EOS Instructional

-

Upload

benjamin-kuriscak -

Category

Documents

-

view

225 -

download

0

description

Transcript of EOS Instructional

For further information visit www.essentialsofsafety.comw w w . m a n c o m m . c o m

2

The Essentials of Safety Training Management System for General Industry or Construction is for anyone teaching the topics included in OSHA 10- and 30-hour training. This comprehensive training system provides safety personnel, professors and their students, trainers, supervisors, and more with an entire curriculum’s worth of material. The Essentials of Safety is so complete, instructors can begin the class within minutes of receiving their package in the mail. Here’s how:

Essentials of Safety Instructor Package includes:� Essentials of Safety Manual: Loose-leaf in three ring binder with tabs� Essentials of Safety: Instructor Notes� Essentials of Safety: Student Workbook� Essentials of Safety: Power Point Presentation on CD-ROM� 5 Completion Certificates and Certificate Holders� Introduction to OSHA� Essentials of Safety: Journal and Pen/Highlighter

With regSMART™ we create a simple approach to safety by rewriting and organizing the regulations into the following categories:

Scope: Application.

Management Controls: Engineering controls, safe administrative controls, and PPE.

Alerts: Postings, signs, tags, markings, and labels.

Records: Written programs, training records, medical records, and inspection records.

Training: Employee training requirements.

Over 1,100Presentation Slides!

Place the instructor materials in the three-ring binder. Also included are tabbed pages designating Volumes I and II. Install the Volume I tab at the beginning of the material. Then turn past Volume I’s index, and place the tab for Volume II. The instructor notes include page numbers associated with the instructor material, showing you just where to insert them. Instructor notes contain additional training tips and points of emphasis, quizzes with answers, references to the PowerPoint slides and student workbooks, and blank pages for your own notes.

Once the instructor materials are assembled, you may hand out the student workbooks, and begin the course. The PowerPoint presentations come in a two-disc set, one for each volume. Snapshots of the slides are located throughout the instructor materials so you can follow along and control the pace of the course. At the end of the course, issue your students completion certificates in sturdy certificate holders to preserve the integrity of their achievement.

ESSENTIALS OF SAFETY � INSTRUCTOR PACKAGE

(EOS: Construction)

Call 1-800-MANCOMM (626-2666) or order online at www.mancomm.com

3

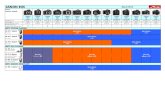

ESSENTIALS OF SAFETY � INSTRUCTOR PACKAGE ESSENTIALS OF SAFETY � CONSTRUCTION � GENERAL INDUSTRY

ESSENTIALS OF SAFETY CONSTRUCTION

ESSENTIALS OF SAFETY GENERAL INDUSTRY

EOS ConstructionInstructor Package

EOS General IndustryInstructor Package

Essentials of SafetyJournal & Pen/Highlighter

5 EOS Completion Certificates & Certificate holders:

EOS Construction10-Hour Student Package:

EOS General Industry10-Hour Student Package:

EOS Construction30-Hour Student Package:

EOS General Industry30-Hour Student Package:

1926 OSHA Construction Industry Regulations:

1910 OSHA General Industry Regulations:

36T-304

36T-104

36T-104 36T-104

36T-101-09

36T-124

36T-101-10

36T-114

1926 Book: 33B-0011926 Book/CD: 33K-001

1926 CD: 33C-001

1910 Book: 31B-0011910 Book/CD: 31K-001

1910 CD: 31C-001

ADDITIONAL MATERIALS:How to Order To order the Essentials of Safety Training Management System for General Industry or Construction call 1-800-MANCOMM (626-2666), or order online at www.mancomm.com. For further information visit www.essentialsofsafety.com.

For further information visit www.essentialsofsafety.com

Spiral BindingAvailable!

Spiral BindingAvailable!

4 Call 1-800-MANCOMM (626-2666) or order online at www.mancomm.com

Intro to OSHA – meets the “Intro to OSHA” requirement of OSHA 30-hour training as it presents an overview of OSHA’s history and purpose while discussing employee rights, training, employer responsibilities, inspection procedures, citations and penalties.RegLogic® – techniques and tips for finding and using OSHA regulations utilizing Mancomm’s user-friendly approach to formatting – RegLogic®.Walking and Working Surfaces – includes general requirements for housekeeping. In addition, it offers information concerning the use of guard rails, fixed industrial stairs, and ladders.Exit Routes, Emergency Action, and Fire Prevention Plans – breaks down OSHA standards regarding exit routes, as well as procedural and training requirements for emergency action and fire prevention plans.Fire Protection –discusses fire protection including classes of fires and fire extinguishers. Also covered are general, training, and inspection regulations for portable fire extinguishers.Electrical Cords – contains regulatory information on damaged cords, as well as the use of flexible cords, extension cords, and power strips in the workplace. An in-depth treatment of electrical standards follows later in Volume I.Recordkeeping and Occupational Injuries/Illnesses Reporting – shows you exactly when and how to fill out the OSHA 300 Log, as well as Forms 300A and 301.Access to Employee Exposure and Medical Records – describes medical and exposure records, and the purpose of maintaining and preserving records including safety data sheets. Employee access and transfer of records are also discussed.Bloodborne Pathogens – defines and identifies bloodborne pathogens and covers engineering and work practice controls including personal protective equipment, housekeeping, and exposure control plans. Regulatory information on communicating hazards including training, signage, and using the sharps injury log is also provided.Hazard Communication – offers the basics of “Employee Right to Know” by defining “hazardous chemical,” discussing the scope of the HazCom standard, and examining the implementation of a written program including training, labeling, and safety data sheets. An in-depth look at the Hazard Communication standard follows in Volume II.Inspections, Citations, and Penalties – lists reasons for inspections as well as classes of violations and their respective penalties. Preparing for an OSHA inspection as well as details of the inspection process including employer rights are also discussed.Noise Exposure – stresses the importance of hearing conservation with a thorough consideration of hearing conservation programs including monitoring, audiometric testing, hearing protection, training, and recordkeeping.

Personal Protective Equipment (PPE) – looks at the responsibilities of employers to provide PPE and perform hazard assessment in the workplace. Respiratory protection programs are also considered, including selection, care, and use of respirators, medical status evaluation, fit tests, training, and recordkeeping. Eye, face, head, foot, and hand protection are discussed as well. Information on electrical PPE is provided in Volume II.Permit-Required Confined Spaces – contains definitions for “confined spaces” and “permit-required confined spaces,” as well as requirements for a permit-required confined space program including training, rescue, and emergency services.Control of Hazardous Energy (Lockout/Tagout) – requirements and procedures for electrical lockout/tagout programs including devices, labels, inspections, and training. Lockout/tagout is addressed in more detail in Volume II.Materials Handling and Storage – offers requirements for clearances for mechanical handling equipment, secure storage, and housekeeping. Also included are safety and maintenance requirements for powered industrial trucks, procedures and standards for fueling and recharging, and regulations concerning forklift safety and operator training.Machine Guarding –general requirements for all machines and methods of safeguarding including presence sensing, electromechanical, and mechanical. Standards for abrasive wheel machinery, mechanical power processes, and power transmission apparatus machinery are also discussed.Electrical Requirements – brief discussion of how electricity works and general electrical requirements, as well as a detailed exploration of standards regarding wiring design and protection; wiring methods, components and equipment; GFCI outlets; health care facilities; hazardous (classified) locations; special systems; and safety-related work practices.Hazardous Waste Operations and Emergency Response (HAZWOPER) – requirements for HAZWOPER including discussions on written emergency response plans, the five levels of emergency responders, documentation, and refresher training.

ESSENTIALS OF SAFETY � GENERAL INDUSTRY � TRAINING & REFERENCE GUIDES

EOS: General Industry Student Workbook:The EOS General Industry Student Workbook includes:

� 29 CFR 1910 Workshops� Labeling Workshops� Sample Forms� Quizes

The following topics are covered in Mancomm’s EOS: General Industry Training and Reference Guide Volume I:

Essentials of Safety: 10-Hour General IndustryOSHA’s 10-Hour Training is intended to provide a variety of training to workers with some safety responsibility in addition to emphasizing hazard identification, avoidance, control and prevention. Mancomm’s Essentials of Safety: General Industry Training Management System Volume I includes all elective topics in addition to the required topics, as well as providing the essential framework of safety awareness, response, and prevention to future safety professionals.

5For further information visit www.essentialsofsafety.com

CFR Workshop – an exercise for trainees covering requirements discussed in Volume I.Safety and Health Program – offers guidelines, standards, and elements of an effective safety and health program including management commitment and employee involvement, worksite analysis, hazard prevention and control, and safety and health training.Emergency Action Plan – begins with workplace disaster statistics moves to the requirements of an effective emergency action plan including training, and concludes with a trainee workshop using specific regulations to design a sample emergency action plan.Sanitation – defines “potable” and “non-potable” water, as well as “wet process.” Also included are requirements for housekeeping, waste disposal, eating and drinking, and restrooms.Signs/Tags – discusses standards for safety color codes, sign classification, and sign design. Accident prevention tags are also covered.Permit-Required Confined Spaces – presents requirements concerning alternate procedures for a permit-required space, reclassifying a permit space, and permit-required confined space written programs. Also included are sample permits, a sample checklist, and fatality statistics and case-studies.Lockout/Tagout – shows how to design a written lockout/tagout program with a sample checklist, lockout/tagout workshop for trainees, and a sample written plan.Welding/Cutting/Brazing – standards concerning welding area designation, precautions for “hot work,” first aid, personnel protection including PPE and ventilation, and safe use of welding and arc welding equipment including training and maintenance.Hand and Portable Power Tools – safety requirements pertaining to the use and maintenance of compressed air, power tools, portable abrasive wheels, explosive actuated fastening tools, power lawn mowers, and jacks.Electrical Personal Protective Equipment – information and requirements regarding electrical hazards, electrical protective devices, and electrocution. Also provided are standards for in-service care and use of electrical protective equipment including PPE, inspections, maintenance, testing, and equipment certification.

DOT Placarding – standards concerning the treatment of DOT markings, placards, and labels.Hazard Communications – describes the employee’s “Right to Know.” A step-by-step for designing a HazCom program is also offered, including regulations regarding identifying responsible personnel, developing a hazardous chemicals list, safety data sheets, labeling, training, and documentation.Industrial Hygiene – explains the important roles industrial hygienists play in developing and issuing OSHA standards. Also provided are directions for worksite analysis of potential hazards including air contaminants as well as chemical, biological, and ergonomic hazards.Open Forum – supplies safety-related topics and questions for classroom discussion.Hazardous Materials – defines “flashpoint,” combustible liquids,” and “flammable liquids.” Regulations on container storage in storage cabinets, warehouses, and inside and outside the workplace, including training, labeling, security, and fire protection are also discussed. Requirements pertaining to process safety management, dip tanks, personal hygiene, and laboratory use of hazardous chemicals, including chemical hygiene plans, training, and respirators are provided as well.Recordkeeping – a trainee workshop using the “8 Steps to Recordkeeping” to complete an OSHA 301 Form and OSHA 300 Logs.Ergonomics – discusses the requirements of OSHA’s General Duty Clause and Ergonomic Voluntary Guidelines. Also addressed are musculoskeletal disorders, as well as benefits of and suggestions for implementing office ergonomics.Medical Services and First-Aid – offers standards related to medical personnel, first-aid treatment, and emergency eyewash and showers.Forklift Workshop – a workshop requiring trainees to use safety regulations to remedy dangerous forklift-related situations presented in case studies.

ESSENTIALS OF SAFETY � GENERAL INDUSTRY � TRAINING & REFERENCE GUIDES

Cover Volume I in General Industryand issue 10-hour OSHA cards.‡

� Essentials of Safety: Manual Volume I - 209 Pages � Essentials of Safety: Student Workbook � Introduction to OSHA (8 1/2" x 11")

Cover Volume I and Volume II within 6 months and issue 30-hour OSHA cards.‡

� Essentials of Safety: Manual Volume I - 209 Pages � Essentials of Safety: Manual Volume II - 146 Pages � Essentials of Safety: Student Workbook � Introduction to OSHA (8 1/2" x 11")

‡OSHA Cards are approved through OSHA. Call for details.*Student Materials are only available upon purchase of the Instructor Package.

EOS General Industry Student Package:*

The following topics are covered in Mancomm’s EOS: General Industry Training and Reference Guide Volume II:

Essentials of Safety: 30-Hour General IndustryOSHA’s 30-Hour Training is intended to provide a variety of training to workers with some safety responsibility in addition to emphasizing hazard identification, avoidance, control and prevention. Mancomm’s Essentials of Safety: General Industry Training Management System includes all elective topics in addition to the required topics, as well as providing the essential framework of safety awareness, response, and prevention to future safety professionals.

6 Call 1-800-MANCOMM (626-2666) or order online at www.mancomm.com

Intro to OSHA – meets the “Intro to OSHA” requirement of OSHA 10-hour training as it presents an overview of OSHA’s history and purpose while discussing employee rights, training, employer responsibilities, inspection procedures, citations and penalties.RegLogic® – techniques and tips for finding and using OSHA regulations utilizing Mancomm’s user-friendly approach to formatting – RegLogic®.General Safety and Health Provisions – requirements concerning contractors, training, and housekeeping. Also provides standards for egress, emergency action plans, medical services and first-aid, and sanitation pertaining to drinking water, toilets on jobsites, washing facilities, eating and drinking areas, lavatories, and vermin control.Fall Protection – fulfills the OSHA Focus Four training requirement for fall protection as it discusses regulations for training, fall protection systems, fall protection hazards, and hazards of scaffolds. A trainee workshop on identifying fall hazards is also included.Electrocution Hazards – satisfies the OSHA Focus Four training requirement for electrocution hazards as it defines “electrical hazards,” provides examples and statistics, identifies the major types of electrocution hazards and how to prevent them, and discusses employer requirements. Also included is a hazard recognition workshop for trainees.Caught-in or –Between Hazards – complies with the OSHA Focus Four training requirement for caught-in or -between hazards by defining caught-in or -between hazards with examples and statistics, identifying common caught-in or -between hazards, and provides employer requirements. A hazard recognition workshop for trainees is also offered.Struck-by Hazards – meets the OSHA Focus Four training requirement for struck-by hazards while defining the types of struck-by hazards with examples and statistics, identifying protective measures against struck-by hazards, presenting employer requirements. Also provided is a hazard recognition workshop for trainees.Personal Protective Equipment (PPE) – looks at the responsibilities of employers to provide PPE and perform hazard assessment in the workplace. Respiratory protection programs are also considered including selection, care, and use of respirators, medical status evaluation, fit tests, training, and recordkeeping. Eye, face, head, foot, and hand protection are discussed as well.Health Hazards in Construction – offers OSHA standards pertaining to heat stress, silicosis, asbestos, cadmium, and lead including permissible exposure limits, training, PPE, and engineering controls where applicable.HazCom 1 – offers the basics of “Employee Right to Know” by defining “hazardous chemical,” discussing the scope of the HazCom standard, and examining the implementation of a written program including training, labeling, and safety data sheets. An in-depth look at the Hazard Communication standard follows in Volume II.Cranes and Derricks – describes the types and components of cranes. Also included are requirements for operation including inspections, training, maintenance, safe practices, hand signals, and hazards.

Excavations – defines “excavation” and “trench,” while exploring regulatory information on site evaluation and planning including inspections and soil classification. Also discussed are requirements concerning excavation hazards and protection covering shoring, loping, hazardous atmospheres, struck-by hazards, and underground utilities.Materials Handling and Storage – requirements for storing, stacking, and disposing of materials. Standards for manually moving materials, earthmoving equipment and lifting and hauling equipment are provided as well.Scaffolds – begins by identifying types of scaffolds and moves on discuss standards regarding scaffold hazards including falling, electrocution, and struck-by hazards. Training requirements and case studies are also presented.Stairways and Ladders – provides training requirements for ladders and stairways including information on points of access, handrails, temporary service stairways, platforms and swing doors, hazards, types and use of ladders, damaged ladders, cross bracing, and case studies.Tools – maintenance, inspection, safety, and use requirements for hand tools and power-operated hand tools including pneumatic, fuel-powered, and powder-actuated tools. Also discussed are standards for abrasive wheel machinery, mechanical power-transmission apparatus, and jacks.Concrete and Masonry Construction – general requirements for construction loads, reinforcing steel, pot-tensioning operations, concrete buckets, working under loads, and PPE. Also included are standards for formwork, shoring, vertical slip forms, reinforcing steel, precast concrete, lift-slab operations, and masonry construction.Confined Space Entry – defines “confined space” and “permit-required confined space” and identifies types of confined spaces. Requirements for contractors, employee training, rescue and emergency services, and written programs are presented as well. Additional information includes a sample confined space entry permit and case studies.Fire Protection and Prevention – provides standards for fire extinguishers as well as other firefighting equipment, and presents the classes of fires and extinguishers. Requirements for fire prevention and temporary heating devices are also covered.

ESSENTIALS OF SAFETY � CONSTRUCTION � TRAINING & REFERENCE GUIDES

EOS: ConstructionStudent Workbook:The EOS Construction Student Workbook includes:

� Workshops & Checklists� SDS Example� Sample Forms� Quizzes

The following topics are covered in Mancomm’s EOS: Construction Training and Reference Guide Volume I:

Essentials of Safety: 10-Hour ConstructionOSHA’s 10-Hour Training is intended to provide entry level construction workers with information about their rights, employer responsibilities, and how to file a complaint, as well as how to identify, abate, avoid and prevent job related hazards. Mancomm’s Essentials of Safety: 10-Hour Construction Student Package Manual Volume 1 goes above and beyond OSHA’s training requirements by including all elective topics in addition to the required topics.

7For further information visit www.essentialsofsafety.com

Steel Erection – provides the definition of “controlling contractor,” and offers regulatory information regarding site layout, hoisting and rigging, structural steel assembly, column anchorage, beams and columns, open web steel joists, systems-engineered metal buildings, falling object protection, fall protection, and employee training.Welding and Cutting – requirements for gas welding and cutting including transportation, placement, safe usage, fuel gas and oxygen manifolds, hoses, and torches. Arc welding standards concerning training, operation, and maintenance, as well as regulations on preservative coatings, ventilation, and PPE are also discussed.Motor Vehicles – light/reflector requirements for equipment, and safety and inspection standards for motor vehicles on the worksite. Information regarding temporary traffic control (TTC), including zone designations and worker safety considerations is provided as well. Also discussed are standards for flaggers including qualifications and safety apparel.Powered Industrial Trucks – includes safety and maintenance requirements for powered industrial trucks. Also presented are safety standards for fueling and recharging operations, trucks and railroad cars, operator training, and forklift operation, as well as case studies examining incident prevention.DOT Placarding – standards concerning the treatment of DOT markings, placards, and labels.Electrical – brief discussion of how electricity works and general electrical requirements, as well as a detailed exploration of standards regarding wiring design and protection; wiring methods, components and equipment; GFCI outlets; and safety-related work practices. Also included are safety recommendations for arc flashes and regulatory information on damaged cords, as well as the use of flexible cords, extension cords, and power strips in the workplace.Lockout/Tagout – definition and scope of “lockout/tagout,” as well as general requirements including lock and tag application and training. Special requirements involving contractors and shift or personnel changes are also presented.Signs/Tags – discusses standards for safety color codes, sign classification, and sign design. Accident prevention tags are also covered.Hazard Communications – describes the employee’s “Right to Know.” A step-by-step for designing a HazCom program is also offered including regulations regarding identifying responsible personnel, developing a hazardous chemicals list, safety data sheets, labeling, training, and documentation is also offered.

Hazardous Waste Operations and Emergency Response (HAZWOPER) – requirements for HAZWOPER including discussions on written emergency response plans, the five levels of emergency responders, documentation, and refresher training. Ergonomics – discusses the requirements of OSHA’s General Duty Clause and Ergonomic Voluntary Guidelines. Also addressed are musculoskeletal disorders, as well as benefits of and suggestions for implementing worksite ergonomics.Safety and Health Program – offers guidelines, standards, and elements of an effective safety and health program, including management commitment and employee involvement, worksite analysis, hazard prevention and control, and safety and health training.Assessing Safety and Health Programs – shows how to use documentation, employee reviews, and site conditions to analyze safety and health programs. Also included is a sample program assessment questionnaire for trainee reference.Industrial Hygiene – explains the important roles industrial hygienists play in developing and issuing OSHA standards. Also provided are directions for worksite analysis of potential hazards, including air contaminants as well as chemical, biological, and ergonomic hazards.Recordkeeping – a trainee workshop using the “8 Steps to Recordkeeping” to complete OSHA Forms 300A and 301, as well as the OSHA 300 Log.Medical Records – describes medical and exposure records, and the purpose of maintaining and preserving records including safety data sheets. Employee access and transfer of records are also discussed.Inspections, Citations, and Penalties – lists reasons for inspections as well as classes of violations and their respective penalties. Preparing for an OSHA inspection as well as details of the inspection process including employer rights and the appeal process are also discussed.Bloodborne Pathogens – defines and identifies bloodborne pathogens and covers engineering and work practice controls including personal protective equipment, housekeeping, and exposure control plans. Regulatory information on communicating hazards including training, signage, and using the sharps injury log is also provided.Open Forum – supplies safety-related topics and questions for classroom discussion

ESSENTIALS OF SAFETY � CONSTRUCTION � TRAINING & REFERENCE GUIDES ESSENTIALS OF SAFETY � CONSTRUCTION � TRAINING & REFERENCE GUIDES

Cover Volume I and issue 10-hour OSHA cards.‡

� Essentials of Safety: Manual Volume I - 210 Pages � Essentials of Safety: Student Workbook � Introduction to OSHA (8 1/2" x 11")

Cover Volume I and Volume II within 6 months and issue 30-hour OSHA cards.‡

� Essentials of Safety: Manual Volume I - 210 Pages � Essentials of Safety: Manual Volume II - 150 Pages � Essentials of Safety: Student Workbook � Introduction to OSHA (8 1/2" x 11")

‡OSHA Cards are approved through OSHA. Call for details.*Student Materials are only available upon purchase of the Instructor Package.

EOS Construction Student Package:*

The following topics are covered in Mancomm’s EOS: Construction Training and Reference Guide Volume II:

Essentials of Safety: 30-Hour ConstructionOSHA’s 30-Hour Training is intended to provide a variety of training to workers with some safety responsibility in addition to emphasizing hazard identification, avoidance, control and prevention. Mancomm’s Essentials of Safety: 30-Hour Student Package Volumes I & II includes all elective topics in addition to the required topics, as well as providing the essential framework of safety awareness, response, and prevention to future safety professionals.

8 Call 1-800-MANCOMM (626-2666) or order online at www.mancomm.com

FORKLIFT TRAINING � BOOKS � CD-ROMS � VIDEO � ESSENTIALS OF SAFETY

ESSENTIALS OF SAFETY FORKLIFT

After trainers have completed their training with Mancomm’s EOS Train-The-Forklift-Trainer program, they can instruct employees to be forklift operators with our Forklift Operator Training System.

OSHA requires forklift training to encompass the hazards and equipment the operator will encounter in the workplace to eliminate employee injuries and property damage. Mancomm’s onsite Forklift Training System (FTS) is designed to be customized for individual worksites. The FTS includes real-world examples, practice drills, review questions, and the following:

Module 1 – Introduction to OSHAModule 2 – Forklift ScopeModule 3 – Forklift Management ControlsModule 4 – Forklift AlertsModule 5 – Forklift RecordsModule 6 – Forklift Training

� Training DVD that covers training and basic principles, operation, loading and pre-operation inspection and refueling/recharging – English or Spanish.

� On-site Trainer's Manual – 48 pages including full color pictures, answer keys, forms, tips, and mirrors the On-site Operator Trainee Learning Guide.

� 10 On-site Operator Trainee Learning Guides - 32 pages including full color pictures and review questions for each chapter. Also included are a Completion Card and Operator Wallet Card - English or Spanish.

Essentials of Safety ForkliftMancomm’s EOS Train-The-Forklift-Trainer program has everything you need to train your own forklift trainers. This course prepares trainers to do OSHA required On-site Forklift Training in General Industry or Construction. See Forklift Operator Training System below.

EOS Forklift Program Includes:

� EOS - Manual loose-leaf in three-ring binder with tabs� EOS - Instructor Notes� EOS - Student Workbook� EOS - Power Point Presentation on CD-ROM� Sample Completion Certificate and Certificate Holder� 5 Additional Certificates� Mancomm Note Pad and Pen/Highlighter

Instructor Book: 116 pages. 224 Slides.Student Workbook: 78 pages

60T-003

60T-011

EOS Forklift Student Package: Future on-site trainers may train General Industry or Construction forklift operators:

� EOS - Manual: Forklift� EOS - Student Workbook: Forklift

Forklift Operator Training System – General Industry or Construction Operator Training

Instructor

On-site TrainerOperator

General Industry: 31V-303Construction: 33V-323

English or Spanish