Evaluation of PDA Applicability in Regard to Heavy...

Transcript of Evaluation of PDA Applicability in Regard to Heavy...

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 1 -

Evaluation of PDA Applicability in Regard to

Heavy Fuel Oil Spray Investigations

Beat von Rotz1,*, Thomas Kammermann2, Bruno Schneider2, Andreas Schmid1, Kai Herrmann3, German Weisser1, Konstantinos Boulouchos2

1: Wärtsilä Switzerland Ltd, CH-8401 Winterthur, Switzerland

2: Aerothermochemistry and Combustion Systems Laboratory, ETH Zürich, CH-8092 Zürich, Switzerland 3: Paul Scherrer Institute, CH-5232 Villigen PSI, Switzerland

* correspondent author: [email protected] Abstract The better understanding of the key in-cylinder processes must be seen as a prerequisite for the further development and optimization of large marine Diesel engine combustion systems. The existing extensive set of reference data with respect to the macroscopic behaviour of fuel sprays at relevant conditions including various fuel qualities, which have been acquired on an experimental facility specifically devised for this purpose, shall now be extended towards microscopic spray characterization. The particular challenge in this context is related to the opaque nature of the heavy fuel oil (HFO) widely used on those engines, which is associated with limitations with respect to the applicability of optical measurement techniques such as PDA. Therefore, a thorough assessment of the practical implications of applying PDA on HFO sprays has been conducted, starting from the theoretical evaluation of the optical properties. The most suitable configuration for the actual experiments has been identified on the basis of extensive pre-studies involving dedicated test setups for validating the PDA droplet size measurements. In this context, in-depth analyses have been made in order to determine the refractive index required for the proper investigation of specific configurations. Using a scattering angle of 90° in combination with perpendicular polarized light, first measurements have been performed in a HFO spray and the results compared against corresponding data obtained for light fuel oil at a scattering angle of 70° and parallel polarization. The fuel quality has a clear impact both on the velocity and size distribution. In particular, the average diameter of the HFO droplets is bigger and the distribution covers a larger range, which is in line with the expectations in view of the different composition and physical properties. Hence, the applicability of PDA for HFO spray investigations could be confirmed and a suitable setup identified for delivering high quality results. 1. Introduction In order to improve large marine Diesel engines to meet upcoming emission requirements (Annex VI of MARPOL 73/78, 2009), the combustion system optimization is one important aspect. A unique optically accessible experimental facility – the so-called Spray Combustion Chamber (SCC) – has been developed, which enables the investigation of injection and combustion processes at relevant physical dimensions (bore) and operational parameters (pressure, temperature), including typical flow characteristics and injection of a wide range of marine Diesel fuel qualities. The use of non-intrusive optical measurement techniques contributes to a better understanding of the fuel injection and the ensuing spray processes as well as mixture formation, ignition behaviour and combustion (see Herrmann et al., 2007). Moreover, it allows the acquisition of reference data for the validation of simulation models (e.g. Schulz et al., 2013).

Phase Doppler Anemometry (PDA) is a well-established experimental technique for droplet velocity and size investigations. In particular, fuel injection and atomization processes of gasoline or Diesel sprays can be characterized with regard to velocity profiles and droplet sizes, see e.g. Wigley et al., 1999 and Schneider, 2003. Due to the optical characteristics of these high quality fuels the light scattered from the droplets is recorded at a specific scattering angle where a single scattering mode dominates. Many investigations are therefore performed with parallel polarized light under the Brewster angle configuration, where first order refraction is the dominant scattering mode. Using this configuration, the refracted light shows a quite good linear dependency of the particle size upon the measured phase difference (Schneider, 2003). At the SCC, first PDA measurements in a light fuel oil (LFO) spray were performed (Schulz et al., 2013)

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 2 -

In marine Diesel engines heavy fuel oil (HFO) is still the main fuel type used. In particular, among other properties (e.g. ash and sulphur content), HFO has a higher density and a much higher kinematic viscosity as well as a large portion of high-boiling components compared to LFO requiring the necessity of heating the fuel before being pressurized and injected into the combustion chamber (see e.g. von Rotz et al., 2011). The long-chain hydrocarbons (API, 2011) also influence the optical properties of the fuel to be rather opaque and highly absorbing compared to the translucent and non-absorbing gasoline, Diesel or LFO.

For the application of the PDA technique to opaque fluids, only a few studies can be found (e.g. Manasse et al., 1992 or Tratnig et al., 2009). Moreover, experiments at particular HFO sprays by means of PDA are rare (Fink et al.) and there is a clear lack of fundamental investigations in this field. Therefore, an evaluation of possible configurations of the PDA technique has been performed, especially with regard to the scattering angle and polarization state of the light. Furthermore, for the Mie scattering calculations and PDA measurements, the complex refractive index for the investigated fuels has been determined by means of refractometry and spectroscopic ellipsometry. The most promising configurations have been validated by dedicated experiments with droplet generation devices. To assess these findings, first PDA measurements in a HFO spray were performed and compared to investigations with LFO under similar conditions. 2. Experimental Setup and Measurement Techniques PDA System The Phase Doppler Anemometry system applied uses two water-cooled optically pumped semiconductor lasers emitting linearly polarized beams at 514.5 and 488 nm, respectively, (see Figure 1, left) as a light source. The optical design of the sending optics is based on the calculations done by G. Wigley (1999) for a high power, high resolution PDA system. The measuring device installed is a Dantec system consisting of a receiver (57X10) and an enhanced signal processor (58N10) including analysis software (SizeWare 2.3). The most important parameters of the laser, respectively the sending and receiving optics, are summarized in Table 1 and documented by Schneider (2003).

Parameter Unit Main Flow Direction Transversal Flow Direction

Wavelength nm 514.5 488

Laser Power mW 20-4000 20-2000

Frequency Shift Bragg Cell MHz 40 40

Polarization State - Linear Linear

Focal Length Transmission Lens mm 350

Beam Separation mm 45

Fringe Spacing µm 4.01 3.80

Number of Fringes - 20 20

Measurement Volume Diameter µm 80 80

Elevation Angle ° 0

Focal Length Receiving Lens mm 310

Scattering Angles ° 70, 90, 105

Tab. 1 Laser, transmission optics, measurement volume and receiving optics.

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 3 -

Fig. 1 Left: Overview of PDA System. Right: Top view on the experimental setup with: (1) monodisperse

droplet generator, (2) front lens PDA transmitting optics, (3) PDA receiver at 105° scattering angle, (4) CCD camera, (5) diffusing plate, (6) Xenon Flash light.

Droplet Generation Steady and reproducible droplet generation is the key to successfully investigate the behaviour of any droplet measurement technique with regard to its capabilities, features and specialities. An aerosol generator (Palas PLG 2010) capable to atomize HFO at elevated temperature level was used to investigate the smaller droplet diameters (up to 10 µm). The working principle is based on a Laskin nozzle, a compressed air nebulizer where the operating part is immersed in the liquid.

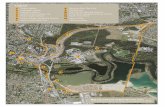

For validation measurements at larger droplet sizes and to further corroborate the results, investigations with a device able to generate droplets of one particular size were performed. For this purpose, a custom-made continuously operating monodisperse droplet generator with heating capabilities – as a prerequisite for the applicability of HFO – has been used (see Rollinger, 2012 and Kammermann, 2013). Imaging System The verification measurements of the droplet diameter have been performed by means of simultaneous shadow-imaging (Schneider, 2013). The background was illuminated by a xenon flash light in combination with a diffusing plate to create a homogeneous background with equally distributed intensity (see Figure 1, right). The images were recorded using a 12bit CCD Camera (resolution 1280 x 1024 pixels) with an exposure time of 2.5 µs at a frame rate of 15 fps. Spray Combustion Chamber The SCC test bed enables the experimental investigation of injection and combustion processes in relation to 2-stroke marine Diesel engines at relevant physical dimensions (bore) and operational parameters (pressure, temperature), including flow characteristics (swirl) and low fuel qualities (HFO) involved. Figure 2 gives an impression of the entire facility (right) and a schematic overview (left) illustrates the setup and its operational principle: The core element is a disk-shaped constant volume spray combustion chamber of diameter 500 mm with peripheral injection into a swirl flow. Optical access is provided by sapphire windows (clear diameter 150 mm) mounted in eccentric revolvable window holders located in the rotatable covers. By means of proper selection of the mounting angle of the cover and/or the eccentric window holders virtually the whole combustion chamber can be made optically accessible. In addition, the housing provides perpendicular optical access at three different locations for specific purposes (e.g. PDA receiver).

Conditions at start of injection similar to those in real engines (up to 13 MPa, 930 K) are achieved by feeding the chamber via inclined intake channels with pressurized and heated process gas provided by pressure vessels connected to a heat regenerating system. The inner core of this regenerator consists of a tensioned package of electrically heated discs with clusters of plates in between and is insulated against the housing by ceramic rings. Two types of those heat disks are used in order to enforce a labyrinth type flow

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 4 -

through specifically designed channels whose high overall volume to surface ratio leads to optimum heat transfer to the process gas. Operational conditions with respect to pressure, temperature and swirl velocity can be adjusted by varying vessel pressure, process gas fill time and regenerator temperature settings.

Fuels Table 2 shows the specifications of the LFO/HFO fuel types used.

Properties Unit LFO HFO HFO (low quality) Method

Density at 15°C kg/m3 851.4 989.7 994 ISO 12185

Viscosity at 40°C / 50°C for LFO / HFO mm2/s 3.284 364.5 1047 ISO 3104

Gross Heat of Combustion MJ/kg 45.02 42.45 42.81 ASTM D240/D4809

Water Content % V/V <0.1 <0.1 <0.1 ASTM D6304

Carbon Residue % m/m <0.10 15.78 17.20 ISO 10370

Sulphur % m/m 0.096 2.39 0.782 ISO 20884

Ash % m/m <0.01 0.046 0.015 ISO 6245

Flash Point °C 81 112 101 ISO 2719

Pour Point °C <-6 -12 6 ISO 3016

Surface Tension nM/m 30.9 NA NA EN 14370

CCAI (Calculated Carbon Aromaticity Index) - - 851.6 845 ASTM D976

Calculated Cetane Index - 49 - 21 ASTMvD976

Tab. 2 Fuel specifications.

3. Results and Discussion Investigations assessing the feasibility and applicability of the PDA technique to measure droplet sizes and velocities in HFO fuel sprays at relevant conditions were conducted. In general, the scattering amplitude of a single droplet in a laser beam depends on the refractive index, the wavelength of the laser, the droplet diameter and the scattering angle. Therefore, the refractive index of droplets of the fuels under consideration had to be determined, including its dependence on operation parameters. This also involves the identification

Fig. 2 Principle of the experimental setup (left). Impression of the spray combustion chamber test facility (right).

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 5 -

of the dominant scattering mode, which is based on the Mie scattering calculations and the assessment of the phase difference - diameter relationship. Determination of the complex refractive index Besides the scattering angle , the relative refractive index is the most important parameter in a PDA measurement setup – apart from more system-related parameters like wavelengths, beam separation and elevation angles. The relative refractive index is defined as

=

with as the complex refractive index of the droplet and of the surrounding media. It influences the measured droplet size distribution profoundly as it determines the relative intensities of the different light scattering modes and thereby the phase difference - droplet size relation for a given scattering angle. The complex refractive index defined as

=

where the real part = describes refraction and the imaginary part = 4 is defined as the extinction coefficient in dependency of the absorption coefficient and the wavelength . Media with strong light absorption behaviour cannot be characterized simply by the refractive index . In this case, the complex refractive index with the extinction coefficient > 0 as the imaginary part needs to be taken into account.

If the scattered light collected by the PDA receiver contains a substantial amount of refracted light, the determination of the relative refractive index must be considered indispensible for valid measurements. In contrast, highly absorbing media allow exploiting reflected light for the phase difference - diameter relationship as almost no refracted light is able to pass through the opaque droplets. This leads to the major advantage that the relative refractive index does not depend on the real part of the complex refractive index. Due to the fact that both mentioned scattering modes have been examined, the measurement of the refractive index was absolutely essential for the refraction case.

Ellipsometry is a well established experimental method for measuring the optical constants (refraction index, extinction coefficient). The technique is based on the effect that polarization changes if light is interacting (e.g. reflected or transmitted) with a media surface. A simple Cauchy model has been fitted with the measured data to obtain the refractive index and the extinction coefficient was identified via the Urbach model (Woollam, 1999).

To validate the measurements of the refractive index, critical angle refractometry experiments have been performed as the measurement technique is able to determine refractive indices of transparent as well as absorbing media. On a digital refractometer, the real part of the complex refractive index could be obtained at the wavelength of 589 nm (NaD-line). The device is equipped with a built-in Peltier element allowing investigations on the temperature dependency of the refractive index (Tmax 60°C).

Investigations have been performed at ambient pressure and temperature conditions using both spectroscopic ellipsometry and refractometry. Furthermore, the heating capability of the refractometer has been exploited for measurements of the temperature influence on . Subsequently, the obtained values have been extrapolated to the temperature level at which HFO is injected into the combustion chamber. Experiments for all fuel types (see Table 2) and water as reference media were intended. However, it was not possible to determine the complex refractive index of the low quality HFO due to certain limitations (e.g. measurement range of the refractometer) of the available test equipment.

The results of the refractometer measurements for both, LFO and HFO (see Kammermann, 2013), showed a decrease of the refractive index with increasing temperature and are in good accordance with earlier measurements by Astachow et al. (1993) and Dombrovsky et al. (2003). For the present investigation, the refractive index was extrapolated to the desired temperature level of about 100°C.

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 6 -

The assessment of the complex refractive index with the ellipsometer offered the possibility to measure in the whole visible spectra and allowed to simultaneously capture the extinction coefficient . Moreover, the values obtained by the refractometer could be compared with the results of the experiments based on spectroscopic ellipsometry. In Figure 3 (left), the refractive indices for HFO, LFO and water over a spectrum of 400 to 1000 nm are shown. The numeric values highlighted at 514.5 nm (emitting wavelength of the laser utilized for size measurement) are in very good agreement with the values obtained by refractometry at 589 nm. Marine Diesel Fuel Droplet Characterization by Means of PDA

Preliminary investigations were performed by Kammermann (2013) in order to evaluate the light scattering behaviour in regard to the corresponding LFO/HFO fuels. Single droplet Mie scattering characteristics show a significant difference for transparent and opaque media, especially for bigger droplet diameters (> 25 µm). For LFO, the first order refraction and the Mie scattering correlate well showing almost the same intensity levels for both, perpendicular and parallel polarization. Furthermore, for parallel polarization at the Brewster angle only refracted light is present as the reflective part vanishes. Therefore, this is a well-known option for PDA measurements in transparent media as seen in earlier investigations (e.g. Wigley, 1998). On the contrary, the Mie scattering intensity for HFO is very close to the reflective part of geometrical orders for both polarizations. For parallel polarized light generally lower Mie scattering intensity is present – compared to perpendicular polarization – with the absolute minimum at the Brewster angle. Thus, for HFO, a reflective mode in combination with perpendicular polarization should be preferred.

Based on these findings, investigations with regard to the phased difference - diameter relationship were performed to determine possible configurations for the scattering angle where the Mie scattering corresponds well to geometrical order as the PDA-processor uses a constant factor between phase difference and diameter to define the droplet size.

Due to the similarity of the fuels, the same approach of using parallel polarization and a scattering angle of 70° (Brewster) as commonly used for PDA measurements in Diesel fuel sprays (e.g. Schneider, 20013) has been applied for the transparent LFO investigations. The phase difference - diameter relationship can be well described by a single phase difference - diameter factor over a wide range of droplet sizes. Since the reflective part of the scattered light is completely missing, this specific configuration would also be favourable for HFO measurements if the intensity of the refracted light passing through the fuel droplet would be sufficiently high. However, as can be seen in Figure 4 (left), which shows the phase difference - diameter relationship determined with light scattering analysis (Saffman et al., 1990) for parallel polarized light collected at 70° scattering angle, this not applicable for the complete size range of interest: The first section from 0 to 5 µm droplet diameter demonstrates good agreement with the refractive part of the geometrical orders; the third section from 12 µm on is almost in perfect agreement with the reflective part. However, due to the increasing absorption of the light in the drop size range between 5 and 12 µm, the

Fig. 3 Refractive index determination: Left, comparison of the refractive index obtained by refractometer and

spectroscopic ellipsometry; Right, extinction coefficient over wavelength.

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 7 -

transition from dominantly refracted to mainly reflected light results in high uncertainty concerning the relation between phase difference and droplet diameters.

Fig. 4 Phase difference - diameter relationship of HFO droplets at 70° parallel and 90° perpendicular polarization.

A further promising PDA configuration for HFO spray investigations with a scattering angle of 90° in combination with perpendicular polarized light has been identified by corresponding Mie scattering / geometric optics calculations. The resulting phase difference - diameter relationship is presented in Figure 4 (right). The comparison of the phase differences for very small droplets indicates that a non-negligible amount of refracted light is still present in this range and the corresponding sizes are generally underestimated. However, for droplet diameters above 5 µm quite pure reflected light is collected by the receiver. For droplets larger than 10 µm, the phase difference - diameter relationship is close to perfect. Another viable scattering angle would be 105° with the same polarization state as at 90°, where reflection is the only dominant mode based on geometrical optics calculations. Therefore, the same tendencies as for 90°, are present and the differences in the resulting phase difference - diameter plot are very small. The scattered light intensity is slightly lower, but the relative error between the phase differences of Mie scattering and reflection at 5 µm is somewhat better (Kammermann, 2013).

To validate and assess the evaluated scattering angles and corresponding polarization states above, PDA measurements with both an aerosol generator (droplets up to diameters of 10 µm) and a monodisperse droplet generator in conjunction with the imaging system have been performed. Due to the inability of the monodisperse droplet generator to create droplets smaller than 60 µm diameter, the aerosol generator is used to gain information with regard to the smaller droplets regimes. Figure 5 shows the HFO droplet size distribution measured for refracted light at 70° scattering angle (parallel polarized, first order refraction) as well as for reflected light at 105° scattering angle (perpendicular polarized, reflected light). Both distributions were derived from 20’000 validated samples. The different results in the lower droplet diameter regime (< 5 µm) illustrate qualitatively the limitations of the PDA system concerning the correct acquisition of small HFO droplets due to arising uncertainty in the phase difference - diameter relationship. As shown in Figure 4, refracted light dominates the phase difference - diameter relationship for very small droplet diameters below 5 µm and reflected light for droplets above 10 µm, which is causing those irresolvable ambiguities in the transition zone in between. This non-linear and discontinuous phase difference - diameter relationship leads to the rejection of such droplets as the processor analysis is based on a constant correlation factor between phase difference and diameter for the size determination.

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 8 -

Fig. 5 Droplet size distribution of HFO (m = 1.538-0.269i) under the Brewster angle (left) and a scattering angle of

105° (right). As described above, only configurations with 90° or 105° scattering angle at perpendicular polarization yield consistent results over a wide range of droplet sizes. However, due to considerations related to the optical accessibility of the Spray Combustion Chamber, only the 90° scattering angle PDA setup is applicable. Hence, corresponding validation measurements using the monodisperse droplet generator have been performed for HFO. In addition, LFO measurements with a scattering angle of 70° and parallel polarization have been conducted. The simultaneously recorded shadow-images of the droplet chain emerging from the generator have been post-processed to gain validation data for LFO/HFO droplet size measurements with the PDA technique. By means of circular Hough transformation (see Atherton et al., 1999), an automated search for the size classification of the droplets could be provided. Figure 6 shows one exemplary HFO droplet size distribution measured by PDA (left) and the corresponding result based on the analysis of the camera images (right). Furthermore, the correlation between PDA results and image analysis in the 100 to 180 µm range for both, LFO and HFO droplet size measurements is displayed (middle).

Fig. 6 Validation experiments with a monodisperse droplet generator for HFO and LFO measurements. One exemplary HFO experiment with PDA measurements (left) and simultaneously acquired shadow-imaging

recordings as well as size distribution (right) is shown. The droplet sizes measured by means of PDA are in good agreement with the droplet size classification on the basis of the shadow-imaging recordings. This clearly indicates the capability of measuring heavy fuel oil droplets with PDA for the configuration and conditions relevant to large marine Diesel injection and combustion systems. PDA measurements with Marine Diesel Fuels at the Spray Combustion Chamber According to the findings and considerations discussed above, first HFO measurements in combination with LFO investigations at engine like conditions in the Spray Combustion Chamber have been performed by means of PDA: For LFO, we have used parallel polarization and 70° scattering angle whereas, for HFO perpendicular polarization and 90° scattering angle have been applied.

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 9 -

The experiments were performed under inert conditions (nitrogen) at pressure and temperature levels of 90 bar and 900 K, respectively. The injected fuel spray (rail pressure 1000 bar) originates from a single hole injector with a co-axial orifice ( 0.875 mm). Figure 7 (left) gives an impression of the nozzle tip location and the optical accessibility with regard to the laser beams defining the measurement volume, respectively the location of the receiver acquiring the scattered light. The measurement position in the spray is located 112.5 d0 downstream and with regard to the sprays centreline at 14.5 d0 of its radial periphery (see Figure 7, right). The presented experiments were performed with LFO and the HFO, which is representative for the lower end of current marine residual fuels in terms of quality (see Table 2).

Fig. 7 PDA Application the Spray Combustion Chamber and schematic illustration of the measurement location the spray.

As proposed by Pitcher et al. (2006), an additionally installed photo diode observed the directly transmitted light from one of the input beams. The signal shows low intensity levels detected during injection. This indicates the very dense nature of the investigated spray at the measured location and hence, only low validation rates could be achieved due to the obscuration of the input beams. Therefore, an adequate number of measurements had to be performed (typically between 50 up to 100) to gain sufficient information for a significant result. Furthermore, not only 2D-PDA measurements have been conducted but also 1D-PDA as well as 2D-LDA experiments with higher data rate were made in order to additionally validate the measurements. These experiments were also included in the analysis to enhance the significance of the results.

In Figure 8, the temporal evolution of droplet velocity (left) and droplet size (right) of the injected HFO spray are shown. Each measured droplet is indicated (blue) and the mean value (red) per evaluated time bin (250 µs) can be seen in the graph. Moreover, the closing of the needle is indicated to highlight the spray boundary conditions. The droplet velocities show the absolute velocity magnitude in the spray derived from the two simultaneously measured velocity components.

In the very initial stage (up to 2 ms after start of needle lift), the velocity at the spray tip is decreased due to not yet fully established momentum of the injection. During the subsequent main injection phase, the resulting droplet velocities show a mean value of about 15 to 17 m/s with peaks up to 50 m/s). This indicates a high degree of interaction between the spray and the surrounding gas yielding highly turbulent recirculation zones in this region of the spray. Moreover, the spray droplet velocity is influenced by the high swirl flow acting on the spray (ca. 13 m/s). At the end of the injection, it can be recognized that the droplets are only transported further by this flow.

The droplet sizes of the injected HFO spray show diameters up to 60 µm. At the beginning of the injection, the measured droplet sizes tend to decrease slightly in correspondence to the droplet velocities due to still increasing injection pressure in this very initial phase (2 ms after start of needle lift). For the period of the main injection, a mean diameter of about 14-18 µm is observed. Towards the end of injection, the size of the droplets measured is increasing again, which can be attributed to the reduced momentum of the spray as a consequence of the decreasing injection pressure after the injector needle has closed.

Measurement Volume

Nozzle Tip

To Receiver

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 10 -

Fig. 8 Droplet velocity (left) and droplet size (right) at 90 bar and 900 K chamber condition

To further assess the measurements performed at the HFO spray, a comparison with experiments at the corresponding LFO spray are presented. In particular, the difference of the fuel quality and its influence on the spray is discussed. Furthermore, this comparison shall put the HFO spray experiments in perspective and can give first indications about the soundness of the PDA measurements.

Figure 9 shows the distribution of the velocity (left) as well as the droplet diameter distribution (right) measured at the same radial and axial position with respect to the centreline of the corresponding injected fuel spray. The velocities observed with LFO are clearly higher and cover a larger range than those measured at the HFO spray. This unequal spread in the distribution of the velocities can be seen as an indication of the different nature of the two investigated fuels. The physical properties of LFO and HFO (especially with regard to difference of density and kinematic viscosity) have a significant impact on their atomization and subsequent evaporation behaviour. Nevertheless, a clear peak around 16 m/s in both velocity distributions can be recognized as most of the droplets tend to follow the high swirl flow in the chamber regardless of the fuel properties.

In the droplet size distribution graph (Figure 9, right), the droplet diameters at the measured location in the HFO pile around a diameter of 16 µm. On the contrary, the peak in the droplet distribution of the LFO spray can be found at roughly 5 µm. Furthermore, a distinctly wider droplet size distribution is observed in the injected HFO spray with diameters reaching up to 50 µm whereas in the low viscosity LFO spray a maximum diameter at about 30 µm can be recognized. The higher viscosity and density of the HFO droplets lead to a clear difference in the droplet breakup and the following evaporation process. Besides the fluid properties, the significant lower content of low-boiling compounds in the HFO influences the evaporation of the droplets recognizably.

Fig. 9 Droplet velocity and size distribution in the LFO (red) and HFO (blue) spray at 90 bar/900 K.

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 11 -

4. Conclusions This study shows that droplet size and velocity measurements in HFO sprays by means of the PDA technique are feasible. For best applicability at the Spray Combustion Chamber a 90° scattering angle with perpendicular polarization configuration is the most suitable choice due to its good phase difference - diameter relationship and with regard to the optical accessibility at the SCC. Specifically, the fact that reflection is the dominant light scattering mode eliminates the dependence of the phase difference on the refractive index as well as the sensitivity to the media temperature associated with refractive index variation. In consequence, there is also no need to perform measurements of the complex refractive index which are very demanding and time consuming. This is of particular relevance as the high variability in HFO qualities and compositions would require a comprehensive mapping of the refractive index for the whole range of possible fuels.

Based on the findings of Mie scattering and geometrical optics investigations, PDA measurements were performed. The results show the first microscopic spray characteristics (droplet velocities as well as droplet diameters) of typical HFO sprays injected at conditions representative of large marine Diesel engines. Furthermore, in order to put the HFO measurement results into perspective, a comparison with corresponding LFO data at the same measurement location is presented as basis for discussing the difference of the atomization and evaporation process in regard to the fuel qualities involved. The measured droplet size and velocity distributions will complement earlier investigations into the macroscopic behaviour of those sprays. These investigations will extend the already comprehensive reference data set concerning fuel spray characteristics at conditions relevant to the operation of large marine Diesel engines and improve the understanding of the fundamental spray and combustion processes governing the performance of those engines. 5. Acknowledgments The present work has been conducted as part of the HERCULES-C project within EC's 7th Framework Program, Contract SCP1-GA-2011-284354. Additional financial support by the Swiss Federal Government (SFOE Contract SI/500940, TP Nr 8100075, Project name “FlexiFuel Combustion”) is gratefully acknowledged. The authors thank Dr. Graham Wigley for fruitful discussions and valuable advice.

17th International Symposium on Applications of Laser Techniques to Fluid Mechanics Lisbon, Portugal, 07-10 July, 2014

- 12 -

6. References

American Petroleum Institute, Heavy fuel oil category analysis and hazard characterization, Technical report, US EPA, 2011. Annex VI of MARPOL 73/78, Regulations for the prevention of air pollution from ships and NOx technical code, Technical report, International Maritime Organization, London, United Kingdom, 2009. Astachow A.N., Fitzky G., and Krüger G., Kraftstoffzerstäubung: Experimentelle Untersuchung zur Zerstäubung von Dieselkraftstoff und Schweröl, Final report, University Rostock and RWTH Aachen, 1993. Atherton T.J. and Kerbyson D.J., Size invariant circle detection. Image and Vision computing, 17(11):795-803, 1999. Dombrovsky L.A., Sazhin S.S., Mikhalovsky S.V., Wood R., and Heikal M.R., Spectral properties of diesel fuel droplets, Fuel, 82(1):15-22, 2003. Fink C., Buchholz B., Niendorf M., and Harndorf H., Injection spray analyses from medium speed engines using marine fuels, In ILASS EUROPE, 2008. Herrmann K, Kyrtatos A. , R. Schulz, and G. Weisser., Validation and initial application of a novel spray combustion chamber representative of large two-stroke diesel engine combustion systems, In ICLASS Conference (Vail, USA), 2009. Herrmann K, von Rotz B., Schulz R., Weisser G, Boulouchos K., and Schneider B., Reference data generation of spray characteristics in relation to large 2-stroke marine diesel engines using a novel spray combustion chamber concept, In ILASS 2010, 23rd Annual Conference on Liquid Atomization and Spray Systems, Brno, Czech Republic, 2010. Herrmann K., Schulz R., and Weisser G., Development of a reference experiment for large diesel engine combustion system optimization, In CIMAC Congress. Vienna, 2007. Kammermann T., Droplet Characterization of HFO Sprays by Means of PDA, Master thesis, ETH Zürich, 2013 Manasse U., Wriedt T., and Bauckhage K., Phase-doppler sizing of optically absorbing liquid droplets: Comparison between mie theory and experiment. Particle & particle systems characterization, 9(1-4):176-185, 1992. Pitcher G., Wigley G. and Stansfield P.A., Interpretation of Phase Doppler Measurements in a Dense Transient Fuel Spray, 13th Int Symp on Application of Laser Techniques to Fluid Mechanics, Lisbon, 2006 Pitcher G., Wigley G., and Saffman M., Sensitivity of dropsize measurements by phase Doppler anemometry to refractive index changes in combusting fuel sprays, In Applications of Laser Techniques to Fluid Mechanics, pages 227-247, Springer, 1991. Rollinger B., Droplet Target for Laser produced Plasma Light Sources, PhD thesis, No. 20804, ETH Zürich, 2012 Saffman M., Pitcher G. and Wigley G., Sensitivity of Dropsize Measurements by Phase Doppler Anemometry to Refractive Index Changes in Combusting Fuel Sprays, Laser Techniques and Applications in Fluid Mechanics. Springer-Verlag, 1990 Schneider B., Experimentelle Untersuchungen zur Spraystruktur in transienten, verdampfenden und nicht verdampfenden Brennstoffstrahlen unter Hochdruck, PhD thesis, No. 15004, ETH Zürich, 2003. Schulz R., Hensel S., Herrmann K, Schmid A., von Rotz B., and Weisser G., Development of spray and combustion simulation tools and application to large two-stroke diesel engine combustion systems, In CIMAC Congress Shanghai, 2013. Tratnig A., Brenn G., Strixner T., Fankhauser P., Laubacher N., and Stranzinger M., Characterization of spray formation from emulsions by pressure-swirl atomizers for spray drying, Journal of Food Engineering, 95(1):126-134, 2009. von Rotz B., Herrmann K, Weisser G, Cattin M., Bolla M., and Boulouchos K., Impact of evaporation, swirl and fuel quality on the characteristics of sprays typical of large 2-stroke marine diesel engine combustion systems, In ILASS Conference (Estoril, Portugal), 2011. Wigley, G., Hargrave, G.K. and Heath, J., ‘A High Power, High Resolution LDA/PDA System Applied to Dense Gasoline Direct Injection Sprays’, Part. Part. Syst. Charact., Vol. 16, No. 1, pp. 11-19, 1999. Woollam J.A., Complete EASE Software Manual Version 3.18. Lincoln, USA, 2007. Woollam J.A., Johs , Herzinger C.M., Hilker J., Synowicki R., and Bungay C.L., Spectroscopic ellipsometry and refractometry: a user's guide, Critical Reviews of Optical Science and Technology, CR72:3-28, 1999.