Evaluation of Combustion Models for High Speed H2/Air ...repository.ias.ac.in/23095/1/322.pdf ·...

Transcript of Evaluation of Combustion Models for High Speed H2/Air ...repository.ias.ac.in/23095/1/322.pdf ·...

Evaluation of Combustion Models for High Speed H2/AirConfined Mixing Layer Using DNS Data

DEBASIS CHAKRABORTY,*† P. J. PAUL, and H. S. MUKUNDADepartment of Aerospace Engineering, Indian Institute of Science, Bangalore 560 012, India

The capability of empirical combustion models to predict the mean reaction rate for supersonic mixing layer isevaluated by using the stored time series data of direct numerical simulations (DNS). The confined supersonicH2/air mixing layer—the prototype representation of the scramjet combustor flow field—is taken as the testcase. The reaction rate profiles of various species obtained from the DNS results are compared with thereaction rate profiles obtained from these combustion models. The combustion models based on fast chemistryapproximation are seen to predict the peak mean reaction rate much higher (about two orders of magnitude)compared to DNS data, particularly in the mixing layer region where the reaction is taking place. The EddyDissipation Concept (EDC) based combustion models for finite rate chemistry suggested by Magnussen andcoworkers predict the mean reaction rate of all the major and minor species extremely well. The EDC modelwith detailed full chemistry (FC) and finite rate single-step chemistry (SSC) captures all essential features ofreaction rate profile distribution with similar order of magnitude peak values, although a thinner reaction zoneis predicted. The comparisons of mean reaction rates with different hydrogen and air stream temperaturesreveal that the model can predict the mean reaction rate for practical scramjet combustor flow field. The modelis also seen to predict the mean reaction rate well at a location close to the occurrence of ignition. Amodification of this model allowing a nonunity Schmidt number, a feature very important for the flow involvinghydrogen, shows little improvement in the prediction of the reaction rates. It is inferred that for hypervelocityreactive flows for which heat release due to chemistry is counteracted by significant enthalpy change due to gasdynamics, the finite rate EDC model with fine tuning for reaction zone width may be adequate to describe fullchemistry effect. © 2000 by The Combustion Institute

INTRODUCTION

The prediction of turbulent reactive flow in thescramjet combustor flow field largely dependson the proper choice of the combustion model.Modeling turbulent combustion continues to bea major challenge in aerospace applications.The major difficulty in modeling turbulence–chemistry interaction in reacting flows is due tothe fact that the mean production rate given bychemical kinetics is a highly nonlinear functionof several fluid dynamical and chemical vari-ables. Due to nonlinearity, the mean value ofthe production rate of the species is not thevalue of the production rate obtained from themean variables. Our understanding of the vari-ous processes taking place in a turbulent react-ing flow field has improved considerably withthe advent of direct numerical simulation(DNS), where the full Navier-Stokes equation issolved exactly along with the species continuity

equations including chemistry by resolving thetime and length scale adequately. Givi [1] andVervisch and Poinsot [2] summarize much ofthe interesting findings from DNS of reactingflows. Although a very useful learning tool, themodel-free simulation for reacting flow is pos-sible only for a simple flow. The search for aproper modeling of mean reaction rate is still achallenge.

Several approaches are proposed in the liter-ature. In the Moment Closure Method [3–5],the exponential term in the Arrhenius equationis expanded in a series, and the higher orderterms are truncated. Truncation of the higherorder terms gives erroneous result if the speciesand temperature fluctuations are significantcompared to their mean values and this severelylimits the validity of this approach. Among theempirical models, Spalding [6] proposed a verysimple but very useful formula for calculatingthe mean reaction rate of the fuel—the EddyBreak Up (EBU) model. The development ofthe model is based on the assumption that therate of burning depends upon the rate at whichthe fragments of unburned gases are broken

*Corresponding author. E-mail: [email protected]†Scientist/Engineer, Aerodynamics Division, VSSC, Thiru-vananthapuram.

COMBUSTION AND FLAME 121:195–209 (2000)© 2000 by The Combustion Institute 0010-2180/00/$–see front matterPublished by Elsevier Science Inc. PII S0010-2180(99)00153-4

into smaller fragments by the action of turbu-lence, and the rate of reaction is supposed to beproportional to the rate of decay of turbulenceenergy. The Eddy Dissipative Concept (EDC)set forth by Magnussen and Hjertager [7] givesan empirical expression for the mean reactionrate based on the assumption that chemicalreaction occurs in an isolated region where thedissipation of turbulent energy is significant.Recently Gran [8] gave the formulation forreaction rates for finite rate chemistry based onthe eddy dissipation concept. The applicabilityof these models is limited todate to low-speedflows only. Although the probability densityfunction (pdf) method [9, 10] is theoreticallysound and the chemical reaction term does notneed any modeling, the method is not com-pletely model-free. The pdf transport equationhas to be coupled with classical turbulencemodels and all important turbulent scalar diffu-sion processes need to be modeled. The case ofa steady one- or two-dimensional parabolic flowwith a simple chemical scheme is tractable, butfor two- or three-dimensional elliptic flow with alarge number of chemical variables with a com-plex chemical scheme, the situation is verydifficult. In the presumed pdf method [11–13]an approximate shape for the pdf is assumeddepending on few parameters. These parame-ters are calculated based on the balance equa-tion for the first few moments. Unfortunately,most of the assumed pdf in the literature so farhave been reasonable only during certain stagesof the mixing process and are quite unrealisticat other stages.

It is clear that the development of the com-bustion models for high-speed reactive flows isin a formative stage. The use of empiricalmodels for the prediction of the mean reactionrate in turbulent flows can be very helpful.Evaluation of these combustion models fromDNS data is an important task, since such anevaluation can bring out the advantages andshortcomings of these models before they areput to regular use. In this paper the time seriesdata of DNS [14, 15] of confined reacting mixinglayer (which represents the scramjet combustorflow field) are used to evaluate the applicabilityof empirical combustion models for the predic-tion of mean reaction rate for hypersonic com-bustion.

DNS CALCULATION—THE CODE ANDTHE COMPUTATIONAL DETAILS

In order to understand the combustion processinside the scramjet combustor, DNS were per-formed for the confined supersonic reactingmixing layer as it contains all the fundamentalprocesses involved in supersonic combustion ina confined environment. The results of the DNScalculations for the H2/air confined supersonicmixing layer are given in the earlier work of thepresent authors [14, 15]. Three different condi-tions were simulated. In the first case, thesimulation is performed for the hypervelocitymixing layer experiment of Erdos et al. [16]. Inthis experiment, the secondary stream (H2)comes in contact with the primary stream (air)at the edge of the splitter plate in an enclosedtest section of size 535 mm 3 25.4 mm. TheMach number and the temperature of the twostreams are 3.99 and 2400 K (air) and 3.09 and103 K (H2) respectively. The convective velocityis 3000 m/s and the convective Mach numbersare 0.85 and 0.82 referred to H2 and air streamsrespectively. The free shear layer experimentsof Clemens and Mungal [17] suggest dominantthree-dimensional effects for this convectiveMach number range and have been supportedby linear instability analyses [18, 19] which haveshown that oblique disturbances become moreand more unstable as convective Mach numberexceeds 0.6. However, Tam and Hu [20] andZhuang et al. [21] have shown that, for laterallyconfined mixing layers, the most unstable modeis the lowest order two-dimensional mode.

The principal point made in these papers isthat the coupling between the motion of theshear layer and the channel acoustic wave pro-duces a new instability mechanism in the super-sonic range which originates from the wall con-finement and is different from the classicalKelvin-Helmholtz instability. Zhuang et al. [21]have shown that the bounded two-dimensionalmodes are in good agreement with the experi-ments of Papamoschou and Roshko [22]. Luand Wu [23] have performed two-dimensionalsimulations for a mixing layer with a convectiveMach number as high as 1.77 citing the work ofTam and Hu [20] who studied the effect ofconfinement on the shear layer development insupersonic streams. These studies have shown

196 D. CHAKRABORTY ET AL.

that two-dimensional simulation is satisfactoryfor confined mixing layers. Apart from confine-ment effect, heat release effect also plays a vitalrole to make the most unstable mode two-dimensional. The linear stability analysis of re-acting compressible mixing layer by Shin andFerziger [24] has demonstrated that heat re-lease makes the dominant mode two-dimen-sional even in the high Mach number region;they have concluded that the most unstablemode for reacting flow is two-dimensional evenif the instability mode is three-dimensional(oblique) for the nonreacting case.

In the present work, both confinement andheat release effects are part of the physicsimplying that the role of large scale two-dimen-sional structures in modulating the chemistry–flow interactions is significant and can be under-stood from two-dimensional simulations.

As the experimental condition is far removedfrom the scramjet operating condition, espe-cially with regard to the temperature of thestreams, two more simulations were made bytaking realistic stream temperatures. In thesesimulations, both the primary and secondarystreams have the same temperature 1200 K and1500 K respectively, while all other propertiesare kept same at the inflow plane. The details ofthe inflow parameters of all the calculations areshown in Table 1. The code used in the DNS isthe SPARK2D combustion code developed atthe NASA Langley Research Center (LaRC) byDrummond et al. [25] and has already beenused in Sekar and Mukunda [26] and Mukunda[27]. It uses a fourth-order compact MacCor-mack scheme with second-order temporal accu-racy. This choice represents a compromise be-

tween the accuracy of higher order numericalalgorithms and the robustness and efficiency oflower order methods. The code has been vali-dated by computing a linearly unstable shearflow problem in the early stages of the growth.Carpenter and Kamath [28, 29] have demon-strated that, with the compact schemes consid-ered here, the growth rates with the initialprofiles based on the eigenfunctions predictthose from linear stability theory for free shearlayers to within 1% for a time duration equal toabout five times the sweep time of the flow field.This accuracy is adequate for the present com-putations needing a maximum of three sweeptimes—one sweep for clearing the flow field,and two more sweeps to collect statistical infor-mation and also to check on the statisticalinvariance of the calculations.

The reaction rates for the first case are cal-culated using both single-step chemistry (SSC)and full chemistry (FC) kinetics whereas for thesecond and third cases only FC kinetics is used.A reaction mechanism involving seven speciesand seven reversible reactions [25, 26] has beenchosen for the FC calculations. This reactionmechanism include the species H2, O2, H2O,OH, H, O, and N2. The species HO2, and H2O2,important in ignition are not included in themechanism. This is because the present study isaimed at examining combustion modeling. Thereaction steps and the rate parameters of thereactions are given in Table 2. For SSC calcu-lations, the following reversible reaction hasbeen chosen.

2H2 1 O2º 2H2O

TABLE 1

Inflow Parameters of the Cases with Various Stream Temperatures

CasesChemicalKinetics Species u (km/s) T (K) M p (MPa)

Case 1 FC H2 2.4 103 3.09 0.021Air 3.8 2344 3.99 0.021

SSC H2 2.4 103 3.09 0.021Air 3.8 2344 3.99 0.021

Case 2 FC H2 2.4 1200 5.63 0.021Air 3.8 1200 0.92 0.021

Case 3 FC H2 2.4 1500 5.06 0.021Air 3.8 1500 0.83 0.021

197EVALUATION OF COMBUSTION MODELS

and the net rate of reaction of H2 (in kg-mol/m3

s) is given by the expression [25, 26]

dcH2

dt5 [email protected] 3 1019

z exp~28052/T!cH2

2 cO22 kbcH2O

2 ] (1)

where c is the molar concentration (in g-mol/cm3) and kb, the rate constant of the reversereaction, is obtained from the forward rateconstant and equilibrium constant.

The boundary conditions set for the presentproblem are as follows: The no slip conditionsand constancy of wall temperature are imposedon the wall. On the inflow stream velocityfluctuations are imposed over a range of fre-quencies at total rms intensity of 0.3% of themean velocity. The frequency has been normal-ized with the mean velocity to channel widthratio. The frequency range allows the mixinglayer to grow as may happen in reality. The exitboundary condition is obtained by second-orderextrapolation and is considered satisfactory forthis problem dominated by supersonic flow.

The calculation used a 1000 3 101 grid withgrid stretching at high gradient zones—nearinterface, near splitter plate, and near the walls.The grid independence of the results was estab-lished [14] by not only comparing the result ofthe simulation with different grids but alsocomparing the spectral content of fluctuationwith different grids.

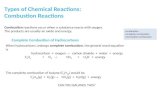

COMBUSTION MODELING

Chemical reactions take place when reactantsare mixed on a molecular scale at sufficiently

high temperature. In turbulent flow, the molec-ular mixing is associated with the smallest scaleof turbulence and the process of molecularmixing is similar to the dissipation of turbulentkinetic energy. In this paper we will discuss thefollowing empirical combustion models for pre-dicting the mean reaction rates: (1) EBU mod-el; (2) EDC with fast chemistry limit; (3) EDCfor finite rate chemistry for both SSC and FC.

EBU Model

The rate of consumption of fuel wf# modeled on

the basis of the EBU model [6] as

wf#5 2A1r# YL

e

k(2)

where overbars indicate the ensemble (Reyn-olds) averages and tildes indicate mass weighted(Favre) averages. As usual r, k, e representdensity, turbulent kinetic energy, and the rate ofdissipation of turbulent kinetic energy. YL 5min(Yf, YOX/s) is the limiting reactant massfraction, Yf and YOX are the fuel and theoxidizer mass fraction, and s is the stoichiomet-ric ratio.

Bilger [30] has proved theoretically that formixing limited reaction, the mean productionrate is proportional to the pdf of the mixturefraction at stoichiometry. Assuming differentshapes of pdf, namely, clipped Gaussian, Beta,and Gamma functions, Brizuela and Bilger [31]have proposed an empirical expression for themean reaction rate

wf#5 A*1r#

e

kYB Yf

mYOX2n S 1

Yf1

1YOX

D2p

(3)

TABLE 2

Elementary Reactions and Reaction Rate Parameters Used for Full ChemistryComputations

No. Reaction A N E/R, K

1 H2 1 O23 OH 1 OH 0.170 3 1014 0 242302 O2 1 H3 OH 1 O 0.142 3 1015 0 82503 H2 1 OH3 H2O 1 H 0.316 3 1008 1.8 15254 H2 1 O3 OH 1 H 0.207 3 1015 0 69205 OH 1 OH3 H2O 1 O 0.550 3 1014 0 35206 OH 1 H 1 M3 H2O 1 M 0.221 3 1023 22 07 H 1 H 1 M3 H2 1 M 0.655 3 1018 21 0

198 D. CHAKRABORTY ET AL.

where YB is a constant and Yf 5 Yf/YB and YOX

5 YOX/sYB. The values of the constants m, n,p, and A*1 are tabulated in Ref. 31 for thedifferent shapes of pdf. For the stoichiometricmixture fraction 0.03 considered in this study,the values of the variables are A*1 5 7.0, m 50.8, n 5 0.6, and p 5 1.1 [31].

Once the mean production rate for the fuel isobtained, the mean production rate for theoxidizer and the product is obtained from

wOX# 5 swf

# (4)

wp#5 ~1 1 s!wf

# (5)

EDC

Fundamental Aspects

EDC gives an empirical expression for the meanreaction rate based on the assumption thatchemical reaction occurs in the regions wherethe dissipation of the turbulent energy is signif-icant. In flows of moderate to intense turbu-lence, these regions are concentrated in isolatedhighly strained regions, occupying only a smallfraction of the flow. These regions consist offine structure whose characteristic dimensionsare of the order of Kolmogorov length scale inone or two dimensions but not in the third [32,33]. The fine structures are responsible for thedissipation of turbulence into heat. Within thesestructures one can assume that the reactants aremixed on a molecular scale.

Magnussen and coworkers [7, 8] proposed thefollowing expression for the mean reaction ratefor the finite rate chemistry.

wi#

r5

g2x

t*~Yi

0 2 Y*i! (6)

where g is the fraction of the flow occupied bythe fine structure region and is modeled as:

g 5 S3CD2

4CD12 D1/4Sn*e

k2 D1/4

(7)

where CD1 5 0.134 and CD2 5 0.5 are modelconstants and n is the kinematic viscosity. Alter-natively g can be expressed as g 5 3.43/=Rel,

where Rel 5 =(20k2)/(3ne) is the Reynoldsnumber based on Taylor length scale.

The time scale for the mass transfer betweenthe fine structures and the surroundings (t*) isestimated as

t* 5 SCD2

3 D1/ 2Sn*eD1/ 2

(8)

x is the fraction of the fine structures wherereaction occurs. Gran [8] demonstrated that theassumption x 5 1 leaves the results almostunaltered. In our analysis the value of x will beconsidered as unity. The superscripts p and 0refer to the fine structure and the surroundingfluids respectively. The fine structure is treatedas constant-pressure homogeneous reactorwhere effects of finite rate chemical kinetics aretaken into account. The properties of constant-pressure homogeneous reactor are assumed tobe time dependent but without any spatial gra-dient. The set of governing equation for such areactor is

dhdt

5 0 (9)

dpdt

5 0 (10)

dYi

dt5

wi

r1

1t*

~Yim 2 Yi! i 5 1, · · · ns

(11)

where the superscript m refers to the fluidentering the reactor. The steady-state solutionof Eq. 11 gives the fine structure state. Thereaction rate wi can be obtained from Eq. 1 orTable 2 depending on whether it is SSC or FCkinetics. The mass fraction of the surroundingfluid Yi

0 is determined from

Yi0 5

Y# i 2 g3Y*i1 2 g3 (12)

Putting Eq. 6 in the nondimensionalized formwe get,

Ri 5

wi#kre

Y# i 2 Y*i5

11.171 2 g3 (13)

199EVALUATION OF COMBUSTION MODELS

Fast Chemistry Limit

The fast chemistry limit is obtained by assumingthat there is sufficient time to achieve equilib-rium in the fine structures. It is assumed that thereaction can be suitably represented by thesingle one-step infinite-rate irreversible reac-tion.

1 kg fuel(f) 1 s kg oxidant(ox)3

~1 1 s) kg product(P) (14)

The following set of scaled mass fractions isintroduced to simplify the model expressions:

Yf 5Yf

1(15)

Yox 5Yox

s(16)

YP 5YP

1 1 s(17)

and

Ymin 5 min@Yf, Yox# (18)

Magnussen [32] suggests the following modelfor x

x 5 x1 z x2 z x3 (19)

where x1 is the probability of coexistence of thereactants

x1 5~Ymin 1 YP!2

~Yf 1 YP!~Yox 1 YP!(20)

x2 expresses the degree of heating

x2 5 minF YP

g~YP 1 Ymin!, 1G (21)

and x3 limits the reaction due to lack of reac-tants

x3 5 minFg~YP 1 Ymin!

Ymin, 1G (22)

With these expressions for x, the constraint0 # x # 1 is always satisfied. The reaction rate,Eq. 6, can now be written as

wf

r5 2

g2x1

t*min@Ymin, YP, ~Ymin

1 YP!g#1

1 2 g3x(23)

The factor 1/(1 2 g3x) is generally very close tounity.

Modifications on EDC Model

The important coefficients involved in momen-tum, energy, and species transport are viscosity,thermal conductivity, and diffusivity respec-tively. The transport of species from the sur-rounding fluid to fine structure is essentiallydependent on diffusion process. In the EDCmodel Eq. 6, t* is modeled as 0.4082=m/re.The fraction of the flow occupied by the finestructure region (g) is modeled as 2.135 (rk2/me)20.25. Both these parameters are function ofm in addition to k and e. For reactions involvingH2 and air, various species will have differentdiffusivities. It is important to bring explicitdependence of mean reaction rate on the diffu-sivity in place of molecular viscosity. Although itis desirable to take different diffusivities fordifferent species in the mean reaction rateequation, as a first step we consider equaldiffusivity of all the species. We propose thefollowing modification in modeling t* and g as:

t* 5 0.4082 ÎDe

(24)

g 5 2.135 S k2

DeD20.25

(25)

These modifications bring explicit dependenceof diffusivity in the mean reaction rate equation.

RESULTS AND DISCUSSION

The details of the DNS of H2/air confinedmixing layer are explained in the previous sec-tion. After the solution has attained statisticalsteady state, several variables such as density,velocities, the mass fractions, and instantaneousreaction rates of all the species were stored atall time steps over one sweep of calculation atall the lateral points of two neighboring axialstations where the flow is well developed. Onesweep is taken as the time the flow takes to crossthe test section with its convective velocity. The

200 D. CHAKRABORTY ET AL.

first axial station is chosen at the distance of0.5 m of the splitter plate and the second axialstation is just adjacent to it. From the storeddata, the average values of the density (r),turbulent kinetic energy (k), rate of dissipationof turbulent kinetic energy (e), and the massfractions of the species are calculated. Withthese calculated mean profiles, the mean reac-tion rates of the fuel (H2) are calculated forthe EBU model with Bilger modificationsfrom Eq. 3, while Eq. 23 is used for calculatingmean reaction rate for EDC fast chemistrylimit. The mean reaction rates of the speciesH2, O2, and H2O have also been calculated forEDC (SSC) from Eq. 6. The values of Y*irequired for the calculation are obtained byintegrating Eq. 11 and the values of wi areobtained from the SSC kinetics Eq. 1. Thecalculated mean reaction rates of H2 from theEBU model and EDC (fast chemistry limit)are compared in Fig. 1a and the mean reac-tion rate obtained from EDC (SSC) comparedin Fig. 1b with DNS (SSC) solution at theaxial location of 0.5 m from the splitter platefor Case 1. The reaction rate profile of DNS isobtained from the averaging of the storedinstantaneous H2 reaction rates. As expected,the fast chemistry results (both for EBU andEDC [fast chemistry limit]) predict muchhigher reaction rate compared to DNS solu-

tions. In the mixing layer region, where thereaction takes place, the reaction rate pre-dicted by fast chemistry is about two orders ofmagnitude higher than the DNS data. Themodified EBU model due to Bilger [31] showsa much broader profile than the EDC (fastchemistry limit). The predicted reaction ratewith EDC (SSC) matches fairly well with theDNS data. The peak values and the shape ofthe reaction rate profile obtained from EDC(SSC) and the DNS match closely, although athinner reaction zone is predicted by EDC(SSC). Mean reaction rate profiles for thespecies O2 and H2O are compared in Fig. 2.As in the case of H2, the mean reaction ratesof O2 and H2O predicted by EDC (SSC)match fairly well with the DNS data.

The necessity of using detailed chemistry forsimulating high-speed H2/air mixing layer hasbeen demonstrated in Ref. 14, which revealedthat SSC predicts much higher temperaturecompared to FC. This is mainly because of theabsence of any heat absorbing reaction path inSSC. The high temperature present in SSCsimulation impedes the growth of the mixinglayer. To illustrate the point further, we analyzefrom DNS data a parameter I which is themeasure of unreactedness of the mixed fluidand is defined as:

Fig. 1. Comparison of models and DNS data for H2 reaction rate profile x 5 0.5 m. (a) between EBU and EDC (fastchemistry limit), (b) between EDC (SSC) and DNS (SSC).

201EVALUATION OF COMBUSTION MODELS

I 5

E0

L

~YH2YO2

!/~ZHZO! d y

E0

L

d y

(26)

where ZH and ZO are the element mass frac-tions of H and O, whereas YH2

and YO2are H2

and O2 mass fractions respectively. Axial varia-tion of time averaging of I is presented in Fig. 3.

Axial distance is nondimensionalized by L(50.0254 mm) 2 the width of the test section. Itis very clear from the figure that SSC is fasterthan FC. Also for the cases considered, reactionis yet to be completed. Axial variation of Iindicates that combustion is reaction-dominatedrather than diffusion-limited. In order to assessthis issue, instantaneous variation of w-H2O/r,ZHZO, YH2

YO2, and T with lateral distance at

x 5 0.5 m is shown in Fig 4. There are severalinteresting features that can be derived from theplot. Even though fuel and oxidizer are avail-able, reaction does not occur in most places asthe temperature is quite low in most places.Reaction therefore occurs in smaller zones. Thewidth of the reaction zone varies from 2.5 to 3mm and is covered by at least 15 grid points.The range of (w-H2O/r) is between 15,000 s21 to12,000 s21. This implies that the reaction time isof the order 50 to 70 ms. The residence time canbe estimated as follows. The vortical structuresare typically 30 mm and the flow velocity 3000m/sec. This give a flow time of 10 ms. TheDamkohler number is 0.15–0.2. This is indica-tive of chemistry-dominated flow. Another wayof understanding the behavior is to look at thereaction width. The reaction zone is typically 2.5mm and the mixed zone is about 20 mm. Thisimplies that mixing has not limited the reaction.

Mean reaction rate profiles of various species

Fig. 2. Comparison of reaction rate profile between EDC (SSC) and DNS (SSC) at x 5 0.5 m (a) O2, (b) H2O.

Fig. 3. Axial variation of I.

202 D. CHAKRABORTY ET AL.

obtained from the DNS results are comparedwith those obtained from the EDC model withFC. The stored time series data from three setsof DNS calculations of confined mixing layerwith FC kinetics are used for this purpose. Thedetails of inflow parameters of these DNS cal-culations are the same as in Table 1. The firstcase, the H2/air confined mixing layer, corre-sponds to the experimental condition of Erdoset al. [16]. In the second case, the temperaturesof both the air and H2 streams are considered1200 K while maintaining all the other condi-tions identical. In the third case the tempera-tures of both the streams are taken as 1500 K.As earlier, the fluid dynamical parameters, themass fractions, and the instantaneous reactionrates of the species are stored over one sweep atall lateral locations of the two neighboring axialstations at a distance of 0.5 m from the splitterplate. From the stored data, we first determinethe mean profiles of k, e, and the species massfractions. The mean reaction rates of variousspecies were then determined from the EDC(FC) model (Eq. 6) and the modified EDC (FC)model as described in the previous section. Thevalues of Y*i required for the calculation areobtained by integrating Eq. 11, and the values ofw-i are obtained from the FC kinetics given inTable 2. The species production rates thusobtained are compared with the averages of the

instantaneous species production rate obtainedfrom the model-free simulation.

The comparisons of H2 and O2 productionrate profiles obtained from these two ap-proaches for the first case (Erdos experimentcase) are presented in Fig. 5 for the axiallocation of 0.5 m from the splitter plate. It isinteresting to note that several peaks and humpspresent in the DNS result are also picked up bythe model. The peak value obtained from themodel is about 15% higher than that obtainedfrom the DNS result. The model predicts athinner reaction zone compared to the DNSresult. The species production rate profile com-parisons for H2O and OH are presented in Fig.6. As in the earlier figure, the shapes of the twocurves are similar and the peak values comparewell with a thinner reaction zone predicted bythe model. Results obtained from the modifiedEDC (FC) model show a small improvementover the original EDC (FC) model. Similarconclusions can be drawn from the reaction rateprofile comparisons of the other minor speciesO and H as well (not presented here for thesake of brevity).

The comparisons of mean reaction rate pro-files of the species H2, O2 for case 2 arepresented in Fig. 7. For H2 profile, the modelpredicts a better comparison for the lower side(air) of the mixing layer whereas the compari-

Fig. 4. Instantaneous profiles of DNS results for case 1 (a) YH2YO2

and ZHZO, (b) w-H2O/r, and temperature at x 5 0.5 m.

203EVALUATION OF COMBUSTION MODELS

son is not good for the upper side (H2) of themixing layer. Although the orders of the meanreaction rates predicted by the two are same,the model predicts a thinner reaction zone as inthe previous case. Also the profile predicted bythe model is not as smooth as the profiles ofcase 1. Because of the high momentum ratio ofthe two streams in the inflow plane, there is ashift in the general structure of the mixing layer

towards the upper wall. The grid used in thesimulation is very fine only near the interfaceand the wall boundary layers but relativelycoarse in other zones. In this case, because ofthe shift of the structures, the flow developmentand the reaction occur in the zones where arelatively coarser grid is employed. As a resultthe turbulent kinetic energy (k) and the rate ofdissipation of turbulent kinetic energy (e) re-

Fig. 5. Comparison of species production rate profiles for case 1 between DNS results and the EDC (FC) models at x 5 0.5m. (a) H2, (b) O2.

Fig. 6. Comparison of species production rate profiles for case 1 between DNS results and the EDC (FC) model at x 5 0.5m. (a) H2O, (b) OH.

204 D. CHAKRABORTY ET AL.

quired for the model are not sufficiently re-solved, particularly in the upper portion of themixing layer. This fact can be viewed from thecomparisons of the e/k profiles for all the casespresented in Fig. 8. The profiles of e/k for case1 are much smoother than the profiles for case2 and case 3. A finer grid in this zone may berequired to have a better match. For the O2reaction rate, the model predicted much lower

peaks and thinner profiles compared to DNSresults. H2O and OH reaction rate profiles arecompared in Fig. 9. As in the case of H2 reactionrate, the comparisons are not very satisfactoryin the upper portion of the mixing layer. Thecomparisons of the mean reaction rates of H2,O2, H2O, and OH between DNS and the EDC(FC) model for case 3 are presented in Figs. 10and 11 respectively.

Fig. 7. Comparison of species production rate profiles for T 5 1200 K between DNS results and the EDC (FC) model atx 5 0.5 m. (a) H2, (b) O2.

Fig. 8. Comparison of e/k profiles at x 5 0.5 m (a) between FC and SSC computations of case 1, (b) between FC for 1200K and 1500 K.

205EVALUATION OF COMBUSTION MODELS

To determine the predictive capability of theEDC (FC) model in the other regions of theflow field, transient data of all the fluid dynam-ical chemical variables are stored at the locationof 0.1 m downstream of the splitter plate edgeof the DNS (FC) results for the first case. As theignition of the mixing layer is seen to occur at adistance of 0.04 m from the splitter plate edge[14], the comparisons of the mean reaction rate

profile at this station can help us to assess theperformance of this model to predict the meanreaction rate in regions near the occurrence ofignition. The mean reaction rate profile com-parison between DNS results and the EDC(FC) model for the axial location of 0.1 m ispresented in Fig. 12 for the species H2 and O2;the comparison for the profiles of H2O and OHis presented in Fig. 13. As earlier, the general

Fig. 9. Comparison of species production rate profiles for T 5 1200 K between DNS results and the EDC (FC) model atx 5 0.5 m. (a) H2O, (b) OH.

Fig. 10. Comparison of species production rate profiles for T 5 1500 K between DNS results and the EDC (FC) model atx 5 0.5 m. (a) H2, (b) O2.

206 D. CHAKRABORTY ET AL.

shape of the profiles and the order of magnitudeof the peak values between the two match fairlywell except for the species O2, although a thin-ner reaction zone is predicted by the model.

The comparisons of the EDC (FC) and EDC(SSC) results discussed so far have brought outclearly that the distribution of the reaction rateprofiles of all the species are not as thick as theprofiles obtained from the DNS results. The

cause of this departure was traced by comparingthe nondimensionalized reaction rate parame-ter Ri (described in Eq. 13) from the DNSresults and the EDC models. The computednondimensionalized reaction rate parametersfor the species H2(RH2

) from the DNS results ofthe various cases are plotted against the Reyn-olds number (Rel) based on Taylor length scalealong with the value of RH2

predicted by the

Fig. 11. Comparison of species production rate profiles for T 5 1500 K between DNS results and the EDC (FC) model atx 5 0.5 m. (a) H2O, (b) OH.

Fig. 12. Comparison of species production rate profiles for case 1 between DNS results and the EDC (FC) models at x 50.1 m. (a) H2, (b) O2.

207EVALUATION OF COMBUSTION MODELS

model in Fig. 14. It is very clear from the figurethat for the higher Rel the computed RH2

deviates much from the model value. The RH2

computed from the EDC model is almost inde-pendent of Rel whereas the computed RH2

dipped down for higher Rel. The correction forhigher Rel is required in the EDC model tomake it work better in the high-speed combus-ting flow.

CONCLUSIONS

Various empirical combustion models wereevaluated for their predictive capability of meanreaction rate for the high-speed confined mixinglayers using the time series data of DNS. Theempirical model based on fast chemistry ap-proximation cannot predict the mean reactionrate accurately. In the mixing layer region,where the reaction takes place, the modelsbased on fast chemistry approximation show themean reaction rate as high as two orders ofmagnitude compared to DNS data. The EDCmodels based on finite rate chemistry (both forFC and SSC) do well in predicting the meanreaction rate of the confined high-velocity mix-ing layer. The general shape of the reaction rateprofile and the peak value computed from theEDC finite rate chemistry model match wellwith the DNS data at different locations of theflow field. The comparisons of the predictedmean reaction rates with different hydrogen andair stream temperatures with the DNS data alsosupport this conclusion. For the hypervelocityreacting mixing layer, where the enthalpychange due to gas dynamics is significant com-pared to the enthalpy change due to chemistry,the finite rate EDC model seems to be adequate

Fig. 13. Comparison of species production rate profiles for case 1 between DNS results and the EDC (FC) model at x 5 0.1m. (a) H2O, (b) OH.

Fig. 14. Comparison of RH2between DNS results and EDC

model.

208 D. CHAKRABORTY ET AL.

to describe turbulence–chemistry interaction. Itis worthwhile to fine tune the model for properprediction of reaction zone width. This work isperhaps the first to test out the efficacy of sucha model for supersonic flow. More effort in thisdirection is valuable to generate calculationmethods for supersonic reacting flows.

The authors express their sincere thanks to Dr.V. Adimurthy of VSSC, Thiruvananthapuram forthe support provided for carrying out this work.

REFERENCES

1. Givi, P., Prog. Energy Combust. Sci. 15:1–107 (1989).2. Vervisch, L., and Poinsot, T., Ann. Rev. Fluid Mech.

30:655–691 (1998).3. Bilger, R. W., in Turbulent Reacting Flows (P. A. Libby

and F. A. Williams, Eds.), Springer-Verlag, 1980,Heidelberg, pp. 65–114.

4. Jones, W. P., and Whitelaw, J. P., Combust. Flame48:1–26 (1982).

5. Borghi, R., Prog. Energy Combust. Sci. 14:245–292(1989).

6. Spalding, D. B., Thirteenth Symposium (International)on Combustion, 1970, The Combustion Institute, Pitts-burgh, pp. 649–657.

7. Magnussen, B. F., and Hjertager, B. H., SixteenthSymposium (International) on Combustion, 1976, TheCombustion Institute, Pittsburgh, pp. 719–729.

8. Gran, I. R. (1994). Ph.D. dissertation, University ofTrondheim, Trondheim, Norway.

9. Pope, S. B., Prog. Energy Combust. Sci. 11:119–192(1985).

10. Eiffer, P., and Kollmann, W., (1993). AIAA Paper93-0448.

11. Zheng, L. L. (1993). Ph.D. dissertation, CambridgeUniversity, Cambridge, U.K.

12. Girimaji, S. S., Combust. Sci. Technol. 78:177–196(1991).

13. Girimaji, S. S. (1991). AIAA Paper 91-1792.14. Chakraborty, D., Nagraja Upadhyaya, H. V., Paul,

P. J., and Mukunda, H. S., Phys. Fluids 9:3513–3522(1997).

15. Nagraja Upadhaya, H. V., Chakraborty, D., Paul, P. J.,

and Mukunda, H. S., Proceedings of the XV NationalConference on I.C. Engines and Combustion, Chennai,India, 1997, pp. 693–700.

16. Erdos, J., Tamagno, J., Bakos, R., and Trucco, R.(1992). AIAA-92-0628.

17. Clemens, N. T., and Mungal, M. G. (1990). AIAA-90-1978.

18. Ragab, S. A., and Wu, J. L., Phys. Fluids A 1:957–966(1989).

19. Sandham, N. D., and Reynolds, W. C., AIAA J. 28:618–622 (1990).

20. Tam, C. K. W., and Hu, F. Q., J. Fluid Mech. 203:51–76(1989).

21. Zhuang, M., Dimotakis, P. E., and Kubota, T., Phys.Fluids A 2:599–604 (1990).

22. Papamoschou, D., and Roshko, A., J. Fluid Mech.197:453–457 (1988).

23. Lu, P. J., and Wu, K. C., Phys. Fluids A 3:3063–3069(1991).

24. Shin, D. S., and Ferziger, J. H., AIAA J. 31:677–685(1993).

25. Drummond, J. P., Carpenter, M. H., and Riggins,D. W., in High Speed Flight Propulsion System, (S. N. B.Murthy and E. T. Curran, Eds.), Progress in Aeronau-tics and Astronautics, Vol. 137, 1991.

26. Sekar, B., and Mukunda, H. S., Twenty-Third Sympo-sium (International) on Combustion, The CombustionInstitute, Pittsburgh, 1990, pp. 707–713.

27. Mukunda, H. S., Combust. Sci. Technol. 89:285–290(1992).

28. Carpenter, M. H., and Kamath, H. (1988). ThreeDimensional Extension of the SPARK CombustionCode. NASA-Langley, NASA-CP-5029, pp. 107–137.

29. Carpenter, M. H. (1988). A Generalized ChemistryVersion of SPARK. NASA-CR-4196.

30. Bilger, R. W., Combust. Sci. Technol. 13:155–170(1976).

31. Brizuela, E. A., and Bilger, R. W., Combust. Flame104:208–212 (1996).

32. Magnussen, B. F., Eighteenth International Congress onCombustion Engines, International Council on Com-bustion Engines, Tianjin, China 1989.

33. Tennekes, H., and Lumley, J. K., A First Course inTurbulence, MIT Press., Cambridge, MA, 1972.

Received 20 December 1998; revised 2 August 1999; accepted18 October 1999

209EVALUATION OF COMBUSTION MODELS