Encapsulation of crosslinked penicillin G acylase aggregates in lentikats: Evaluation of a novel...

-

Upload

lorena-wilson -

Category

Documents

-

view

212 -

download

0

Transcript of Encapsulation of crosslinked penicillin G acylase aggregates in lentikats: Evaluation of a novel...

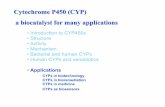

Encapsulation of Crosslinked Penicillin GAcylase Aggregates in Lentikats: Evaluationof a Novel Biocatalyst in Organic Media

Lorena Wilson,1 Andres Illanes,2 Benevides C. C. Pessela,2 Olga Abian,2

Roberto Fernandez-Lafuente,1 Jose M. Guisan1

1Departamento de Biocatalisis, Instituto de Catalisis,Campus UAMCantoblanco, 28049 Madrid, Spain; telephone: +34-91-585-4809;fax: +34-91-585-4760; e-mail: [email protected] of Biochemical Engineering, Universidad Catolica de Valparaıso,Valparaıso, Chile

Received 15 October 2003; accepted 13 January 2004

Published online 15 April 2004 in Wiley InterScience (www.interscience.wiley.com). DOI: 10.1002/bit.20107

Abstract: The encapsulation of crosslinked enzyme aggre-gates (CLEA) of penicillin G acylase into a very rigid poly-mericmatrix basedonpolyvinyl alcohol (LentiKats) hasbeenused successfully to improve the inadequate mechanicalproperties of CLEA. This encapsulation decreased CLEAactivity byonly around40%.Ascompensation, a significantimprovement in the stability of the CLEA in the presence oforganic solvents was detected. This could be related to thehighly hydrophilic environment inside the LentiKats bio-catalysts: Partition experiments showed that the concen-tration of dioxane inside LentiKats was lower than in thereaction medium. In fact, thermal stability was about thesame as in the corresponding CLEA. This permitted greatimprovement in the reaction rate for thermodynamicallycontrolled synthesis of a model antibiotic (using phenyl-acetic acid and 7-amino-deacetoxycefalosporanic acid).Even more importantly, yields could be improved by usingLentiKats-encapsulated CLEA, very likely by a favorableproduct/substrate partition. Thus, this very simple tech-nique not only provides an efficient technique for solving themechanical stability problemassociatedwithCLEA,but alsogreatly improves the behavior of CLEA in organic media.B 2004 Wiley Periodicals, Inc.

Keywords: LentiKats; entrapment; immobilization; poly-vinyl alcohol; hydrogel; crosslinked enzyme aggregates;penicillin acylase; enzymes in organic solvents

INTRODUCTION

One of the challenges of using enzymes for organic synthesis

is to produce biocatalysts that are strong enough to cope with

the harsh conditions of nonaqueous media, which are often

required for such reactions (Klibanov, 2001). Crosslinked

enzyme crystals (CLEC) (Noritomi et al., 1998) and cross-

linked enzyme aggregates (CLEA) (Broun, 1977; Cao et al.,

2003; Tyagi et al., 1999) have been found to be powerful

catalysts in organic media. The former have the drawback of

cost, mainly because very pure enzyme preparations are

required for the crystallization step.This is certainlynot so for

CLEA, where themain drawback is the difficulty in handling

and recovery of biocatalyst particles due to their low

mechanical resistance. Khare et al. (1991) tried to solve this

problem by aggregation of proteins inside polymeric beads

(i.e., Sephadex).

Lens-shaped polyvinyl alcohol (PVA) hydrogel particles

(LentiKats) are very promising as matrices for biocatalysis

because of their good mechanical properties and adequate

geometry in terms of mass transfer and ease of separation

(Jekel et al., 1998). LentiKats have been used successfully

for cell immobilization (Durieux et al., 2000; Lozinsky

and Plieva, 1998). However, enzymes are too small to be

retained effectively and therefore some kind of supra-

molecular coupling is required, such as complexation of

the enzyme with polyelectrolytes (Czichocki et al., 2001;

Groger et al, 2001). Use of CLEA is very promising for the

creation of a supramolecular protein structure, which is

explored in this work for the enzyme penicillin acylase.

Penicillin acylase (penicillin amidohydrolase, E.C.3.5.1.11)

is a remarkably versatile enzyme that not only catalyzes the

hydrolysis of h-lactam antibiotics, which is its present

industrial application (Bruggink et al., 1998; Parmar et al.,

2000), but also, under the proper reaction conditions, can

catalyze reverse reactions of syntheses to yield semi-

synthetic h-lactam antibiotics (Arroyo et al., 2003; Wegman

et al., 2001) and many other reactions of organic synthesis

(Basso et al., 2001; Ebert et al., 1996; Fernandez-Lafuente

et al, 1998; Fite et al., 1997; Illanes and Fajardo, 2001;

Rocchietti et al., 2002; Roche et al., 1999; Stambolieva et al.,

1998; van Langen et al., 2000).

Penicillin acylase in the form of CLEC is already in the

market, and CLEA of penicillin acylase have been produced

at the laboratory scale and tested for the synthesis of

h-lactam antibiotics (Cao et al., 2001). In this work, the

B 2004 Wiley Periodicals, Inc.

Correspondence to: R. Fernandez-Lafuente

Contract grant sponsors: Spanish CICYT; Program of International

Cooperation CSIC (Spain); CONICYT (Chile); AECI

Contract grant numbers: PPQ 2002-01231 A; COST 840

preparation of LentiKats from CLEA of penicillin acylase is

reported. This encapsulation may solve the problem

associated with the poor physical properties of the final

biocatalyst. Moreover, the stability of CLEA in organic

media can potentially be increased even further by creating

a more hydrophilic microenvironment surrounding the

enzyme, such as that provided by PVA within LentiKats.

This may promote a certain partition of the hydrophobic

organic solvent molecules away from the biocatalyst, in a

manner similar to when using polymeric hydrophilic

polymers (Abian et al., 2001).

MATERIALS AND METHODS

Materials

Soluble enzyme Penicillin G acylase (PGA-SE) from

Escherichia coli (with a purity of only 10%) and 7-amino-

deacetoxycephalosporanic acid were kindly provided by

Antibioticos SA (Leon, Spain). Sodium borohydride and

phenylacetic acid were from Sigma, and polyethylene-

glycol 600 (PEG) was from Merck. Glutaraldehyde solu-

tion was from Fluka. All other reagents were of analytical

grade. LentiKat Liquid and LentiKat Printer, used to

form identical lens-shaped LentiKats containing CLEA,

were from GeniaLab (Braunschweig, Germany). PGA

immobilization on glyoxyl-agarose (GA), was carried out

as previously described using an enzyme loading of

200 IUH/mL (Fernandez-Lafuente et al., 1998). Immobi-

lized PGA (Fluka) was also used (PGA-Fluka) under assay

conditions of 50 IUH/mL.

Assays

Enzyme activity of hydrolysis was determined using a

pH-stat (Model DL50, Mettler-Toledo) to titrate the H+

produced by the hydrolysis of 10 mM Penicillin G in 0.1 M

sodium phosphate (pH 8) at 25jC, using 50 mM NaOH as

titrant. One international unit of hydrolytic activity of PGA

(IUH) was defined as the amount of enzyme that could

hydrolyze 1 Amol of Penicillin G per minute under the

conditions just described.

Enzyme activity of synthesis was determined as the

initial rate of synthesis of deacetoxycephalosporin G

(DCG) at 4jC, from 12.5 mM 7-amino-deacetoxycephalo-

sporanic acid (7-ADCA) and 12.5 mM phenylacetic acid

(PAA), in a medium composed of 75% (v/v) dioxane and

25% (v/v) 100 mM phosphate buffer (pH 7.0). The reaction

mixture was gently stirred and samples were taken at

different timepoints; the mixture was then dissolved in 25%

(v/v) acetronitrile in 10 mM phosphate buffer (pH 3.0)

and residual substrates and product assayed by high-

performance liquid chromatography (HPLC). One interna-

tional unit of synthetic activity of PGA (IUS) was defined

as the amount of enzyme that synthesizes 1 Amol of DCG

per minute under the aforementioned conditions.

Protein was determined according to the method

described by Bradford (1976).

Preparation of Biocatalysts

CLEA

CLEA of penicillin acylase were prepared by adding 20 mL

of PEG to 10 mL of PGA solution (purity 10%) under

strong agitation. Glutaraldehyde (2 mL) was then added

to crosslink the enzyme precipitate. The reaction volume

was then duplicated by adding 100 mM sodium bicarbo-

nate solution (pH 10) and 60 mg of sodium borohydride.

After 15 min, 60 mg more of sodium borohydride was

added and, 15 min later, the CLEAs produced were washed

repeatedly with 100 mM sodium phosphate buffer (pH 7.0)

and centrifuged.

CLEA into LentiKats

LentiKats were produced according to the protocol from

GeniaLab (Lentikats Tips & Tricks, Braunschweig; Ger-

many), as reported previously (Jahnz et al., 2001).

Encapsulation of CLEA into Lentikats was done as pre-

viously reported (Wilson et al., 2002). LentiKat Liquid and

a suspension of wet CLEA were mixed at a mass ratio of

4:1. The mixture was then fed to the LentiKat Printer where

small droplets were dripped over a plastic dish and exposed

to drying and stabilization to produce the encapsulated

CLEA (CLEA-LK).

Stability of Biocatalysts

Stability in Organic Solvent

Dioxane was selected as a suitable cosolvent to study bio-

catalyst stability because it is highly polar and deleterious

for penicillin acylase (Abian et al., 2001). To determine

inactivation in the presence of the organic cosolvent, the

biocatalysts were washed and equilibrated at 4jC with

75% (v/v) dioxane in 100 mM phosphate buffer (pH 7.0).

Periodically, samples were withdrawn and the residual

activity of synthesis was determined. Experiments were

performed in triplicate.

Thermal Stability

To determine thermal inactivation of the biocatalysts, the

previously described procedure was followed; this time,

however, after equilibration in 100 mM phosphate buffer

(pH 8.0), the temperature was raised to 50jC and the residual

hydrolytic activity of each sample was determined. Results

were adequately represented by a first-order mechanism

of inactivation, which was used to determine biocatalyst

half-life from extrapolation of the experimental data (Illanes

et al., 1996). Experiments were performed in triplicate.

WILSON ET AL.: EVALUATION OF A NOVEL BIOCATALYST IN ORGANIC MEDIA 559

Mechanical Resistance of LentiKats

Structural integrity of CLEA-LK in aqueous and organic

media was tested by incubation at 20jC for 50 days under

agitation at 40 rpm in a rotary shaker (Selecta, Movil-Rod).

Twenty grams of CLEA-LK was suspended in 200 mL

of either aqueous (100 mM phosphate buffer, pH 7.0) or

organic (50% [v/v] dioxane in 100 mM phosphate buffer,

pH 7.0) media, in a flask with a diameter of 10 cm.

Samples were taken at different intervals and filtered

through a metallic mesh. Residual activity was

measured for CLEA-LK and the filtrate to determine the

released CLEA to the medium from the LentiKats.

Experiments were performed in triplicate. Shape and

weight of the ‘‘Lents’’ were also evaluated.

Synthesis of DGC

The reaction was conducted using a batch reactor thermo-

stated at 4jC, with 12.5 mM 7-ADCA and 12.5 mM PAA

in a medium composed of 75% (v/v) dioxane and 25% (v/v)

25 mM phosphate buffer (pH 7.0). DCG was determined by

HPLC. Experiments were performed in triplicate.

RESULTS AND DISCUSSION

Preparation of Biocatalysts

The activity of the CLEA was around 350 IUH/g, bearing in

mind that we used a nonpurified PGA preparation (only

10% purity). The low purity of the sample showed that: (i)

the aggregation did not require use of purified proteins; and

(ii) the presence of a large amount of other nonactive

proteins could reduce the diffusion limitations (and thus

reduce volumetric activity). In fact, a yield close to 70%

was achieved during preparation of the CLEA.

These CLEA were encapsulated in LentiKats (20% in

weight). The activity of CLEA-LK was >40 IUH/g (bearing

in mind that 80% of the mass was wet PVA). The activity

recovery after trapping the CLEA in the LentiKats was

around 60%. This decrease in activity could be promoted

by diffusion restrictions within the LentiKats, although

some enzyme inactivation during the drying or stabilizing

process may have occurred. In fact, some activity could

have been recovered if the CLEA-LK were broken into

smaller fragments.

Stability of Biocatalysts

Stability in Organic Solvent

The inactivation courses in the organic medium of CLEA-

LK PGA and the corresponding CLEA, along with other

PGA preparations, is shown in Figure 1A.

Stability was greatly enhanced by encapsulation of the

CLEA; that is, the half-life of CLEA was only 8.9 h,

whereas CLEA-LK remained fully active after 300 h of

incubation at this high dioxane concentration. The prepa-

ration from Fluka was much less stable than the CLEA

preparation, whereas soluble enzyme was readily inacti-

vated under these conditions. The enzyme immobilized on

glyoxyl agarose (a derivative very stabilized via multi-

point covalent attachment) exhibited a stability slightly

higher than that of CLEA, but it clearly had less stability

than CLEA-LK.

To determine whether the hydrophilic environment with-

in the LentiKats promoted cosolvent exclusion from the

enzyme microenvironment, the dioxane partition between

the external medium and the LentiKats was studied. Ten

grams of LentiKats with 80% moisture was placed in the

same amount of pure dioxane and left at room temperature

for 3 h under agitation. Samples were taken at the beginning

and at the end of the incubation period and the amount of

Figure 1. (A) Stability of different PGA preparations in the presence of

75% (v/v) dioxane and 25% (v/v) 100 mM phosphate buffer (pH 7) at 4jC.(B) Thermal inactivation at 50jC in 100 mM phosphate buffer (pH 8.0).

(.) CLEA, (o) CLEA-LK, (n) PGA-Fluka, (X) glyoxyl-agarose PGA,

and (E) soluble PGA.

560 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 86, NO. 5, JUNE 5, 2004

dioxane in the external medium was determined by HPLC.

The dioxane concentration in the external medium at the

end of the experiment was 71% (v/v), which is considerably

higher than the dioxane concentration under nonpartition

conditions (55%). Longer incubation times did not show a

change in these percentages. Thus, a clear partition effect

of dioxane from the LentiKats was demonstrated; this

lowering in the solvent concentration promoted high

stabilization of the PGA (Fernandez-Lafuente et al.,

1996). Therefore, CLEA-LK is a biocatalyst well-equipped

to perform at high cosolvent concentrations, which is rel-

evant for the enzymatic production of semisynthetic

h-lactam antibiotics.

Thermal Stability

Figure 1B shows similar thermal inactivation profiles for

CLEA and CLEA-LK, with no significant differences in

thermal stability. Thermal inactivation was adequately

described by a first-order mechanism of inactivation, and

the extrapolated values of half-life for CLEA and CLEA-LK

were 9.7 h and 8.7 h, respectively. The half-lives of these

biocatalysts were about the same (in fact, somewhat lower

for CLEA-LK). This result is not surprising because there is

no reason to believe that CLEA encapsulation would

contribute to stabilization of the enzyme structure.

In this case, CLEA and CLEA-LK proved considerably

less stable than the GA preparation, yet much more stable

than the Fluka preparation or soluble PGA.

These results suggest that the stability of CLEA-LK in

organic media is a consequence of the hydrophilic micro-

environment that surrounds the protein enzyme rather than

a conformational effect. In contrast, multipoint covalent

attachment in GA stabilized the conformation of the en-

zyme, making it more rigid and thus more thermostable.

Mechanical Resistance of LentiKats

CLEA-LK was incubated for 50 days at 20jC under

agitation in aqueous medium and in the presence of 50%

dioxane. No protein or enzyme activity was detected out-

side the LentiKats, meaning that no leakage occurred

during the prolonged incubation. Neither fracture nor alter-

ation in LentiKat shape was observed. The stability of

CLEA-LK after such prolonged incubation was very high,

with a residual hydrolytic activity of >95% in both media.

This behavior makes CLEA-LK a very promising bio-

catalyst for reactor operation.

Synthesis of DCG

Synthesis of DCG under thermodynamic control with

CLEA-LK and the corresponding CLEA is presented in

Figure 2. Although the initial rates were quite similar for

both preparations (using similar weight of CLEA in both

cases), the final yield was significantly higher in CLEA-LK

than in CLEA (55% and 43%, respectively). This is a

promising result, suggesting that conversion in thermody-

namically controlled synthesis can be modified as a

consequence of the partition effect provoked by the hydro-

philic environment within the LentiKats. This is done by

producing a favorable partition of substrates (more hydro-

philic) to the surrounding enzyme and product (more

hydrophobic) removal from the enzyme. A more compre-

hensive study of the effect of LentiKats on partition of

substrates and products in different organic medium is

underway.

The operational stability of CLEA-LK was assessed by

performing five successive batches of DCG production.

Full activity was recovered in the different reaction cycles

and identical yields were maintained.

CONCLUSIONS

Encapsulation of PGA CLEA in PVA hydrogels produced

LentiKats biocatalyst having greatly improved mechanical

properties with respect to fragile, nonencapsulated CLEA.

The hydrophilic environment of CLEA encapsulated into

LentiKats protected the enzyme from inactivation in or-

ganic media, but conferred no protection against heat

inactivation. These results are consistent with the proposed

mechanism of cosolvent exclusion from LentiKats particles,

which is further supported by the study on dioxane partition

between the external medium and the inside of the

LentiKats. This hydrophilic environment of LentiKats

favored the thermodynamically controlled synthesis

of deacetoxycephalosporin G in organic medium not

only by increasing synthesis rate, as expected, but also

increasing final equilibrium conversion, which could be

attributed to the favorable partition of the (more) hydrophilic

Figure 2. Synthesis of deacetoxycephalosporin G from 12.5 mM

7-ADCA and 12.5 mM PAA using different preparations of PGA at 4jCin a medium composed of 75% (v/v) dioxane and 25% 100 mM phosphate

buffer (pH 8.0). Two grams of CLEA (.) or 10 g CLEA-LK (o),

previously equilibrated with the reaction media, were mixed with 23 or

15 mL (respectively) of reaction media.

WILSON ET AL.: EVALUATION OF A NOVEL BIOCATALYST IN ORGANIC MEDIA 561

substrates into the enzyme hydrophilic environment

within the LentiKats and the (more) hydrophobic product

away from it.

The present results show that PGA CLEA LentiKats are

particularly suitable biocatalysts for the synthesis ofh-lactamantibiotics at high concentration of organic cosolvents,

conditions at which enzymes are usually unstable and poorly

active, although adequate for synthesis due to depressed

water activity and displacement of ionic equilibrium toward

nonionized reactive forms of substrates.

LentiKats, successfully used for cell immobilization, are

proposed as suitable matrices for the immobilization of

enzyme aggregates. Lower specific activities and eventual

diffusion restrictions are problems that remain to be solved

by optimizing enzyme immobilization procedures.

The authors thank Antibioticos SA (Leon, Spain) for the generous

supply of penicillin acylase. LentiKats Printer was kindly donated

by M. Schlieker and K.-D. Vorlop. We also thank Dr. A. Berenguer

for his valuable suggestions.

References

Abian O, Mateo C, Fernandez-Lorente G, Palomo J, Fernandez-Lafuente

R, Guisan J. 2001. Stabilization of immobilized enzymes against

water-soluble organic cosolvents and generation of hyperhydrophilic

microenvironments surrounding enzyme molecules. Biocatal Biotrans-

form 19:489–503.

Arroyo M, de la Mata I, Acebal C, Castillon M. 2003. Biotechnological

applications of penicillin acylases: State of the art. Appl Microbiol

Biotechnol 60:507–514.

Basso A, Biffi S, de Martin L, Gardossi L, Linda P. 2001. Quantitative

acylation of amino compounds catalysed by penicillin acylase in

organic solvent at controlled water activity. Croat Chem Acta 74:

757–762.

Bradford M. 1976. A rapid and sensitive method for the quantitation of

microgram quantities of protein utilizing the protein-dye binding. Anal

Biochem 72:248–254.

Broun G. 1977. Chemically aggregated enzymes. In: Mosbach K, editor.

Methods in enzymology. New York: Academic Press. p 263–269.

Bruggink A, Roos E, de Vroom E. 1998. Penicillin acylase in the industrial

production of h-lactam antibiotics. Org Proc Res Devel 2:128–133.

Cao L, van Langen F, van Rantwijk F, Sheldon R. 2001. Cross-linked

aggregates of penicillin acylase: Robust catalysts for the synthesis of

h-lactam antibiotics. J Mol Catal B Enzym 11:665–670.

Cao L, van Langen L, Sheldon R. 2003. Immobilised enzymes: Carrier-

bound or carrier-free?. Curr Opin Biotechnol 14:1–8.

Czichocki G, Dautzenberg H, Capan E, Vorlop K. 2001. New and effective

entrapment of polyelectrolyte – enzyme complexes in LentiKats.

Biotechnol Lett 23:1303–1307.

Durieux A, Nicolay X, Simon J. 2000. Continuous malolactic fermentation

by Oenococcus oeni entrapped in LentiKats. Biotechnol Lett 22:

1679–1684.

Ebert C, Gardossi L, Linda P. 1996. Control of enzyme hydration in

penicillin amidase catalyzed synthesis of amide bond. Tetrahedr Lett

37:9377–9380.

Fernandez-Lafuente R, Rosell C, Guisan J. 1998. Modulation of the

properties of penicillin G acylase by acyl donor substrates during N-

protection of amino compounds. EnzymeMicrob Technol 22:583–587.

Fernandez-Lafuente R, Rosell CM, Guisan JM. 1996. Dynamic reaction

design of enzymatic biotransformations in organic media: Equilibrium

controlled synthesis of antibiotics by penicillin G acylase. Biotechnol

Appl Biochem 24:139–143.

Fite M, Capellas M, Benaiges M, Caminal G, Clapes P, Alvaro G. 1997.

N-protection of amino acid derivatives catalyzed by immobilized

penicillin G acylase. Biocatal Biotransform 15:317–332.

Groger H, Capan E, Barthuber A, Vorlop KD. 2001. Asymmetric synthesis

of an (R)-cyanohydrin using enzymes entrapped in lens-shaped gels.

Org Lett 3:1969–1972.

Illanes A, Altamirano C, Zuniga M. 1996. Thermal inactivation of pen-

icillin acylase in the presence of substrate and products. Biotechnol

Bioeng 50:609–616.

Illanes A, Fajardo A. 2001. Kinetically controlled synthesis of ampicillin

with immobilized penicillin acylase in the presence of organic

cosolvents. J Mol Catal B Enzym 11:605–613.

Jahnz U, Wittlich P, Prusse U, Vorlop K-D. 2001. New matrices and

bioencapsulation processes. In: Hofman M, Thonart P, editors.

Engineering and manufacturing for biotechnology: Focus on bio-

technology. Dordrecht: Kluwer. p 293–307.

Jekel M, Buhr A, Willke T, Vorlop K. 1998. Immobilization of biocatalysts

in LentiKats. Chem Eng Technol 21:275–278.

Khare S, Vaidya S, Gupta M. 1991. Entrapment of proteins by aggregation

within Sephadex beads. Appl Biochem Biotechnol 27:205–216.

Klibanov A. 2001. Improving enzymes by using them in organic solvents.

Nature 409:241–246.

Klibanov A. 1997. Why are enzymes less active in organic solvents than in

water? Trends Biotechnol 15:97–101.

Lozinsky V, Plieva F. 1998. Polyvinilalcohol cryogels employed as

matrices for cell immobilization. 3. Overview of recent research and

developments. Enzyme Microb Technol 23:227–242.

Noritomi H, Koyama K, Kato S, Nagahama K. 1998. Increased thermo-

stability of cross-linked enzyme crystals of subtilisin in organic

solvents. Biotechnol Techniq 12:467–469.

Parmar A, Kumar H, Marwaha S, Kennedy J. 2000. Advances in enzymatic

transformation of penicillins to 6-aminopenicillanic acid. Biotechnol

Adv 18:289–301.

Rocchietti S, Urrutia A, Pregnolato M, Tagliani A, Guisan J, Fernandez-

Lafuente R, Terreni M. 2002. Influence of the derivative preparation

and substrate structure on the enantioselectivity of penicillin G

acylase. Enzyme Microb Technol 31:88–93.

Roche D, Prasad K, Repic O. 1999. Enantioselective acylation of h-aminoesters using penicillin G acylase in organic solvents. Tetrahedr

Lett 40:3665–3668.

Stambolieva N, Mincheva Z, Galunsky B. 1998. Kinetic comparison of

penicillin amidase transfer of nonspecific and specific acyl moieties to

7-ADCA. Biocatal Biotransform 16:225–232.

Tyagi R, Batra R, Gupta M. 1999. Amorphous enzyme aggregates:

Stability toward heat and aqueous–organic cosolvent mixtures.

Enzyme Microb Technol 24:348–354.

van Langen L, Oosthoek N, Guranda D, van Rantwijk F, Svedas V,

Sheldon R. 2000. Penicillin acylase catalyzed resolution of amines in

aqueous organic solvents. Tetrahedr Asymm 11:4593–4600.

Wegman M, Janssen M, van Rantwijk F, Sheldon R. 2001. Towards

biocatalytic synthesis of h-lactam antibiotics. Adv Synth Catal

343:559–576.

Wilson L, Illanes A, Abian O, Fernandez-Lafuente R, Guisan J. 2002.

Encapsulation of very soft cross-linked enzyme aggregates (CLEAs)

into very rigid LentiKats. FAL Agric Res 241:121–125.

562 BIOTECHNOLOGY AND BIOENGINEERING, VOL. 86, NO. 5, JUNE 5, 2004