EW T VERSIO - inkanto by Armor · 2020-03-09 · EN ISO 105-D01 : 2010 AATCC 132-2009 Colour...

Transcript of EW T VERSIO - inkanto by Armor · 2020-03-09 · EN ISO 105-D01 : 2010 AATCC 132-2009 Colour...

10%30%60%

NEWA

ppli

cati

on’s

requ

ired

leve

l

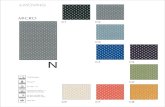

Vellum paper Matt coated paper

Glossy coated paper

Synthetic (PE, PP, PET...)

Specific (Polyimide, textile…)

Market size in printed surface

Wax

Wax-Resin

Resin

product life cycle

AXR®TX has been specially designed to meet ARMOR’s high-quality standards, offering optimum durability in line with the highly specific demands of textile product life cycles.

Your ribbon identity

The specialty resin for fabric label materials

Colours:

Length (m): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Width (mm): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part number: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Your distributor: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

®

Traceability

100%COTTON

XLIdentification

Transportation Purchase/Sale

90

Instructions

Cleaning

Resistance

Usage

Print resistance

98

0

wax

20 40 80 100

wax-resin resin

60

Printing receptorspecificNylon taffeta

Satin polyester

Polyester taffeta

wax wax-resin resin

Low Medium High

Energy

Compliant with the following regulationsOEKO-TEX® Standard 100 - Class I - CQ1172/1 IFTH

REACH / SVHC 1907/2006/EC

Food Contact 1935/2004/EC

Heavy metals 2011/65/EU

California Proposition 65

Halogen restrictions

SPECIALTY RESIN FOR TEXTILE APPLICATIONS

NEWVERSION

NEWVERSION

NEWVERSION

FLAT

H

E A D

FLAT HEAD

NE A R E D G E

PET filmInk layer(s

)

Backcoating

print quality

90°Barcode Small characters Logos

0°Barcode 2D BarcodeBlackness

technical resistances

storage conditions12 months recommended

20-80 % Humidity Rate, 5-35°C (40-95°F)

product structurePET film Thickness: 4 μm

Ink* Resin

Melting point 75°C/167°F

Backcoating Silicon based

Coefficient of Friction Kd < 0.2

Ribbon thickness < 8 μm

The ribbon is anti static build-up treated

Product physico-chemical features

Storage Waste management

inkanto rolls and their packaging allow an optimised waste management. For more information please contact ARMOR.

Product performance

Application fields

®

www.inkanto.com

SPECIALTY RESIN FOR TEXTILE APPLICATIONS

*Optical Density by Reflection,measured using a densitometer.

Fabric label materials

0100

0

0100

1000

200°C

3000

1,9 ODR*

2,5

0100

7,50

8

0100

85

010090

010090

98

0100

85

0100

80

0

0

90

95

L sizeMade in

EN ISO 105-E01 : 2010Colour fastness in water.EN ISO 6330/A1 : 2009AATCC 61-2009Domestic washing and drying.

Dry cleaningEN ISO 105-D01 : 2010AATCC 132-2009Colour fastness to dry cleaning using perchlorethylene solvent.

Rubbing

Washing

EN ISO 105-X12: 2003AATCC 8-2007Colour fastness to rubbing.

Sweat EN ISO 105-E04 : 2009Colour fastness to sweat.

NEWVERSION

NEWVERSION

NEWVERSION

Stonewash

BLEACH

Bleach UV

IroningAATCC 132-2009Colour fastness for hot pressing.

Other resistances:

Crease removal

FLAT

H

E A D

FLAT HEAD

NE A R E D G E

*Compatible with both Flat head & Near edge printers