EVE MARINE SURVEYORS, INC. · EVE MARINE SURVEYORS, INC. ... 110 lb. plow anchor, stainless swivels...

Transcript of EVE MARINE SURVEYORS, INC. · EVE MARINE SURVEYORS, INC. ... 110 lb. plow anchor, stainless swivels...

EVE MARINE SURVEYORS, INC. THOMAS M. EVE, Marine Surveyor 31 Richmond Drive, Savannah, GA 31406

Office: (912) 355‐5911 Fax: (912) 355‐5913 Website: www.marinesurveyor.com/ems/

Email: [email protected] Tax ID: 58‐2105719

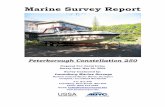

1982 55’ CHEOY LEE LONG RANGE MOTOR YACHT

I owned and cruised a 33’ Model Choey Lee offshore for 15 years, in an earlier

time between running repair yards and then my own marine business conducting repairs, restorations and rebuilds on various types and models of yachts.

I have also represented the Lo brothers whose family owns Choey Lee in a

matter concerning one of their 105’ motor yachts, and visited their yard in Hong Kong in years past. I have also fully restored my own Cheoy Lee 33’ offshore

ketch also a 31’ ketch and a 44’ flush deck ketch. Choey Lee has produced thousands of boats, sail, motor yachts and trawlers.

The names and addresses have been redacted on the following survey.

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

2

EVE MARINE SURVEYORS, INC. THOMAS M. EVE, MARINE SURVEYOR

31 Richmond Drive, Savannah, GA 31406 Office: (912)355‐5911 Fax: (912)355‐5913

Email: [email protected] Tax ID: 58‐2105719

Website: www.marinesurveyor.com/ems/

VESSEL SURVEY REPORT

Prepared for Redacted

December 8‐10 & 23, 2011

“name of vessel”

1982 55’ Cheoy Lee Long Range Motor Yacht

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

3

VESSEL SURVEY REPORT

VESSEL PARTICULARS Date of Survey: December 8-10, 2011

Sea Trialed December 23, 2011 Our File #: 3046/11

Vessel Name: Redacted. Hull Identification #: Redacted. Registration: Redacted. Type Vessel: FRP Motor Yacht Builder: Cheoy Lee Shipyards Limited; Kowloon, Hong Kong When Built: 1982, model 55 Long Range Motor Yacht Description: Twin engine, diesel propelled, dual station, pilothouse motor

yacht with flybridge Length O/A: 55’ Beam: 17’ Depth: 10.5’ Draft: 5/4” Gross & Net Tons/Weight: 72 Gross Tons, 53 Net Tons; Displacement: 80,000 lbs.

OWNER/BUYER PARTICULARS

Owner/Buyer: Redacted. Address: Redacted. Home #: Redacted.

PURPOSE & SCOPE

In accordance with instructions, I proceeded to Hinckley Yacht Services, Thunderbolt, Georgia on December 8-10, 2011, where the above captioned vessel was located hauled out. The survey was conducted hauled out without sea trials. The purpose of this survey was to inspect the vessel for condition and valuation related to prepurchase and insurance purposes. On December 23, 2011, I returned to Hinckley Yacht Services, Thunderbolt, Georgia to conduct a sea trial on the vessel. Refer to Sea Trial Data for results. The following is a description of the vessel, her equipment, machinery and inventory. Remarks, Recommendations and General Condition statements follow at the end of the report.

ESTIMATED VALUATION

ESTIMATED VALUATIONS ARE BASED ON THE SURVEY IN CONJUNCTION WITH COMPARABLE VESSELS FACTORED AGAINST THE BUC USED BOAT PRICE GUIDE, VOLUME II 2010, 98th EDITION. DURING THE COURSE OF THE SURVEY, NFPA302 AND ABYC STANDARDS WERE CONSIDERED.

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

4

Present Value: $270,000 Replacement Cost: $1,800,000.00 approximately

CORROSION

There are various types of corrosion that effect all types of metal used in vessel construction, above and below the waterline. This is a subject that all boat owners should be familiar with in order to identify and recognize what is occurring with these materials. Types of corrosion can occur in both fresh water and salt water. This survey does not include the removal, other than readily accessible areas, of any mechanically secured items, or items not readily accessible by usual means without mechanical assistance.

HULL

Type Hull: Round chine, raked stem, square transom, shallow draft full run keel displacement style hull.

How Laid Up: Hand laid up, female mold, matte, cloth, woven roving with polyester resins. For hull construction particulars related to the hull below the waterline, topsides, deck, and deck and deck house refer to the manufacturer or onboard owner’s manuals.

Bulkheads: Transverse ply partials throughout with a full bulkhead in the aft engine room.

Type Decks: FRP Type Construction: Sandwich

Bottom: Refer to Haul Out Sides: Fair condition, consistent with age,

compounding and waxing will clean them up to some extent. Ultimately, the topsides need painting to include the strakes, rub rails, and exterior moldings as needed.

Decks: Original teak removed and then glassed over

Reinforcements: Adequate throughout Keel: See recommendations

Condition:

Rigidity of Hull: Adequate throughout

UNDERWATER MACHINERY Steering Gear: Dual station, hydraulic wheel steering with autopilot with dual shift and

throttle controls equipped with Glendenning synchronizer Spade: Yes Skeg Stepped: -

Rudders:

Other: -

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

5

Bow Thruster: - Propellers: 4-blade bronze 30” x 22”, see recommendation. Spare 3-blade bronze

propellers located below the master stateroom berth. These have been reconditioned. Another set of 3 blade bronze propellers under the swim platform.

Propeller Condition: Good: --- Fair: --- Poor: XXX Shafts: 2 ½” stainless steel running through vee struts, equipped with cutters Trim Tabs: - Packing Gland: Conventional glands, see recommendation Stabilizers: WesMar model CPS1000 Gyro, controller on bridge, see

recommendation

DECK MACHINERY, HARDWARE & EQUIPMENT 1. Polished stainless steel anchor chute with double rollers 2. (1) 66 lb. Bruce anchor 3. (1) 110 lb. plow anchor, stainless swivels on the chain, dual chain locks and hawse pipes 4. (1) Fortress FX-55 anchor 5. Foredeck Ideal hydraulic windlass, double vertical drum for rode and chain with foredeck

touch pads, 3/8” chain 6. Stainless steel bow rail and stanchions with lower section life line and raised bulwarks from

amidship back aft to the cockpit 7. Fenders 8. Aft deck camera 9. Cleats and hawse pipes forward, amidship, and back aft 10. Boarding gates to starboard and port and in the transom 11. Electric lift, transom mounted teak swim platform 12. (1) Rod holder per side back aft in the corner of the cockpit 13. Mechanically radar mast for antennas and lights for low bridges 14. Custom chocks for the Boston Whaler mounted on the aft deck of the flybridge 15. Hydraulic crane on the aft deck 16. Dockside water inlet 17. Water Purification System 18. Nautical Structures aluminum davit with hydraulic winch 19. ACR 406 EPIRB 20. Transom mounted ladder 21. Bimini top fore and aft of arch 22. Adequate Chocks and cleats, fore and aft 23. Adequate lights and signals for type and use.

DECK HOUSE ARRANGEMENTS

Flybridge with (2) pedestal mounted swivel chairs, centered helm, adjustable signal mast with

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

6

DECK HOUSE ARRANGEMENTS table around, bench seats to either side. The bridge leads back aft with a Taylor grill to port and propane storage locker to starboard with (4) 64 lb. propane bottles and an un-mounted Fire Boy Clean Agent FE241 bottle in the propane locker. The aft deck is open with a crane on the starboard side and the Boston Whaler mounted in chocks on the port side and a smaller inflatable dinghy. The flybridge is nonskid throughout. There are steps leading down from the flybridge to the pilothouse. The pilothouse entrance doors are to either side and a centered helm, at sea berth with storage below. There are steps leading from the pilothouse down the port side back to the galley/main salon area. The galley is equipped with a Panasonic Convection Model Genie 1300W Microwave Oven and a 4-burner Force Ten LPG stove with oven. There is a double stainless steel sink with hot and cold pressurized running water and a Maytag side-by-side refrigerator/freezer with water and ice through the door. There is a Viking garbage disposal on the aft sink, a EuroPro countertop mounted grill, and a toaster. There is storage below the C-shaped galley counter. The passageway leads back aft to the main salon. The main salon is equipped with a bar, wine rack. There is a large recessed flat screen television, an adjustable main salon table, an L-shaped couch to port and an extendable dining table, and an entertainment center in the starboard aft corner. The entertainment center is equipped with a 42” flat screen television with Bose speakers, Toshiba Digital Cinema Progressive System, a Yamaha Natural Sound model RXV740 Receiver, DISH DVR HD Satellite Receiver, and an Emerson model Extra Bass. In the forward port corner of the salon, there is built in cabinetry with storage, housing one of the A/C units. The main salon is carpeted throughout. All of the wood work is naturally finished in satin coats. The general appearance of the interior of the pilothouse and main salon would be considered good. The carpet is somewhat aged but serviceable at the moment. The brightwork, with some minor exceptions on the interior framing joints around the window where there is slight lifting of varnish would be considered in overall good condition. There are Levelar blinds on the house windows. There is a sliding door opening to the aft cockpit. The aft cockpit is equipped with a table with piano hinge and adjustable with storage below. There is a transom mounted gate ladder and swim platform. There is a spiral staircase leading down to the lower deck. The engine room is at the end of the passageway. The engine room is equipped with an insulated door. Going forward from the engine room, there is a port side head. The head is equipped with entrance doors from the passageway and from the port side guest stateroom. The head is equipped with a vacu-flush toilet, separate shower stall, opening port, marble countertop with stainless steel sink with hot and cold pressurized running water, and storage below. The head is carpeted. Going forward on the starboard side, there is a guest stateroom.

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

7

DECK HOUSE ARRANGEMENTS The guest stateroom is equipped with double bunks, a small desk/vanity area, remote stereo speakers, hanging locker, and carpet throughout. On the port side of the passageway, there is a guest stateroom common to the aft port side head. The stateroom is equipped with double deck bunks, hanging locker, (2) opening ports, remote speakers, house phone, clock, and fan. The passageway continues forward. On the forward port side, there is an Asko model 7003 dryer and a Supra washer, stacked units. The passageway continues forward to the forward stateroom. The forward stateroom is equipped with a vee berth, overhead opening hatch, two opening ports to either side, hanging locker, built in cabinetry, a Samsung Syncmaster flat screen television, and a Satellite receiver. The stateroom is carpeted. There is a starboard side forward stateroom head equipped with a marble style counter, stainless steel sink with hot and cold pressurized running water, and a vacu-flush style electric head. There is a separate shower stall with teak grate. All of the accommodation spaces and passageways are equipped with carpet. In the starboard side main salon there are steps leading down to the aft stateroom. The aft stateroom is equipped with a centered queen size bed, built in cabinetry to either side, enlarged cedar lined closet, and a drop down flat screen television. The stateroom is carpeted throughout. There is a small desk area in the starboard forward corner. In the port corner there is an enclosed head equipped with a vacu flush toilet, sink with hot and cold pressurized running water, and separate shower stall. Small open cockpit with transom gate.

NAVIGATIONAL AND ELECTRONIC GEAR

1. Raymarine model RL80C Plus Pathfinder 2. Raytheon model ST80 Multi View for Speed and Depth 3. Raytheon model ST80 Digital Depth Sounder/Speed 4. Raymarine model ST6001 Plus Autopilot 5. Garmin model 320C Fishfinder 6. Remote Control Spotlight 7. Loud haler 8. Raymarine model RAY Handheld VHF Marine Transceiver, see recommendation 9. Icom model HC Marine IC-M802 10. Icom model IC-M32 Water Proof VHF Marine Transceiver 11. Standard Horizon model GPS Chart 150C 12. Raymarine handheld VHF 13. Garmin Fishfinder 320C 14. Raytheon model ST80 Masterview for apparent wind and speed 15. Raymarine model ST6001 Plus Autopilot with ST6000R Remote

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

8

16. Raytheon model ST80 Digital Depth and Speed 17. Phillips HDTV 18. Raymarine model L1250 Plus Ray Chart Plotter 19. Davis model Vantage ProWeather System 20. Raymarine model ST60 Apparent Wind and Speed 21. WesMar CPS1000 Gyro Controlled Stabilizing System 22. Computer keyboard 23. KVH antenna 24. (2) small bridge mounted lights in the overhead for the console 25. HP Computer 26. Ditch Bag with ACR EPIRB, see recommendation 27. Horn 28. Icom model IC-M802 HF Marine with Distress 29. 162 MHz Weather Alert NOAA System 30. Quartz Hi/Lo Tide Clock 31. HDTV Flat Screen television in wheel house as part of the Multiplexer Camera System 32. Danforth Compass 33. Tellular Telephone System 34. ProSine Control ACS Xantrex 3000 Watt Inverter System 35. Tank Levelers Inclinators 36. Fireboy Engine Fire Suppression System 37. SearchLite System with twin SearchLite Controls 38. Adequate lights and signals for type and use.

GENERATOR

Number: (2) Generator Type: Onan Diesel , equipped with sound shields and start/stop controls, water

temp, oil, and volts on the gen sets Model: Starboard: MDKAV-5667723

Port: MDKAV-56677249 Serial: Starboard:

Port: AC/DC: 120 VAC KW Output: 9 KW Hours: Reportedly 1400 hours Automatic Shut Offs: Yes, not tested General Appearance: Very Good: XXX Good: --- Fair: ---

MAIN ENGINES

Number: (2) Type & Make: Caterpillar

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

9

MAIN ENGINES Model: 3208N Serial Number: Starboard:

Port: Date of Manufacture: 1982 Engine Hours: Starboard: 1,129.5 hours

Port: 1,130.4 hours Cylinders: V-8 Fuel: Diesel Horsepower: 210 HP each Cooling Systems: Raw water/fresh water

Type- Injectors Drip Pans- Yes

Carburetors:

Backfire Arrestors- - Wet- Yes Dry- - Lagged Properly- Yes

Exhausts:

Exhaust Clear of Wood & Other Combustibles-

Yes

Water Temperature- (2) Oil Pressure- (2) Gear Oil Pressure- (2) Volts- (2) Revolutions- (2) Other- Dual FlowScans, Remote Fire Boy with

override and engine shut down, AC Systems loads, triple AC amp meter, one dedicated per line and air conditioning, DC amps, (2) dual gen set controls with start/stop/hour meter, air conditioner control, bilge pump controls, tank level indicator with visual read outs for fresh water/black water/grey water and level indicator, Inverter control panel, AC volt meter and hertz meter for shore power, power selector switch for shore power, gen set 1 & 2, Camera selector controls

Engine Synchro Unit- Glendenning

Gauges:

Alarms- Low engine oil pressure, high engine water temperature, Weather One Weather Alert System

General Appearance Engine: Very Good: --- Good: XXX Fair: ---

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

10

TRANSMISSION

Make: Twin Disc Model: MG506 based on onboard ship’s papers Serial Number: Inaccessible to view Ratio: 2.96:1 General Appearance: Very

Good: --- Good: XXX Fair: ---

ENGINE ROOM VENTILATION

Cowls: Yes Ducts to Bilge: Naturally aspirated Blowers: Yes Hatches: Engine room door

ELECTRICAL SYSTEMS

Shore Line Connections: (2) 50 amp outlets in the engine room above the panels Polarity Indicator: - Circuit Breaker/Fusing Controls: Circuit breakers Bonding or Grounding Systems: Generally good throughout, see recommendation BATTERIES: (6) D4, divided into 3 banks

Secured- Boxed in an FRP pan and secured across the top System Voltage- 12 volt DC Battery Master Switch- (7) Switches, various functions Charging Unit- Newmar 40 amp Adequate Ventilation- Yes Inverters- 3000 watt ProSine Inverter Type Wiring- Multi Strand

Properly Led/Supported- Generally, see recommendation Main Panel(s): The main panels are located in the pilothouse. (2) 12 volt DC panels

equipped with circuit breakers throughout. There are three primary panels in the engine room. There is (1) 12 volt DC panel equipped with circuit breakers throughout. Below that there are (2) 120 volt panels equipped with circuit breaker throughout. Below that there are (2) 240 volt panels equipped with circuit breakers.

FUEL SYSTEM

Fuel Used: Diesel Tanks (Capacity, Construction & Location): (2) tanks located to starboard and port in the

engine room, reported capacity 1400 to 1600

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

11

gallons, equipped with large inspection ports, sight gauges, a fill rate meter, a Racor, and an Esi-Clean Fuel System model CFS1000FRO

Integral with Hull: No Vented: Yes Fill Pipes Flush with Deck: Yes Type Valves & Accessibility: Inline packless type Flexible Sections at Engines: Yes Fuel Filters: Remote Racors for starboard, port, and generator Oil Exchange System: 3-manifold Reverso Oil Exchange System

FIRE PROTECTION AND SAFETY EQUIPMENT

Fixed Fire Protection: Halon 1301 Fire Suppression System Area Covered: Engine room Bottles Size & Condition: Label blocked from view by mounting brackets Tagged: Dated Portable Extinguishers (type, size, locations): Multiple extinguishers located throughout the

vessel which should be mounted in plain sight with ready access and serviced. Kidde Fyrnetics portable Halotron I extinguisher

Charged: Yes Dock Side Water Inlet: Yes Adequate USCG Life Jackets: Approximately (10) Type I jackets, Some inflatable

vests Flare Kit: Multiple flare kits with handheld flares, flare pistol

and shells, rocket propelled flares, and smoke canister, in good condition but dated, see recommendation

Additional Safety Gear: Life Sling Man Overboard Rescue System Boats or Life Rafts: (1) Mercury RIB Inflatable, Serial Number: (1)

13’ Boston Whaler with a 40 HP Yamaha outboard motor with hydraulic steering, fixed fuel tank, wheel steering, and Bimini top. The outboard motor transom numbers were inaccessible due to the location of the dinghy, same with the motor. The HIN# on the Boston Whaler is BWCJ1948M82L.

CO Detector: See recommendation Smoke Alarm: -

BILGE PUMPS

Manual: - Electric: (5) Confirm operation. Some operable, others not.

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

12

BILGE PUMPS Submersible/Dry Mount:

Yes

Make: Rule High Water Alarm: Yes, not tested

DOMESTIC EQUIPMENT

Heads: (3) Holding Tank: Black water tank with sanitation hoses and inspection

port and wires for tank monitor. Grey water tank aft of the black water tank, equipped with sanitation hoses. There is a bladder located under the starboard side stateroom bunk, appears to be empty. The Power Boat Guide states that there is a 125 gallon holding tank.

Shower Baths: (3) Manual- - Hot- Yes

Pressure Water System:

Cold- Yes Washer/Dryer: Asko model 7003 dryer and a Supra washer Air Conditioning: (6) Air Conditioners: 12,000 BTU & 16,000 BTU with SMX

control panels Television(s): Forward stateroom flat screen, master stateroom flat

screen, main salon flat screen Hi-Fi System/Other: DISH Antenna, DVD Player in the aft stateroom, Toshiba

Digital Cinema Progressive System, a Yamaha Natural Sound model RXV740 Receiver, DISH DVR HD Satellite Receiver, and an Emerson model Extra Bass

Domestic Water Tankage: (2) FRP tanks Ice Maker: In refrigerator Water Maker: Spectra Water Making System w/20 Micron and 5

Micron filters (2009)

PIPING SYSTEMS THROUGH-HULL FITTINGS Galvanized- Yes Copper Tubing- Yes Hose- RE Rubber and other

Piping Material:

Plastic- PVC and other Type Hose Clamps: Stainless steel flat screw Sea Connections/Sea Cocks: Yes Valves: Ball type Doubling Blocks: Adequate

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

13

Material – Thru Hull Fittings: Bronze

VESSEL MAINTENANCE Excellent: --- Good: XXX, subject to

recommendations Poor: ---

Very Good: --- Fair: --- Undesirable: --- Remarks: The vessel is in good condition but in need of some upgrades related to the following recommendations, sea trial, and engine surveys.

HAUL OUT

At the time of the survey, the vessel was hauled out and had reportedly been out of the water for a few months. Refer to the following advisories and recommendations related to the hull below the waterline. This was the first part of a two part survey hauled out and then afloat and sea trialed: 1.) There are (6) areas of blue tape on the starboard side hull at the garboard. (4) of these are parallel lines. The hull has been re-faired and possibly re-glassed from the chine down to the keel at some point in the past. The hull below the waterline was reported by the broker to have been peeled. Extent unknown. Request repair invoices. The area between the blue parallel lines in the photographs are lifted fairing compound as a result of fairing in the garboard. Some of this lifting compound had bottom paint below it. It will likely taper off down to whatever type of glass or fairing compound below that, but it would be necessary to sweep these areas with a grinder to determine exactly what the material is. It looks as though glass was carried down from the garboard to the side of the keel. Determine the degree of delaminated fairing in the garboard which does not appear to be extensive then prep and clean the keel and route the keel on the bitter ends where the glass terminated at the bottom of the keel. The keel is easily accessible for that type of repair. 2.) Clean the raw water intakes and Sea Chest free of marine growth and also around the tops of the stabilizers. 3.) Replace the paddle wheel. 4.) On the port side forward bow between the chine and the keel, there is a circled area of tape. There is some slight waffling in the hull with about 3”-4” intervals. It appears to be an isolated area. There are some other highs and lows randomly in the hull; however the hull as sounded produced a very uniform sound from the mallet. There does not appear to be any apparent delamination in the hull beyond the areas noted running through the garboard based on a previous repair, glass, and fairing compound from the garboard down to the keel.

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

14

HAUL OUT The areas that are marked with blue tape are the only areas noted with lifting fairing compound.

SEA TRIAL DATA

In accordance with instructions on December 23, 2011, I proceeded to Hinckley Yacht Services, Thunderbolt, Georgia to conduct a sea trial on the captioned vessel. Present at this meeting were Jeff from Performance Power, Bob, who operated the vessel and has authority to go through the equipment and machinery with me, and Mike Pranschke, general manager of Hinckley Yacht Services. The AC systems were checked on shore power. Both gen sets were run under load. Refer to the following sea trial results and findings. The windlass, swim platform, and crane were all tested and found to be operable. 1.) The DC light in the port side aft stateroom powers up but is off of the mounting base. 2.) The AC outlet in the port side aft stateroom is showing an open ground as tested. 3.) In the starboard side aft stateroom there are Sea Lion components and accumulated tanks. Some of the wiring is showing evidence of having been submerged. At the time of the survey, I was unable to get the vacu-flush heads to function properly or the fresh water to the sinks. The heads ultimately worked sporadically but all need to be cleaned and serviced to include the seals. 4.) Advisory: It was reported to me that water, due to bilge pumps failures, flooded the bilge, reportedly up to the underside of the main engines. Consequently any wiring below that level would have been subject to saltwater intrusion. Have the electrician go through and identify all submerged wires, determine their condition, and address accordingly. I would recommend discussing this with Hinckley Yachts Services. Hinckley washed down the submerged areas and addressed wiring to some extent. I was unaware of this event until the end of the survey when I saw the high water marks in the engine room. 5.) The starboard side vacu-flush head is producing water in the bowl but does not appear to be producing a sufficient vacuum to evacuate the bowl. After flushing a few times, the vacu-flush pump came on and the head functioned properly but still slow to produce water for flushing purposes. 6.) The port side aft stateroom vacu-flush control switch and head initially powered up but then quit producing.

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

15

SEA TRIAL DATA 7.) The freshwater system operated intermittently. Check the pump, trace problem to source, and repair accordingly. 8.) The windlass is controlled from (3) different stations. There is a glitch in one of the controls that may be blocking the others out. Trace problem to source and repair accordingly. 9.) The swim platform operated. This is hydraulic. 10.) Advisory: All of the galley equipment was tested. The freshwater pump was intermittent and the quit. Tank level monitor indicated low levels. I did not check the 4-burner LPG stove. There was an LPG gas odor around the tanks. I also identified the LPG vapor detector alarm which was powered up but not producing an alarm. I would recommend inspecting the LPG tanks to determine where this odor was coming from. None of the sensors seemed to be picking it up. Inspect the bottles and the lines. Replace the sensors. 11.) Advisory: The alarm system with audio/visual lights in the master stateroom was tested and appeared to function properly. 12.) At sea trial, the Glendenning synchronizer needs adjustment. 13.) The Raymarine model 1250 Plus Chart Plotter produced within a 3mile range but would not expand out. 14.) The Phillips HDTV related to the multi plexer powered up and produced a screen but were unable to operate individual cameras. Ultimately produced a screen. Appears to work, but consult manual to test all functions. 15.) Secure the (4) LPG bottles located on the flybridge against all movement in all directions. 16.) The flybridge canvas is weathered. The portion inspected has cracked glass and broken zippers. Other sections were stored. 17.) There is a vertical crack in the glass on the port side right at the arch support for the wing. In the bulwarks noted with some brown staining. Navigational Lights: The stern light is inoperable. The forward side lights are operable. The spotlights are operable. The masthead lights, unable to determine, directly in the sunlight. Sea Trial: Both main engines and gen sets started readily and appeared to run clean. Performance Power

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

16

SEA TRIAL DATA conducted engine surveys on all (4) pieces of machinery to include swapping loads between the gen sets. The gen sets were tested under loads. Refer to Performance Power’s report submitted independently. Vibrations noted in the aft stateroom during the sea trial. This vibration is likely related to the galvanic corrosion and general poor condition noted in each main engine shaft propeller. There are (2) spare sets of propellers carried onboard. When the propellers are replaced and the (2) main engine shafts pulled for inspection, I would also notice the offset of the (2) shafts at the coupling as a rough indicator of alignment. I would reinstall the shafts with new cutlass bearings and insure that both sets of spare propellers will in fact fit the existing engine shafts. Check the alignment at that time. The electronics powered up and appeared to perform properly, both stations. During the course of the sea trial which lasted approximately 1 hour, both main engines and both gen sets started readily and performed properly. The gen sets carried normal loads. Refer to Performance Power’s engine surveys. The overhead power vent in the pilothouse functioned properly. All gauges within normal operation range. Speeds: At 2700 RPM’s = 8.5 knots bucking a 2 knot current At 1900 RPM’s = 6.8 knots to 7 knots bucking tide and wind Bridge Top RPM’s Starboard 2669, Port 2700 with the tide10.7 knots Stabilizers appear to function properly. Tachometers at pilothouse have approximately 200 RPM variance.

GENERAL CONDITION

The flybridge electronics powered up. They produced a screen. The vessel was hauled at the time of the survey, consequently beyond powering up all electronics were not tested. Interior: The overall general appearance of the interior of the vessel reflects good housekeeping and generally good maintenance. There are some clouded areas on the interior finish on the walls in the salon which I have photographs. Some other areas are similar to that but no apparent rotten wood and the overall general appearance of the wood and soft goods would be considered serviceable. There are carpets throughout the vessel, in all accommodation spaces. They are

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

17

GENERAL CONDITION serviceable but showing some age. Gen Sets: The two gen sets appear in like new condition other than some surface rust in the pans, more on the starboard side than the port but beyond that the alternator and diesel end are almost new in appearance. Flybridge: Plywood seats, benches, and structures: There has been some water seepage into the foundation of the seats and other plywood structures on the bride that have seeped up into the ingrain. These areas can be individually repaired by scarfing in new material. It won’t require the removal of any of the structures in total. The flybridge decks were sounded and appear to be free of any delamination. On the wing decks outside of the combing of the flybridge, there are two areas on the port side forward corner of the combing and two areas on the starboard side. Other than that, visually these areas look okay but are in need of prepping and priming. Some other small areas might need repair but in general they are acceptable cosmetically.

# REMARKS RECOMMENDATIONS 1. The swim platform is rigged on a mechanical

lift, aluminum housing. There is electrolysis or galvanic corrosion in the portion of aluminum that was submerged. This is evident in the base of the main track and the support arms.

Refer to the manufacturer and repair accordingly.

2. The swim platform is teak grating rigged on I-beams.

The teak grating is broken in numerous places and will require rebuilding.

3. The four blade bronze propellers mounted on the shafts are thin, bent, and show signs of galvanic corrosion.

The propellers should be sent to a prop shop. The starboard propeller has more galvanic corrosion than the port. There are bent tips on both.

4. There are three blade bronze propellers stored underneath the swim platform.

Condition unknown.

5. There are halos in the antifouling paint around the bar zinc on the transom, the two main engine exhaust outboard mounting flanges, struts. This is a type of electrical current reacting with the metals in the antifouling paint.

Address the bonding/grounding system throughout. Check for continuity.

6. The main engine shafts and shaft cutters have been sand blasted. The same with the vee struts and rudders. There are rust deposits on the struts, rudders, and rudder post housings.

Considering the rust deposits that have developed, I would recommend fully prepping all of the underwater running gear, applying barrier coat primers

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

18

# REMARKS RECOMMENDATIONS These rust deposits have occurred since the underwater running gear was sandblasted. These appear to be stainless steel construction.

compatible with this metal, and topcoat.

7. Zincs. Renew zincs throughout. Presently (2) rudder zincs, (1) bar zinc, and (1) port side shaft zinc are largely wasted.

8. Raw water. Clean all of the underwater through hull fittings and intakes free of marine growth.

9. The paddle wheel for speed starboard side forward has one missing blade and the housing around the propeller is bent.

Repair or discontinue.

10. The aft strakes to either side, just above the waterline, need to be prepped, primed, and painted, both sides.

Address accordingly.

11. The port side stabilizer is pinned, the starboard side is not.

Test the stabilizers at sea trial.

12. Bottom. Sand, prep, and paint the hull below the waterline.

13. The hull is weathered and based on appearance has been painted with a polyurethane topcoat at some point in the past.

The topside hulls are in need of painting at this time. Compounding and waxing would improve the appearance in the mean time.

14. There is trim just below the bulwarks as observed on the outside, teak. There is lifting paint on this teak channel which is the cap rail.

Prep, prime, and paint.

15. The brightwork on the vessel has weathered and reveals lifting varnish throughout.

All of the exterior brightwork will need to be prepped and rebuilt with sufficient coats.

16. The electric motors on the lift for the swim platform have some discontinued wires.

Service the lift to include the electric motors.

17. In addition to the lower aft strakes, the rub rail will have to be stripped and painted.

Address accordingly.

18. Foredeck. Replace the foredeck cushions, (3) sets of 2.

19. The power cord to the handheld VHF on the bridge is deteriorated.

Replace the cord.

20. ACR EPIRB. Have the EPIRB inspected. 21. Flare Kit. Upgrade the flare kit. 22. Packing Glands. Service both main engine shaft packing

glands. They are presently drawn down 80%

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

19

# REMARKS RECOMMENDATIONS through their travel, both sides.

23. The shafts on the exterior have been sandblasted. As viewed from the interior, the shafts are showing rust perforations and corrosion just forward of the packing gland.

Based on the age of the vessel and if no history is known related to the shafts, I would recommend pulling the shafts to address the corrosion that is obvious around the packing gland and also check the main strut and bearings at that time. With the propellers removed you will be able to see the tail pieces of the shaft to determine that condition.

24. There are heavy water stains at the head of the vee berth bunk, brown stain over approximately 1 square foot running down from the anchor locker.

There are stains in the anchor locker likely related to this. Refer to photographs of anchor locker.

25. The chain locker has two spots of moisture intrusion based on stains on the port side of the chain locker and one on the starboard side. Two of the three are in the corners of the chain locker partition separating it from the vee berth. Accessible to view from the forward stateroom with the baffle boards removed from the back of the chain locker.

Address accordingly.

26. There is a tank on top of the port side fuel tank in the engine room. This looks like a hydraulic tank. The components on the top of the tank need to be cleaned up.

Address accordingly.

27. Stabilizers. Based on appearance, the stabilizers need to be serviced. There is some fluid on the top of the port one. The upper flange of the Naiad is secured with Allen head bolts. Some of these are rusted on the lower inboard side. There are hoses and components in direct contact with the stabilizers. These should be pulled back and secured.

28. In discussion with the yard, the two Onan gen sets were installed approximately 3 years ago. The starboard side gen set has a water leak on one of the hoses visible on the port side of the engine.

This appears to be related to a clamp on a hose. Investigate the leak, repair accordingly, and clean up the pans.

29. On the port side of the black water tank in the passageway, there is a hose that is

Go through the hoses associated with the vacu-flush head as viewed in the bilge and

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

20

# REMARKS RECOMMENDATIONS detached from another hose as pictured in the photographs. At the time of the survey, there was a motor that was running.

renew clamps as needed. The majority of the clamps are in acceptable condition. The sanitation hoses also are serviceable.

30. There are numerous wires associated with the sending units on the tank.

These should be sorted out and bundled neatly.

31. Packing glands. Have the two main engine shaft packing glands serviced.

32. Inline strainers. Clean all four inline strainers for the two mains and the gen sets.

33. There are numerous wires on both main engines in direct chafe.

These wires should be inspected by a marine electrician and Chafe Guard installed on all wire runs to include the principle runs on the inboard stringer of the port engine.

34. There are Rule 2000 bilge pumps as noted. As tested in the engine room, the forward of the bilge pumps was inoperable on the float switch. The one aft of that functioned properly.

Go through the vessel. Clean the engine room bilge. Test the existing pumps for possible replacement and test the high water alarm.

35. There are hoses located in the centerline bilge in the engine room that need replacing.

Replace to include the raw water intake hoses from the Sea Chest to the two primary inline strainers and the hoses between the strainers and the Sea Chest dedicated to the gen sets. There are surface cracks in theses hoses and other hoses. There are also other hoses that are hardened, some showing bulges and cracks. Go through all hoses in the engine room and address as needed.

36. Gen set muffler. Replace the hose clamps on the starboard side generator at the muffler and check the port at that time.

37. Main engines exhaust and hose clamps. Replace the hose clamps on the starboard engine exhaust at the exit in the starboard aft corner of the engine room. There is an exhaust leak and the majority of the T-style clamps are badly rusted. Same thing with the port engine exhaust.

38. Fixed fire extinguishing system. The fixed fire extinguishing system needs to be inspected. It is equipped with a remote readout, engine override, and engine stop in the pilothouse.

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

21

# REMARKS RECOMMENDATIONS 39. In the aft head, forward of the engine room,

in the bilge, there is a Scott pump going into a 6-section manifold. The principle hose coming into this pump is detached. The pump looks relatively new.

Re-attach and test.

40. The starboard side guest stateroom with double bunks in it has a partition at the desk separated out from the hull approximately ¼”. This has resin at the partition to the hull. Evidence of some shifting.

Under the starboard side guest stateroom bunk, there is a head component. The hose clamp securing it is broken. Other hose clamps in the area below the bunk need to be addressed.

41. There is a drawer in the starboard forward head that is off of the frame located just below the vacu-flush switch.

Repair.

42. The valance in the starboard lower stateroom is detached.

Repair accordingly.

43. There are leaks coming into the starboard forward head cabinetry above the vacu-flush head. This is based on brown water stains.

As a result of this leak, the base of the cabinetry, ply construction is soft and rotten and will need to be cropped out and replaced.

44. There are some scratches in the veneer on the spiral staircase leading down to the lower deck. This was a result of the generators being installed and bumping up against it.

This can be addressed cosmetically.

45. Overall, the opening ports look good. There are some minimal water traces.

Address as needed.

46. Rudder post packing glands. Service both rudder post packing glands. Wire brush the body of the rudder post packing glands in addition to general service.

47. There are approximately 20 iron construction pigs located below the master stateroom bunk. These are being used for ballast.

The concern would be point loading the hull in this area with too much weight. Disperse the pigs out and secure in place against movement.

48. CO Detectors. Install CO Detectors throughout all accommodation spaces.

49. Zippers. Replace the zippers on the flybridge seat covers.

50. Flybridge starboard side molded in bench seat: There is rot extending over approximately 24” x 10” in the base of the seat where it meets the deck.

Crop out. There could be more soft wood not found without disassembly.

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

22

# REMARKS RECOMMENDATIONS There is soft and rotten wood in the corner of the partition immediately forward of the flybridge grill. This extends from the outboard corner down around the base of the molded in port side bench seat on the aft end. Also some soft wood noted in the plywood box around the grill on the flybridge and on the scupper drain, port aft corner of the combing for the flybridge. There is soft wood noted in the starboard side forward end of the bench seat just aft of the mate seat. There is randomly soft wood in the plywood around the bench seats on the flybridge to include the LPG locker and the box housing the grill.

Most of these areas can be repaired individually without requiring rebuilding the majority of the structure. All of the exterior seams around these flybridge seats and others should be reefed and re-caulked.

51. Flybridge cushions. Replace the flybridge cushions 52. The Plexiglas cover for the flybridge

instrumentation and gauges is clouded. Replace it and insure the new gasket is sealed properly.

53. Caulking. Renew the caulking around the forward deckhouse, bench seats, and other areas previously caulked.

54. On the interior bulwarks, starboard side inboard immediately below the cap rail and outboard of the pilothouse door, there is a 6” crack running down from the cap rail as sounded. There is softness around it.

It appears to be isolated. Address accordingly.

55. There are some paint blisters below the port side pilothouse door. The area appears solid.

Address the blisters and prep, prime, and paint accordingly.

56. The paint is peeling on the threshold of the starboard side gate. Looking from there to the molding, the paint is peeling, the wood appears solid except in a few places which are retaining dampness.

Prep and paint.

UNUSUAL EXPOSURES

Area of Mooring: Hauled out at time of survey. Crew Exposure: Usual to this type of vessel.

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

23

AREA OF OPERATION

RECOMMENDED FOR INLAND AND OFFSHORE NAVIGATION. RECOMMENDED FOR INSURANCE PURPOSES WHEN THE RECOMMENDATIONS CONCERNING ALL RAW WATER CONNECTIONS, VALVES, HOSE CLAMPS, AND HOSES HAVE BEEN ADDRESSED. OTHER RECOMMENDATIONS CAN BE ACCOMPLISHED ON A MORE CASUAL BASIS. OWNER: Redacted VESSEL: Redacted _________ ______

Terms, Conditions, and Limitations

In accepting this report or instrument, it is agreed that the extent of the obligation of this firm with respect thereto is limited to furnishing a surveyor believed to be competent, and in the making of this report or instrument the surveyor is acting on behalf of the person, company and/or firm requesting the same and no liability shall attach to this firm for the accuracy, errors, and omissions thereto:

In all cases, new owners are advised to contact the manufacturers of the vessel, the engine, and other vessel component equipment to register their ownership and to obtain up to date information pertaining to the vessel and its equipment and possible recall campaigns or other warnings and advisories. The use of the word “appears” is intended to indicate that a close or complete inspection was not possible or it was not deemed appropriate at the time of this survey. The deficiencies reported herein reflect the conditions observed at the time the survey was conducted. This vessel survey report is issued by the undersigned who has exercised reasonable care in conducting a visual inspection of the accessible area in connection with a marine survey of the subject vessel.

All details and particulars in this report are believed to be true, but are not guaranteed accurate. No part of this report is issued as an expressed or implied warranty of the condition of the vessel, of the value of the vessel, or the cost of any repairs. This survey was carried out without removals. The statements in the report pertain to accessible areas throughout the vessel only and do not in any way address areas not readily accessible without removals. Unless specifically stated otherwise in this report, the surveyor has not removed fasteners, fixed structures, or equipment and has not dissembled hull or machinery for inspection or testing. This vessel survey report does not cover latent defects not readily discovered without such removal or disassembly. This vessel was surveyed without the removal of any parts, including fittings, tacked carpet, screwed or nailed boards, anchors and chain, fixed partitions, instruments, clothing, spare parts and miscellaneous materials in the bilges and lockers, or other fixed or semi-fixed items. Locked compartments or

Name of Buyer 1982 55’ Cheoy Lee Long Range Motor Yacht Vessel Name Location of Survey December 8-10 & 23, 2011 File Number: 3046/11 Eve Marine Surveyors, Inc. Survey Conducted by Thomas M. Eve

24

otherwise inaccessible areas would also preclude inspection. Buyer/Owner should open all such areas to inspect further.

The undersigned has not operated the engines, machinery, or equipment unless specifically stated otherwise. The undersigned has conducted his survey and issued this report for the sole use of the specified requesting party for an agreed fee based on the intended use of the report and the legal liability of the undersigned shall not exceed the fee paid by the requesting party for issuance of this report, regardless of the number of claims or suits and regardless of whether under theory, tort, contract, warranty, products, outrage, or otherwise. This survey report represents the condition of the vessel on the above dates and is the unbiased opinion of the undersigned. This report should not be used for any purpose other than as described under purpose and scope.

Submitted,

® ®

Thomas M. Eve, SAMS AMS President, Eve Marine Surveyors, Inc.

Enclosures

Member of SAMS, ABYC, NFPA, and IAMI