Engine Alt

-

Upload

ruban-vijaya-singh -

Category

Documents

-

view

220 -

download

0

Transcript of Engine Alt

-

8/12/2019 Engine Alt

1/27

-

8/12/2019 Engine Alt

2/27

Mechanical

AlternatorEngine

Energy

Chemical

Energy ofFuel

Electrical

Energy

A Block Diagram -Engine Alternator

-

8/12/2019 Engine Alt

3/27

An Installation

-

8/12/2019 Engine Alt

4/27

When the fuel ignites in the combustionchamber, energy in the form of heat andgases is generated. The rapid expansionof hot gases creates pressure in thecombustion chamber which pushes thepiston away. The reciprocating motion ofthe piston is converted in to the circular

motion by the engine crankshaft, which isconnected to the piston by the connectingrod.

Principle of operation of

Engine

-

8/12/2019 Engine Alt

5/27

-

8/12/2019 Engine Alt

6/27

ADMISSION STROKE

The piston draws fresh air into the

cylinder on its downward travel

through the open admission valve.With turbo charged engines the air is

first compressed by a blower and

admitted to the cylinder underincreased pressure.

-

8/12/2019 Engine Alt

7/27

COMPRESSION STROKE

On its upward travel the pistoncompress the fresh air in the cylinder

with the valves closed. Thetemperature of the fresh air is thusincreased to exceed the ignitiontemperature of the fuel. Shortly

before the piston reaches the topdead centre, fuel is injected into thecombustion space.

-

8/12/2019 Engine Alt

8/27

POWER STROKE

The fuel injected ignites in the hot air

and burns. The combustion causes a

high pressure which forces thepiston down. Resulting into

reciprocating movement of the shaft.

-

8/12/2019 Engine Alt

9/27

EXHAUST STROKE

The piston moving upward forces the

exhaust gas through the open

exhaust valve into the exhaust pipe.When the exhaust stroke is

terminated the exhaust valve close

and the admission valve opens for anew operation cycle.

-

8/12/2019 Engine Alt

10/27

SYSTEMS OF

AN ENGINE

-

8/12/2019 Engine Alt

11/27

LUBRICATION SYSTEM

The moving parts of the dieselengine are lubricated for their

optimum operation by thislubrication system. A dipstick in theoil sump serves to check the oillevel. The lub oil level and the

lubrication oil pressure have to bechecked for satisfactory performanceand long life of the engine.

-

8/12/2019 Engine Alt

12/27

FUEL SYSTEM

Depending on the position of the

fuel, the fuel is supplied to the

distributing pipe through fuel filtereither by natural head from an

elevated tank or by a fuel pump. Fuel

is supplied inside the cylinder byinjection nozzles.

-

8/12/2019 Engine Alt

13/27

AIR EXHAUST SYSTEM

For the combustion of fuel sufficient

quantity of the filtered air is taken in

the combustion chamber. After thecombustion the exhaust gases are

taken away from the engine through

suitable ducting or piping. This isknown as air exhaust system.

-

8/12/2019 Engine Alt

14/27

COOLING SYSTEM

Cooling System is essential for

cooling the engine body, and to act

as a heat exchanger for lubricatingoil. This can be either water-cooled

or air cooled.

-

8/12/2019 Engine Alt

15/27

STARTING SYSTEM

The Diesel Engine can be equippedwith the starting system i.e. with

an electric starter with a pinion,which engages with the fly wheel ofthe engine. The power to the electricstarter is provided by means of a

battery which is kept in chargedcondition by means of a dynamo orelectric rectifier.

-

8/12/2019 Engine Alt

16/27

ALTERNATOR

Alternator works on Faradays law ofElectromagnetic induction. There are tworequirements for the functioning of Alternator(1) Magnetic field& (2) Rotation. Magnetic fieldis produced by passing direct current throughthe field winding of the Alternator and rotationis achieved by means of coupling the alternator

from engine. The Automatic Voltage regulator(AVR) is provided in the alternator formaintaining the terminal voltage within theclose limits over wide operating condition.

-

8/12/2019 Engine Alt

17/27

-

8/12/2019 Engine Alt

18/27

INDICATIONS OF A HEALTHY

ENGINE Good Compression:

The temperature of the induced air whenentrapped and compressed in the

combustion chamber is about 540 deg Cto 560 deg C.

Good Combustion:

Fuel is sprayed in atomized form to ensure

proper ignition of the fuel. Burningtemperature is about 1425 deg C.

-

8/12/2019 Engine Alt

19/27

Clean exhaust:

The exhaust system is clean and

back pressure is with in permissiblelimits. The general condition of theEngine can be determined by the typeof smoke it emits. This can be said asThe pulse of the engine. Smokeshould be of brown colour (Barelyvisible haze). Any other colour of smokeindicates some problem in the engine.

-

8/12/2019 Engine Alt

20/27

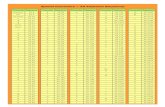

IMPORTANT MAINTENANCE CHECKS

FOR ENGINE ALTERNATOR SETDaily Check Engine oil level and leakage if any.

Check Radiator for water level and leakage if any.

Check fuel level.

Check that ventilation of the EA Room is proper.

Check oil pressure.

Check if lights and exhaust fan are working properly.

Check physically before start for loose connection/nut

bolt.

-

8/12/2019 Engine Alt

21/27

Weekly

Check Air filter.

Check fan belt, and its tension

-

8/12/2019 Engine Alt

22/27

Fortn ight ly Check Battery voltage, Terminals, Electrolyte

level (Top up if necessary) .

Check Specific Gravity of Electrolyte.

(After the above checks, start theEngine for No Load/Connected Load and testfor 10 m inutes the fo l lowing)

Check for any abnormal noise. Shut down theE/A immediately and cause be examined.

-

8/12/2019 Engine Alt

23/27

Check frequency, out put voltage, colourof exhaust etc.

Record various readings in the logbook.

-

8/12/2019 Engine Alt

24/27

Monthly Check for tightness of connections in

Engine and Control Panel.

Watering of earth pits and tightening ofconnections.

Check functioning of safety devices.

Check belt tensions.

Check battery charger.

Check for leakage of fuel line.

Check for leakage in exhaust pipes.

-

8/12/2019 Engine Alt

25/27

Half Yearly

Cleaning of bus bars chambers and

tightening of nut bolts.

Checking of protective devices

Earth testing and Meggering.

-

8/12/2019 Engine Alt

26/27

Yearly

Tighten all mounting, nut and bolt.

Clean and calibrate all injectors.

Check fuel pump calibration.

-

8/12/2019 Engine Alt

27/27