EVG 620 MASK ALIGNMENT SYSTEM OPERATING MANUAL 620 Alligner.pdf · DOCUMENT: EVG 620 MASK ALIGNMENT...

Transcript of EVG 620 MASK ALIGNMENT SYSTEM OPERATING MANUAL 620 Alligner.pdf · DOCUMENT: EVG 620 MASK ALIGNMENT...

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

` EVG 620 MASK ALIGNMENT SYSTEM

OPERATING MANUAL Version: 3.0 Nov 2011

UNIVERSITY OF TEXAS AT ARLINGTON

Nanofabrication Research Center (NRC)

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

2

TABLE OF CONTENTS 1. Introduction…………………………………………….…………..2

1.1 Scope of Work…………………………………….…......3

1.2 Description…………………………………….…….……3

1.3 Safety……………………………………………....……..3

2. Hardware..............................……………………………….….....5

3. Requirements……………………………………..….….…….…..5

3.1 Training…………………………………….……..…...….5

3.2 System Restrictions………………………...……..…....5

3.3 xxxx

4 Operating Procedures.………………………..…..…………......6

4.1 System Pre-Checks………………………….…....…….6

4.2 Hg Lamp Start up …………………………………………..x

4.3 Preparing system for Alignment/Exposure…………...7

4.4 Anodic Bond Alignment ………………………………. 13

5 Recipes…….………………………..…..……………….…..….....14

5.1 Recipe Guidelines...................................................14

5.2 Creating a recipe.....................................................15

5.3 Editing a recipe........................................................17

5.4 Nanofab Recipes.....................................................18

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

3

1.0 INTRODUCTION

1.1 Scope

These procedures apply to the EVG 620 Mask Alignment Wafer system. All maintenance should follow the procedures set forth in the manufacturer’s maintenance and operations manuals. This document is for reference only. Users must be trained by Nanofab staff before operating this equipment.

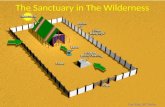

1.2 Description

The EVG 620 mask alignment system is a dual-use tool designed for optical double-side lithography and precision alignment for 2” to 4” diameter wafer size and small sample pieces. Top side alignment accuracy of ± 1.0µm 3σ , bottom side alignment ± 1.25µm 3σ, large gap alignment ± 1.5µm 3σ, IR alignment (substrate depending), bond alignment of ± 5.0µm 3σ. An ultra-soft wedge compensation together with a computer controlled contact force between the mask and wafer ensures that both wafer damage is minimized while mask lifetime are dramatically increased. High resolution of 2um is achieved in four exposure modes: proximity, soft, hard, and vacuum contact modes utilizing 350 Watt Mercury arc lamp calibrated to 16 Mw/cm2 light intensity using 365 nm uv probe.

1.3 Safety

1.3.1 This machine is connected to HIGH VOLTAGE. Be very careful and remain aware of electrical hazards. If you encounter any electrical malfunctions, contact NanoFAB staff immediately

1.3.2 Always keep finger clear of the moving parts such exposure head, mask loader and wafer tray. Failure to do so may result in personal injury.

1.3.3 This equipment uses a Hg-Arc lamp UV light source that is subjected to 20 to 30 atmospheres of internal pressure. There is always the possibility of a lamp exploding due to internal strains, high lamp temperature or physical abuse. Any vapor released by an exploded lamp would be highly dangerous. In the event of a lamp explosion, clear the area of personnel and contact the NanoFAB staff immediately. Do not return to the area until staff gives the OK to return.

http://www.cdc.gov/niosh/npg/npgd0384.html http://www.halcolighting.com/pdf/MSDS/Mercury_Vapor_MSDS.pdf

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

4

1.3.4 Be aware of UV light intensity when performing the Lamp start up procedure or when exposing wafers:

The light emanating from the light source is a hazard to vision. DO NOT LOOK INTO THE OUTPUT BEAM of the UV Lamp or reflection of the beam. Permanent damage to the retina of the eye and subsequent blindness can result. When checking whether the Lamp is ON , open the Lamp viewport window shutter just a very small amount and for the minimum time to see if the light is ON (the window is equipped with a short UV wavelength filter)

Short UV wavelength filter (green-yellow light)

1.3.5 Do not operate the system without proper room ventilation as some Deep

UV lamps produce significant levels of OZONE. http://www.cdc.gov/niosh/topics/ozone/ http://www.ozoneapplications.com/info/Ozone%20Solutions%20MSDS%20Ozone.pdf

1.3.6 This machine has an EMO (Emergency Off) switch/button mounted on the

top panel to the right of the keyboard. The EMO switch should be pressed only in an emergency. An emergency would be fire, smoke, electrocution hazards, or an impending injury to anyone using this particular piece of equipment. If the EMO is pressed notify NanoFAB staff immediately.

1.3.7 Read any posted NanoFAB Engineering Change Notices (ECN) for any hardware, process or safety changes before running the tool.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

5

2.0 HARDWARE

2.1 Vibration isolation table

2.2 Hg-Arc lamp calibrated at 365 nm wavelength

2.3 Wedge compensation: Internal 0.5 - 40N contact force

2.4 Manual substrate and mask loading

2.5 High resolution top and bottom side split field microscopes

2.6 Alignment stage precision micrometers

3.0 REQUIREMENTS

3.1 Training

All users must be trained and authorized on the EVG 620 Mask Aligner to use this system. Training is supplied by a Nanofab staff member please contact the tool owner to schedule training.

3.2 System Restrictions

3.2.1 Users must be logged into the EVG computer under operator name/password and log out of the computer when finished with the system.

3.2.2 Only NanoFab supplied recipes are to be stored on the system computer. Custom user recipes must be stored on a USB drive and should NOT be removed from the system or taken out of the NanoFab building.

3.2.3 USERS are not allowed to save UV light probe intensities to the hard drive. If you

need the intensity uniformity checked notify staff. The UV intensity uniformity is checked on weekly schedule.

3.2.4 If a system fault is display during an initialization or run sequence notify Nanofab staff.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

6

3.2.5 2” to 4” diameter wafer size and small sample pieces can be aligned/exposed. 2”, 3” diameters wafers and small sample pieces need to be fixed at a 4” carrier wafer.

3.2.6 Only 5” x 5” x ( 0.065-0.1 “) Mask can be used.

3.2.7 Recipe Requirements for all Alignment Modes: For top side , bottom side, Anodic bond and 1st mask Do not change the Separation parameter of 30um. The alignment camera objectives are 10X so a 30um separation will be within the focal range of the objectives. If you are aligning a deep buried layer or using very thick resist > 50 um and both alignment marks are not in focus call staff to check.

3.2.8 Ensure your softbake (pre-exposure) bake process is correct so your wafers resist coating does not stick to the mask during wedge compensation.

3.2.9 Follow the Lamp startup procedure per section: 4.1.7 Hg-Lamp Start-up procedure

3.2.10 Follow the Lamp Shutdown procedure per section: 4.2.30 Hg-Lamp Shut-down procedure

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

7

4. OPERATING PROCEDURES

4.1. System Pre-Checks

4.1.1. Check to ensure the hard contact pressure is 2.3 ± .05 barr.

4.1.2. Check to ensure system N2 and CDA pressure gauges are 0.6 barr. These gauges are located on the back of the tool as shown.

4.1.3. Check to ensure the Hg-Arc lamp is ON by moving the Lamp viewport window shutter just a very small amount and for the minimum time to see if the light is ON. (The Lamp viewport window is equipped with a short UV wavelength filter)

Short UV wavelength filter (green-yellow light)

If the Lamp looks like it is OFF proceed to section 4.1.4 to check the Lamp power supply LCD displays are within specifications.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

8

4.1.4. Check to ensure Hg-Arc lamp power supply is ON and the power supply knobs are set for Temperature display (T) and Constant Intensity setting CI1. If these knobs are not set for T and CI1 then move them to these settings. Check to ensure the Lamp power supply LCD displays are within the following spec limits.

o The Lamp Temperature should be 155C°-180C°

o The Lamp power at 350 ± 3 Watts.

o Incoming N2 pressure at 6 ± .05 barr (red LED) as shown. If the Lamp power supplies LCD displays are not within these specifications and tolerances call Nanofab Staff immediately.

4.1.5. If the Lamp power supply is already ON and within spec limits proceed to section: 4.2 Preparing System for Alignment/Exposure to continue your photolithography process. If the lamp looks OFF verify this by the next section 4.1.6

4.1.6. Check to ensure Lamp power supply is OFF by looking at the power supply LCD displays will be OFF and the Main power breaker/switch will be in the down position as shown.

If the lamp is OFF proceed to section: 4.1.7 Hg-Lamp start-up procedure to turn ON the lamp.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

9

4.1.7. Hg-Lamp start-up procedure :

4.1.8. Check to ensure the EVG or Microsoft desktop screen software is not currently running or ON. If the EVG software is running logout and shutdown the tool per section 4.3.34 to 4.3.36

4.1.9. Shut down then Microsoft /EVG Explorer desktop by clicking on the red shut down icon then choose shutdown option the press OK.

(failure to close the software and computer could result is damaging the computer when re-starting the Hg-Arc lamp)

4.1.10. Turn OFF the system Power Control by turning the power switch to OFF position as shown. The computer monitor will turn OFF.

Power Control by turning the power switch to OFF

4.1.11. Check to Hg-Arc lamp power supply knobs are set for Temperature display (T) and Constant Intensity setting CI1. If these knobs are not set for T and CI1 then move them to the correct settings.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

10

4.1.12. Turn ON Hg-Arc lamp power supply ON by moving the power switch/breaker to the UP position as shown. The green 5, ±12, 24 volt LED’s should all be ON. Call staff if these LEDS do not turn ON

4.1.13. Turn ON (ignite) Hg-Arc lamp by press the Lamp Start button down for 1-2 seconds.

4.1.14. The Lamp Power LCD display should display 350 ± 3 Watts and the Lamp temperature should start to increase from room temperature to ~ 160C°.

If the Lamp Power still displays -000 Watts and the temperature is not increasing then the Lamp didn’t ignite. Press the Stop button down and press the Lamp Start button again per section 4.1.13 . If the power LCD does not display 350 ± 3 Watts call staff to check.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

11

4.1.15. Let the Lamp warm up for 15 to 20 minutes then check the Lamp power supply Temperature, Power and N2 parameters are with spec limits as per section 4.1.4

o The Lamp Temperature should be 155C°-180C°

o The Lamp power at 350 ± 3 Watts.

o Incoming N2 pressure at 6 ± .05 barr (red LED) as shown.

If the Lamp power supply LCD displays are not within these specifications and tolerances call Nanofab Staff immediately.

4.1.16. Turn ON the system Power Control by turning the power switch to ON position as shown.

Power Control by turning the power switch to ON

4.1.17. The tool computer will boot up and will start the Microsoft / EVG Explorer software.

4.1.18. Now the lamp is ON and stable , the EVG Explorer software is running on the desktop you are able to continue your photolithography process per section 4.2 Preparing System for Alignment/Exposure

4.1.19. Check to insure the system Main Power and computer are ON .The computer screen should have the EVG 620 desktop displayed as show

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

12

4.2. Preparing System for Alignment/Exposure

4.2.1. If you have not completed the System Pre-Checks in steps 4.1.1 – 4.1.6

then you must complete those before proceeding.

4.2.2. When you first approach the screen the EVG 620 desktop screen is displayed as shown. Double click on EVG6XX tab to run wafer processing software.

4.2.3. In the grey login screen click on the LOGIN tab at the top left side of the

screen. A pop up window will display. Enter user ID and password. User : Operator Password : operator

4.2.4. Wait for system initialization to complete. Keep fingers clear of the moving parts such exposure head and mask loader. Failure to do so may result in personal injury. During initialization system will prompt you to pull tray out. Gently pull tray out. Follow any initialization prompts and DO NOT do any manual operations unless there is a system prompt. If initialization is OK then continue, if there is any fault code message call staff.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

13

4.2.5. Select the new folder or open folder icon to create a new or download a previously stored recipe.

4.2.6. If the new folder icon was chosen a temporary recipe template will display. At this point you create a recipe depending your device requirements ( i.e. 1st mask, top side alignment, bottom side alignment ,bond alignment) There are four process modes you enter by clicking on the arrow down drop down menu : Process , Process Mode, Exposure Mode, Contact Mode .Do not change the Separation parameter( 30um ), Mask thickness or Substrate thickness .The alignment camera objectives are 10X so a 30um separation will be within the focal range of the objectives. If you know the distance from the wafer alignment marks to the surface of the resist coated wafer ( i.e. buried layer+ thick resist) is much greater than 30 um the mask to wafer alignment mark focusing will not be a sharp image. Ok to enter your resist thickness.

Here are examples of the four different process mode screens you will need to set up depending on your device requirements and processing step.

1st mask top side align bottom align bond align

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

14

4.2.7. In each of these General Process Modes you will have to set up the following recipe parameters. Alignment Mode : top side ,bottom side,bond,1st mask. Exposure Mode : constant dose, dose interval, constant time, constant interval time. Contact Mode : hard contact, proximity, soft contact, V+H contact, vacuum contact Note : V+H contact and vacuum contact modes require the use of the vacuum contact oring.

Again here are examples of the four different process mode screens you will need to set up depending on your device requirements and processing step.

1

st mask top side align bottom align bond align

4.2.8. After you are finished creating a new recipe press the Green arrow at the bottom left to begin the Semi-Automatic alignment / exposure program.

4.2.9. Each Alignment Mode and Contact Mode recipes will have a different semi-automatic computer controlled sequences. The USER simply needs to follow the software prompt at all times. Note : V+H contact and vacuum contact modes require the use of the vacuum contact oring

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

15

4.2.10. To begin the process press Continue or Exit to stop (abort) the sequence. The first screen configure optics (no options they are10X). Press continue.

4.2.11. Insert mask holder as press continue (if mask holder is already inserted press continue). To insert the mask holder mate the two brackets 1st and gently mate the single bracket at the top on the mask as shown.

4.2.12. Fix mask holder with the three thumbs screws finger tight as press continue.

4.2.13. Insert chuck and air line press and continue .

(if chuck is already installed and air line is connected press continue).

4.2.14. Insert load frame and PhotoMask as shown and press continue. (mask chrome side down, mask edge aligned with white tray bumpers).

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

16

4.2.15 Move Tray in and press continue.

4.2.16 Move stage to center position by adjusting X,Y and theta micrometers to 5mm on the scaled line and ZERO on the dial.

The micrometers zeroing accuracy is critical for the mask vacuum to hold the mask in the subsequent steps.

After zeroing the micrometers press continue.

4.2.17 Adjust optics by using joystick knob for X, Y motion. Rotate knob for Z

axis adjustments. Click on [ L ] and [ R ] optic icons to move objectives independently. Adjust left and right camera brightness and contrast as needed.

4.2.18 Use the pin icon, + , -, 4X, 2X,1X to find and save the recipe’s

optics step count, ZL and ZR information.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

17

4.2.19 Adjust theta to correct for mask to optics rotation. After mask adjustments

are finished press continue.

4.2.20 Gently move tray out and remove load frame then press continue.

Note : If you do not remove load frame and press continue the auto optics focusing of the wafer marks and mask marks will not focus correctly.

4.2.21 Insert substrate as shown for WEC ( Wedge Compensation) and press continue.

No load frame at this step

4.2.22 Move tray in and press continue. Wait for WEC and Auto Position Optics to

complete.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

18

4.2.23 Aligne substrate to mask by using previously stored alignment mark positions

then perform a fine manual alignment at the left and right side of the wafer by using X ,Y, theta micrometers to optimize the alignment. Save alignment

positions per section 4.2.18.

( Note: Refer to section 4.2.17 to 4.2.18 for camera optics operation and functions )

4.2.24 When alignment is complete press Continue to exposure the wafer to UV light. Wait for exposure to finish. End of process screen will display.

End of Process

4.2.25 If you are finished processing your wafers press the Exit icon at lower right

side of screen. The status screen will display.

4.2.26 To remove your wafer click on Tray out icon on the upper task bar. Follow the software prompts only.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

19

4.2.27 To remove your Mask click on Mask out icon on the upper task bar. Follow the software prompts only.

4.2.28 Log out of the EV6XX program.

4.2.29 After you have logout of the EV6XX software, the Microsoft /EVG Explorer software will be on the desktop screen. Leave the computer ON with the EV6XX software running.

4.2.30 Hg-Lamp Shut-down procedure

4.2.31 Leave the computer ON with the EV6XX software running.

4.2.32 Turn OFF Hg-Arc lamp by pressing the lamp power supply Lamp Stop button down for 1-2 seconds as shown.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

20

4.2.33 The Lamp Power LCD display will show -000 Watts and the lamp will be off and the lamp temperature will start to cool down to room temperature.

4.2.34 Allow the lamp to cool down properly by waiting 30 minutes before turning lamp power supply OFF.

4.2.35 After 30 minute cool down time turn OFF the Lamp power supply by the moving the switch/breaker to the DOWN position as shown. The previously green 5, ±12, 24 volt LED’s and all LCD displays be OFF.

4.2.36 Enter the required information in the logbook.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

21

4.3 Anodic Bond Alignment.

4.3.1 If you have not completed the System Pre-Checks in steps 4.1.1 – 4.1.3 then

you must complete those before proceeding. For Anodic bonding alignment OK to leave the Hg-Arc lamp OFF.

4.3.2 When you first approach the screen the EVG 620 desktop screen is displayed as shown. Double click on EVG6XX tab to run wafer processing software.

4.3.3 In the grey login screen click on the LOGIN tab at the top left side of the screen. A pop up window will display. Enter user ID and password.

User : Operator Password : operator

4.3.4 Wait for system initialization to complete. Keep fingers clear of the moving parts such exposure head and mask loader. Failure to do so may result in personal injury. During initialization system will prompt you to pull tray out. Gently pull tray out.

Follow any initialization prompts and DO NOT do any manual operations unless there is a system prompt. If initialization is OK then continue, if there is any fault code message call staff.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

22

4.3.5 Remove Mask Holder and 4” wafer chuck and carefully place on storage tray below tool.

4.3.6 Select the new folder or open folder icon to create a new or download a

previously stored recipe.

4.3.7 If the new folder icon was chosen a temporary recipe template will display. There are four process modes you enter by clicking on the arrow down drop down menu : Process , Process Mode, Exposure Mode, Contact Mode .Do not change the Separation parameter( 30um ), Mask thickness or Substrate thickness .

4.3.8 Click on the Process arrow down drop down menu and click on

Man. Anodic Bond and choose Crosshair mode.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

23

4.3.9 After you chosen Man. Anodic Bond and Crosshair mode press the Green arrow at the bottom left to begin the Semi-Automatic Bond alignment.

4.3.10 The Man. Anodic Bond and Crosshair recipe will have a semi-automatic computer controlled sequences. The USER simply needs to follow the software prompt at all times.

4.3.11 To begin the process press Continue or Exit to stop (abort) the sequence. The first screen configure optics (no options ) .Press continue.

4.3.12 The system will prompt for “Save changes to Recipe1? “ Press NO. The process sequence will begin.

4.3.13 Insert Bonding tool with clamp levers facing up and press continue as

shown (if mask holder is already inserted follow prompts to remove.)

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

24

4.3.14 Remove clamps by rotating left clamp lever CW and right clamp lever CCW

as shown then press continue.

4.3.15 Remove separation flags by gently pushing the arm outwards and press continue. (separation flag arm @ 12,4,8 o’clock positions)

4.3.16 Insert chuck connect vacuum line and press continue.

4.3.17 Insert bond glass (correct side up) and ruler as shown and press continue.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

25

4.3.18 Load top substrate as shown and press continue.

4.3.19 Remove ruler and press continue.

4.3.20 Gently move tray IN as shown.

4.3.21 Move to center stage by adjusting the three X,Y and theta micrometers to 5mm on the scaled line and zero on the dial. Then press continue. Wait for wedge compensation to complete( WEC).

4.3.22 Adjust microscope and press continue ( refer to sections 4.2.17 to 4.2.18)

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

26

4.3.23 Adjust crosshair and press continue.

4.3.24 Gently move tray OUT and press continue.

4.3.25 Insert bond glass and press continue.

4.3.26 Insert ruler and press continue.

4.3.27 Insert bottom substrate and continue.

4.3.28 Remove ruler and press continue.

4.3.29 Gently move tray IN and press continue.

4.3.30 Pre-aligne substrate and press continue. Wait for WEC

4.3.31 Aligne substrate and press continue. Wait for WEC.

4.3.32 Insert clamps by rotating left clamp lever CCW and right clamp lever CW as shown then press continue. Wait for bond alignment to complete.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

27

4.3.33 Remove bond tool and press continue.

4.3.34 Gently move tray OUT. End of Process.

4.3.35 Press Exit icon at lower right side of screen. The status screen will display.

4.3.36 To move tray IN click on Tray out/in icon on the upper task bar. Follow the software prompts only.

4.3.37 Log out of system and enter the required information in the logbook.

DOCUMENT: EVG 620 MASK ALIGNMENT SYSTEM OPERATING PROCEDURES Version: 1.0

28

5 RECIPES

5.1 Recipe Guidelines

5.1.1 Users must store all of their recipes on a USB drive. This drive must not leave the NanoFab building .Warning - Recipes left on the main system hard drive will be deleted.

5.1.2 Editing a recipe must be approved by Nanofab Staff before proceeding.

5.2 Creating a recipe

5.2.1 You must be logged into the EVG system software in order to create a recipe.

5.2.2 To create a recipe to sections 4.2.5 to 4.2.7 .

5.3 Nanofab recipes