FACTS and FIGURES

description

Transcript of FACTS and FIGURES

3rd International Conference on Working on Safety12-15th September, 2006

1

1

FACTS and FIGURES

Analysis of the storybuildsLinda J Bellamy, White Queen BV

& the Storybuilder team of Martijn Mud (RPS) & Martin Damen (RIGO),

Marjolijne Samwell (CSI), Vanessa van Eijk (CSI), Cees Paas (TU Delft) and others

W O R M

3rd International Conference on Working on Safety12-15th September, 2006

2

2

Horrible stories

• 17-year-old male warehouse worker died when the forklift he was operating tipped over and crushed him.

How can that happen?

3rd International Conference on Working on Safety12-15th September, 2006

3

3

1 CEIn or on(moving) vehicle

with loss of control

56 [58]

2 GVEHICLE/DRIVER FAILURE

GROUP

56 [58]

6 (1) GRegulations violate

d

56 [58]

7 GSUBSTANDARD GEOMETRY/

INFRASTRUCTUR

56 [58]

8 GVEHICLE TYPE

GROUP

56 [58]

9 GLOCATION OF

VEHICLE

56 [58]

10 AActivity of victim

56 [58]

11 AActivity ofVehicle(s)

0 [0]

21 (4) ET

INSIDE

19 [19]

27 (4) ET

OUTSIDE

36 [38]

28 (4) ETHarbour/ waterwa

y

0 [0]

29 (4) ETGeneral(industrial) site

(outside)

25 [26]

30 (4) ET

Normal road

2 [2]

31 (4) ETLogistic area (outside loading/

unloading or

4 [4]

32 (4) ET

Railway

0 [0]

33 (4) ET

Other

3 [4]

34 (4) ET

Unknown

1 [1]

35 (4) ETESAW09.00 Machinesand equipment -

0 [0]

42 (4) ETESAW11.00 Conveying,

transport and

56 [58]

43 (4) ETESAW11.02 Elevators,

lifts - hoists, bucket

0 [0]

44 (4) ETESAW11.03 Fixed cranes,

mobile cranes,

0 [0]

45 (4) ETESAW11.04 Mobile

handling devices,

56 [58]

46 (4) ETFork lift trucks

56 [58]

47 (4) ETPoweredstacking trucks,

pallet truck,

0 [0]

48 (4) ETPoweredstacking trucks,pallet trucks,

0 [0]

49 (4) ETPoweredstacking trucks,

pallet truck,

0 [0]

50 (4) ET11.04Mobile handling

device -manually

0 [0]

51 (4) ETESAW 12.00 Land

vehicles

5 [5]

57 (4) ETESAW13.00 Other

transport vehicles

0 [0]

66 B

Barrier

0 [0]

69 1_BFMSubstandardgeometry/

infrastructure

27 [28]

70 1_BGeometry/

infrastructure

0 [0]

88 (2) 1_IFLack ofsuitable marking,signalling, barriers

6 [6]

89 (2) 1_IFInsufficient space/

separation

1 [1]

92 (2) 1_IFInsufficient lighting

0 [0]

94 (2) 1_IFObstruction(s)

7 [7]

101 (2) 1_IFUneven or slippery

surface

10 [11]

104 (2) 1_IFSubstandard support (structural

failure)

8 [8]

105 (2) 1_IFUnexpected, sudden ship

motion

0 [0]

106 (2) 1_IFGroundslides/ collapse of

surface

3 [3]

107 (2) 1_IFloading bridge failur

e

4 [4]

108 (2) 1_IFsubstandard rail

condition

0 [0]

3 B

Barrier Group

0 [0]

225 2_BFMLocation/ position

failure

6 [7]

250 3_BFMMechanicalfailure or othermalfunction of

1 [2]

275 4_BFMAbility todrive/ operate failur

e

29 [30]

314 5_BFM

Overspeeding

18 [19]

333 LCEVehicle turnsover (capsizes),

falls down or jumps

56 [58]

336 6_BFMVehiclestabilising/ support

related failure

13 [13]

366 7_BFMLoad related failure

21 [21]

Using Storybuilder

1) Select forklift trucks and loss of control event vehicle turns over…….

3rd International Conference on Working on Safety12-15th September, 2006

4

4

1 CEIn or on(moving) vehicle

with loss of control

56 [58]

2 GVEHICLE/DRIVER FAILURE

GROUP

56 [58]

6 (1) GRegulations violate

d

56 [58]

7 GSUBSTANDARD GEOMETRY/

INFRASTRUCTUR

56 [58]

8 GVEHICLE TYPE

GROUP

56 [58]

9 GLOCATION OF

VEHICLE

56 [58]

10 AActivity of victim

56 [58]

11 AActivity ofVehicle(s)

0 [0]

21 (4) ET

INSIDE

19 [19]

27 (4) ET

OUTSIDE

36 [38]

28 (4) ETHarbour/ waterwa

y

0 [0]

29 (4) ETGeneral(industrial) site

(outside)

25 [26]

30 (4) ET

Normal road

2 [2]

31 (4) ETLogistic area (outside loading/

unloading or

4 [4]

32 (4) ET

Railway

0 [0]

33 (4) ET

Other

3 [4]

34 (4) ET

Unknown

1 [1]

35 (4) ETESAW09.00 Machinesand equipment -

0 [0]

42 (4) ETESAW11.00 Conveying,

transport and

56 [58]

43 (4) ETESAW11.02 Elevators,

lifts - hoists, bucket

0 [0]

44 (4) ETESAW11.03 Fixed cranes,

mobile cranes,

0 [0]

45 (4) ETESAW11.04 Mobile

handling devices,

56 [58]

46 (4) ETFork lift trucks

56 [58]

47 (4) ETPoweredstacking trucks,

pallet truck,

0 [0]

48 (4) ETPoweredstacking trucks,pallet trucks,

0 [0]

49 (4) ETPoweredstacking trucks,

pallet truck,

0 [0]

50 (4) ET11.04Mobile handling

device -manually

0 [0]

51 (4) ETESAW 12.00 Land

vehicles

5 [5]

57 (4) ETESAW13.00 Other

transport vehicles

0 [0]

66 B

Barrier

0 [0]

69 1_BFMSubstandardgeometry/

infrastructure

27 [28]

70 1_BGeometry/

infrastructure

0 [0]

88 (2) 1_IFLack ofsuitable marking,signalling, barriers

6 [6]

89 (2) 1_IFInsufficient space/

separation

1 [1]

92 (2) 1_IFInsufficient lighting

0 [0]

94 (2) 1_IFObstruction(s)

7 [7]

101 (2) 1_IFUneven or slippery

surface

10 [11]

104 (2) 1_IFSubstandard support (structural

failure)

8 [8]

105 (2) 1_IFUnexpected, sudden ship

motion

0 [0]

106 (2) 1_IFGroundslides/ collapse of

surface

3 [3]

107 (2) 1_IFloading bridge failur

e

4 [4]

108 (2) 1_IFsubstandard rail

condition

0 [0]

3 B

Barrier Group

0 [0]

225 2_BFMLocation/ position

failure

6 [7]

250 3_BFMMechanicalfailure or othermalfunction of

1 [2]

275 4_BFMAbility todrive/ operate failur

e

29 [30]

314 5_BFM

Overspeeding

18 [19]

333 LCEVehicle turnsover (capsizes),

falls down or jumps

56 [58]

336 6_BFMVehiclestabilising/ support

related failure

13 [13]

366 7_BFMLoad related failure

21 [21]

2) Loss of control event – vehicle turns over – we have 56 cases with 58 victims

3) We can examine the causes: Load related, speeding, ability to drive related etc…

3rd International Conference on Working on Safety12-15th September, 2006

5

5

The data are at a very detailed level of underlying causes

366 7_BFMLoad related failure

21 [21]

367 7_B

Loading

0 [0]

385 (2) 7_IFConnection failure

0 [0]

386 (2) 7_IFFork/ loadtoo high when

driving

13 [13]

387 (2) 7_IFSharp turn with

high load

4 [4]

388 (2) 7_IFLoad notequally distributedand/or overloading

7 [7]

3rd International Conference on Working on Safety12-15th September, 2006

6

6

It is also possible to look at the management failures to deliver the safety barrier:

Here failure to provide competence and motivation not to drive too fast dominate

3rd International Conference on Working on Safety12-15th September, 2006

7

7

A horrible story in the pizzeria

• 15-year-old male pizzeria worker was killed when he became entangled in a machine used to mix pizza dough.

• He apparently lifted the cover of the mixer, uncovering the 32-inch-diameter mixing bowl, and started the machine.

• As he reached in to the bowl to clean it, he became entangled on a large mixing fork (beater) that rotated inside the mixing bowl. His co-workers heard him scream, but were unable to reach him in time.

3rd International Conference on Working on Safety12-15th September, 2006

8

8

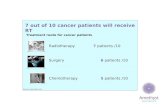

8.1 Machine accidents• Every year around 400 reported machine accidents in

the Netherlands involving contact with moving parts• Occurs mostly in manufacturing industry

1

57

11

1

57

11

1

57

11

Deaths

Permanent injuries

Recoverable injuries

3rd International Conference on Working on Safety12-15th September, 2006

9

9

8.1 CONTACT WITH MOVING PARTS OF FIXED MACHINE

• In 80% of cases the machine is onon when the accident happens

• In 20% of cases the machine is offoff but then suddenlysuddenly switched onswitched on/ or there is still residual movement i.e. lock-out/ tag-out or mechanical (un)blocking failure.

3rd International Conference on Working on Safety12-15th September, 2006

10

10

Entering the danger zone

• 66% of accidents result from entering the danger zone of the machine, half of the time intentionally …so..

• …in 35% of cases the person consciously ignores the danger zone

• Errors in operating the machine occurs in 11% of cases, resulting in ejected parts or unintended movement of machine.

3rd International Conference on Working on Safety12-15th September, 2006

11

11

8.1 CONTACT MOVING PARTS OF MACHINE – Management failures

• Management failed to provide adequate equipment to prevent the accidents (30% of accidents )

• Procedural failures in providing prevention measures (30% of accidents )

• Safety motivation failures in operating machines safely and not entering the danger zone (20% of accidents)

3rd International Conference on Working on Safety12-15th September, 2006

12

12

Machine guarding

• 30% of cases had no machine guard provided

3rd International Conference on Working on Safety12-15th September, 2006

13

13

8.1 MACHINES – type of contact

• Pinching/crushing/trapping was the dominant problem (65%)

• Piercing/cutting (23%)

• Pulled in by clothes/hair entanglement (10%)

3rd International Conference on Working on Safety12-15th September, 2006

14

14

MACHINES: Limiting factors after contact

• In 20% of cases the emergency stop wasn’t used, was out of reach or not provided

• In 20% of cases it was used to limit injury

3rd International Conference on Working on Safety12-15th September, 2006

15

15

MOVING MACHINES: INJURIES

• Around 50% of injuries involve traumatic amputations of body parts

• Practically all of these are lost fingers or lost hand

• 50% of known cases of lost time were more than 1 month of which 10% of all known cases were more than 6 months

• When deaths occurred head, shoulders and whole body injuries were indicated

3rd International Conference on Working on Safety12-15th September, 2006

16

16

Dutch top 10 1998-Feb 2004

– (3150) 8.1 Contact with moving parts of a machine– (1658) 3 Contact with falling/dropped/collapsing object/person

falling under gravity– (1135) 1.1.3 Fall from height roof/floor/platform– (1066) 1.1.1 Fall from height ladder– (556) 1.1.2 Fall from height scaffold– (552) 2 Struck by moving vehicle – (517) 11 In or on moving vehicle with loss of control– (412) 1.2 Fall on same level– (302) 8.3 Trapped between/against– (279) 1.1.5.3 Working on height unprotected

3rd International Conference on Working on Safety12-15th September, 2006

17

17

Construction industry 1998-Feb 2004 (NL)

576

472

425

338

311

88

63

60

53

47

1.1.3 Fall fromheightroof/floor/platform

3 Contact withfalling/dropped/collapsing

object/person/wall/vehicle/crane

1.1.1 Fall from height ladder

1.1.2 Fall from height scaffold

8.1 Contact with moving parts ofa machine

1.1.5.1 Fall from moveableplatform

8.2.1 Contact with hanging orswinging objects

2 Struck by moving vehicle

8.3 Trapped between/against

4.1 Contact with object ejectedfrom machine

3rd International Conference on Working on Safety12-15th September, 2006

18

18

Country comparisons: reporting differences

BOWTIE REPORTED CASUALTIES PER YEAR1

NETHERLANDS (GISAI)

DENMARK (RAW)

Per working POP. 7 million workers 2.5million workers FALL FROM HEIGHT

552 1975

Roofs/platforms 178 123 Ladders 170 878 Scaffolds 84 173 Unprotected height 39 464 Non-moving vehicle 27 216 Hole 10 44 FALLING OBJECTS 265 2641 CONTACT MOVING PARTS

607 3464

1 Reporting criteria differ

3rd International Conference on Working on Safety12-15th September, 2006

19

19

OATS:Occupational Accident Triangles

1

57

11

1 Dead

2

4

1

17

64

1

2

7

1.2 Fall on same level (around 70 accidents including 8 permanently

injured per year)

1.1.3 Fall from height roof/floor/platform (around 175 accidents including 12 deaths

per year)

8.1 Contact with moving parts of a machine (around 400 accidents including 5 deaths per

year for 2002 and 2003)2 Struck by moving vehicle (around 85 accidents including 7 deaths per year)