square• Saw• Any other tools required for making a running mould

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Materials for making running moulds

• Timber• Metal• Nails

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Construction of a running mould

• Method of forming a template • Forming the stock• Fixing stock to horse or slipper• Attaching a hand brace

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Construction of a circular running mould

• Purpose of a gig stick or extended stock

• Fixing of gig stick andturning eye

• Fixing of turning block to bench

Running mould with an extended stock

Running mould with a gig stick and turning block

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Equipment for running

• Bowls • Buckets• Plaster bin • Canvas bin• Water tanks/slosh tanks• Timber bench with a plaster top

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Materials for running

Plasters• Fine casting• Super fine casting• Coarse plaster• Hessian/canvas• Grease/release agent• Shellac• Nails

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Methods of running out mouldings

Running out this type of moulding uses the same method as for running out any moulding. Only the size changes.1. Make good a bench.2. Grease working area.3. Mark length of moulding required.4. Place nail.5. Mix up your plaster.6. Apply method for running panel moulding.7. Clean down bench, running mould and equipment.8. Remove moulding from bench and store.

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Turning a circular moulding

• Fix block for turning point.• Prepare bench and running area.• Apply method of turning running mould.• Remove moulding, clean down and store.

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Tools for casting

• Splash brush• Canvas knife or scissors• Busks• Joint rules• Small tools• Saw• Hammer

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Equipment for casting

The same as running out mouldings, with the addition of a tank for soaking timber laths.

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Materials for casting

As for running out mouldings but with the following additions:• size• laths.

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

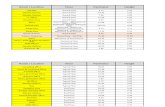

Casting a simple plainface

• Make good a bench.• Construct and fix mould from wood to

sizes given.• Cut canvas as shown in drawing.• Cut laths, which have been soaked

in water.• Lightly French Chalk and grease mould.

Mixing plaster• Use two gauge system.• Add sufficient water and size to bowl

and bucket, for firstings and seconds.• Method of casting with firstings

and seconds. Exploded view of canvas for a plainface slab

Laps

Ropes150 mm canvasand plaster

Side laps

Main canvasMain canvas

Casting rules

Plainface 600 x 900 x 40 mm

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

One-gauge system

• The method of casting in one-gauge system• Advantages of system• Disadvantages of system

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Method of forming different joints in plainface slabsReasons for using different jointsTypes of joints• Method of forming SQUARE joints• Method of forming REBATED joints• Method of forming LAPPED joints• Method of forming LAPPED and

REBATED joints

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Constructing a reverse cornice running mould

• Constructing a running mould• Method of coring out for saving materials• Running out a muffle run• Keying muffle run• Run out finish to template outline• Cutting run to length and sealing plaster surface

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Method of running out a reverse cornice mould• Running out this type of moulding is the

same method as for running out any moulding.

Method of forming and using a muffle• Methods of constructing a muffle• Reasons for using a muffle

A template with a false profile or muffle

Hand brace

6 mm

Plaster muffledStock

Slipper

Hardboard Metal Plaster

Nails

Muffle protection6 mm

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Casting from a reverse cornice mould

• Position of canvas• Position of laths• Striking off from strike offs and its

importance for fixing

Method of casting is the same as for casting a plainface

Method of storing fibrous plaster casts and mouldings

Exploded view of canvas reinforcement for a cornice cast

Wads (canvas dipped in plaster)

Main canvas

Reverse mould

End laps

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Faults that may happen in casting

Faults and how they occur• Cockling• Casts sticking in the mould• Holes and misses• Grease on the face• Cracks on the face of casts• Strike-offs not correct

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Moulding techniques

Types of moulding techniques• Flood mould• Case mould• Skin mould

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Materials for moulding techniques

Polyvinyl chloride (PVC)• Advantages of PVC• Disadvantages of PVC• Equipment required for melting PVC• Safety equipment for using PVCCold pour moulding compounds• Advantages of cold pour• Disadvantages of cold pour• Equipment required for cold pour• Safety equipment for cold pourClay• Use of clay in moulding techniques• Producing boards of clay

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Flood mould

• Advantages of a flood mould• Disadvantages of a

flood mould• Preparing the model

for pouring• Method of forming a

flood mould• Forming a back case

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Case mould of a centre piece

• Purpose of using a case mould• Preparing the model for pouring• Forming a case mould• Preparing the case mould for pouring• Pouring the moulding compound

NVQ and Technical Certificate Level 2 Plastering

© Pearson Education Ltd 2008. Copying permitted for purchasing institution only. This material is not copyright free.

Skin mould

• Reasons for using a skin mould• Method of preparing the mould for pouring• Method of forming the skin mould• Forming a back case