EMM2512 Assignment

-

Upload

venkatesh-gangadhar -

Category

Documents

-

view

9 -

download

0

description

Transcript of EMM2512 Assignment

PT-2013 EMM2512

Form – 43 Ver: 3 Date: 20-04-2013

1

M.S.Ramaiah School of Advanced Studies - Bengaluru Postgraduate Engineering and Management Programme [PEMP]

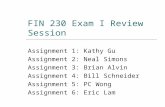

Department MME Course M.Sc.[Engg.] in Engineering and Manufacturing Management

Batch PT-2013 Module Start Date 22nd June 2013 Module Code EMM2512 Module Title Engineering Materials and Manufacturing

Processes Module Leader(s) Dr. N S Mahesh

Module Assessment Reg.No. Name of the Student

Component - 1: Assignment

Sect

ions

Marking Scheme

(The Module Leader is required to appropriately modify the contents of this table to suit the FT and PT assessment schemes appropriately)

Marks

Max

Mar

ks

ML

Mar

ks

Part

Tota

l

Rev

iew

er

Mar

ks

Part

- A

1.1 1) Introduction and stance taken 05

1.2 2) Discussion of Properties and performance of MMCs 07

1.3 3) Discussion about Manufacturability 04

1.4 4) Discussion about Cost and environmental issues. 05

1.5 5) Case studies or example to justify your stand 05

1.6 6) Conclusions 04 Part-A Max Marks 30

Part

- B

2.1 1) Selection of five components and its functions in wind mill 10

2.2 2) Description of properties requirements for each 10

2.3

3) Comment on materials used with justification 10

Part-B Max Marks 30

Part

- C

3.1

1. Selection of suitable material for rotor hub of a wind mill using CES (selection procedure+ CES screen shots with description)

05+08

3.2 2. Critical analysis of the characteristics of selected material

based on suitability to its application 07

3.3 3. Selection of suitable process for manufacturing rotor hub and

description of the same with process parameters 10

3.4 4. Analysis and justification for the selected processes 05

3.5 References and citation of references 03

3.6 Benefits you have derived by solving this assignment. Whether the assignment was able to assess module learning outcomes or not? 02

Part-C Max Marks 40

Total Marks 100 Remarks:

PT-2013 EMM2512

Form – 43 Ver: 3 Date: 20-04-2013

2

Component - 2: Examination Marking Scheme

(The Module Leader is required to appropriately modify the contents of this table to suit the FT and PT assessment schemes)

Marks Max

Marks ML

Marks Reviewer

Marks 1. Written examination [For FT courses only] [QNo. 1 – 4] N/A -- 2. ICA [For PT courses only] 30 ICA-1 10

ICA-2 10

ICA-3 10

3. Presentation [QNo. ] N/A -- Technical Content 05

Grasp and Explanation 05

Quality of Slides and Delivery 05

Q & A 05

4. Laboratory Exam / Tool Test / Report submission, etc. [Q.No.4 ] 20 Lab Test 15

Viva 05

5. Clay modeling / Video / any other assessment [Q.No. ] --

[Examination Maximum Marks for FT: 100 and for PT: 50] Total Marks 50

Module Result Components Assessor Reviewer Result

1. Assignment (Out of 50 Marks) Pass Fail

2. Examination (Out of 50 Marks ) Pass Fail

Total Marks (Max 100 ) Grade

A+ A A- B+ B B- C+ C FAIL F2 100-75 74-70 69-65 64-60 59-55 54-50 49-45 44-40 Less than 40

IMPORTANT

1. The assignment and examination total marks have to be rounded off to the nearest integer and entered in the respective fields 2. A minimum of 40% required for a pass in both components, i.e. assignment and written test individually

Signature of Module Leader Signature of Reviewer Please note:

1. Documental evidence for all the components/parts of the assessment such as the reports, presentation slides, posters, laboratory exam / tool tests are required to be attached to the assignment report in a proper order.

2. The marks for all the 3 parts of the assignment have to be written only in the Component -1: Assignment table given above.

3. The individual question marks have to be entered on the table of the Answer book for written exam and only the total marks are entered in Component-2: Examination table above.

4. The marks with break-ups for the other parts under Component-2: Examination have to be entered only in the table above.

5. The module leader has to submit the following to ARO after the review process: Assignment documents, Grade-sheet data file and PMARs.

6. The module leader is required to mark the comments in RED ink and the reviewer’s comments should be in Green ink.

PT-2013 EMM2512

Form – 43 Ver: 3 Date: 20-04-2013

3

Assignment

Instructions to students:

1. The assignment consists of THREE parts. 2. Part A: 30 marks, Part B: 30 marks, and Part C:40 marks 3. The assignment has to be neatly word processed as per the prescribed format. 4. The maximum number of pages should be restricted to 35. 5. Use only SI units. 6. Submission Date: 17-08-2013 7. Submission after the due date is not permitted. 8. Method of evaluation as per the submission and marking scheme 9. At the end, you are required to comment on -

a. Benefits you have derived by solving this assignment b. Whether assignment was able to access module learning outcomes or not?

10. IMPORTANT: It is essential that all the sources used in preparation of the assignment must be suitably referenced in the text.

Introduction:

Materials and processes have been the key issues for successful design, production and service of any product. It has become inevitable to carry out materials selection and process selection concurrently during the conceptual design itself. On the other hand newer materials have been flooding the materials library. Engineering materials have become engineered materials. We are living in an era of exotic materials which have been synthesized for advanced applications like aerospace. Moreover, there has been a paradigm shift in manufacturing methodologies which are now becoming materials oriented. In addition, advanced manufacturing processes have been developed to achieve commercially viable route for processing new age materials.

The current assignment has been set so that the students get a feel of the materials used in a

typical engineering environment. It is aimed at developing an understanding of interrelationship between material properties and manufacturing processes. The student should select candidate materials for particular applications, recognizing the relative merits and limitations of materials and also suggest appropriate manufacturing methods.

Part-A

Problem statement Many of our modern technologies require materials with unusual combination of properties that cannot be met by the conventional metal alloys, ceramics and polymeric materials. A metal matrix composite (MMC) is a macroscopic combination of two or more distinct materials, having a recognizable interface between them. MMCs are used not only for their better structural properties, but also for improved electrical, thermal and tribological properties. Modern Metal Matrix composites (MMCs) are usually optimized to achieve a particular balance of properties for a given range of applications. But these composites have economic, environmental and manufacturing issues. MMCs are costlier and difficult to recycle or dispose.

In this background a statement is made as “Metal Matrix Composites are designer’s choice for Engine parts” Debate on above statement. Support your opinion with examples, illustrations and case studies. Following points to be considered in this discussion

• Properties and performance of metal matrix composites • Manufacturability • Cost, environmental issues.

PT-2013 EMM2512

Form – 43 Ver: 3 Date: 20-04-2013

4

30 Marks

Part-B Problem statement

A wind mill is a machine that converts wind into usable energy through the rotation of a wheel made up of adjustable blades. The purpose of wind mill is to convert the energy of wind into rotational energy thus generating electricity. Today wind mill technology is experiencing a revival and wind energy promises to be an important alternative to fossil fuels in the future. Carry out Liturature survey and

1) Identify Important five parts (apart from rotor hub) of wind mill and its functions 2) List and analyze important material property requirement of these parts 3) Comment on materials used with justification

30 Marks

Part-C

Problem statement Selection of materials and manufacturing technique while designing the components is a challenging task. The selection of materials for any component must be made on the functionality of the component and also the manufacturing aspects including the joining of the parts in the final assembly. Cambridge Engineering Selector (CES) is a useful tool in selecting the materials and also their manufacturing processes. Wind turbine consists of rotor hub to which blades are attached externally. The rotor hub is provided for coupling blades and the rotor shaft. It is one of the critical parts of wind turbine. You are required to

1. Select a suitable material for rotor hub of a wind mill using CES 2. Critically analyse the characteristics of selected material based on suitability to its application 3. Select suitable process for rotor hub manufacturing (include primary and secondary

processes) 4. Critically analyse and justify the processes selected

CES screen shots are to be pasted as per relevance and a brief description should accompany each Figure for evaluation. 35 marks

Guidelines for Submission Citation of the references in the text is necessary in all the parts. Part B & C:

• Restrict your report for Part-B and C to a maximum of 12 and 20 pages respectively • Divide your discussions clearly as per the sections mentioned above and draw the conclusion

at the end of each section. • Please note: Marks will be awarded only to the sections and sub-sections clearly indicated

as per the problem statement.