Fabricating a heavy duty Rocket Stove

description

Transcript of Fabricating a heavy duty Rocket Stove

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

Food Living Outside Play Technology Workshop

Fabricating a Heavy-Duty Rocket Stoveby eaahnen on April 9, 2012

Table of Contents

Fabricating a Heavy-Duty Rocket Stove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intro: Fabricating a Heavy-Duty Rocket Stove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Step 1: Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Step 2: Methods of Fabrication and Tools Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step 3: Cutting the Stove Tank to Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Step 4: The Burning Chamber Weldment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Step 5: Making Legs and Carrying Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Step 6: Positioning the Burning Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Step 7: Positioning the Stove Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Step 8: Fitting and Welding the Baseplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 9: Installing the Baseplate Burner-Risers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 10: Drilling Depressurizing Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Step 11: Grinding, Deburring, and Applying Stove Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Related Instructables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Advertisements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

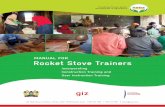

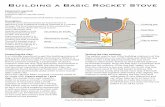

Intro: Fabricating a Heavy-Duty Rocket StoveRocket stoves are small efficient stoves that can produce a hot flame with only a few small pieces of wood. The reason it is called a rocket stove is because when woodis added to the fire the flames create an internal draft. As the draft is created, the fire begins to produce a jet of fire coming through the stove pipe. The stove flameeventually becomes so hot that it produces very little smoke. The stove should be able to produce a hot continuous flame that will lick the bottom surface of a pot or panplaced on top of the stove.

These stoves were created out of necessity in third world countries to cook small meals and have recently become more popular as a do-it-yourself camping stove. Arocket stove is usually made from readily available materials that can be recycled for reuse. To make a large stove, it is not unusual for the outside shell of the stove tobe made from an old propane tank, Freon tank, or air compressor tank. To complete the following instructions for making a rocket stove, experience in welding andmetalworking is needed as this project requires a great deal of it.

Step 1: MaterialsChanges may be made to the materials in the schematic according to personal preference or based on availability of materials. Materials for fabricating stove legs are notpresent because many different configurations may be acceptable. Any design may be accepted for personal preference, as long as it is able to support at least 100lbsand withstand high temperatures for this model.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

Step 2: Methods of Fabrication and Tools NeededThere are many different methods and materials that could be used to make a rocket stove. The methods detailed in this instruction set have been selected to make aheavy-duty model. This model may also be used as a small forge to melt soft materials such as lead and bronze. In order to make a simpler model, materials like tincontainers and tin cans can be cut with simple tin snips and fitted together. Brazing or soldering is a good alternative to welding when working with light tin materials tomake a smaller stove.

Common tools used for fabrication of this project are:• Grinding/Cutoff Wheel• Horizontal Bandsaw• Pneumatic Cutoff Tool• MIG Welder

Step 3: Cutting the Stove Tank to SizeWhen selecting an old steel tank, precautions must be made to be sure that the tank is no longer under pressure and that the contents have been completely removed. Amultitude of different tanks may be used for this project depending on the desired size of the stove. This rocket stove was made from an old propane tank purchased froma scrap metal yard. Before cutting into the tank, have it completely emptied of all contents and remove the valve from the top to expose the tank to atmospheric pressure.Fill the tank with water and empty it several times to remove any leftover propane fumes and gas. This will ensure that the denser-than-air propane is flushed from thetank. Next, the top of the tank must be cut off just below the top curve in the tank, and a hole must be cut in the lower bottom side of the tank for the feed tube to comethrough.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

Step 4: The Burning Chamber WeldmentThe burning chamber of the rocket stove is where hot coals, heat, and flames are contained when the stove is in use. Before welding the plates into place, the hole for thefeed tube must be cut because warping may occur after welding. Next, the bottom plate is centered and welded into place at the seam of the burning chamber tube. Thetop plate is also centered and welded, and has a hole where the stove pipe will be welded later. These plates are cut 0.5in larger than the tube to apply welds. The feedtube must be inserted into the hole in the burning chamber 0.5in and welded into place, but be careful to not cut the feeding tube too long, because later it will have to befitted through the hole on the side of the stove tank.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

Step 5: Making Legs and Carrying HandlesThe legs of the stove are usually meant to be short, as to be able to easily look into a pot or pan on top of the stove from a standing position. Any design may beaccepted for personal preference, as long as it is able to support at least 100lbs and withstand high temperatures. For this stove, small lengths of C-channel were used tomake a sturdy base. Weld the legs to the tank before going any further; when the tank is full it is very heavy. Another feature that may be added and/or altered on thestove are the carrying handles.

Step 6: Positioning the Burning ChamberThe burning chamber weldment must be positioned a few inches off of the bottom of the tank. In order to seat the burning chamber in the proper place, use some of thesand to pack a level surface 2-3in high to place the burning chamber on. After fitting the feed tube through the side of the tank and centering the burning chamber in thetank, the feed tube can be welded into place.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

Step 7: Positioning the Stove PipeUse a square to position the stove pipe at a 90 degree angle, and tack weld it on one side. To check the positioning of the stove pipe, place the baseplate on top of thetank and see if the stove pipe clears the baseplate hole. The stove pipe will be easier to weld to the top of the baseplate if it sticks 0.125-0.25in above the baseplate. If itis not close enough to finish welding into place, use the square and a hammer to tap the stove pipe into proper alignment. After matching the stove pipe alignment withthe baseplate, finish welding the base of the stove pipe. Next the burning chamber and the stove pipe must be covered and packed with sand all the way to the top of thetank to insulate the burning chamber and stove pipe. The sand should be packed tightly to eliminate air pockets.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

Step 8: Fitting and Welding the BaseplateAfter filling the entire inside of the tank with sand, put the baseplate into position and weld all the way around the top of the stovepipe. The baseplate must be cut 0.5inlarger than the diameter of the tank to get a good weld all the way around the bottom edge of where the baseplate meets the tank wall. Next, weld the area between thehole in the baseplate and the stovepipe.

Step 9: Installing the Baseplate Burner-RisersIn order for the stove to be able to push hot air and smoke from the stove pipe, risers must be welded to the baseplate to elevate the cooking surface from the stove pipe.A few simple spot welds on each end will firmly hold them in place.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

Step 10: Drilling Depressurizing HolesDuring the first fire that will be burned in the new rocket stove, moisture trapped in the sand may become pressurized and possibly hazardous. Drill a few small holes ahalf inch below the weld seam of the baseplate so that the pressure inside of the tank can always adjust to the outside atmosphere.

Step 11: Grinding, Deburring, and Applying Stove PaintTo complete the fabrication on the rocket stove, remove all sharp exposed edges, deburr all surfaces, and surface grind all weld beads. To protect the exposed steelsurfaces and weld beads, apply two evenly spread coats of black stove paint. Do not use regular spray paint for this step, or it will bubble and burn during use. Hightemperature stove paint is required to adequately protect all outer surfaces. Allow 2-3 days of drying time before firing up the stove for the first time.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

Related Instructables

Rocket StoveMass Heater bySeniortrader

mini rocketstove fromchips box(Photos) byVitizop

Building ARocket StoveFor The Cabinbyfoodplotsurvival

Gravity fedpellet burner bySeniortrader Pocket Rocket

Stove Heater bykahuna

concrete rocketstove (Photos)by Tim Temple

Advertisements

Comments

33 comments Add Comment

avatar_i says: Jan 11, 2013. 3:08 PM REPLYNice desigh and beautiful workmanship, but I don't understand where the initial wood smoke/gas is being recirculated into the flame. Please explain what Iam missing...Thanks.

fretted says: Dec 12, 2012. 3:09 AM REPLYI think some folks are thinking of rocket mass heaters when they see this and confusing the 2 a rocket mass stove just burns hotter and faster than a regularstove for cooking a rocket mass heater burns and re burns wood gasses for a greater and longer heating time with less fuel and burn time !

FrankGregg says: Apr 27, 2012. 8:22 PM REPLYGreat looking stove!I would caution all against using vermiculite as insulation for something like this. Vermiculite has a small amount of asbestos in it. Not a good thing to bereleasing into the immediate environment where you might inhale in into your lungs.Cheers!

andrewsvan says: Oct 22, 2012. 2:00 PM REPLYI notice a lot of guys using pearlite

SIRJAMES09 says: Apr 22, 2012. 4:39 AM REPLYregardless of weather it fits the bill to be considered a rocket grill or not, I love this idea & wish I had the knowledge & tools to build one.

I thank you for sharing Sir, I love this thing!!!

Dockbob says: Apr 19, 2012. 2:23 PM REPLYI don't understand how this is a rocket stove. There doesn't seem to be anyway the secondary gases can join the flame. It appears to me to be a very niceinsulated wood stove.

Jislizard says: Apr 21, 2012. 4:47 PM REPLYFrom my understanding, the length of the chimney, approx 3 times the hieght of the burning chamber, will be long and hot enough for completecombustion of all the gasses.

oking says: Apr 19, 2012. 6:54 PM REPLYI second your question.

vincent7520 says: Apr 20, 2012. 2:51 PM REPLYAmen to that !

mpmitri says: Apr 21, 2012. 2:37 PM REPLYIt's great, keep up the good work.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

totally_screwed says: Apr 20, 2012. 12:02 AM REPLYI'm afraid while it may appear like a rocket stove, unfortunately if I am correct, the similarity is only skin-deep. It's a just very nice stove, well constructed.Rocket stoves have certain characteristics, which are essential to performance [efficiency and low emissions], a design that departs significantly from thosecharacteristics means it isn't one and it will most probably be not as efficient. IIRC, there are stoves which are not of the rocket type which achieve similar orgreater efficiencies, but are much harder to construct. Rocket stoves are intended to be very simple to make.

See the 'Ten Design Principles'

The Rocket stove was invented by Dr Winiarski at the Aprovecho Research Centre.

References

Design Principles for Wood Burning Cook Stoves

http://bioenergylists.org/stovesdoc/Pcia/Design%20Principles%20for%20Wood%20Burning%20Cookstoves.pdf

Designing Improved Wood Burning Heating Stoves

http://bioenergylists.org/stovesdoc/apro/Heat/Heating%20Stoves%20LO-RES.pdf

eaahnen says: Apr 21, 2012. 1:10 PM REPLYI definitely agree with you that it is a bit of a deviation from the rocket stove design. I wanted to feature an inner chamber so that it may function like arocket stove if you want, but it may also function as a forge.

The addition of a removable platform plate in the feed tube helped it to function like a rocket stove so that a draft could go underneath long sticks, andthe material burned hotter and more efficiently with even less smoke. The inner chamber was added to the stove so that after getting some hot coals inthe chamber from burning sticks, charcoal could be added to the chamber if forging applications were desired.

Also, thank you for the references they were great to look at.

maka says: Apr 21, 2012. 6:02 AM REPLYi look forward to hearing a response from the author on this, because the understanding of several folks who've commented here mirrors mine: Thisdoesn't appear to actually function like a rocket stove.

stoobers says: Apr 19, 2012. 12:50 PM REPLYHi,I made something similar, to melt aluminum which used a hair dryer to create the air blast, instead of convection.

The problem I had - sparks coming out the top. No smoke, but LOTS of sparks. I deemed my project a failure due to the fire risk. I never got to meltaluminum with it. :( I toasted a few marshmallows with it, though.

Based on your experiences with this type of stove, which is a sort of "self-blasted" furnace, please comment on these questions:

1. How did you address the spark issue? Does it make many sparks?2. Have you checked for sparks AT NIGHT when you can see them up in the sky?

Thanks!

eaahnen says: Apr 21, 2012. 12:55 PM REPLYAt first it may seem that the stove produces lots of sparks, but once some hot coals form in the inner chamber the smoke dwindles to barely any and thesparks also die down.

I agree with what rallen71366 said, using uncompressed charcoal briquettes make great heat.

rallen71366 says: Apr 20, 2012. 12:00 PM REPLYI've managed to melt aluminum in a coffee can w/hair drier, and you're right, there are a LOT of sparks at first. I found that using a hardwood charcoal(Kingsford (tm) was a good brand) got hotter, quicker, and had fewer sparks. The cheap charcoal was held together with a lot of binder and filler, andproduced a lot of ash, sparks, and sometimes wouldn't get hot enough to melt.

If you have access to knot-free hardwood, and a method to cut it into fist sized chunks, you might investigate making your own charcoal.

The old steam locomotives used "spark catchers" to keep from setting everything ablaze. I believe it was just a heavy gauge screen, across the exhauststack, and far enough from the burner to keep from melting.

cliqboom says: Apr 20, 2012. 6:50 AM REPLYWhile this is a nice cook stove and good quality work, I don't think it would qualify as a rocket stove since a true rocket stove takes advantage of thegassification process of the wood. This is the process that enables them to be truly efficient and produce the low smoke output.

The gasses are recirculated into the fire in a manner that there is enough heat and oxygen present to ignite the remaining flammable gasses left in the initalburn smoke. When those gasses and particulates ignite it burns away the majority of the normally wasted material and produces an extremely efficient andhot fire with less material.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

eaahnen says: Apr 21, 2012. 12:51 PM REPLYIt does work similar to what you described above. It produces little smoke to no smoke when the fire burns hot and plenty of hot flame.

oking says: Apr 19, 2012. 6:59 PM REPLYSo why only sand?

Why not vermiculite or perlite? If it was to insulate then perlite or vermiculite would work better.

Ash seems to work well too. Sand would just seem to add extra unneeded weight. Perlite, vermiculite, or ash would all reduce the weight of the finishedproject.

eaahnen says: Apr 21, 2012. 12:50 PM REPLYNext time when I make a more portable version, I will be sure to put something lighter inside.

Jislizard says: Apr 19, 2012. 6:20 PM REPLYNice to see one completed and not looking like it has been thrown together out of scrap metal.

A quick question, most of the designs I have seen have a platform for holding the fuel off the bottom of the feeder which allows the air to pass unobstructedunder the fuel to feed the flame, not necessary?

Also have you seen the gravity fed fuel hoppers where you can drop sticks down and the tips slowly burn, apparently good for controlling the speed of theburn. Is that something you considered for this build and dismised, or is it very difficult to get set up correctly?

I have seen some filled with concrete + vermiculite/perlite mix. Seems like a lot more work than just filling with perlite but might hold the bits in places better.

I like this and I have access to a scrap metal dealer and a welding set.

If anyone needs me this weekend I will be in the Emergency Department.

eaahnen says: Apr 21, 2012. 12:48 PM REPLYJislizard,I recently made a removable feeder-platform plate and it made it easier to burn longer sticks and scrap woood.

Also I had considered the angled fuel hopper but decided against it due to the fact that sometimes I may want the stove to function more like a meltingforge than a stove, and the angle may make it harder to pump air into the inner chamber.

Kelticpaddler says: Apr 19, 2012. 7:33 AM REPLYA great little stove!

Might I suggest that you use only three legs as the fourth leg makes anything (stool, table etc) wobble.

Obviously make them equi-distant (120 degrees) apart.

Same for the pot supports, just use three instead of four.

eaahnen says: Apr 21, 2012. 12:42 PM REPLYI know what you mean, if I ever make another I will consider 3 legs.

zer0vector says: Apr 19, 2012. 6:32 AM REPLYMy only concern is that is looks a bit "tippy" being so top heavy. How does it handle getting bumped?

eaahnen says: Apr 21, 2012. 12:41 PM REPLYIt seems ok when it gets bumped, the legs were made very sturdy. Before lighting the stove I always make sure it's on level ground too.

tfraser2 says: Apr 19, 2012. 2:24 PM REPLYAnother wonderful device that moves me forward to getting off the grid. I love the idea!! Now to build one and see it in practical use. Thanks eaahnen!! Keepit up...!!

...Todd

bennelson says: Apr 19, 2012. 8:39 AM REPLYNice job! Looks great! I did mine in the style of a backyard grill.

http://www.instructables.com/id/Rocket-Grill/

A friend of mine builds a lot of rocket stoves and wood gasifiers and LOVES using old propane tanks. They are nice metal, well-suited for projects likethese.

http://www.instructables.com/id/Fabricating-a-Heavy-Duty-Rocket-Stove/

Hoard-n-Hack says: Apr 13, 2012. 8:32 PM REPLYVery nicely done. It ought to last a lifetime (or two!)

I wonder, though, at the use of sand to fill the void between the shell & the combustion chamber. If perlite, vermiculite or some other type of lightweight &non-combustible insulation were used instead, the resulting structure would not be as top-heavy, have greater insulating effects and less heat transfer to theouter shell, which would lessen the risk of burns to the user.

Kelticpaddler says: Apr 19, 2012. 7:36 AM REPLY...or wth a filler at the top, and a tap at the bottom, you could boil water with it!!

See Kelly Kettles for details

http://kellykettle.com/

bartolo says: Apr 15, 2012. 11:49 AM REPLYI like it, sooner or later I'll make one too!

rimar2000 says: Apr 13, 2012. 3:38 PM REPLYVery good work!

Reading your intro I understant why my stove "roars".

buirv says: Apr 13, 2012. 12:30 PM REPLYGreat Work!!! I like it.