Fan Trim Balance

-

Upload

sylvester-obara -

Category

Documents

-

view

249 -

download

3

Transcript of Fan Trim Balance

-

8/2/2019 Fan Trim Balance

1/44

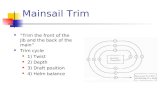

Page 1Aug 9971-00-00

CFM56-7B TRAINING MANUAL

ENGINE FAN TRIM BALANCE (3 SHOT PLOT)

Objectives:Given an Objective Exercise, the student will:- identify the conditions where fan trim balance must be performed on the CFM56-7engine. (1.A.a.)

- state the purpose of the engine fan trim balance. (2.B.a.)- identify the methods used for balancing the engine. (1.B.a.)- Perform the maintenance practice calculations for the 3 shot plot procedure. (3.E.a.)

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

2/44

Page 2Aug 9971-00-00

CFM56-7B TRAINING MANUAL

FAN TRIM BALANCE

IntroductionWhy is fan trim balance necessary for the CFM56-7Bengine?

Purpose (2.B.a.)The purpose of the engine fan trim balance is to bringback the engine vibration level to a satisfactory level.

This ensures that:

- The engine reliability will not be affected byabnormal vibration,

- Engine performance level is maintained for alloperational phases,

- Cabin noise is maintained to a satisfactory level.

The trim balance procedure should limit vibration levelsmeasured on fan and Low Pressure Turbine to 1.5 AVMunits during all engine ground runs.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

3/44

Page 3Aug 9971-00-00

CFM56-7B TRAINING MANUAL

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

FAN TRIM BALANCE

-

8/2/2019 Fan Trim Balance

4/44

Page 4Aug 9971-00-00

CFM56-7B TRAINING MANUAL

FAN TRIM BALANCE

Identification (1.A.a)These are the conditions where Fan Trim balanceprocedure is performed on the CFM56-7B to reduceengine vibration levels:

- Fan or/and LPT vibrations are equal or morethan 3 AVM units or 6 mils Double Amplitude.

- After the replacement of 1or more fan bladesand the correction weight installed on the spinnercone is more than 3.36 pound inches or 600 cm.g.

- After the repair of 1or more fan bladesand the correction weight installed on the spinner

cone is more than 3.36 pound inches or 600 cm.g.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

5/44

Page 5Aug 9971-00-00

CFM56-7B TRAINING MANUAL

REASONS TO PERFORM A FAN TRIM BALANCE

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

6/44

Page 6Aug 9971-00-00

CFM56-7B TRAINING MANUAL

FAN TRIM BALANCE

Maintenance Practice (3.E.a)These are the two different maintenance practiceprocedures available to perform fan trim balance:- Airborne Vibration Monitoring Unit (AVM) Method-The 3 Shot Plot Method

Airborne Vibration Monitoring Unit (AVM)

The procedure using the Boeing on board optionalequipment installed in the airplane electronic bay on theE3-2 shelf. This procedure is uses the vibration data forphase angle and vibration levels collected during the last32 flight legs and when necessary during engine groundruns.

The AVM uses these signal inputs to calculate vibrationlevels:-Vibration sensor from N1 bearing-Vibration sensor from the FFCCV-N1 Speed Sensor-N2 Speed SensorThe AVM signal conditioner continuously calculatesvibration data for several areas of each engine.

-Fan and LP compressor-HPC Compressor-HPT Turbine-LPT turbineThe highest vibration level is displayed on the CDS, onthe vibration indicator.

The four possible vibration monitoring units are the(Endevco -203, -213 and Vibrometer -103, -113). Theseunits calculate the amount and location of weightnecessary to balance the engine back to a normal level.

The PO weight is selected and then needs to be installed

in the engine rear cone by the technician.

(Refer to the AMM 71-00-00 for more information.)

The 3 Shot Plot MethodIn case your aircraft is not equipped with such optionalvibration monitoring units, you still have one way to getyour engine balanced using the alternate manualprocedure called "the 3 shot plot."

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

7/44

Page 7Aug 9971-00-00

CFM56-7B TRAINING MANUAL

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

8/44

Page 8Aug 9971-00-00

CFM56-7B TRAINING MANUAL

FAN TRIM BALANCE

General (3.E.a)

The 3 shot plot procedure philosophyThis method is used when no equipment is available tofind out the phase angle of the engine unbalance.

To find out the location and amount of weight to install on

the engine rear spinner cone, engine runs must beperformed.

A minimum of 5 runs are necessary.

Initial runThe actual engine unbalanced condition is recorded

through different engine speeds.

First runBalance weights are installed on the spinner cone, andengine is operating at the same speeds that during theinitial run and vibration levels are recorded. Obviously,the vibration amplitudes change and are more or lessimportant that the one recorded during the initial run.

Second runBalance weights installed for the engine first run areremoved and installed in different position 120ap art) ,

Engine is run again at the same speeds that the earlierruns, and vibration levels are recorded.

Once again, Vibration amplitudes change, and are moreor less important that previous engine runs.

Third runBalance weights installed for the engine second run areremoved and installed in a different position (120 apart)from the second run. Engine is run again at the same

speeds, and vibration levels are recorded.Once again, Vibration amplitudes change, and are moreor less important that amplitudes recorded duringprevious engine runs depending on the position ofunbalance.

Engine runs analysisFrom the engine runs recorded data, a manual vectorial

construction is performed to determine the amount ofbalance weight to install, and the position to install theweight. This is calculated using the different formsavailable within the Boeing Maintenance Manual.Weight is then installed on the engine rear spinner coneaccording to the analysis calculation.

Final runThe engine is operated to record the engine vibrationamplitude, and to verify that the level is within limits.

NOTE: If during engine run with test weights installed thevibration level is measured within limits, the fan trimbalance procedure is finished.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

9/44

Page 9Aug 9971-00-00

CFM56-7B TRAINING MANUAL

3 SHOT PLOT PHILOSOPHY

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

10/44

Page 10Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)Aircraft and engine preparation is to be performed priorto operation of the engine.

To read vibration in mils, vibration equipment is to beinstalled. The vibration indicator in the flight compartmentreads in units and is not possible to read vibration in mils.

If the aircraft is not equipped with unbalance phase anglerecording features, it is not possible to know if vibration isgenerated by the N1 bearing vibration sensor or th eFFCCV sensor. It isn't possible to read vibration in milseither.

To obtain more information, install a selector switchwhich isolates the signals coming from the vibrationsensors, and install the breakout cable. Disconnect theAVM signal conditioner from its support (Refer to theAMM 77-31-00), and connect the breakout cable to theelectronic shelf connector. Route the breakout cable upto the flight compartment area and connect it with theselector switch.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

11/44

Page 11Aug 9971-00-00

CFM56-7B TRAINING MANUAL

PREPARATION

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

12/44

Page 12Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Initial runPrior to start the engine, a careful record of the actualbalanced screws installed on the rear spinner cone mustbe performed. Record the configuration on the Balancescrew location chart.

Then start the engine, and bring it to stabilized thermalcondition if the engine was shut down for more than 6hours. The stabilized engine thermal condition isobtained running the engine at 80% N1 for at least 5minutes.

If the engine was not shut down the last 6 hours, stabilizethe engine in idle for 3 minutes, and then slowlyaccelerate the engine until the takeoff N1 target of theday is reached.

Important: Stop engine acceleration if the vibration levelequals 4 units on the vibration gage or 8 mils scale onthe indicator overlay.

Stabilize the engine at the T/O N1 target (if you canreach this RPM) and record the vibration amplitude forboth N1 bearing sensor and FFCCV sensor. Selectionof sensors output is selected through the selectorswitch.

Decrease the engine speed to the next lower N1 speedtarget defined in the AMM, (now 93,7%) and record thevibration levels red from the N1 bearing sensor an dFFCCV sensor.

Important: Wait engine EGT and N1 parameters tostabilize prior to record those data.

Follow the same exact procedure to record vibrationlevels for the next lower speeds. (85%, 81%, 66%, and54%).

Shut down the engine, and prepare balance weights forthe next run called engine first run.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

13/44

Page 13Aug 9971-00-00

CFM56-7B TRAINING MANUAL

ENGINE INITIAL RUN

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

14/44

Page 14Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

First runInstall three balance screws P05 instead of P07 balancescrews installed on the rear spinner cone.

You can now start the engine, stabilize it in idle. The

engine warm up procedure (stabilization at 80% N1) isnot needed.

Repeat exactly the same running procedure that theinitial run to record vibration amplitudes for both N1bearing sensor and FFCCV sensor.

Record the vibration amplitudes into the second columnof the three shot plot worksheet form.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

15/44

Page 15Aug 9971-00-00

CFM56-7B TRAINING MANUAL

ENGINE FIRST RUN

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

16/44

Page 16Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Second runRemove the three P05 screws which have been installedduring the last run, and replace them with P07 screws.120apart from their latest position, install the threebalance screws P05 instead of P07 balance screws .

You can now start the engine, stabilize it in idle. Theengine warm up procedure (stabilization at 80% N1) isnot needed.

Repeat exactly the same running procedure that the lastrun to record vibration amplitudes for both N1 bea ringsensor and FFCCV sensor.

Record the vibration amplitudes into the third column ofthe three shot plot worksheet form.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

17/44

Page 17Aug 9971-00-00

CFM56-7B TRAINING MANUAL

ENGINE SECOND RUN

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

18/44

Page 18Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Third runRemove the three P05 screws which have been installedduring the second run, and replace them with P07screws. Next install 120from P05 second run posit ion,install the next three balance PO5 screws after removing

the P07 balance screws.

Now start the engine, stabilize it in idle. The engine warmup procedure (stabilization at 80% N1) is not needed.

Repeat exactly the same running procedure that the lastrun to record vibration amplitudes for both N1 bea ringsensor and FFCCV sensor.

Record the vibration amplitudes into the fourth column ofthe three shot plot worksheet form.Shut down the engine and proceed to the next step.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

19/44

Page 19Aug 9971-00-00

CFM56-7B TRAINING MANUAL

ENGINE THIRD RUN

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

20/44

Page 20Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processOnce all data have been accurately recorded,determinate the location and amount of weight to installon the rear spinner cone to correct the engine unbalance.

Note: To facilitate the calculation, select only the speedswhere the three highest vibration amplitudes from eachsensor have been recorded in the initial run.

Give an identification letter to each one of the recordedvibration amplitude;

- A = highest vibration level- B = second highest vibration level- C = third highest vibration level

for N1 bearing sensor.

- D = highest vibration level- E = second highest vibration level- F = third highest vibration level

for the FFCCV sensor.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

21/44

Page 21Aug 9971-00-00

CFM56-7B TRAINING MANUAL

3 SHOT PLOT EXERCISE

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

22/44

Page 22Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processRepresent the initial unbalance on a polar graph. Choosea correct scale size that will fit on the polar graph.

Represent each of the 6 points A-B-C and D-E-F on a

different polar graph to get accurate representation.

For each point, draw one circle from the center of thepolar graph. The radius of the circle you draw is equal tothe vibration amplitude that was recorded for the pointselected.

Note: For training purposes, only one point (A)construction will be demonstrated in detail, the otherpoints will be shown later.

For the point A, the vibration amplitude equals to 6.5mils. First define a scale which suits the amplitudes forpoint A, and then draw a circle of radius 6.5 from thecenter of the polar graph.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

23/44

Page 23Aug 9971-00-00

CFM56-7B TRAINING MANUAL

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

-

8/2/2019 Fan Trim Balance

24/44

Page 24Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processRepresent the First engine run vibration behavior withthe set of PO5 balance weights installed.

To represent it, draw a circle which has the radius of the

vibration level for the selected point (A), using theidentical scale used the step earlier.

For this example, the vibration level recorded for thepoint A was 4 mils, so, draw a circle with the radiustaken from the scale.

Its center is located at the intersection of the initialunbalanced condition circle and the radius passing fromthe center of the graph to the central balance screwposition (here position 35).

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

25/44

Page 25Aug 9971-00-00

CFM56-7B TRAINING MANUAL

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

-

8/2/2019 Fan Trim Balance

26/44

Page 26Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processRepresent the second engine run vibration behavior withthe set of PO5 balance weights installed.

To represent it, you must draw a circle which has the

radius of the Vibration level for the selected point (A),using the identical scale you used the step earlier.

For this example, the vibration level recorded for thepoint A was 8.6 mils.

Its center is located at the intersection of the initialunbalanced condition circle and the radius passing fromthe center of the graph to the central balance screwposition (here position 23).

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

27/44

Page 27Aug 9971-00-00

CFM56-7B TRAINING MANUAL

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

-

8/2/2019 Fan Trim Balance

28/44

Page 28Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processRepresent the third engine run vibration behavior withthe set of PO5 balance weights installed.

To represent it, you must draw a circle which has the

radius of the balance level recorded at the third run forthe selected point for the (A).

For this example, the vibration level recorded for thepoint A was 7.8 mils, so, with the scale, it is representedwith a 47 mm radius circle.

Its center is located at the intersection of the initial

unbalanced condition circle and the radius passing fromthe center of the graph to the central balance screwposition (here position 11).

The scale used is: 6 mm for 1 mils of vibration.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

-

8/2/2019 Fan Trim Balance

29/44

Page 29Aug 9971-00-00

CFM56-7B TRAINING MANUAL

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

-

8/2/2019 Fan Trim Balance

30/44

Page 30Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processThe resultant R for the point (A) is the vector which isdrawn from the center of the polar graph, and theintersection of the 3 circles drawn for each run.

NOTE: If during your construction, the 3 circles do notcross in one point, draw the vector from the center ofthe polar graph to the center of the common area ofthose 3 circles.

For this point (A), according to the scale we used, theamplitude in mils equals 2.7 mils.

The angle of this vector has to be measured from thevertical axis, so for this point (A), the angle equals 5degrees.

Calculate the balance weight W6 corresponding tothe point (A) using the formula.

W6 = 831.8 x U0 (initial unbalance)R1 (calculated resultant for

point A)

For point (A), this is 831.8 x 6.5 = 2002 cm.g2.7

The final calculation for the point (A) concerns thesensitivity. It represents how the additional weightsPO5 added to the engine in 3 different positions (120 apart) affect the balance condition of the engine for thisparticular speed.

Sensitivity = 831.8 = 831.8 = 308R1 2.7

Calculate and fill in the information for all the remainingpoints onto the corresponding form .

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

C R G

-

8/2/2019 Fan Trim Balance

31/44

Page 31Aug 9971-00-00

CFM56-7B TRAINING MANUAL

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

CFM56 7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

32/44

Page 32Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processThe angle of this vector has to be measured from thevertical axis, so for this point (A), the angle equals 5degrees.

You must also calculate the balance weight W6corresponding to the point (A) using the formula Theangle of this vector has to be measured from the verticalaxis, so for this point (A), the angle equals 5 degrees.

Calculate the balance weight W6 corresponding to thepoint (A) using the formula

The next step is to represent graphically each calculatedbalance weight W6 for all the different points A, B, C, D,E, F onto one polar graph.

Note: You must select a scale which permits you to draweach point onto the polar graph.For this example a scale of 1 cm for 500 cm.g is

selected.

Report each balance weight point at the correct angleonto the polargraph.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

CFM56 7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

33/44

Page 33Aug 9971-00-00

CFM56-7B TRAINING MANUAL

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

CFM56 7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

34/44

Page 34Aug 9971-00-00

CFM56-7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processUsing the last polar graph fill out the form to calculate themaximum amplitude for each vector.

To calculate it, you must graphically joint each point

which is mentioned in the form, starting by AB, then AC,then AD, up to EF.

Note: Once you measure the distance in between a andB, A and C, don't forget to transform this distance intomoment weight using the same scale as used earlier 1cm corresponding to 500 cm.g.

For vector AB:To fill out the first Sensitivity P1 column, get theinformation (point A) from the chart . To fill out thesecond Sensitivity P1, get the information (point B) fromthe chart.

You just need to make the addition of those two columns

to fill out the SP1+SP2 column.

To calculate the amplitude (U), use the formula providedinto the form which corresponds to the distance of theconsidered vector (AB) divided by the sum of thesensitivity you calculated in column SP1+SP2.

Do the same for all the remaining vectors AC, AD, etc.

Once all amplitudes (U) have been calculated, select thehighest one to calculate the distance from P1.

In this example, the selected one is corresponding to thevector AD, where the amplitude equals 2.623.

Using the formula which is the amplitude multiplied bythe sensitivity of the point A, we will find the distancefrom point A.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

35/44

Page 35Aug 9971-00-00

CFM56-7B TRAINING MANUAL

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

36/44

Page 36Aug 9971-00-00

CFM56 7B TRAINING MANUAL

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processOn the polar graph you used earlier and using the samescale, report the distance you calculated onto the form,starting at the point A.

Draw the vector from the center of the graph to this point,and measure it.

Transform this distance into balance weight using thescale, and measure the angle from the vertical axis.

Record this value on the form, this is what you need tobalance the engine.

In this example, the result is 1550 cm.g at 26.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

37/44

Page 37Aug 9971-00-00

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

38/44

Page 38Aug 9971-00-00

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processIn this example, the result is 1550 cm.g at 26.

Going to the balancing weight location form, find out thephysical location of balancing weight position.

In this example, the measured angle is 26, so thecalculated angle selection is the one in between 23 and27 degrees.

The balancing weight must be centered into 2 screwspositioned in 34 and 35.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

39/44

Page 39Aug 9971-00-00

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

40/44

Page 40Aug 9971-00-00

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Balancing weights calculation processUsing the PO weight chart, find the balancing weightrequired centered into two screws in figure 514.

Find on the right hand side column, the closest balance

weight corresponding to the calculated balance weightneeded.

For this example, 1527cm.g is the closest to the 1550cm.g needed.

Balance screws selection is mentioned on the horizontalline corresponding to the 1527 cm.g.

For this example, 6 screws are needed, and they are:- 2 P06 screws- 4 P04 screws.

To install them, number the screws from the horizontalcenterline in counterclockwise direction, corresponding tothe balance screws position Aft Looking Forward.

In this example, install P06 screws in position 34 and 35,and P04 screws in position 32, 33, and 36 and 1.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

41/44

Page 41Aug 9971-00-00

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

42/44

Page 42Aug 9971-00-00

THE 3 SHOT PLOT EXERCISE

Maintenance Practice (3.E.a)

Last Engine RunRemove the old balance screws and install the newbalance screws at the correct position in the rear spinnercone.

Start the engine and operate it at the same speeds asbefore on the run sheets.

Record the vibration levels at the determined speeds andrecord them onto the vibration recording form.

Check that all vibration levels are below the limits foundin the AMM 71-00-00.

This concludes the fan trim balance "3 shot plot"procedure.

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

43/44

Page 43Aug 9971-00-00

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION

3 SHOT PLOT EXERCISE

CFM56-7B TRAINING MANUAL

-

8/2/2019 Fan Trim Balance

44/44

Page 44Aug 9971-00-00

THIS PAGE INTENTIONALLY LEFT BLANK

EFFECTIVITY 737-600/700/800/900/BBJ/COMBI/C40A

CFMI PROPRIETARY INFORMATION