ENZYME ACTIVITY AND QUALITY OF FROZEN GREEN BEANS AS AFFECTED BY BLANCHING AND STORAGE

Transcript of ENZYME ACTIVITY AND QUALITY OF FROZEN GREEN BEANS AS AFFECTED BY BLANCHING AND STORAGE

ENZYME ACTIVITY AND QUALITY OF FROZEN GREEN BEANS AS AFFECTED BY BLANCHING AND STORAGE

C.Y. LEE and N.L. SMITH

Department of Food Science and Technology New York State Agriculture Experiment Station Cornell University, Geneva, New York 14456

and

D.E. HAWBECKER

Comstock Foods Rochester, New York 14602

Accepted for Publication May 25, 1988

ABSTRACT

Effects of different blanching conditions on residual enzyme activities and quality changes in green beans during frozen storage were studied. Green beans were blanched at various temperature and time combinations at both pilot plant and commercial scales. Afrer storage at -23 "C for 3, 6, 9 and 12 months they were analyzed for residual activities of catalase, lipoxygenase, polyphenolox- idase and peroxidase; changes in sensory quality as evaluated by a taste panel; and color and firmness as measured with instruments. Most of enzymes were in- activated during normal blanching but the residual activities varied among en- zymes. Beans blanched above 82 "C for 3.5 min yielded higher sensory scores for the quality attributes tested than those blanched at the lower temperatures. However, there appears to be no direct relationship between the quality at- tributes measured and the residual enzyme activities during 12 months storage.

INTRODUCTION

Blanching is an important process for maintaining the quality of frozen vegetables during storage. Underblanched frozen vegetables lose color and flavor due to enzymes when tissue cells are injured during processing and storage. Of the enzymes naturally occurring in vegetables, peroxidase has been found to be a useful indicator of deterioration of frozen, stored vegetables. Because it is one the most heat stable enzymes in plants (Joslyn 1949; Reed 1966), conventional blanching treatments have been designed on the basis of its destruction.

Journal of Food Quality I 1 (1988) 279-287. All Rights Reserved. @Copyright 1988 by Food & Nutrition Press, Inc., Trumbull. Connecticut. 279

2 80 C.Y. LEE, N.L. SMITH AND D.E. HAWBECKER

Though peroxidase has served well as an indicator, the use of this enzyme has been questioned because heat resistant peroxidase isoenzymes are also present in most frozen vegetables; furthermore, peroxidase has not been shown to be directly responsible for quality deterioration during frozen storage (Bottcher 1975; Winter 1969). Therefore, blanching to inactivate peroxidase may lead to an unnecessarily severe heating, consequently impairing the quality of the frozen product and also wasting energy.

At present, the commercial blanching operation for frozen green beans is car- ried out at 98-100°C for 3.5 min based on the residual peroxidase activity after blanch. In the present investigation, attempts have been made to determine whether the conventional blanching conditions for green beans are proper or un- necessarily severe by analyzing the effect of various blanching conditions on en- zymes and by monitoring quality changes during 12 months of storage.

MATERIALS AND METHODS

Pilot Experiment

Fresh green beans were obtained from Comstock Foods, Rochester, New York during the 1985 processing seasons. Beans (cv. BBL47) were immediately transferred after harvest to our experiment station pilot plant and processed on the same day. The beans were snipped, cut, graded, and blanched in an automatic rotary hot water blancher in batches of 25 Kg. The following blan- ching treatments were included:

1 . 60°C (140") for 5.5 min 2. 74°C (165") for 4.5 min 3. 82°C (180") for 3.5 min 4. 99°C (210") for 3.5 min (commercial control) and 5. 99°C (210") for 2.0 min

The blanched beans were cooled quickly in an ice water for 5 min, spread on trays, and then frozen overnight at -40 "C (-40 OF). The frozen beans were then transferred into 5-gallon plastic containers within two layers of plastic bags and stored at -23 "C ( - 10" F). Enzymes and quality analyses were performed after 3, 6 , 9 and 12 months of storage.

Commercial Experiment

Green beans (cv. Blue Lake 47) were processed at a Comstock Foods Plant, Bergen, NY during the 1986 processing season. Lots of lo00 Kg were snipped, washed, cut, and graded according to commercial practices and then blanched.

FROZEN GREEN BEANS 28 I

The following treatments were included:

1. 82°C (180") for 3.5 min 2. 88°C (190") for 3.5 min 3. 99°C (210") for 3.5 min

The blanched beans were cooled in cold water, then transferred to a blast freezer (-20°F) on a conveyor. The exposure time in the blast freezer was 10 min. The frozen beans were stored in a 1-ton bin covered with plastic at -23 "C (- 10 OF) and then analyzed at intervals described in Pilot Experiment,

Extraction of Enzymes

Frozen green beans (100 g) were ground with 200 mL cold McIlvaine's buffer solution at pH 7.0 in a prechilled Waring Blender for 3 min, then further macerated 2 min using a Polytron homogenizer with the blender jar placed in an ice bath. An additional 50 mL of chilled buffer was used to rinse the homogenizer and blender jar. The homogenate was filtered through %layers of cheesecloth using a potato ricer, Tween-20 (0.25% v/v) was added to the filtrate which then was incubated for 1 h with stirring at 4 "C. The filtrate was then cen- trifuged at 13,000 x g for 20 min in a Sorvall refrigerated centrifuge. The supernatant was filtered through glasswool and then subjected to enzyme activity measurements using a Varian Cary Model 2 19 spectrophotometer. Extraction was made in duplicate for each sample.

Analysis of Enzymes

Four enzymes which may be associated with the quality of green beans were analyzed. Catalase activity was measured as the decrease in absorbance at 240 nm with HzOz with the catalytic content of each sample being measured at 30s intervals (Aebi 1983). Lipoxygenase activity was measured at 234 nm with linoleic acid solubilized in Tween 20 as the substrate according to the method of Surrey (1964). One unit of lipoxygenase activity was defined as the amount of enzyme in one gram of beans that produced a change in absorbance of 0.01 per min. Peroxidase activity was measured at 470 nm using guaiacol and H202 as substrates (Flurkey and Jen 1978). One unit of enzyme activity was expressed as the amount of enzyme in one gram of beans that changed absorbance of 0.1 per min. Polyphenoloxidase activity was measured at 420 nm with catechol as the substrate using the modified procedure of Wassemann and Lee (1980). One unit of enzyme activity was expressed as the amount of enzyme in one gram of beans that changed absorbance of 0.001 per min. All enzyme analyses were carried out in triplicate in each replication.

282 C.Y. LEE. N.L. SMITH AND D.E. HAWBECKER

Quality Evaluation

In order to evaluate sensory quality, beans prepared in the following manner were presented to panel members: frozen beans (500 g) were added to two cups of boiling distilled water contained in a 3-quart sauce pan. After cooking for 5 min with the lid on, the beans were drained in a colander for 1 min and then presented to 16 panel members using a balanced block design. Samples were evaluated for color, texture, and flavor by ranking each sample in comparison with beans blanched according to the commercial control. Panelists were asked to judge each sample using the commercial control as a reference which had been given the value of 5 (mid-scale). This reference sample was also presented to the panelists as one of the unidentified coded samples.

The cooked bean samples were also evaluated for color and firmness using in- strumental procedures. For color, beans were placed in a 10 cm square acrylic cell container and readings were made with a Hunter Color Difference Meter D 25-3 standardized with a white plate (K2-9766) using a large optical head. Hunter values “L”, “a”, and “b” were recorded a minimum of 5 replicates per blanching treatment. Firmness of beans was measured by Instron. Six replicates for each treatment were run using a back extrusion cell (capacity of 250 g sam- ple) having a 4 mm annulus (Bourne and Moyer 1968). Statistical analyses of quality measurements among blanching treatments were carried out by a multi- ple range test (Duncan 1955) using a Minitab computer program.

RESULTS AND DISCUSSION

In order to understand the nature of enzyme activities and quality changes in green beans during frozen storage, a wide range of timehemperature combina- tions were used for the pilot plant study in 1985. Then three blanching conditions were selected for the commercial scale study in 1986 which were based on the results of 1985.

A substantial reduction of enzyme activity occurred as a result of the blan- ching operation but it varied with the enzyme. Peroxidase was the most heat stable among the four enzymes tested, followed by lipoxygenase, polyphenolox- idase and catalase. The residual peroxidase activity of beans blanched at 60°C for 5.5 min was 92% of the level for raw beans after blanching while residual catalase activity was only 8%. Enzyme activity in beans blanched at the higher temperature (99 “C) was less than 1 % of their original activity of raw product.

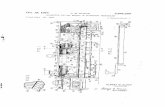

There was no significant change in catalase activity during the 12 month storage (data not shown). As shown in Fig. 1, the residual lipoxygenase ac- tivities in beans blanched at temperatures above 74 “C were very low compared to those beans blanched at 60°C. Their activity levels were within the same range, including those blanched at 74”, 82”, and 99°C. This may indicate the

FROZEN GREEN BEANS

h v1

9 0 4000- D M

.t

283

3 6 9 12 u---

0 Storage (month)

FIG. 1. EFFECT OF BLANCHING TREATMENTS ON LIFQXYGENASE ACTIVITY IN FROZEN GREEN BEANS DURING STORAGE

#1=6O0C/5.5min, #2=74"C/4.5 min, #3=82"C13.5 min, #4=99"C/3.5 min, and #5=99°C/2.0min.

presence of some isoenzyme(s) with a high heat stability. Similar results were obtained with the commercially blanched beans. Polyphenoloxidase activity was relatively low and most of it was deactivated by all blanching treatments (data not shown). Relatively large residual peroxidase activity was observed in beans blanched at 60 " and 74 "C; beans blanched at 82 W 3 . 5 min retained more than 10% of the original activity (Fig. 2). The commercial scale study in 1986 show- ed results similar to that of the 1985 pilot plant trial. During storage, the residual peroxidase activities in beans blanched at 82 O and 99 "C showed some increase. Based on the patterns of enzyme activities in frozen green beans, peroxidase ap- pears to be the only one that showed higher residual activity among enzymes studied during the 12 month storage.

Organoleptic evaluations showed that blanching treatments at 60 and 74 "C significantly lowered color scores as compared to those beans blanched at 82 and 99°C throughout the storage period (Table 1). Panel members also noted differences in texture among bean samples: beans blanched at 99 O C were given higher scores than beans blanched at 60" and 74°C. It appeared that scores in

284 C.Y. LEE, N.L. SMITH AND D.E. HAWBECKER

'5 40 - 2 30 -.

20

10

.- - -.

# 4 ('

0 0

x > .-a .- .- - 2

40 - 30 -.

20

10

-.

# 4 ('

0 0

Storage (month)

FIG, 2. EFFECT OF BLANCHING TREATMENTS ON PEROXIDASE ACTIVITY IN FROZEN GREEN B€ANS DURING STORAGE

#I =60" C15.5 min, #2=74" C14.5 min, #3=82" U 3 . 5 min. #4=99" C13.5 min. and #5=99" U 2 . 0 min.

TABLE 1 . EFFECT O F BLANCHING ON SENSORY COLOR OF FROZEN GREEN BEANS

Blanching Treatment Storage (month) 60CIS.Smin 14CI4.Sm 02C13.5m 99CI3.5m 99CI2m

b b b 0 2.3? 3 . 0 2 4.27 4.29 5 .27

a a b b b 3 2.16 2.19 4 . 4 9 5 .19 5.55

6 2.51a 2 . 5 9 4 . 6 8 5.01b 5 . 6 9 b b b

9 2.6: 2 - 6 8 4 .64 5 .17 5 .86 a a b b C

1 2 2.59 3.22 4 .13 4 . 6 6 5 .56

a-b%qerscripts in the Same row are significantly different at the 95% level.

FROZEN GREEN BEANS 285

beans blanched at 82°C were in between (Table 2). There were no significant changes in color and texture during storage. Results of the flavor scores (Table 3) were also similar to those of color and texture. Panel scores for the commer- cially blanched bean samples of 1986 clearly indicated that beans blanched at 88 " and 99 "C were significantly higher on all scores of color, texture (Table 4), and flavor than those beans blanched at 82 "C. These results indicated that blan- ching at 82 "C (1 80 OF) was the transitional temperature with respect to quality of frozen beans.

TABLE 2. EFFECT OF BLANCHING ON SENSORY TEXTURE OF FROZEN GREEN BEANS

Storage Blanching Treatment

(month) 6QCf5.5min 14Cf4.5m 02Cf3.5m 99Cf3.5m 99Cf2m b b

0 3.2; 3.1; 4.4; 4.96 5.13 a a a b a b b

3 3.44 3.12 4.46 4.66 5.29 a a ab a b b

6 3.32 2.90 4.23 4.99 5.76 b b

a a a ab b 9 2.528 2 . 4 2 3.378 4.95 5.11

12 2.87 2.76 3.92 5.09 5.49

a.b,CSuperscripts in the same row are significantly different at the 95% level.

TABLE 3. EFFECT O F BLANCHING ON SENSORY FLAVOR OF FROZEN GREEN BEANS

Blanching Treatment Storage (month) 60C15.5min 14CI4.5m 82CI3.5m ggc/3,5m ~ 9 c f 2 m

b b b 0 3 . 0 c 3 . 4 c 4.92 5.14 5.03

a a b b b 3 3.08 3.59 4.82 5.04 5.13

a a ab bc C

6 3.54 3.09 3.98 4.99 5.50 ab b b

a a ab b b 9 2.89" 3 . 0 g 4.04 4.67 4.49

1 2 3.51 3.64 4.09 4.97 5.33

a.b%uperscripts in the same row are significantly different at the 95% level.

286 C.Y. LEE, N.L. SMITH A N D D . E . HAWBECKER

TABLE 4. EFFECT OF BLANCHING ON SENSORY TEXTURE QUALITY OF FROZEN GREEN BEANS

Storage Blanching treatment

(month) 82C13.5mln 88CI3.5m 99C/3.5m

0 4 .19 ’ 6 .84 7.34 = 3 3.91 5.34 6 .06

6 3.62 5 .81 6.75

9 3 .84 ’ 6 .31 7.03

1 2 4.1 9 ’ 6.06 6.81

d*b5Superscripts in the same row are significantly different at the 95% level.

Some differences were noticed in Hunter Color “L” and “a” values among samples (data not shown). Beans blanched at the lower temperature were higher in “L” values (lighter in color) with both the pilot plant and commercial scale samples. However, the overall differences were statistically insignificant at 5% level. A significant difference was observed in the “a” value among samples. Those beans blanched at lower temperatures (below 82°C) were less green as compared to those blanched at higher temperatures (above 82°C). This result coincided with that of the organoleptic tests. There was no statistical difference in “b” value among all samples. The firmness measured by Instron followed the panel results but the differences among samples were more distinctive and significant.

CONCLUSIONS

This study revealed that most enzymes in green beans were inactivated during the normal blanching conditions and that peroxidase showed relatively high residual activity among the four enzymes that were studied. No direct relation- ship between the enzyme activities and quality attributes was found during the course of the 12 month storage. These quality differences are possibly due to other factors affected by the blanch that were not evaluated in this study. However, one imponant observation was that blanching at 82 “C (180 OF) for 3.5 min appeared to be the borderline process: beans blanched at temperatures under 82°C showed a lower score in color, texture, and flavor while those blanched above 82 “C scored higher. Pilot plant and commercially processed beans gave

FROZENGREENBEANS 287

similar results. It may be concluded from this study that green beans can be blan- ched at temperatures lower than the present standard (98-100" C), but they should be blanched above 82 "C.

REFERENCES

AEBI, H.H. 1983. Catalase. In Method ofEnzymatic Analysis. Vol. 3. (H.U.

BOTTCHER, H. 1975. Enzyme activity and quality of frozen vegetables. Part I.

BOURNE, M.C. and MOYER, J.C. 1968. The extrusion principle in texture

DUNCAN, D.B. 1955. Multiple range and multiple F tests. Biornetrics 11, 1. FLURKEY, W.H. and JEN, J.J. 1978. Peroxidase and polyphenoloxidase ac-

JOSLYN, M.A. 1949. Enzyme activity in frozen vegetable tissue. Adv. En-

REED, G. 1966. Enzymes in Food Processing. Academic Press, New York. SURREY, K. 1964. Spectrophotometric method for determination of lipoxy-

WASSEMANN, K. and LEE, C.Y. 1980. Polyphenoloxidase activity during

WINTER, E. 1969. Behavior of peroxidase during blanching of vegetables. Z.

Bergmeyer, ed.) p. 273. Verlag Chemie, Deerfield Beach, FL.

The residual activity of peroxidase. Die Nahrung 19, 173.

measurement of fresh peas. Food Technol. 22, 1013.

tivities in developing peaches. J. Food Sci. 43, 1826.

zymol. 9, 613.

genase activity. Plant Physiol. 39, 65.

grape maturation and wine production. Am. J. Enol. Vitic. 31, 206.

Lebensm-Unters. Forsch. 141, 201.