Epitaxial Growth and Characterization of Self-Doping ${\rm Si}_{1-{\rm x}}{\rm Ge}_{\rm x}{\rm/Si}$...

Click here to load reader

Transcript of Epitaxial Growth and Characterization of Self-Doping ${\rm Si}_{1-{\rm x}}{\rm Ge}_{\rm x}{\rm/Si}$...

JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 23, NO. 1, FEBRUARY 2014 213

Epitaxial Growth and Characterization ofSelf-Doping Si1−xGex/Si Multi-Quantum

Well MaterialsBo Jiang, Tao Dong, Member, IEEE, Yan Su, Yong He, and Kaiying Wang

Abstract—This paper presents self-doping Si1−xGex/Si mul-tiquantum wells (MQWs) with35 nm buffer layers where self-doping occurs to allow free carriers in the quantum well. Thefilm grown through ultra-high vacuum chemical vapor depositionmethod can easily achieve a good lattice quality. The crystallattice is verified through scanning electron microscopy, X-ray diffraction,and secondary ion mass spectrometry. Uniquestructures are applied in the Temperature Coefficient of Resis-tance (TCR) measurement to obtain electrical characteristics ofMQWs. The TCR of Si0.65Ge0.35/Si obtained in the experimentis about-2.5%/K at 20 °C, which meets the requirements of athermistor. The TCR decreases from 2.5%/K to 1.1%/K asthe size of the MQWs increases from 100 μm × 100 μmto 400 μm × 400 μm. Annealing is necessary for the forma-tion of an ohmic contact between electrodes and high contactlayers. [2013-0056]

Index Terms—Crystal growth, materials testing, quantumwells, thin films.

I. Introduction

THERMISTOR materials are widely used for exother-mic reactions detection. Such an effective and non-

destructive detection method allows an easy operation inthermal biosensors and bolometers [1]–[5]. As the essen-tial sensing component in calorimetric measurement, thermalbiosensors incorporate biological materials with a physico-chemical transducer or transducing microsystem, which hasthe potential to shorten the time span from sampling to result[6]–[8]. Traditional thermistor materials in bolometers, suchas vanadium oxide(VOx) [9], [10] and amorphous Si [11]–[13], have achieved great success in thermal imagers andthe night vision equipment market [14]. Nevertheless, thesetraditional thermistors have some limitations, including theirincompatibility with the MEMS process. More efforts havebeen made in developing new generation materialsto obtain

Manuscript received March 11, 2013; revised May 21, 2013; acceptedJune 7, 2013. Date of publication July 12, 2013; date of current versionJanuary 30, 2014. This work was supported in part by the Scientific ResearchProject, China, under Grant A2620110012, in part by NorFab under Grant197411/V30, and in part by Oslofjorfondet, Norway, under Grant 226001and Grant 220635. Subject Editor R. R. A. Syms. (Corresponding author:T. Dong.)

B. Jiang, Y. Su, and Y. He are with Nanjing University of Science andTechnology, Nanjing 210094, China (e-mail: [email protected]).

T. Dong and K. Wang are with the Department of Micro and NanoSystems Technology, Faculty of Technology and Maritime Sciences, VestfoldUniversity College, 3103 Tønsberg, Norway (e-mail: [email protected]).

Color versions of one or more of the figures in this paper are availableonline at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/JMEMS.2013.2269612

higher Temperature Coefficient of Resistance(TCR) and over-come the disadvantages [15], [16]. As a typical representativeof these materials, Si1−xGex/Si multiquantum wells (MQWs)have been proposed recently as a new thermistor material[17], [18]. This material consists of several mono-crystallinequantum well structures, which are thick buffer layers used toprevent self-doping from contact layers in a high-temperatureenvironment during the epitaxial process. Each quantum wellcontains an alternating undoped mono-crystalline Si as thebarrier layer and a p-doped mono-crystalline Si1−xGex asthe quantum well layer [19]. MQWsare also employed inthe calorimetric measurement, acting as energy harvestingmaterial from environment, to monitor biochemical reactions[20], [21]. Combining with themicro-fabrication technology,the biosensor employed the material can be typically made ina small volume which enablesa low thermal capacity and ashort response time [22].

Even though this new design has achieved good perfor-mance, it also leads to some difficulties because of the practicalgrowth process. With the rising complexity in this process,the cost and difficulties also increase to maintain the latticequality. As a result, a structure with reliable and stableprocessesshould be considered as an optimized option. Threegas sources (Si2H2Cl2, GeH4, and B2H6) are available forthe reported design in the epitaxial growth of Si-Ge layer[23]. By contrast, the current paper presents an optimizedSi1−xGex/Si MQWs structure, containing thinner buffer layers,undoped mono-crystalline Si and Si1−xGex. The thinner bufferlayers, where the self-doping occurs, enable free carriers inthe quantum wells. This structure simplifies the process andcan also promise a high lattice quality through an ultra-high vacuum chemical vapor deposition (UHVCVD) epitaxialgrowth process. In addition, the pixel support layers basedon MQWs materials could be thicker, thereby increasing themechanical strength of the pixel [24].

The MQWs models and the valence band energy levelsimulations are introduced in the paper. Then, the details of theUHVCVD processes applied in the Si1−xGex/Si MQWs epi-taxial growth are presented. Characterizations, including Scan-ning Electron Microscopy (SEM), X-ray Diffraction (XRD),and Secondary Ion Mass Spectrometry (SIMS), have beencarried out to verify the lattice quality. Furthermore, resis-tance measurements have been conducted and the resultsare consistent with the theoretical model well. Finally, the

1057-7157 c© 2013 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission.See http://www.ieee.org/publications standards/publications/rights/index.html for more information.

214 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 23, NO. 1, FEBRUARY 2014

Fig. 1. UHVCVD equipment in the Pen-Tung Sah Micro-Nano TechnologyInstitute of Xiamen University: (a) Injection chamber, pretreatment chamber,and growth chamber, (b) Wafer brackets, (c) Equipment pneumatic controlpanels.

Fig. 2. TCR test sample process and schematic diagram. (a) Process flow:(I) Clean process; (II) Definition of test unit; (III) Electrode pad deposition;(IV) Trench formation. (b) TCR test schematic diagram and the currentorientation.

experimental results are illustrated and discussed. It will beshown that the proposed material has a TCR of –2.5%/K at20 °C, which indicates that it may be used as a promisingthermistor material.

II. Experimental setup

Instead of an Low Pressure Chemical Vapor Deposi-tion [25], this paper presents the MQWs process using aUHVCVD, which has a lower pressure and a higher temper-ature [26]. Using this process is beneficial to an atomistic-level epitaxial growth and enhances the lattice quality of thematerial.

In pretreatment, the samples were cleaned in CRA-cleanmethod. Washed with deionized water and dried with nitrogen,the substrate wafers were placed on the brackets in theinjection chamber. The chamber was closed and the vacuumpump was set to 10−6 Pa. Then the wafers were transferred to apretreatment chamber using an operating handle, as shown inFig. 1, and were heated at 250 °C for 2h to remove the surface

Fig. 3. Schematic diagrams of two kinds of MQWs structure and valencebands in calculation. (a) MQWs structure reported and corresponding valencebands, (b) Self-doping MQWs in the paper and corresponding valence bands.

Fig. 4. Relationship between the TCR and the self-doping Si1−xGex/SiMQW parameters: different well width, Si-Ge layer thickness, with differentGe content.

moisture. The temperature of the pretreatment chamber wasraised to 950 °C after filling it with a protective gas (H2) untilthe pressure reached 10−2 Pa to remove the natural oxide layeron the top of the substrate wafers.

After pretreatment, the substrate wafers were transferred tothe growth chamber with the vacuum pump set at 10−6 Pa. Inthe mono-crystalline Si layer growth, the temperature was keptat 625 °C and the inlet rate of Si2H6was 8 sccm to 10 sccm. Inthe mono-crystalline Si-Ge layer growth, the temperature wasset at 575 °C and the inlet rates of Si2H6/GeH4 were set at

JIANG et al.: SELF-DOPING Si1−xGex/Si MULTI-QUANTUM WELL MATERIALS 215

Fig. 5. SEM photographs of the epitaxial Si1−xGex/Si MQW material with35%Gecontent.

Fig. 6. (a) XRD and (b) SIMS patterns of the Si0.65Ge0.35/Si MQW material.

5.25 sccm/4.5 sccm. The growth thicknesses of these materialswere 30 nm/10 nm respectively and the growth rate is about8 nm/min for both of Si and Si-Ge alloy at the condition.

SEM, XRD and SIMS were conducted to verify the latticequality [27]. SEM was used to obtain the material profile(Sirion200 Field emission SEM). Sputtering a thin Au beforethe test is necessary to improve the electrical conductivity ofthe cross section. The crystal orientation, lattice quality and

Fig. 7. TCR test structure micrograph.

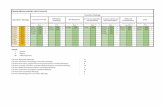

TABLE I

Relationship between the boron concentration in the

Si1−x Gex /Si cycles and the TCR value

TABLE II

Cycle and cycle thickness based on the XRD calculation

results

dopants (Ge and Boron) depth distributions were examinedthrough XRD (X’Pert PRO) and SIMS (IMS4F/E7).

Fig. 2(a) shows the process flow of the TCR test sample.In the clean process, the wafer was immersed into a mixtureof H2SO4 and H2O2 (4:1) at 120 °C for 15 min (I). Then, thewafer was etched using an SF6/O2-based inductively coupledplasma (ICP) etching process, with the ICP power of 2200W/200 W, intake rate of 40 sccm/10 sccm, and etching timeof 40 s (II) [28]. Subsequently, 50 nm Ti and300 nm Alsputtered on the surface of top contact layer were employedas adhesion layer and electrodes. The depositing rates of Ti/Alare 4 nm/min and 14.3 nm/min respectively. (III). Finally, thewafer was etched with the depth of about400 nm, stopping atthe contact layer. The etching time was 22 s to 23 s (IV). In the

216 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 23, NO. 1, FEBRUARY 2014

TABLE III

TCR test sample numbers and parameters

process, the electrode (aluminum) was used as the mask. Thecurrent path went vertically through the Si1−xGex/Si MQWsstack. Fabricating a special structure was used to providea current loop in the TCR test experiment. The TCR testprogram for Si1−xGex/Si MQWs is shown in Fig. 2(b). Thecurrent was flowing in a U-shaped when voltage was appliedon both sides of the trench.

III. Results and discussion

A. Model Analysis and Simulation

The material resistance of semiconductors is dependenton temperature. The p-doped semiconductor resistance isinversely proportional to the hole concentration, which can bedescribed as R = β · p−1

0 , where β is a constant and p0 is thehole concentration. The hole concentration takes the followingform:

p0 = 2

(2πmp ∗ kT

h2

)3/2

e−(Ef −Ev)/kT , (1)

where Ef is the Fermi level, Ev is the valence band barrierheight, k is the Boltzmann constant, 8.62e-5 eV · K−1, T is thetemperature, mp is the carrier effective mass, and h is Planck’sconstant, 4.14e-15 eV s.

Combined with the definition of the TCRα, where α =(∂R/∂T ) /R, the TCR in the p-doped semiconductor can alsobe derived as the following equation [29]:

α = − 1

kT 2

(3

2kT + Ef − Ev

). (2)

The Eq. (2) showsthat alarger difference between the Fermilevel and the valence band barrier energy (Ef - Ev) inducesahigher TCR value.

Studies on the relationship between the semiconductorband structure and the structure parameters have been widelyreported in the literature. In Si1−xGex/Si MQWs, Si andSi1−xGex act as the barrier and well, respectively. Consideringthe strains caused by the lattice mismatch of Si and Ge, thevalence band splits into light hole (LH), heavy hole (HH),and spin-split-off (SO) bands, where each band has two states,that is, spin-up and spin-down [30]–[32]. The Ef - Ev valuecan be calculated coupled with the Schrodinger equation,(H± − V0) · �± = Ev · �± where H± is the Hamiltonianmatrix and the subscripts “+” and “-“ represent a spin-up andspin-down, respectively. The Si1−xGex/Si MQWs TCR can beobtained by substituting the Ef - Ev value into (2).

The calculated valence bands and two types of Si1−xGex/SiMQWs schematic diagrams are shown in Fig. 3. Both

Fig. 8. Si1−xGex/Si MQW material I-V test curves.

structures consist of highly boron-doped (more than1019 cm−3)contact layers, buffer layers, and Si1−xGex/Si mul-tilayer. In QWs-a, the buffer layer is thick (more than 100 nm)to block the boron atom from the contact layer into theSi1−xGex/Si cycles. The free carriers in the Si1−xGex/Si areprovided by the Si-Ge layer, which is p-doped in the structure[19]. By contrast, thin buffer layers are applied in QWs-b.More free carries are available, causing a proportion of boronatoms to diffuseinto Si1−xGex /Si.

For both structures, the energy levels aredegenerated in thebarriers and split into three energy levels (HH, LH, SO) inthe wells. The differences between the barrier energy and theFermi level are 0.237 eV and 0.214 eV, respectively, as listed inTable I. In the simulations, the TCR of the QWs-b structure is-3.26%/K, while the QWs-a structure has a TCR of -3.56%/K.

Although the TCR of a semiconductor is negative accordingto (2), describing its temperature effect in an absolute valueis more relevant. For convenience, the following TCRs arepresented in positive values.

As for QWs-a, under the high temperature during theepitaxial growth (about 700 °C), boron atoms diffusedfromthedoped Si1−xGexlayers into the undoped Si layer, reducing theTCR. The theoretical calculation values under different boron-doping concentration are listed in Table I. When the boronconcentration in the Si1−xGex layer is 1e19 cm−3, theTCR-value decreases from 3.56%/K to 3.09%/Kwith the boronconcentration in the Si layer from 1e16 cm−3 to 1e18 cm−3.

The relationship between the TCR and the self-dopingSi1−xGex/Si MQW parameters are provided in Fig.4, wherea wider well induces a higher TCR under a certain Ge content[33]. However, this effect is weakened when the well width ismore than 10 nm. Moreover, a larger Ge content also leads toahigher TCR. In practical applications, when the Si1−xGex layerexceeds the critical thickness at the corresponding Ge content,dislocations arise because of the lattice constant differences (Si0.5431 nm, Ge0.5658 nm). This formation should be avoidedin the epitaxial growth epitaxial process.

According tothe simulations results, the TCR is approx-imately inversely linear with the logarithmic boron-dopingconcentration under a 30% Ge content and 10 nm well. Thistrend indicates the importance of the boron-doping control inthe processes [9].

JIANG et al.: SELF-DOPING Si1−xGex/Si MULTI-QUANTUM WELL MATERIALS 217

Fig. 9. Resistance-temperature characteristic tests of the Si0.65Ge0.35/SiMQWs in different sizes.

Fig. 10. TCR test results of the different samples listed in Table III.

B. Self-doping Si1−xGex/Si MQW Structures

Fig. 5 shows the SEM photographs of the epitaxialSi0.65Ge0.35/Si MQW material. The material was grown on aSOI wafer because of the further usage during the uncooledFPA fabrication [34]. EachSi0.65Ge0.35/Si is about 40 nm.The Si0.65Ge0.35 layers,with a thickness of 10 nm can beobserved. The flat interface between each layer is crucial inthe performance of the quantum well structures.

The XRD results and SIMS characterizations are illustratedin Fig. 6. The diffraction peak at A is caused by the sub-strate,while the others, the primarily peaks at B–K and thesecondary peaks, such as P1 and P2 between H and G, indicatethe Si1−xGex/Si multilayers. All of these peaks confirmthemono-crystalline structure of the film [35]. The Cycle Dand cycle thickness Mcan be calculated with XRD results asfollow,

D =λ|γH |

θn sin 2θB

M = θn

θmwhere λ is wavelength of incidence X-ray, γH is the

cosine of the angle between the direction of the diffractionwave vector and the normal direction of thecrystalsurface, θB

is the Bragg’s angle of the Si substrate, �θ∞n and �θ∞m

are angular distances among the primarily peaks and thesecondary peaks respectively.

Table II lists the XRD calculation results, which coincidewith the design value and indicate a high quality of depositedMQWs.Cycle D is 4.4 and the cycle thickness is 40.4 nmbased on the calculation.

Fig. 6(b) depicts the concentration profile of the boron andGe atoms in the deposited MQWs, in whichthe peaks presentthe Si1−xGex layers and the contact layers. The curves reflectthe depth distribution uniformity of each dopant.

C. TCR Test Structure

Unlike ordinary thermistor materials such as VOx, thecurrent path goes vertically through the Si1−xGex/Si MQWstack. Fig. 7 shows the micrograph of the TCR test samples,containing four units in different sizes (50 μm × 50 μm,100 μm × 100 μm, 150 μm × 150 μm, 400 μm × 400 μm).Al wires connected the electrodes and the pads ofthe shellsin the package. The chamber was used to vary circumstancetemperature and the signal was transmitted through wirelesstechnologyto the circuit for subsequent data processing.

The I-V curves in Fig. 8 shows the results with an ap-plied voltage ranging from -2.5 V to 2.5 V. The materialexhibitsa slight nonlinearity of resistance asthe momentaryJoule heatingis increased with increasing voltage [36].

The resistance and fitted curves of the Si1−xGex/Si MQWsunder different sample sizes are shown in Fig. 9. The threesets of data correspond to the three samples in different sizesrespectively. The resistance of the p-doped semiconductor isin accordance with (3), whose resistance natural logarithmis welllinear with the temperature reciprocal. The Ef - Ev

is 0.15 eV, as observed from the curve slope of Sample.A1.The deviation of the result from the simulation data is 0.06eV. This deviation could be caused by the imperfect latticequality as the dislocations are ineluctablein the deposition.This difference reflects the importance of the epitaxial latticequality for the Si1−xGex/Si MQW material.

R = R0 · e

(Ef −Ev

k

(1T− 1

T0

))

The TCR can be derived from the resistance. The samplenumbers and the detailed parameters of various samples arelisted in Table III.

The results from Samples 1,3,and 4 indicate that the TCRdecreases when the sample size is400 μm × 400 μm. TheTCR at 20 °C decreases from 2.5%/K to 1.1%/K as the sizeincreased from 100 μm × 100 μm to 400 μm × 400 μm. Thisdecrease might be due to the following reasons. The latticedefects increase as the cross-sectional area increases, leadingto the TCR drop. However, the electrical equipotential surfacepostulate is invalid across the cross-sectional area when thesize of the plane is much larger than in the vertical. Therefore,a sample size of less than 150 μm × 150 μm should be appliedto avoid this effect. The test results from Samples 2 and 4show that the TCR declines by 0.7%/K as the Ge contentdrops from 35% to 30% in the Si1−xGex/Si MQWs. This trendis consistent with the previous theoretical analysis. In this

218 JOURNAL OF MICROELECTROMECHANICAL SYSTEMS, VOL. 23, NO. 1, FEBRUARY 2014

paper, more studies about the annealing effects on the TCRtest structures were conducted The TCR of the Si1−xGex/SiMQW material decreases as the temperature increased. ForSamples 5 and 6, a larger TCR was obtained at highertemperatures. Incomplete contacts, such as barriersbetween ametal and a semiconductor, suggest an inverse TCR trend withthe semiconductor. These characteristics could be potentiallyapplied to other uncooled infrared detection or thermistorapplications in which the operating temperature is high(40 °Cto 50 °C).

Characterizations on the self-doping Si1−xGex/Si MQWsmaterial verify a high TCR value and fine crystal lattice,which promises anotable sensitivity. The material can beused as thermistorin exothermic reactions detection devices,such as thermal biosensors or bolometers. The application ofthe adhesive bonding process makes the sensor fabricationconvenient and cost-effective [21], [37]. The micro-fabricationof potential device would be easily implemented for MEMSprocess compatibility of the material.

IV. Summary and conclusion

This work presents a high TCR material with self-dopingSi1−xGex/Si MQWsfilms. The material has a thin bufferlayer, where aproportion of boron atom diffusionis allowed.The MQW material deposited using the UHVCVD processhas a good morphology, as verified by theSEM, XRD, andSIMS characterizations. The difference between the Fermilevel and the valence band barrier energy is 0.15 eV, witha deviation of 0.06 eV as compared with the simulationresults. This deviation is caused by the dislocationsarise inthe practicalsituation. This work also determined that theSi1−xGex/Si MQW TCR decreases when the size is increased.The TCR of the material is about -2.5%/K at 20 °C, whichis similar with earlier reported results [38]. However, moredetailed work needs to be done to determine the temperature-dependent performance with different buffer layer thicknesses.Self-doping management might be the focus of further work.

Acknowledgment

The authors are grateful to the Pen-Tung Sah Micro-Nano Technology Institute (Xiamen University, China) andTrilobite Microsystems AS (Norway) for the helpful workin experiments and the VRI preproject. The authors alsowould like to acknowledge IHP Microelectronics GmbH (Ger-many), Grünberg Institute for Semiconductor Nanoelectronics(Forschungszentrum Jülich, Germany) and FoU- forprosjekti VRI, “Novel thermal Biosensors based on Quantum wellfor Ultra-sensitive Detection of Pathogen” for the technicalsupport.

References

[1] A. Rogalski, “Infrared detectors: An overview,” Infrared Phys. Technol.,vol. 43, nos. 3–5, pp. 187–210, Jun. 2002.

[2] T. Dong, Z. Yang, Q. Bi, and Y. Zhang, “Freon R141b flow boiling insilicon microchannel heat sinks: Experimental investigation,” Heat MassTransfer, vol. 44, no. 3, pp. 315–324, Jan. 2008.

[3] S. Eminoglu, M. Y. Tanrikulu, and T. Akin, “A low-cost 128 × 128 un-cooled infrared detector array in CMOS process,” J. Microelectromech.Syst., vol. 17, no. 1, pp. 20–30, Feb. 2008.

[4] X. Zhao, T. Dong , Z. Yang, N. Pires, and N. Høivik, “Compatibleimmuno-NASBA LOC device for quantitative detection of waterbornepathogens: Design and validation,” Lab Chip, vol. 12, no. 3, pp. 602–612, 2012.

[5] C. M. Travers, A. Jahanzeb, D. P. Butler, and Z. Celik-Butler, “Fab-rication of semiconducting YBaCuO surface-micromachined bolometerarrays,” J.. Microelectromech. Syst., vol. 6, no. 3, pp. 271–276, 1997.

[6] O. Lazcka, F. Campo, and F. X. Munoz, “Pathogen detection: A per-spective of traditional methods and biosensors,” Biosensors Bioelectron.,vol. 22, no. 7, pp. 1205–1217, Feb. 2007.

[7] N. Tran-Minh, T. Dong, Q. Su, Z. Yang, H. Jakobsen, and F. Karlsen,“Design and optimization of non-clogging counter-flow microconcen-trator for enriching epidermoid cervical carcinoma cells,” Biomed.Microdevices, vol. 13, no. 1, pp. 179–190, Feb. 2011.

[8] T. Dong, Z. Yang, Q. Su, N. M. Tran, E. B. Egeland, F. Karlsen,Y. Zhang, M. J. Kapiris, and H. Jakobsen, “Integratable non-cloggingmicroconcentrator based on counter-flow principle for continuous en-richment of CaSki cells sample,” Microfluid. Nanofluid., vol. 10, no. 4,pp. 855–865, Apr. 2011.

[9] B. Xiao, T. Dong, E. Halvorsen, Z. Yang, Y. Zhang, N. Hoivik, D.Gu, N. M. Tran, and H. Jakobsen, “Integrated micro Pirani gaugebased hermetical package monitoring for uncooled VO (x) bolome-ter FPAs,” Microsyst. Technol., vol. 17, no. 1, pp. 115–125, Jan.2011.

[10] R.T. Rajendra Kumar, B. Karunagaran, D. Mangalaraj, Sa.K. Narayan-dass, P. Manoravi, M. Joseph, and V. Gopal, “Pulsed laser depositedvanadium oxide thin films for uncooled infrared detectors,” Sens. Actu-ators A, Phys., vol. 107, no. 1, pp. 62–67, Oct. 2003.

[11] L. Dong, R. Yue, and L. Liu, “Fabrication and characterization ofintegrated uncooled infrared sensor arrays using a-Si thin-film transistorsas active elements,” J. Microelectromech. Syst., vol. 14, no. 5, pp. 1167–1177, 2005.

[12] J. Gaspar, V. Chu, and J. P. Conde, “Electrostatic microresonators fromdoped hydrogenated amorphous and nanocrystalline silicon thin films,”J. Microelectromech. Syst., vol. 14, no. 5, pp. 1082–1088, Oct. 2005.

[13] T. Schimert, J. Brady, T. Fagan, M. Taylor, W. McCardel, R. Gooch,S. Ajmera, C. Hanson, and A. J. Syllaios, “Amorphous silicon basedlarge format uncooled FPA microbolometer technology,” in Proc. SPIEDefense Security Symp., 2008, pp. 694023–694027.

[14] A. Rogalski, “Recent progress in infrared detector technologies,” In-frared Phys. Technol., vol. 54, no. 3, pp. 136–154, May 2011.

[15] E. Iborra, M. Clement, L.V. Herrero, and J. Sangrador, “IR uncooledbolometers based on amorphous GexSi1−xOy on silicon micromachinedstructures,” J. Microelectromech. Syst., vol. 11, no. 4, pp. 322–329, 2002.

[16] S. Sedky, P. Fiorini, K. Baert, L. Hermans, and R. Mertens, “Characteri-zation and optimization of infrared poly SiGe bolometers,” IEEE Trans.Electron. Devices, vol. 46, no. 4, pp. 675–682, Apr. 1999.

[17] F. Forsberg, N. Roxhed, P. Ericsson, S. Wissmar, F. Niklaus, and G.Stemme, “High-performance quantum-well silicon-germanium bolome-ters using IC-compatible integration for low-cost infrared imagers,”in Proc. Solid State Sensors, Actuators Microsyst. Conf., 2009, pp.2214–2217.

[18] S. Wissmar, H. H. Radamsson, Y. Yamamoto, B. Tillack, C. Vieider, andJ. Y. Andersson, “SiGe quantum wells for uncooled long wavelengthinfra-red radiation (LWIR) sensors,” J. Phys., Conf. Ser., vol. 100, no.4, p. 042029, Mar. 2008.

[19] J. Andersson, “Structures for temperature sensors and infrared detec-tors,” U.S. Patent 6 292 089 B1, Sep. 18, 2001.

[20] Z. C. Yang, E. Halvorsen, and T. Dong, “Power generation fromconductive droplet sliding on electret film,” Appl. Phys. Lett., vol. 100,no. 21, pp. 213905-1–213905-4, May 2012.

[21] L. Zhang and T. Dong, “A Si/SiGe quantum well based biosensorfor direct analysis of exothermic biochemical reaction,” J. Micromech.Microeng., vol. 23, no. 4, pp. 045011–045019, Apr. 2013.

[22] T. Dong and Z. Yang, “Measurement and modeling of R141b condensa-tion heat transfer in silicon rectangular microchannels,” J. Micromech.Microeng., vol. 18, no. 8, pp. 085012–085027, Aug. 2008.

[23] M. Kolahdouz, J. Hallstedt, A. Khatibi, M. Ostling, R. Wise, D.J.Riley, and H. Radamson, “Comprehensive evaluation and study ofpattern dependency behavior in selective epitaxial growth of B-doped SiGe layers,” Nanotechnology, vol. 8, no. 3, pp. 291–297,May 2009.

[24] T. Schimert, J. Brady, T. Fagan, M. Taylor, W. McCardel, R. Gooch, S.Ajmera, C. Hanson, and A. J. Syllaios, “Amorphous silicon based largeformat uncooled FPA microbolometer technology,” in Proc. InfraredTechnol. Applicat. XXXIV , vol. 6940. Orlando, FL, USA, Mar. 2008,pp. 694023-1–694023-7.

JIANG et al.: SELF-DOPING Si1−xGex/Si MULTI-QUANTUM WELL MATERIALS 219

[25] M. Kolahdouz, A. A. Farniya, M. Östling, and H. H. Radamson, “Theperformance improvement evaluation for SiGe-based IR detectors,” SolidState Electron., vol. 62, no. 1, pp. 72–76, Aug. 2011.

[26] J. Thomas, “UHV/CVD growth of Si and Si:Ge alloys: Chemistry,physics, and device applications,” Proc. IEEE, vol. 80, no. 10, pp. 1592–1608, Oct. 1992.

[27] S. Franssila, Introduction to Microfabrication. West Sussex, U.K.: Wiley,2004.

[28] K. R. Williams and R. S. Muller, “Etch rates for micromachiningprocessing,” J. Microelectromech. Syst., vol. 5, no. 4, pp. 256–269, Dec.1996.

[29] W. Stanley and H. Linda, “High signal to noise ratio quantum wellbolometer materials,” in Proc. Optical Mater. Defence Syst. Technol.III, Sep. 2006, p. 6401.

[30] C. G. Van de Walle and R. M. Martin, “Theoretical calculations ofheterojunction discontinuities in the Si/Ge system,” Phys. Rev. B, vol.34, no. 8, pp. 5621–5634, Oct. 1986.

[31] Y.-H. Kuo, Y. K. Lee, Y. Ge, S. Ren, J. E. Roth, T. I. Kamins,D. A. B. Miller, and J. S. Harris, “Quantum-confined stark effect inGe/SiGe quantum wells on Si for optical modulators,” IEEE J. QuantumElectron., vol. 12, no. 6, pp. 1503–1513, Nov.–Dec. 2006.

[32] B. A. Foreman, “Effective-mass Hamiltonian and boundary conditionsfor the valence bands of semiconductor microstructures,” Phys. Rev. B,vol. 48, no. 7, pp. 4964–4967, Aug. 1993.

[33] S. G. E. Wissmar, H. H. Radamsson, Y. Yamamoto, B. Tillack, C.Vieider, and J.Y. Andersson, “SiGe quantum well thermistor materials,”Thin Solid Films, vol. 517, no. 1, pp. 337–339, Nov. 2008.

[34] F. Niklaus, E. Kalvesten, and G. Stemme, “A new concept for CMOS-compatible fabrication of uncooled infrared focal plane arrays usingwafer-scale device transfer bonding,” in Proc. Infrared Technol. Applicat.XXVII , Apr. 2001, vol. 4369, pp. 397–404.

[35] S. R. Sheng, M. Dion, S.P. McAlister, and N.L. Rowell, “Growth andcharacterization of Si/SiGe strained-layer superlattices on bulk single-crystal SiGe and Si substrates,” J. Crystal Growth, vol. 253, nos. 1–4,pp. 77–84, Jun. 2003.

[36] J. Y. Andersson, P. Ericsson, H.H. Radamson, S.G.E. Wissmar, and M.Kolahdouz, “SiGe/Si quantum structures as a thermistor material for lowcost IR microbolometer focal plane arrays,” Solid State Electron., vol.60, no. 1, pp. 100–104, Jun. 2011.

[37] F. Niklaus, A. Decharat, F. Forsberg, N. Roxhed, M. Lapisa, M. Populin,F. Zimmer, J. Lemm, and G. Stemme, “Wafer bonding with nano-imprintresists as sacrificial adhesive for fabrication of silicon-on-integrated-circuit (SOIC) wafers in 3-D integration of MEMS and ICs,” Sens.Actuators A, Phys., vol. 154, no. 1, pp. 180–186, Aug. 2009.

[38] P. Ericsson, A. C. Fischer, F. Forsberg, N. Roxhed, B. Samel, S. Savage,G. Stemme, S. Wissmar, O. Öberg, and F. Niklaus, “Towards 17 μmpitch heterogeneously integrated Si/SiGe quantum well bolometer focalplane arrays,” in Proc. SPIE, 2011, pp. 801216–801221.

Bo Jiang was born in Jiangsu, China, in 1988.He received the bachelor’s degree in mechanicalengineering from the Nanjing University of Scienceand Technology, Nanjing, China, in 2010, wherehe is currently pursuing the Ph.D. degree in theDepartment of Mechanical Engineering. His currentresearch interests include multiquantum wells calcu-lation, mechanical analysis, and MEMS processes.

Tao Dong (M’10) received the Ph.D. degree inmechanical engineering from Nanjing University ofScience and Technology, China, in 2003 and ob-tained the Post-Doctoral Diploma from the sameuniversity in 2005.

He is currently an Associate Professor and aPrimary Supervisor for Ph.D. candidates in the De-partment of Micro and Nano Systems Technology,Norwegian Center of Expertise on Micro and Nan-otechnology, Faculty of Technology and MaritimeStudy, Vestfold University College, Tonsberg, Nor-

way. He is also the Chair Professor at the Nanjing University of Science andTechnology, Nanjing, China, and a Guest Professor with Xiamen University,China. He has 57 academic publications as the first author or correspondingauthor, and 11 patent applications. His current research interests include heatand mass transfer in micro and nano scales, microfluidics and nanofluidics,lab-on-chip devices, and energy conversion in microsystems.

Yan Su was born in Su Zhou, China, in 1967.He received the Ph.D. degree in instrument scienceand technology from Southeast University, Nanjing,China, in 2001.

Since 2005, he has been a Professor with the Me-chanical Engineering Department, Nanjing Univer-sity of Science and Technology, Nanjing, China. Hehas published over 30 articles and holds 15 patents.His current research interests include MEMS devicesand systems.

Yong He received the M.S. degree in mechanicalengineering from the East China Institute of Tech-nology, Shanghai, China, in 1986, and the Ph.D.degree in mechanical engineering from the Nan-jing University of Science and Technology, Nanjing,China, in 1998.

From 1999 to 2008, he was an Assistant Professorwith the School of Mechanical Engineering, NanjingUniversity of Science and Technology, where he hasbeen a Professor since 2008. He is the author ofthree books and over 50 articles. His current research

interests include microfabrication, target detection, and reliability controltechnology.

Kaiying Wang received the M.S. degree in inorganicchemistry from Northwest University, Shaanxi,China, in 1992, and the Ph.D. degree in condensedmatter physics from the Institute of Physics, ChineseAcademy of Sciences, Beijing, China, in 1995.

He was a Post-Doctoral Researcher at the Univer-sity of New Orleans, LA, USA, and was involvedwith Canadian companies as a Scientist for nineyears. He joined the Vestfold University College,Tonsberg, Norway, in 2007 as an Associate Professorand was promoted to Professor in 2010. His current

research interests include microfabrication and nanotechnology, functionalthin films, magnetic and superconductive materials, nanostructure characteri-zation, and nanodevices for environment and energy applications.