ENVIRONMENTAL PROTECTION PLAN FOR THE PROPOSED …

Transcript of ENVIRONMENTAL PROTECTION PLAN FOR THE PROPOSED …

ENVIRONMENTAL PROTECTION PLANFOR THE PROPOSED

TRANSCANADA VAUGHAN MAINLINE EXPANSIONPROJECT

October 2016

Prepared for:

TransCanada PipeLines Limited 450 – 1st Street SW Calgary, Alberta

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page i

TABLE OF CONTENTS Page

1.0 INTRODUCTION .............................................................................................................................. 1

2.0 PURPOSE ........................................................................................................................................ 2

3.0 ENVIRONMENTAL PROTECTION PLAN ORGANIZATION .......................................................... 3

3.1 Organization ........................................................................................................................ 3 3.2 Environmental Setting ......................................................................................................... 4 3.3 Extent and Limits of the EPP .............................................................................................. 5

4.0 ENVIRONMENTAL COMPLIANCE ................................................................................................. 7

5.0 NOTIFICATION OF CONCERNED PARTIES ............................................................................... 13

6.0 CONSTRUCTION PREPARATION ............................................................................................... 14

7.0 PROJECT SPECIFIC PROTECTION MEASURES ....................................................................... 15

7.1 Resource Specific Protection Measures ........................................................................... 15 7.2 Additional Project Specific Protection Measures .............................................................. 28

8.0 PIPELINE CONSTRUCTION ......................................................................................................... 29

8.1 General Environmental Protection Measures ................................................................... 29 8.2 Clearing and Disposal ....................................................................................................... 31 8.3 Topsoil/Strippings Salvage and Grading .......................................................................... 33 8.4 Watercourse Crossings ..................................................................................................... 36 8.5 Pipe Activities (Trenching, Stringing, Bending, Coating, Lowering-In) ............................. 50 8.6 Backfill ............................................................................................................................... 52 8.7 Pressure Testing ............................................................................................................... 54 8.8 Clean-up and Reclamation ............................................................................................... 56

9.0 POST-CONSTRUCTION MONITORING ....................................................................................... 61

LIST OF APPENDICES APPENDIX 1A EMERGENCY CONTACTS .............................................................................................. 63 APPENDIX 1B CONTACTS ....................................................................................................................... 65 APPENDIX 1C APPROVALS/PERMITS POTENTIALLY REQUIRED FOR PIPELINE

DEVELOPMENT ............................................................................................................... 68 APPENDIX 1D TYPICAL DRAWINGS ...................................................................................................... 69 APPENDIX 1E CONTINGENCY PLANS ................................................................................................. 142 APPENDIX 1F MANAGEMENT PLANS .................................................................................................. 167 APPENDIX 1G INDUSTRY GUIDELINES, REGULATIONS AND CODES OF PRACTICE ................... 196

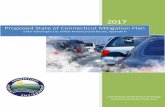

LIST OF FIGURES Figure 1 Regional Location of the Project ......................................................................................... 6

LIST OF TABLES TABLE 1 RESOURCE-SPECIFIC MITIGATION TABLE ........................................................................... 18 TABLE 2 SUMMARY OF WATER CROSSINGS AND CONSTRUCTION

CONSIDERATIONS .......................................................................................................... 42

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 1

1.0 INTRODUCTION

This Environmental Protection Plan (EPP) outlines environmental protection measures to avoid or reduce potential effects during construction of the Vaughan Mainline Expansion Project (the Project), proposed by TransCanada PipeLines Limited (TransCanada or the Company). The proposed 11.7 kilometer (km) long, 1,067 millimeter (mm) (Nominal Pipe Size [NPS] 42) Project is located in the Greater Toronto Area in the City of Vaughan, within the Regional Municipality of York, Ontario.

The Project will connect into TransCanada’s approved 914.4 mm (NPS 36) King’s North Connection Pipeline Project and the existing TransCanada Line 200-2, 914.4 mm (NPS 36) pipeline, northwest of the Major McKenzie Drive and Huntington Road intersection. The Project will run north and east before heading south to connect into the existing TransCanada Line 200-3, 1,067 mm (NPS 42) pipeline near the existing MLV 201A crossover valve site located southeast of the intersection of Kirby Road and Kipling Avenue. The existing crossover valve MLV 201A and associated crossover piping will be removed. A receiver barrel and associated piping will be installed at the existing TransCanada Maple Compressor Station (Station 130), approximately 3.2 km east (Figure 1).

Design, construction and operation of the pipeline will be in compliance with all applicable codes, standards and regulations.

The EPP is written in construction specification format and should be read in conjunction with the Project-specific environmental documents such as the Environmental Alignment Sheets. This EPP provides Project-related environmental mitigation measures and commitments to be considered during the detailed engineering design, and carried out during the construction and post-construction reclamation phases of the Project.

The EPP is based on:

TransCanada’s Health, Safety and Environment (HSE) Commitment;

TransCanada’s HSE Management System;

feedback obtained through consultation and engagement;

results of the biophysical field programs;

commitments made in the ESA; and

professional experience.

Revisions to the EPP may occur as a result of:

results of supplemental studies;

commitments made during the regulatory review process, including information requests (IRs);

regulatory approval conditions; and

ongoing engagement programs with Aboriginal communities and other stakeholders.

Subject to regulatory approval, construction of the Project is anticipated to commence in November 2016, with a target completion date of November 2017. Clean-up and post-construction reclamation of disturbed portions of the construction footprint will be conducted immediately following construction, or as soon as weather, ground and seasonal conditions allow.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 2

2.0 PURPOSE

The purpose of the EPP is to describe the environmental mitigation measures and commitments to be carried out by the Company, their Contractor(s) and subcontractors during construction and post-construction reclamation phases of the Project to avoid or minimize potential environmental effects of the Project. The EPP includes both general and site-specific environmental protection measures which have been developed and refined over time based on past project experience, input from Aboriginal communities, landowners, stakeholders and regulators during consultation, and reflect current industry best management practices where they are applicable to the Project activities.

Specifically, the EPP:

outlines environmental protection measures related to Project activities;

provides instructions for carrying out construction activities to minimize negative environmental effects; and

serves as reference information to the construction staff and personnel to support decision making and provide links to more detailed information.

Following completion of construction, this EPP will be used as a guide during Project operation.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 3

3.0 ENVIRONMENTAL PROTECTION PLAN ORGANIZATION

This section provides an overview of the organization and scope of the EPP.

3.1 Organization

The EPP provides Project-related environmental protection measures and commitments to be carried out during the construction and post-construction reclamation phases of the Project. A large portion of environmental protection measures are standard across all TransCanada projects. Additional Project-specific measures are identified in Section 7.0 of the EPP.

The EPP applies to the approved Project construction footprint (the construction footprint). The construction footprint may include, but is not limited to, a pipeline right-of-way (ROW), temporary workspace (TWS), permanent and temporary access roads, staging areas, facility sites, construction yards, office site and pipe storage areas. If there are lease agreements in place for some Project areas then the conditions within those lease agreements will apply to those specific areas.

Environmental protection measures are identified under the headings below in accordance with the progression of construction activities, and are intended to be read in conjunction with the Environmental Alignment Sheets. The Environmental Alignment Sheets identify specific locations where mitigation measures will be applied.

The EPP is intended to provide the Company and their Contractor(s) and subcontractors’ personnel with an understanding of the general environmental setting of the Project, extent and limitations of the EPP, specific or unique protection measures for the Project, and general environmental protection measures or industry best management practices that are typically applied to each construction activity in sequence.

Sections 1-3 outline the purpose and organization of the EPP, place the EPP in context with respect to geographic location and identify where information can be found in the EPP.

Section 4 "Environmental Compliance" provides information about the tools and process to facilitate compliance with all regulatory approvals, permits, commitments and specific requirements of the EPP.

Section 5 "Notification of Concerned Parties" provides details on specific activities to be followed to ensure all relevant stakeholders are properly notified of Project activities before the commencement of construction.

Section 6 "Construction Preparation" outlines activities to clearly delineate the boundaries of approved work areas and to ensure environmentally sensitive features are properly identified prior to any ground disturbance. Proper identification avoids potential impacts to resource features and ensures that the Company and its Contractors are aware of the limits of the approved work areas.

Section 7 "Project Specific Protection Measures" outlines procedures to be undertaken to protect environmental and cultural features that were identified pursuant to the environmental assessment or that are unique to the Project. Information in Section 7.0 is documented and displayed on the Environmental Alignment Sheets, where applicable.

Section 8 "Pipeline Construction" outlines the environmental protection measures associated with general pipeline construction, topsoil handling, strippings, salvage, grading, water crossings, pipe installation activities, backfill, pressure testing, and clean-up and reclamation activities that will be executed. These measures are applicable to the construction footprint.

Section 9 "Post-Construction Monitoring" outlines activities to take place once construction and post-construction reclamation activities have been completed to evaluate the success of reclamation activities, compliance with commitments and the stability of the disturbed lands.

Appendices to the EPP include drawings, Project contacts, contingency plans and management plans to support the specific mitigation measures identified in the EPP and provide guidance to decision making processes should conditions arise that require implementation of contingency measures.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 4

3.2 Environmental Setting

The Project involves the construction and operation of a new buried pipeline to transport sweet natural gas, and will include approximately 11.7 km of 1,067 mm (NPS 42) pipeline and associated assembly pipe at the upstream and downstream tie-in locations, including a launcher and receiver. The Project is entirely located in the City of Vaughan.

The Project is planned for construction within a new approximately 18 m wide right-of-way (ROW). Additional workspace will also be required for staging areas, water body and infrastructure crossings, topsoil storage, sidebends and where grading is necessary. The Project parallels existing disturbances for approximately 35% of its length; including power transmission lines for approximately 3.0 km, a rail line for approximately 0.2 km and roads for approximately 0.7 km. The Project crosses five roads: Nashville Road, Kirby Road [twice], Huntington Road, Highway 27 and Kipling Avenue. It also crosses a Canadian Pacific Railway line between kilometre post (KP) 3 and KP 4.

The Project crosses 40 water crossings, including watercourses and field drains (Table 2); twenty-three (23) of these watercourses are regulated by the Toronto and Region Conservation Authority (TRCA), including crossings at the Main Humber River, East Humber River, and various unnamed tributaries of the East Humber River, Purpleville Creek, Robinson Creek and Rainbow Creek. The majority of the land use crossed by the Project is agricultural or natural areas. The Project crosses environmentally distinct features, several of which overlap along the route, as follows:

1.9 km of the Project falls within TRCA land.

90 m via trenchless method of one (1) wetland, which is a provincially significant wetland (PSW).

90 m via trenchless method of one (1) watercourse listed as occupied by Redside Dace.

0.5 km of environmentally sensitive areas.

6.7 km of Natural Heritage Network (NHN) core area.

1.2 km of significant forest.

7.3 km of Greenlands.

8.5 km of the Greenbelt.

8.0 km of the TRCA Natural Heritage System (NHS).

None of the groundwater wells identified for the Project are directly along the pipeline centreline, and the 25-year Wellhead Protection Area (WHPA) for municipal production overlaps the western section of the ROW.

Approximately 3.4 km of the pipeline will be constructed using trenchless construction methods, resulting in limited surface disturbance at road crossings, and select watercourse crossings and woodlots. For typical trenched construction the minimum construction width required for safe construction will be approximately 32 m, which includes approximately 18 m of the new permanent ROW and 14 m of temporary workspace (TWS) for construction. In addition to the construction TWS along the ROW, the construction footprint includes TWS required for staging and topsoil storage areas, crossings, sidebends and where grading is necessary. Existing highways, public roads, and the proposed Project ROW will be used to access the Project workspace, where feasible. Other temporary access will use existing disturbances where feasible. No new permanent access is anticipated to support the Project.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 5

3.3 Extent and Limits of the EPP

Contents of the EPP apply to construction and post-construction reclamation activities occurring under non-frozen and frozen ground conditions. There may also be a need to revise specific measures as a result of on-going consultation and landowner discussions or to address unforeseen site-specific conditions that may arise during construction. If this were to occur, the Company will resolve the issue with the Project Manager, the Construction Manager, the Environmental Inspector and the Environmental Advisor in consultation with the appropriate regulators, as required. The Company confirms assurance of its commitment to taking responsibility for potential environmental effects of the Project through informed environmental planning, assessment, mitigation and reclamation. Indefinite terms may be included in some environmental protection measures in order to provide the Company with the flexibility needed during construction and reclamation phases to accommodate unique situational circumstances where general environmental protection measures must be refined or site-specific environmental protection measures applied as part of the adaptive management process.

!(

!(

!(

"

"

"

"

"

"

"

"

" "

"

"

"

!

!

TRAN

SCANAD

A LINE

200-2

HUNTINGTON ROAD

MAJOR

MACKEN

ZIE DR

IVE WEST

KIPLING AVENUE

ISLIN

GTON AV

ENUE

TESTON

ROAD

CLAR

KWAY D

RIVE

ALBION VAUGHAN ROAD

MAYFIELD ROAD

COUNTRYSIDE DRIVE

NASHVI

LLE RO

AD

COLER

AINE D

RIVE

HIGHWAY 50

KING R

OAD

KING V

AUGHAN

ROAD

BELSITECOURT

ROE RO

AD

HIGHWAY 27

KIRBY

ROAD

Kleinburg

Nashville

Kleinburg

Station

T O W N S H I PO F K I N G

C I T Y O F

VA U G H A N

C I T Y O FB R A M P T O N

HumberRive

r (r ivière Humber)

Eas

t Humber River

Humber River

KP 0

KP 1

KP 2

KP 3

KP 4

KP 5

KP 6

KP 7

KP 8 KP 9

KP 10

KP 11.7419

KP 11

King's NorthConnection(Tie-in Point)

MLV 201A(Tie-inPoint)

S:\Clients\Transcanada\Vaughan\99_PROJ\1416218_TransCanada_VaughanLoop\40_PROD\0014_EPP\1416218_0014_GA_0001.m

xd

IF THIS M

EASUREMENT DOES NOT M

ATCH W

HAT IS SHOWN, THE SHEET SIZE HAS BEEN M

ODIFIED FROM:

25mm

0

1,000 1,0000

1:30,000 METRES

CLIENT

TRANSCANADA PIPELINES LIMITED

REFERENCE(S)

1. PROJECT ROUTE, RIGHT-OF-WAY, AND TEMPORARY WORK SPACES COMBINED MAKE THEPROJECT FOOTPRINT

1. BASE DATA: MNRF 2016, TRCA 2015, CITY OF VAUGHAN 20152. ROUTE: PROVIDED BY TRANSCANADA 2016-09-09 (REV. 13)3. PROJECTION: TRANSVERSE MERCATOR DATUM: NAD 83 COORDINATE SYSTEM:UTM ZONE17N

PROJECT

VAUGHAN MAINLINE EXPANSION

TITLE

REGIONAL LOCATION OF THE PROJECT

1416218 0017 0 1

2016-09-16

SO

CGE

CL

TS

CONSULTANT

PROJECT NO. CONTROL REV. FIGURE

YYYY-MM-DD

DESIGNED

PREPARED

REVIEWED

APPROVED

LEGEND

!( City

Road! ! Utility Line

Rail Line

Future 427 Transportation Corridor

King's North Connection Route

Pipeline (natural gas, underground)

Watercourse

Wetland

Waterbody

Wooded Area

Municipality

Conservation Area

Built Up Area

Vaughan Mainline Expansion Project Components" Kilometre Post (KP) Marker

Proposed Route (Conventional Construction)

Proposed Route (Trenchless Construction)

Proposed Project Footprint1

PROJECT LOCATION

KEY MAP

NOTE(S)

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 7

4.0 ENVIRONMENTAL COMPLIANCE

Introduction

Environmental compliance is facilitated through sharing of information, providing orientations/training, hiring qualified staff and providing onsite inspection of activities through a proactive and adaptive inspection program.

Objective

The objective of these mitigation measures is to ensure that:

The Company, its authorized representatives, Contractor(s) and subcontractors are aware of relevant environmental regulatory requirements;

processes are in-place that allow the Company, its authorized representatives, Contractor(s) and subcontractor(s) to access Project environmental information to aid in decision making at the field level; and

Environmental Inspectors assigned to the Project are qualified and properly trained.

Specific Measures

Activity Preparation Measures

Approvals and Licenses

1. Obtain all necessary licenses and approvals before the commencement of construction. The Company, its authorized representatives, Contractor(s), and subcontractors, will comply with all conditions as presented to the Company on permits, approvals, licences, certificates and Project-specific management plans. Resolve any inconsistencies between permit conditions and contract documents as they arise.

Environmental Commitment Tracking List (ECTL)

2. An ECTL will be created for the Project and will include commitments resulting from the NEB application and subsequent filings, undertakings made during the hearing, and information or requirements on any Federal, Provincial or Municipal permits and approval conditions.

3. The ECTL will be maintained at the construction office(s) and during construction. Environmental commitments will be tracked and updated by the Environmental Inspector(s).

4. Environmental commitments contained in the ECTL will be signed off by the Environmental Inspector(s) as they are completed during construction, reclamation and post construction monitoring phases.

Information Sharing 5. The Environmental Inspector(s) and the Environmental Advisor will facilitate the transfer of environmental information and information updates to all Company field staff and the Contractor in a timely manner.

6. Keep a complete set of Environmental Alignment Sheets and documents at each construction field office.

EPP and Distribution 7. Provide controlled copies of the EPP and associated environmental documents to all key Project construction and Contractor staff members during construction.

8. The EPP serves as the construction guide for environmental issues and commitments and includes all pertinent environmental information from the ESA.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 8

Activity Preparation Measures

Environmental Alignment Sheets

9. The Environmental Alignment Sheets provide information regarding environmental requirements and serve as detail to the Construction Alignment Sheets.

ESA Reports and Preconstruction Surveys

10. Provide all Contractor and Project inspection staff with relevant results of preconstruction surveys to identify known locations of environmentally sensitive features. Indicate specific mitigation for these sites on the Environmental Alignment Sheets and/or corresponding tables, with reference to specific environmental information. Identify sites with suitable markers and/or record GPS locations for any post-construction monitoring (PCM) requirements.

Landowner Line List 11. Review landowner requests as they appear on the landowner line list, or as they arise in the field to ensure conformance with the environmental commitments.

Industry Guidelines, Regulations and Codes of Practice

Industry Guidelines, Regulations have been considered in the creation of the EPP and are included in Appendix 1G, as appropriate.

Federal

Fisheries Act, 1985 (RSC 1985) and regulations and operational statements, e.g.:

– Fisheries and Oceans Canada (DFO) Measures to Avoid Causing Harm to Fish and Fish Habitat (DFO 2013)

Migratory Birds Convention Act, 1994 (MBCA)

National Energy Board Act, regulations, and guidelines

Navigation Protection Act

Species at Risk Act, 2002 – Federal species recovery plans

Provincial

Conservation Authorities Act – Development, Interference with Wetlands and Alternations to

Shorelines and Watercourses (Ontario Regulation [O. Reg.] 166/06)

Environmental Protection Act – General – Waste Management regulation (O. Reg. 347), as

amended by O. Reg. 558/00 – Spill Prevention and Contingency Plans (O. Reg. 224/07)

Endangered Species Act, 2007 – Provincial species recovery plans

Fish and Wildlife Conservation Act, 1997

Fire Protection and Prevention Act, 1997 – Fire Code (O. Reg. 231/07) – Liquid Fuels regulation (O.Reg. 217/01) under the Technical

Standards and Safety Act, 2000

Occupational Health and Safety Act and regulations

Ontario Heritage Act

Ontario Water Resources Act – Water Taking regulation (O. Reg. 387/04)

Public Transportation and Highway Improvement Act

Weed Control Act

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 9

Activity Preparation Measures Funeral, Burial and Cremation Services Act, 2002

Other Guidelines

Canadian Standards Association Standard Z662, Oil and Gas Pipeline Systems (CSA Z662);

Guidelines for the Reclamation of Pipeline Rights-of-Way (CPA 1990);

Guidance for Development Activities in Redside Dace Protected Habitat (MNRF 2011)

Guideline: Planning Horizontal Directional Drilling for Pipeline Construction (CAPP 2004);

Pipeline Associated Watercourse Crossings, 4th Edition (CAPP, CEPA 2012); and

Toronto and Region Conservation Authority Horizontal Directional Drill Guideline (TRCA 2010)

Ministry of Tourism, Culture and Sport Standards and Guidelines for Consultant Archaeologists (MTCS 2011)

Environmental Inspectors Qualifications

12. The Environmental Inspector(s) hired for the Project is required to have experience in environmental inspection and/or planning. The Environmental Inspector(s) will have an understanding of pipeline construction techniques and take a preventative approach to environmental issues. In addition, the Environmental Inspector(s) will be supported by appropriate Resource Specialists who have expertise in the particular issues associated with the Project and who will be available onsite or consulted, as required.

Environmental Inspection Responsibilities

13. The Environmental Inspector’s main responsibility is to ensure that all environmental commitments, undertakings and conditions of authorizations are met and that work is completed in compliance with applicable environmental regulations and Company policies, procedures and specifications in the most efficient and effective way possible.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 10

Activity Preparation Measures

Environmental Inspection Responsibilities (cont’d)

14. Other responsibilities of the Environmental Inspector(s) include:

providing expert advice and guidance on major decisions or courses of action to deal with major environmental conditions;

reporting any spills in accordance with federal and/or provincial regulations and advising Company management on the clean-up and disposal of the material and any affected soils or vegetation;

monitoring delivery of environmental orientation presentations to the Company, regulatory, and Contractor staff, as directed by the Construction Manager and the Environmental Advisor;

preparing daily reports;

preparing, collecting, organizing, and disseminating all environmentally-related information and documentation that arises during construction;

liaising with appropriate government agencies;

supervising the environmental Resource Specialists that may be required to support the Project;

organizing onsite meetings as the need arises, to address site-specific issues;

participating in discussions with landowners/occupants, as requested by the land representative and the Construction Manager;

reviewing construction methodologies with the Project team; and

collecting environmental information throughout construction for documentation and project reporting.

Project Training and Orientation

15. Develop and implement an environmental orientation program to ensure that all personnel working on the construction of the Project are informed of the environmental requirements and sensitivities.

16. Hire the Environmental Inspector(s) before the commencement of construction with sufficient lead time to enable training and participation in the orientation of other construction staff, as well as sufficient on site time to facilitate review of environmentally sensitive aspects of the project.

17. The Environmental Inspector(s) will be briefed by the Environmental Advisor on the environmentally sensitive aspects of the project, and the environmental processes and agreements that have taken place to date.

18. The Environmental Inspector(s) will review all Project-related information.

19. The Environmental Inspector(s) will ensure an environmental orientation program is presented to the Contractor and all Project construction personnel.

Non-Compliances and Resolution

20. The Environmental Inspector(s) will be notified by the responsible person onsite when non-compliance is identified and it will be his/her responsibility to contact the Construction Manager. If the Construction Manager is not available during a non-compliance situation, the Environmental Inspector(s) has the authority to modify work procedures or initiate work stoppage.

21. The Construction Manager will make a determination to either modify the work practice or shut the activity down until corrective actions are determined and implemented. The Environmental Inspector will assist in this decision making process.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 11

Activity Preparation Measures

Non-Compliances and Resolution (cont’d)

22. If the work is shut-down, it will resume only when corrective actions have been developed and approved by the Company. Once approved by the Company, the Contractor will inform the work crew and work will proceed following the corrective action plan.

23. The Environmental Inspector(s) are responsible for documenting all procedure modifications and environmental non-compliances.

Change Management

During the course of construction it may be necessary to modify or create new procedures to address site conditions not anticipated in the EPP. These procedures will outline the process to be followed.

Activity Preparation Measures

Modifications 24. Contact the Environmental Inspector(s) if site conditions warrant a change in procedure that has environmental implications.

25. Develop the modification to the procedure in co-operation with the Construction Manager, Environmental Inspector(s), and the Company's Project Management Team.

Modifications contd. 26. The modification to the procedure will include the following: description of the modification; location; rationale for change; environmental criteria reviewed as part of modification request; consideration of environmental objectives; equivalent or approved standard of mitigation; additional environmental protection measures required; site sketch or photo documentation; and

sign-off by the Construction Manager, Environmental Inspector(s), Environmental Advisor and/or Project Manager.

27. Discuss changes to an existing procedure with the appropriate regulatory agencies, as necessary, and seek the appropriate authorization should the revised procedures require further regulatory approval. If the modification meets the environmental objectives, and there is no specific regulatory approval required for the change, no additional discussions with regulatory agencies are necessary.

28. Document the resolution and/or revision and communicate it to the appropriate parties.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 12

Activity Preparation Measures

Issue Resolution and Escalation

29. Environmental issues will be reviewed and resolved by the Environmental Inspector following consultation with the construction inspectors, and, when additional expertise is required, the environmental resource specialist/ monitor (soils specialist, wildlife biologist, archaeologist, etc.), Typical issues to be addressed may consist of inquiries from the Contractor, construction inspectors, and land representatives directed to the Environmental Inspector and related to providing clarity on mitigation measures or other Project environmental commitments and requirements. If necessary and to ensure consistency, the Environmental Inspector will consult with the Lead Environmental Inspector.

30. Environmental issues or inquiries may arise that require escalation to the Lead Environmental Inspector for resolution. The Lead Environmental Inspector will review the issue and will consult with the Construction Manager or designee to ensure potential impacts to other aspects of the Project are fully understood prior to making the decision on a path forward.

31. Should issues arise that cannot be resolved at the field level due to their complexity, the Construction Manager and Lead Environmental Inspector will consult with the Project Manager and the Environmental Compliance Manager or designee. During consultation and collaboration at this level, and similar to review at the field level, all aspects of the issue related to potential Project impacts will be reviewed as part of the decision making process.

32. Project commitments related to environmental compliance will not be compromised as a result of the issue resolution. Final decision making authority and accountability at this level is with the Project Manager.

33. Decisions made that require a modification to a procedure and have the potential to change the intent of a Project commitment will be fully evaluated, as they could result in a Project variance. Requests for variance from an approved procedure or for a new procedure will be discussed with the appropriate provincial or federal regulatory authority and submitted for approval per the variance process.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 13

5.0 NOTIFICATION OF CONCERNED PARTIES

Introduction

Notification of the construction schedule and timing of specific construction activities will facilitate awareness of upcoming activities, and allow landowners, regulatory agencies and other stakeholders to plan as appropriate for construction activities in their area.

Objective

The objective of these mitigation measures is to ensure:

interruptions to other land use activities are minimized during construction of the Project;

affected stakeholders are aware of Project activities; and

communication is maintained with relevant regulatory agencies throughout construction.

Specific Measures

Contacts Measures

Federal, Provincial and Municipal Agencies

1. Inform all appropriate federal and provincial resource agencies and interested municipal officials of the Project developments as warranted.

Landowners and Lessees

2. Notify all landowners and lessees along the route of the intended Project schedule before the start of construction to prevent or reduce impacts to their operations or activities.

Aboriginal Communities

3. Provide Aboriginal Communities affected by the Project with the proposed construction schedule and pipeline route maps.

Trappers 4. Notify registered trappers at least two weeks prior to construction.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 14

6.0 CONSTRUCTION PREPARATION

Introduction

The following measures will be implemented by the Company's Contractor(s) and subcontractor(s) before the initiation of ground disturbance activities.

Objective

The objectives of these mitigation measures are to ensure:

all resources are properly identified and marked in the field before the initiation of ground disturbance to avoid or minimize potential Project effects;

the construction ROW and TWS is properly delineated to prevent inadvertent trespass; and

all access to and from the work sites are properly marked to maintain safety and environmental compliance.

Specific Measures

Activity/Concern Mitigation Measures

Staking 1. To prevent inadvertent trespass, stake the right-of-way, staging areas and temporary workspace to clearly delineate all boundaries.

2. Mark and locate all foreign lines and cables using One-Call services before the start of construction to ensure the safety of the workers and public.

Environmental Resource Delineation

3. Prior to the start of clearing, clearly mark all sensitive resources identified on the Environmental Alignment Sheets and/or other Project-specific documents and in the site-specific mitigation tables (Table 1 and 2).

4. Following clearing, re-mark all sensitive resources as necessary and supplement markings with signage.

5. The Environmental Inspector(s) will confirm the accuracy of all environmentally sensitive resource locations, and will ensure marking is maintained during construction.

6. The Environmental Inspector(s) will identify and notify the Contractor of the appropriate locations for wildlife gaps.

Access Delineation 7. Clearly delineate areas that have access restrictions. Restrict access to essential construction personnel only. Direct all other personnel to the right-of-way via alternate access routes.

Hot Line Exposure/ Hydrovac

8. Salvage topsoil prior to exposing hot lines.

9. Empty the hydrovac truck onto subsoil at approved locations (e.g., at road crossings where the topsoil has been stripped). Ensure that hydrovac material is contained within the designated release area (i.e., will not migrate to a waterbody or onto topsoil). Refer to the Hydrovac Cutting Slurry Handling Management Plan (Appendix 1F).

Grade Plan 10. The Contractor shall provide a grade plan for approval, as specified in the contract documents. The grade plan will be reviewed by the Environmental Inspector(s) to ensure identified environmental resources are not impacted as a result of grading activities.

11. Prior to commencing work, the Company will obtain approval for additional temporary workspace required for storage of grade or ditch spoil.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 15

7.0 PROJECT SPECIFIC PROTECTION MEASURES

7.1 Resource Specific Protection Measures

Introduction

This section of the EPP describes the specific mitigation measures that will be used on the Project to protect sensitive environmental features as identified in the ESA. All specific resource protection measures are marked on the Environmental Alignment Sheets and entered in the Resource-Specific Mitigation Table (RSMT) (Table 1). Topsoil depth and handling procedures are indicated on the Environmental Alignment Sheets. Watercourse crossing requirements are provided in Table 2 and in Section 8.4 of the EPP, and are indicated on the Environmental Alignment Sheets.

Objective

The objective of these mitigation measures is to:

ensure the identification and protection of biophysical and cultural resources identified in Project-specific environmental documents; and

implement Project-specific construction and reclamation mitigation measures to minimize disturbance to environmental features, where avoidance is not technically or economically feasible.

Specific Measures

Activity/Concern Mitigation Measures

Signage 1. Post signs to clearly identify sensitive environmental features to ensure they are protected. See the Environmental Alignment Sheets as well as RSMT - Table 1 and Table 2 for a listing of sensitive environmental features located along the pipeline right-of-way.

Water Wells 2. Provide shallow domestic well owners within 200 m of the Project the option to participate in a water well monitoring program prior to construction to determine preconstruction quality and quantity conditions.

Hydrology 3. If springs and ground water are encountered, the Company will review the area and determine the appropriate mitigation.

4. Leave gaps in windrows at obvious drainages, on sidehill terrain and wherever seepage occurs to reduce interference with natural drainage patterns.

Wildlife 5. Discuss wildlife issues that are identified during construction as necessary between the Environmental Inspector(s), Wildlife Resource Specialists and the appropriate regulatory agencies.

6. Unanticipated wildlife issues encountered during construction will be discussed and resolved by the Environmental Inspector(s) Wildlife Resource Specialist(s), and the responsible regulatory agencies, if necessary.

7. If wildlife or livestock are discovered in the trench, or in association with any other activity or facility, report to the Environmental Inspector(s) who will contact the applicable regulatory agencies, as required. In the case of livestock, the land agent assigned to the Project will contact the landowner.

8. In the event of clearing or construction activities within the nesting periods for migratory birds, implement mitigation identified in the RSMT – Table 1.

9. Project personnel are not permitted to hunt or fish on the construction footprint.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 16

Activity/Concern Mitigation Measures

Wildlife (cont’d) 10. Do not harass or feed wildlife or livestock. Do not permit construction personnel to have dogs on the right-of-way. Firearms are not permitted in project vehicles, on the right-of-way, or at associated Project facilities. In addition, prohibit the recreational use of all-terrain vehicles (ATVs) or snowmobiles by construction personnel on the construction footprint. Report any incidents with wildlife to a TransCanada Representative immediately.

Listed or Sensitive Wildlife Species

11. If previously unidentified listed or sensitive species or their site-specific habitat are identified during construction of the Project, report to the Environmental Inspector(s) and implement the Wildlife Species of Concern Discovery Contingency Plan (Appendix 1E), or the Breeding Bird and Nest Management Plan (Appendix 1F), as appropriate.

12. Report sightings of Project-specific species of interest to the Environmental Inspector(s). Specific protection measures may be implemented and the sighting will be recorded.

Wildlife, Livestock and Vehicle Passage

13. Leave gaps in windrows (i.e., grubbing piles, topsoil, grade spoil, rollback) and strung pipe at obvious drainages and wildlife trails, and to allow for livestock and vehicle/machinery passage across the right-of-way. Locations where wildlife gaps are appropriate will be determined in the field by the Environmental Inspector(s). Gaps should align.

Rare Plants / Rare Ecological Communities

14. If previously unidentified rare plants or rare ecological communities are found on the right-of-way prior to construction, implement the Plant Species and Ecological Communities of Concern Discovery Contingency Plan (Appendix 1E).

15. Clearly mark identified rare plant locations before the start of right-of-way preparation and construction.

16. Review mitigation for rare plants / rare ecological communities with Contractor personnel in advance of construction to ensure there is full understanding of the procedures involved.

Use of Herbicides 17. Restrict the general application of herbicide near rare plants or rare ecological communities. Spot spraying, wicking, mowing, or hand-picking are acceptable measures for weed control in these areas.

18. Prohibit the use of herbicides within 30 m of an open body of water, unless the herbicide application is conducted by ground application equipment, or otherwise approved by the relevant regulatory agency.

Weeds and Clubroot Disease

19. All equipment must arrive at the Project site clean and free of soil or vegetative debris. Equipment will be inspected by the Environmental Inspector(s), or designate, and if deemed to be in appropriate condition will be identified with a suitable marker or tag. Any equipment which arrives in a dirty condition shall not be allowed on the construction footprint until it has been cleaned, re-inspected by the Environmental Inspector(s) or designate, and deemed suitable for use.

20. Ensure equipment that is brought to site is sanitized by misting with a weak disinfectant solution (i.e., 1-2% bleach) prior to its arrival in order to minimize the spread of clubroot disease.

21. Apply mitigations for any locations identified as having noxious or prohibited noxious weed infestations, as identified in the RSMT - Table 1.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 17

Activity/Concern Mitigation Measures

Weeds and Clubroot Disease (cont’d)

22. Conduct shovel and sweep or compressed air cleaning before moving equipment from locations identified as having a noxious weed infestation in RSMT - Table 1 or by the Environmental Inspector(s). High pressure water may be required to remove debris, as deemed necessary by the Environmental Inspector(s).

23. Strip topsoil/strippings from the construction footprint on lands where localized weed infestations are encountered. Store soil piles containing noxious weeds to prevent mixing with the surrounding soil during regrading and final clean-up.

24. Monitor topsoil/strippings piles for weed growth during the course of construction and implement corrective measures (e.g., spraying, mowing, hand pulling) to avoid infestation when warranted.

25. Record locations of equipment weed cleaning sites and monitor during the following growing season.

Wetlands 26. Construct wetland crossings as per the conditions of approval from the appropriate regulatory agency or conservation authority, as applicable. See RSMT – Table 1.

27. Reduce the removal of vegetation in wetlands to the extent possible.

28. Conduct ground level cutting/mowing/mulching of wetland vegetation instead of grubbing. The method of removal of wetland vegetation is subject to approval by the Company.

29. Direct grading away from wetlands.

30. Reduce grading within wetland boundary. Do not use temporary workspace within the boundaries of wetlands, unless required for site specific purposes. Temporary workspace within the boundary of a wetland must be approved by the Environmental Inspector(s).

31. If ground conditions are encountered that create potential for rutting, admixing or compaction on the workside, minimize ground disturbance by using a protective layer such as matting geotextile (typical or biodegradable) and clay ramps or other approved materials between wetland root/seed bed and construction equipment.

32. Replace trench material as soon as possible, and re-establish preconstruction contours within wetland boundary to ensure cross right-of-way drainage.

33. Install berms, cross ditches and/or silt fences between wetlands and disturbed areas when deemed necessary by the Environmental Inspector(s).

34. Natural recovery is the preferred method of reclamation. Do not seed wetland areas, unless approved by the Environmental Inspector(s).

Heritage and Archaeological Resources

35. If heritage or archaeological resources (e.g., arrow heads, modified bone, pottery fragments, fossils) not previously identified are found on the right-of-way or facility site during construction follow conditions outlined in the Heritage Resource Discovery Plan (Appendix 1E). See RSMT – Table 1.

36. Prohibit the collection of heritage or archaeological resources by Project personnel.

Traditional Land Use Resources

37. If traditional land use (TLU) sites not previously identified are found on the construction footprint during construction, implement the measures outlined in the Traditional Land Use Sites Discovered Contingency Plan (Appendix 1E).

Table 1 summarizes the unique resource-specific protection measures required on the Project.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 18

TABLE 1

RESOURCE-SPECIFIC MITIGATION TABLE

Resource Code(a)

Restrictions / Mitigation

Code(a) Feature(a) Restriction Mitigation

WILDLIFE RESTRICTIONS

AMP WR-00 Potential AMP critical habitat

Approximate dates: With the exception vegetation clearing, no ground

disturbance shall be conducted until the late breeding period (i.e. after April 15).

Where tree removal is required, tree roots and stumps cannot be removed during the hibernation period.

Stop vegetation clearing work prior to the early breeding period (i.e., approx. March 20).

Conduct call-count surveys for monitoring AMP prior to installation of exclusion fencing.

At the start of the late breeding period, the contractor will erect the appropriate signage and supply and install AMP exclusion fencing, as directed by the EI in consultation with the Wildlife Resource Specialist (see AMP Exclusion Fencing guideline and figures in Appendix 1D).

Exclusion fencing should not be removed until construction is complete.

If AMP are encountered during construction, the Wildlife Species of Concern Discovery Contingency Plan (Appendix 1E of the EPP) will be implemented.

If additional work, including clean-up and restoration, is required in subsequent seasons, repeat steps above.

Conduct post-construction call-count surveys for monitoring AMP for two years after restoration.

October 1 to March 20:

hibernation period

March 20 to mid/late April:

early breeding period

Mid/late April to June 11:

late breeding period

(ECCC 2015a,b, 2016)

30 m: setback surrounding wetland

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 19

Resource Code(a)

Restrictions / Mitigation

Code(a) Feature(a) Restriction Mitigation

AMP WR-01 Potential AMP critical habitat

Approximate dates: Commence construction work during the fall/winter

hibernating period (approximately October 1 to March 20).

Stop work prior to the early breeding period (i.e., approx. March 20) in AMP habitat and surrounding 30 m setback, as directed by the EI in consultation with the Wildlife Resource Specialist.

During the early breeding period, minor vehicle access may be required to monitor and maintain erosion and sediment control measures as deemed appropriate by the EI.

Conduct call-count surveys for monitoring AMP prior to installation of exclusion fencing.

At the start of the late breeding period, the contractor will erect the appropriate signage and supply and install AMP exclusion fencing, as directed by the EI in consultation with the Wildlife Resource Specialist (see AMP Exclusion Fencing figure in Appendix 1D).

During the late breeding period and the active period, work may occur in AMP habitat and the 30 m setback only if fencing was installed during the peak or latter half of the breeding period (i.e., mid/late April).

Exclusion fencing should not be removed until construction is complete.

If AMP are encountered during construction, the Wildlife Species of Concern Discovery Contingency Plan (Appendix 1E of the EPP) will be implemented.

If additional work, including clean-up and restoration, is required in subsequent seasons, repeat steps above.

Conduct post-construction call-count surveys for monitoring AMP for two years after restoration.

October 1 to March 20:

hibernation period

March 20 to mid/late April:

early breeding period

Mid/late April to June 11:

late breeding period

June 11 to October 1:

active period

(ECCC 2015a,b, 2016)

30 m: setback surrounding wetland

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 20

Resource Code(a)

Restrictions / Mitigation

Code(a) Feature(a) Restriction Mitigation

AMP WR-01A Potential AMP suitable habitat

Approximate dates:

During the early breeding period, conduct call-count surveys for monitoring AMP prior to installation of exclusion fencing.

At the start of the late breeding period, the contractor will erect the appropriate signage and supply and install AMP exclusion fencing, as directed by the EI in consultation with the Wildlife Resource Specialist (see AMP Exclusion Fencing figure in Appendix 1D).

Exclusion fencing should not be removed until construction is complete.

If AMP are encountered during construction, the Wildlife Species of Concern Discovery Contingency Plan (Appendix 1E of the EPP) will be implemented.

If additional work, including clean-up and restoration, is required in subsequent seasons, repeat steps above.

Conduct post-construction call-count surveys for monitoring AMP for two years after restoration.

October 1 to March 20: hibernation period

March 20 to mid/late April: early breeding period

Mid/late April to June 11: late breeding period

June 11 to October 1: active period

(ECCC 2015a,b, 2016)

30 m: setback surrounding wetland

BAT WR-02 Potential bat (BAT) maternity roosting habitat in woodlands

June 1 to July 31: peak maternity roosting period

(MNRF, pers. comm. 2015; MNRF IGF Letter 2016)

Trees will not be cleared during peak BAT maternity roosting period between June 1 to July 31 to avoid incidental harm to roosting bats.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 21

Resource Code(a)

Restrictions / Mitigation

Code(a) Feature(a) Restriction Mitigation

MIB1 WR-03 Potential migratory birds (MIB) nesting habitat (general)

April 10 to August 15:

general nesting period (ECCC 2014a,b)

Environment Canada’s Avoidance Guidelines (ECCC, 2014a,b) and policy on Incidental Take of MIB in Canada (ECCC, 2015c) will be followed to determine the presence of nesting birds and to prevent disturbance to active nests.

Construction and clean-up activities will occur outside of the MIB1 nesting periods, where feasible.

Where clearing or construction activities will occur during the MIB1 nesting periods in nesting habitat, a non-intrusive pre-construction breeding bird survey will be conducted unless the area has been pre-cleared.

If an active nest is identified within the Project footprint, the Breeding Bird and Nest Management Plan (BBNMP) will be implemented to avoid or minimize risks of negative effects to MIB, their nests and eggs.

MIB2 WR-04 Potential open country migratory bird (MIB) nesting habitat

May 1 to August 16:

open country migratory bird nesting period (MNRF, pers. comm. 2015)

Environment Canada’s Avoidance Guidelines (ECCC, 2014a,b) and policy on Incidental Take of MIB in Canada (ECCC, 2015c) will be followed to determine the presence of nesting birds and to prevent disturbance to active nests.

Construction and clean-up activities will occur outside of the MIB2 nesting periods, where feasible.

Where clearing or construction activities will occur during the MIB2 nesting periods in nesting habitat, a non-intrusive pre-construction breeding bird survey will be conducted unless the area has been pre-cleared.

Habitat is to be reinstated prior to May 1 of the year immediately following construction.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 22

Resource Code(a)

Restrictions / Mitigation

Code(a) Feature(a) Restriction Mitigation

WEED POTENTIAL (EQUIPMENT CLEANING STATIONS)

— UR-01

Start of areas of low non-native vegetation species and noxious weeds invasion:

KP 3.76 – KP 3.92

KP 11.25 – KP 11.30

—

Topsoil handling (i.e., stripping and replacement) equipment will be cleaned prior to entering areas of low degree of invasiveness along the Project.

Location of equipment cleaning stations to be confirmed by the Environmental Inspector.

WETLAND RESTRICTIONS

— WT-01

Provincially Significant Wetlands (PSW):

Wetland 07 (East Humber River HDD) – KP 9.45 to KP 9.76

Wetland 08 (TWS only) – KP 9.76 to KP 10.21

Wetland 09 (Purpleville Creek Bore) – KP 10.95 to KP 10.98

Wetland 10 (TWS only) – KP 11.59 to KP 11.65

—

Measures will be implemented in accordance with the conditions of permits from the TRCA under O. Reg. 166/06 – Toronto and Region Conservation Authority: Regulation of Development, Interference with Wetlands and Alterations to Shorelines and Watercourses.

If the wetland boundaries are disturbed by construction activities (e.g. clearing, stripping):

Prior to construction, Project footprint wetland boundaries will be clearly marked.

Refer to the following typical drawings (EPP - Appendix 1D): 18275-03-ML-05-511; 18275-03-ML-05-512; 18275-03-ML-05-543; and 18275-03-ML-05-544.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 23

Resource Code(a)

Restrictions / Mitigation

Code(a) Feature(a) Restriction Mitigation

— WT-02

Non-Provincially Significant Wetlands (non-PSW):

Wetland 00 (Access Road only) – KP 1.00 to KP 1.20

Wetland 01 (HDD) – KP 0.84 to 0.99

Wetland 02 (Nashville Road HDD) – KP 1.40 to 1.82

Wetland 03 (Nashville Road HDD) – KP 2.11 to 2.25

Wetland 04 (TWS only) – KP 3.06 to KP 3.70

Wetland 05 (part of WC-30) –KP 8.50 to KP 8.52

Wetland 06 (East Humber River HDD) – KP 9.10 to KP 9.17

Wetland 10 (TWS only) – KP 11.70 to KP11.75

—

Measures will be implemented in accordance with the conditions of permits from the TRCA under O. Reg. 166/06 – Toronto and Region Conservation Authority: Regulation of Development, Interference with Wetlands and Alterations to Shorelines and Watercourses.

If the wetland boundaries are disturbed by construction activities (e.g. clearing, stripping):

Prior to construction, Project footprint wetland boundaries will be clearly marked.

Refer to the following typical drawings (EPP - Appendix 1D): 18275-03-ML-05-511; 18275-03-ML-05-512; 18275-03-ML-05-543; and 18275-03-ML-05-544.

VEGETATION AND WETLAND RECLAMATION

— RCL-01 Riparian and erosion prone areas

— Where required, base the seed mix and/or cover crop

on input from landowners, permit requirements, and the availability of seed at the time of reclamation.

— RCL-02 Wetlands — No seeding in wetlands. Allow for natural recovery.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 24

Resource Code(a)

Restrictions / Mitigation

Code(a) Feature(a) Restriction Mitigation

HERITAGE RESOURCES

HR-001

HRR-01

10436 Huntington Road (349 m from ROW, 151 m from access road): Listed, Gothic Revival 1875

—

Project personnel will be briefed prior to the construction phase about the locations of heritage properties and be encouraged to exercise caution when working with heavy equipment in the immediate vicinity of heritage structures.

HR-002 10090 Huntington Road (788 m from ROW): Listed, no additional details

HR-003

11720 Kipling Avenue (224 m from ROW): Property of Interest, no additional information

HR-004

11291 Kipling Avenue (257 m from ROW): Property of Interest, no additional information

ARCHAEOLOGICAL RESOURCES

ARP1 ARP-01 Areas of archaeological potential – surveyed

— Install a protective barrier 20 m from site ARP1 (ARP1

is within 70 m of the construction footprint) for the duration of construction activities.

ARP2 ARP-02 Areas of archaeological potential —

Complete ongoing archaeological assessments as required under the Ontario Heritage Act.

Implement conditions outlined in the compliance letter(s) from the MTCS under the Ontario Heritage Act prior to and during construction, as applicable.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 25

Resource Code(a)

Restrictions / Mitigation

Code(a) Feature(a) Restriction Mitigation

SOILS

HANDLING MITIGATION

Soil Handling Procedure Ground Conditions Typical Drawings – EPP Appendix 1D

— S-01

Cultivated, Hay, Pasture Full Width (2-lift) ROW Non-frozen, Frozen STDS-03-ML-05-401 (1-2) STDS-03-ML-05-401 (2-2)

Wooded, Bush Grubbing and Topsoil Conservation for Treed Land

Non-frozen, Frozen STDS-03-ML-05-443 (1-2) STDS-03-ML-05-443 (2-2)

— S-02 Disturbed Land(1), Cleared Land

No stripping to Full Width depending upon site-specific details and conditions

Non-frozen, Frozen Various

— As Required Cultivated, Hayland, Pasture, Other Approved Areas

Blade Width(2) Non-frozen, Frozen STDS-03-ML-05-404 STDS-03-ML-05-431 (Secondary Stripping)

— As Required Cultivated, Hayland, Pasture, Other Approved Areas

Full Width soil handling for ramped line crossing

Non-frozen, frozen STDS-03-ML-05-424 (1-2) STDS-03-ML-05-424 (2-2)

— As Required Cultivated, Hayland, Pasture, Other Approved Areas

Full Width (areas requiring grading)

Non-frozen, frozen STDS-03-ML-05-421

— As Required Wetlands Wetland Mitigation – Typical crossing(3)

Non-frozen, frozen 18275-03-ML-05-511 (1-2) 18275-03-ML-05-543 (1-2)

SALVAGE CRITERIA

— NTS — — No topsoil stripping applicable to trenchless locations

— STC — — Strip to colour change including access roads

— STD — — Strip to depth indicated including access roads

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 26

Resource Code(a)

Restrictions / Mitigation

Code(a) Feature(a) Restriction Mitigation

POTENTIAL CONSTRUCTION CONSIDERATIONS

Surface

— SC-01 — — Potential for high or severe wind erosion

— SC-02 — — Potential for soil compaction and rutting

— SC-03 — — Potential for high or severe water erosion, rutting and

compaction

Trench

— TC-01 — — Potential for trench wall instability

Notes: — = Not applicable (a) In order to protect sensitive information regarding potential occurrences and habitat of species at risk, species names and location-specific information concerning endangered, threatened and/or

species of special concern has been kept confidential per MNRF guidance. Updates to the confidential information will be provided to regulators under separate cover, as appropriate. These and other resource, restriction and mitigation codes are referenced in the Environmental Alignment Sheets.

(1) Disturbed Land – consists of anthropogenic features such as roads, well pads and industrial areas. (2) Under frozen ground conditions or on well-sodded pasture lands, the blade width topsoil conservation procedure may be used in place of full width or other variable width topsoil conservation

procedures. Location and extent will be determined by the construction schedule, and will be applied in areas where approved by TransCanada in consultation with the resource specialist. Secondary Stripping for Spoil Displacement will be required in areas where blade width soil handling is conducted under frozen ground conditions.

(3) Wetland area impacted by the footprint will dictate the applicable soils handling procedure and will be assessed on site conditions at the time of construction.

Acronyms:

ECCC = Environment and Climate Change Canada

EI = Environmental Inspector

ELC = Ecological Land Classification

EPP = Environmental Protection Plan

KP = Kilometer post

MNRF = Ministry of Natural Resources and Forestry

MOECC = Ministry of the Environment and Climate Change

MTCS = Ministry of Tourism, Culture and Sport

PSW = Provincially Significant Wetland

RAP = Restricted Activity Period

ROW = Right-of-way

TRCA = Toronto and Region Conservation Authority

TWS = Temporary workspace (include temporary access roads and pullback areas)

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 27

References – Wildlife Restrictions and Guidelines:

Environment and Climate Change Canada (ECCC). 2014a. General Nesting Periods of Migratory Birds in Canada, Long description for nesting calendars in zone C (webpage). Available at: https://www.ec.gc.ca/paom-itmb/default.asp?lang=En&n=4F39A78F-1#_05. Accessed March 2016.

ECCC. 2014b. Avoidance Guidelines, Technical Information – Specific Considerations Related to determining the presence of nests (webpage). Available at: https://www.ec.gc.ca/paom-itmb/default.asp?lang=En&n=8D910CAC-1#_03_1. Accessed March 2016.

ECCC. 2014c. Management Plan for the [Confidential Species] in Canada (Proposed), Species at Risk Act Management Plan Series.

ECCC. Pers. comm. 2015a. Email communication between D. Morningstar and Denise Fell, Environmental Assessment Officer, Environment Canada. January 2015.

ECCC. 2015b. Recovery Strategy for [Confidential Species], Great Lakes / St. Lawrence – Canadian Shield Population, in Canada, Species at Risk Act Recovery Strategy Series.

ECCC. 2015c. Incidental Take of Migratory Birds in Canada. Available at: http://ec.gc.ca/paom-itmb/Default.asp?lang=En&n=C51C415F-1. Accessed March 2016.

ECCC. 2016. Letter of Comment to the National Energy Board on Hearing Order GH-001-2016 – TransCanada PipeLines Ltd. Vaughan Mainline Expansion Project (dated May 24, 2016).

Ministry of Natural Resources (MNR). 2011. Bats and Bat Habitat: Guidelines for Wind Power Projects.

MNR. 2013. Reptile and Amphibian Exclusion Fencing: Best Practices, Version 1.0. Species at Risk Branch Technical Note. Prepared for the Ontario Ministry of Natural Resources, Peterborough, Ontario. 11 pp

Ministry of Natural Resources and Forestry (MNRF). 2014. Significant Wildlife Habitat Mitigation Support Tool (Bat Habitat). Available at: https://dr6j45jk9xcmk.cloudfront.net/documents/4773/mnr-swhmist-accessible-2015-03-10.pdf.

MNRF, pers. comm. 2015. Conference call between TransCanada (Amanda Abbate), Golder (Derek Morningstar, Heather Melcher, Richard Booth and Tamara Skillen) and the MNRF (Mark Heaton and Megan Eplett). December 18, 2015.

MNRF. 2016. Information Gathering Form Letter of Advice. Dated March 14, 2016.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 28

7.2 Additional Project Specific Protection Measures

Introduction

This section of the EPP describes the specific mitigation measures that are unique to the Project, in addition to the resource specific measures outlined in Table 1.

Objective

The objective of these mitigation measures is to:

ensure that mitigation measures are relevant to the project area and unique circumstances of the project; and

ensure that unique Project mitigation measures are easily identifiable and clearly understood by the Company, its representatives, Contractors(s), and sub-contractor(s).

Specific Measures

Activity/Concern Mitigation Measures

Clearing 1. The Company will compensate or replace trees removed from the areas outlined by the City of Vaughan in accordance with agreements made with the City of Vaughan and the TRCA.

Heritage and Archaeological Resources

2. If potential human remains are found on the construction footprint during construction implement the measures outlined in the Heritage Resource Discovery Plan (Appendix 1E).

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 29

8.0 PIPELINE CONSTRUCTION

8.1 General Environmental Protection Measures

Introduction

The general environmental protection measures provided below are applicable to all work areas and activities throughout the construction phase. These general measures are followed by detailed protection measures for each new pipeline construction activity.

Objective

The objective of these mitigation measures is to avoid and reduce the potential environmental effects associated with general pipeline construction activities.

Specific Measures

Activity/Concern Mitigation Measures

Regulatory Contact 1. Document all field regulatory contacts and forward to the Construction Manager and the Environmental Advisor.

Waste Disposal 2. The Contractor will collect all construction debris and other waste materials and dispose of daily at an approved facility and in accordance with the Waste Management Plan (Appendix 1F) and the Release Contingency Plan (Appendix 1E) unless otherwise authorized by the Environmental Inspector(s).

Drill Slurry Management

3. The Drilling Mud Release Contingency Plan must be adhered to (Appendix 1E).

4. All drilling fluid that returns to the surface following completion of drilling and reaming and during pipeline pull back operations, should be contained and disposed of with an approved disposal method.

5. Drilling slurry should be hauled to a Ministry of the Environment and Climate Change (MOECC) approved waste receiving facility.

6. Drilling slurry contained within holding tanks or sumps should be analyzed in accordance with MOECC regulations and guidelines prior to disposal.

Contaminated Soils 7. In the event contaminated soils are encountered during construction, implement the TransCanada Waste and Hazardous Materials Management Manual and the Contaminated Soils Contingency Plan (Appendix 1E).

Fire Prevention 8. Ensure that personnel are made aware of the proper disposal methods for welding rods, cigarette butts and other hot or burning material.

9. Smoke only in designated areas.

10. Ensure the Contractor has the necessary fire-fighting equipment on hand that is capable of controlling any fire that may occur as a result of their activities, as regulated by provincial regulations and government agencies.

11. In the event of a fire or high fire hazard conditions, follow the measures outlined in the Fire Suppression Contingency Plan (Appendix 1E).

Use of Workspace 12. Restrict all construction activities to the approved surveyed right-of-way, and approved temporary workspace, existing roads and approved shoo-flies. All construction traffic will adhere to safety and road closure regulations.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 30

Activity/Concern Mitigation Measures

Fences 13. Properly brace all fences cut for construction and equip with temporary gates. Temporary gates will be a minimum of three-wire. Keep gates closed, except during passage of vehicles.

Equipment Refuelling and Servicing

14. The Contractor will ensure equipment is well-maintained and free of fluid leaks.

15. Bulk fuel trucks, service vehicles, and pick-up trucks equipped with box-mounted fuel tanks shall carry spill prevention, containment, and clean-up materials that are suitable for the volume of fuels or oils carried. Spill contingency material carried on bulk fuel and service vehicles shall be suitable for use on land and water.

16. Do not allow fuel, oil, or hazardous material storage within 100 m of a watercourse or waterbody except where secondary containment is provided.

17. Conduct refuelling at least 100 m away from any watercourse or waterbody, when feasible.

18. Employ the following measures to reduce the risk of fuel spills in water. Where equipment refuelling is required within 100 m of a watercourse, ensure that:

All containers, hoses, nozzles are free of leaks;

All fuel nozzles are equipped with automatic shut-offs; and

Always have operators stationed at both ends of the hose during fuelling.

19. In the event of a release, refer to the Release Contingency Plan (Appendix 1E)

20. Do not wash equipment or machinery in watercourses or waterbodies.

21. Equipment to be used in or adjacent to a watercourse or waterbody will be clean or otherwise free of external grease, oil or other fluids, mud, soil and vegetation, prior to entering the waterbody.

Air Quality/Emissions 22. Reduce idling of equipment, where possible.

23. The Contractor will ensure equipment is well-maintained.

24. Where practical and applicable, use multi-passenger vehicles for the transport of crews to and from job sites.

Dust Control 25. Where traffic as a result of the Project creates a hazardous or irritating level of dust to nearby residents, dust control on existing access roads will be achieved through the application of calcium chloride (or equivalent) or water. Only water will be used for dust control on the right-of-way.

Noise 26. Ensure that noise abatement equipment on machinery is in good working order. Take reasonable measures to control construction related noise near residential areas.

Public Access 27. Discourage unauthorized public vehicle access along the right-of-way during construction through the use of signs.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 31

8.2 Clearing and Disposal

Introduction

The following measures will be implemented by the Company’s Contractor and subcontractor(s) during the clearing phase of pipeline construction.

Objective

The objectives of these mitigation measures are to:

restrict the Project Footprint to approved workspace;

limit the disturbance to vegetation (i.e., crops and native vegetation) to the extent practical; and

reduce surface disturbance to the extent practical.

Specific Measures

Activity/Concern Mitigation Measures

Clearing 1. Clear timber, stumps, brush and other vegetation within the marked right-of-way and temporary workspace boundaries. Clearing methods will take into account landowner/leaseholder requirements.

2. Remove off right-of-way trees that are a safety hazard during construction activity following notification to the Environmental Inspector(s).

3. Fell all trees damaged during clearing and construction immediately. A damaged tree is defined as one that has fractures or bark loss for 50% of its circumference.

4. Conduct clearing near watercourses or wetlands as described in Section 7.0 and 8.4 of this EPP.

5. During clearing, fell trees towards the right-of-way, wherever possible. Recover trees that inadvertently fall into adjacent undisturbed vegetation.

6. Avoid disturbance to environmentally sensitive features during clearing as identified by the appropriate signage and/or fencing. The Environmental Inspector(s) and appropriate Resource Specialist will determine the size of avoidance buffer surrounding these features, if appropriate.

7. Where practical, leave stumps in place, particularly on streambanks, to provide surface stability. Dispose of stumps removed from the required work areas by burning or chipping.

Known Archaeological Sites

8. Do not permit clearing in proximity to known archaeological sites unless otherwise approved by the responsible regulatory agency.

Rollback 9. Where segments of the right-of-way require rollback for access management or erosion control, ensure sufficient timber of appropriate size is available.

10. In consultation with the landowner(s) or appropriate regulatory agency, determine potential rollback locations, and material to be used.

11. Place rollback in a manner that does not create or enhance a fire hazard along the right-of-way.

TransCanada PipeLines Limited Environmental Protection Plan Vaughan Mainline Expansion Project October 2016

Page 32

Activity/Concern Mitigation Measures

Wet Terrain / Muskeg 12. Where non-frozen soils are encountered during construction, refer to the Wet Soils Contingency Plan (Appendix 1E). Install corduroy, subject to regulatory approval, wooden mats or equivalent in areas of wet soils to reduce terrain disturbance and soil structure damage. These materials will be removed during clean-up.

Merchantable/ Salvageable Timber

13. Salvage and deck timber in accordance with landowner requests.

14. Do not bulldoze salvageable timber.

15. Suspend timber skidding operations or implement alternative measures, if the potential exists for merchantable timber to be damaged through contact with wet or muddy soils.

Grubbing 16. Grub tree roots, where required, with a hoe and thumb or alternate equipment to preserve surface organic material.

17. Use a stump mulcher rather than grubbing on areas where stripping and grading is not necessary.