Experimental demonstration of corrosion phenomena: Part II. corrosion phenomena of steel in aqueous...

Transcript of Experimental demonstration of corrosion phenomena: Part II. corrosion phenomena of steel in aqueous...

Experimental Demonstration of Corrosion Phenomena

Part II. Corrosion Phenomena of Steel in Aqueous Media

Elsa M. Arce, Roman Ramirez, and Felipe C o r t k lnstituto Politecnico National, ESIQIE, Div. ingenieria Metalurgica, Ap. Postal 75-874, Mexico, D.F., Mexico

Jorge G. Ibaiiezl Universidad Iberoamericana, Depto. de lng. y C. Quimicas, Prol. Reforma 880, 01210, Mexico, D.F., Mexico

Modern applications of steel are innumerabk, from basic construction materials to the fabrication of so~histicated reaction vessels used in highly aggressive environkents. Un- fortunately, corrosion affects steel to the ~ o i n t that it has been estimated that approximately 25% of the world produc- tion of steel is lost due to corrosion ( I ) . In Part I (2), we showed the phenomena of corrosion, passivation and pitting of an iron electrode in aqueous media. In the experiments described below, we use a sample of carbon steel SAE 1065 (or UNS-G-10650 using the Unified Numbering System (3)) with an approximate weight percent composition as follows (4): C 0.60-0.70, Mn 0.30-0.60, P (max) 0.040, and S (max) 0.050 (the rest is Fe) to show the effect of aeeressive ions .... (e.g., CI-) and inhihiting ions (e.g., NO?-) upon its corrosion behavior. bv wine the ootentiodvnamic anodic ~olarization technique (2,5,6j. In addition, the effect that ihe C1- con- centration has uDon the time reauired for the initiation of the breakdown the passive filmon the surface of the steel electrode (induction time, T ) is put in evidence.

Experlrnental A 0.5 M HzSOa stock solution was prepared with deionized water,

and three aliauots where taken: (a) with no additives. h) enoueh NaCl was ad& to make a 1.0 M KaCl solution, and (r; I \ ' ~ c I u& addednsin h,nndao wnsNaNOlnstomakra0.5M UaNO~solutiun. All reagents were anal>~ieal grade.

The experiments were performed in a conventional three-elee- trode (working, WE; auxiliary, AE, and reference, RE) Pyrex cell, with an approximate capacity of 100 mL.

The working electrode was a steel 1065 rod ($ = 11.1 mm), encap- sulated into an eooxv resin matrix: the exnosed electrode surface . . was mirror-polished beforr earh run with sandpaper s6OO and wirh sureersively liner alumina suspensions tdom t o 0.0:) rm) and washrd wirh deionized water. The auxiliary electrode wa- a aplral madeof platinum wire, prevrously cleaned h y immersion in hot aqua rrgia tnirrohvdrorhl~rric acid). The reference electrode was a ratu- rated calomel electrode W E ) , and all the wtentials measured were given with reference to the SCE. Each soluiion was de-aerated with N. before each run. and a Ng atmos~here was maintained inside the eeil durine the wh& exoeriknt. ?he tem~erature was maintained ~~~~~~~~~~ -~~~ ~~~ . at 15 T. For earh sysrrm thun generated, the corrosion plmntial (E , , , , ) was measured at open circuit hetween the W E and the R E from this potential, the potentiodynamie anodic polarization ex- periments were performed for earh system, at a scan rate of 5U m\' s :.The applied potential was controlled with a BAS potentiostat model CV.2". and the obtained rirnal (, vs. E ) was plottrd with a BAS X-Y recorder; however, pra>tically any simpier equipment could be used as well.

As for the induction time experiments, the 0.5 M Hi301 stoek solution and the cell described above were also used following the same procedure. A potential was then applied to the WE so as passivate it at E = 1.25 V during 10 min. Enough NaCl was then added to different aliquots of the H2SO4 stock solution to prepare Clsolutions with the following concentrations: (a) 5 X M, (b) 1

Presented at the 199th Meeting of the American Chemical Society. Boston. MA. April 22-27. 1990.

' Author to whom correspondence should be addressed.

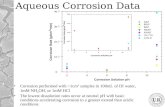

Figure 1. Anodic potentlodynamlc polarization curves of 1065 carbon steel in: (a) 0.5 M H.S04. (b) 0.5 M H.SOdl.0 M NaCI, and (c) 0.5 M H2S0,11.0 M NsCII 0.5 M NaN03.

X M, and (c) 5 X M; the electrodes were then immersed in each solution, and the current produced at E = 1.25 V was recorded. The time elapsed from here to the onset of the current production is taken as the pitting induction time, 7 (7).

Results and Dlscuslon The anodic polarization c w e obtained for the 1065 steel

electrode in 0.5 M H2SOa is shown in Figure la. This c w e shows an active dissolution zone up to a critical point where the current starts decaying drastically due to the formation of a passivating layer that reduces corrosion in a small pas- sive zone (2, 7,8).

As the scan is continued, a zone is reached where the current increases due to either the solvent decomposition and/or to the breakdown of the passivating layer and the dissolution of the metallic substrate (transpassive zone) (5). When the C1- ions are added to the system, the passive zone disappears (see Fig. Ib) due to the localized breakdown of the passivating layer (pitting) (2, 7,8). When the Nos- ions are added to the steell0.5 M HzS04/1.0 M NaCl system, the active dissolution zone is followed by a drastic current de- crease, by a small peak and by a wider passive zone (Fig. le). The first two features were explained above, whereas the small peak observed is due to the initiation of pitting by the C1- ions, which is then inhibited by the NO3- ions; the presence of the Nos- induces the repassivation of the steel

Volume 68 Number 4 April 1991 351

/.XI@ M ,,/-ixl0-/-" I ly Several shown hy corrosion-related using the anodic phenomena potentiodynamic of steel may polarization he easi-

technique. These experiments can he performed in a 3-h lab session.

Acknowledgment E= 1.25V One of us (JI) acknowledges partial support from PEMEX

and from Project INQ-050 of the Universidad Iheroameri- cana. "

5 10 15 2 0 25 3 0 Literature Clted TIME ( MIN.) 1. J. chem.Educ. SteftJ.Cham.Edue. 1979.56.673-674.

2. Solona. 0:Ibhdoe. J. G.; Olivares, L. J. Cham.Educ. 1991,68,175-177. 3. ~ i l l ~ ~ . C . P. Corrosion Control in the ChamicdPracers Industrie8;McGrav-Hill: New

Figure 2. Potentiastatic ivs. f cuwes (at E = 1.25 V) for 1065 carbon steel in York, 1986: p 97. 0.5 M HzS04 with different CI- concentrations: (a) 5 X M. (b) 1 X M, 4. Norden. R. B. In ChemicolEnginear's Handbook, 5th ad.; Perry, R. H.; Chilton, C. H.,

and (c) 5 X M. Eds.: MeGraw-Hill: New York. 1975;Senion 23, p51.

5. Uhlia, H. H.: Revie, R. W. Corrnrion and Corrosion Control; Wiley: Neu York, 1985: chapters 5 and 6.

6. E. G, and G. princeton AppliedResearch. Appliestio" Notecon. 1,Bosics of corroaian

(7). As for the induction-time experiments, the time re- ~ ~ ~ ~ ~ ~ ~ ~ e n t s : ~ r i n ~ ~ t o ~ , NJ, 1982: p 2.

quired for the onset of the pitting of the passivating layer ( r ) 7. Gaivele. J. R. 1" Passivity ofMetais: FrankenUlal, R. P.: Kruger,J., Eda.: The Elrctro-

chemical Society: Princeton, NJ, 1977; p 285. decreases as the concentration of the aggressive ion increases 8, wrang~en. G. an mrwiuction to corrosion and ~ ~ o t r c t i o n oi M ~ I ~ I Z : chapman and

(Fig. 2). Hall: London, 1985: Chapter 5.

352 Journal of Chemical Education