'felting printer' creates soft 3d printed teddy bears

description

Transcript of 'felting printer' creates soft 3d printed teddy bears

-

"Felting printer" creates soft 3D-printed teddy bears

'Felting printer' creates soft 3D-printed teddy bears.htm[2014-04-29 11:23:02 AM]

New-and-improved gecko-inspired adhesive sticks to more surfaces

Formula One technology funded for use in vehicles

Naim launches stunning Muso high-end wireless music system

Five of the best: High-tech hammers

Tajima Motor Company to produce floating tsunami shelter

ELECTRONICS

By Ben CoxworthApril 28, 2014

2 Comments2 Pictures

"Felting printer" creates soft 3D-printed teddy bears

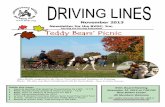

One of the finished felt teddy bears, alongside its digital modelImage Gallery (2 images)

Ask someone to think of a 3D-printed object, and chances are they'll picture something hard ... or perhaps rubbery. Thanks to new technology developed by Carnegie Mellon University and Disney Research Pittsburgh, however, it's now possible to make soft and fuzzy 3D-printed items, using yarn instead of plastic or resin. Among the first items to be created were little felt teddy bears.

Designed by Carnegie Mellon's Prof. Scott Hudson, the "felting printer" used to make the items actually looks a lot like an embroidery machine.

Recent popular articles in Electronics

Introducing the Gizmag Store

MORE TOP

STORIES

hereO GPS watch lets parents track their child's location

-

"Felting printer" creates soft 3D-printed teddy bears

'Felting printer' creates soft 3D-printed teddy bears.htm[2014-04-29 11:23:02 AM]

However, it actually works on the same principle as fused deposition modeling (FDM), the 3D printing process in which items are built up in successive layers deposited one on top of another.

On a regular FDM printer, spools of filament line are pulled into the machine and melted, then extruded from the print head to form each layer. On the felting printer, the filament is replaced with yarn. And instead of being melted, the yarn is repeatedly pierced with a barbed felting needle, which drags individual fibers down into the layers of yarn below. This causes the fibers of adjacent layers to become entangled, thus joining the layers to one another.

As with other 3D printers, it builds objects based on computer models.

Due to the fact that yarn is much thicker than the layers extruded by a conventional FDM machine, the resolution of the printed objects is correspondingly coarser. Additionally, because the felt objects can be pulled apart quite easily, they must incorporate a base of stronger material such as nylon mesh, if plans call for them to be attached to anything.

As demonstrated by Hudson, it's possible to incorporate electronics into the items, and to manipulate their level of pliability, although doing so does involve manually placing components within them. Down the road, however, he hopes that it will be possible to use one multi-material machine to create such composite objects, all within a single build.

Along with li'l teddy bears, such machines could be conceivably be used to manufacture items such as winter clothing, or parts for soft-bodied robots.

The felting printer can be seen in action, in the video below.

Source: Disney Research Pittsburgh

SectionsFeatures

Reviews

Aircraft

Architecture

Around The Home

Automotive

Bicycles

Children

Nanoelectronic circuits reach speeds of 245 THz

BAE Systems develops a flat lens that acts like it's curved

Trinity portable wind turbine takes a breezy approach to charging-on-the-go

IBM creates world's smallest magazine cover

Nanodot-based smartphone battery that recharges in 30 seconds

DPI details 10,000 lumen laser projector ahead of July release

Sensabubble notifies you with bubble-borne lights, text, and smells

Review: Favi Audio+ wireless speaker

Local Disk"Felting printer" creates soft 3D-printed teddy bears

VkJTIwdGVkZHklMjBiZWFycy5odG0A: form1: q: sa: