LETTER FOR CHRIS FROM DON - cia.gov fileLETTER FOR CHRIS FROM DON - cia.gov

Email - From: Dyksterhouse, Don [don.dyksterhouse@pgnmail ...

Transcript of Email - From: Dyksterhouse, Don [don.dyksterhouse@pgnmail ...

_ _e

Sengupta, Abhijit

From:Sent:To:Subject:Attachments:

Dyksterhouse, Don [[email protected]]Wednesday, January 27, 2010 7:57 AMLake, LouisDesign Basis Calculations0102-0135-02 concrete strength and elastic modulus rO final.pdf; 0102-0135-03_rO0final.pdf;0102-0135-04 FE Model Description signed.pdf; 0102-0135-05 Conduit Local Stress Analysissigned (2).pdf; 0102-0135-07 concrete moment capacity load rO (2).pdf; 0102-0135-08seismic wind tornado rO.pdf

Lou,Sorry about that.

From: Dyksterhouse, DonSent: Saturday, January 23, 2010 3:34 PMTo: Thomas, George'Cc: Dyksterhouse, Don; Miller, GarrySubject: Design Basis Calculations

George,Please find attached the following calculations: For your information, the attached MPR signed calculations

have the number listed in the left column. The calculation numbers in the red are the Progress Energy Calculationnumbers. I expect the Tendon Detensioning Calculation to be approved early next week and will trans nit thecalculation to you after approval. -,

0101-0135-jlh-20101-0135-010101-0135-020101-0135-030101-0135-040101-0135-050101-0135-060101-0135-070102-0135-08Detensioned State

S09-0054 Radial Pressure at Hoop Tendons (provided on 1/8/10)S09-0055 Reinforcement Ratio and Effective Modulus of Elasticity (provided 1/8/10)S09-0056 Concrete Modulus of Elasticity and Minimum Compressive StrengthS10-0001 Tendon Tension CalculationS10-0002 Finite Element Model DescriptionS10-0003 Conduit Local Stress AnalysisS10-0004 Tendon Detensioning Calculation (not approved at this time)S10-0005 Bending/Tension Interaction Diagrams for Selected SectionsS10-0006 Seismic Wind, and Tornado Evaluation and Delamination Depth Evaluation for

From: Thomas, George [mailto: [email protected]]Sent: Friday, January 22, 2010 1:27 PMTo: Dyksterhouse, DonSubject: Design Basis Calculations

Hello Don,

Do you have any more Design Basis calculations ready for NRC review. If you do, please email them to me, orlet me know when they would be available.Thanks.

George ThomasCR-3 Containment Delamination SIT

1

PI-28

MPR Associates, Inc.

0MPR 320 King StreetAlexandria, VA 22314

CALCULATION TITLE PAGE

Client:

Progress Energy Page 1 of 30

Project: Task No.CR3 Containment Calculations

0102-0906-0135

Title: Calculation No.Interaction Diagrams for Selected Sections 0102-0135-07

Preparer / Date Checker / Date Reviewer & Approver / Date Rev. No.

J. L. Hibbard Chris Bagley D. Werder1-19-2010 1-19-2010 1-19-2010

QUALITY ASSURANCE DOCUMENTThis document has been prepared, checked, and reviewed/approved in accordance with the Quality Assurance

requirements of 1OCFR50 Appendix B, as specified in the MPR Quality Assurance Manual.

MPR-QA Form QA-3.1-1, Rev. 1

MPR Associates, Inc.

*M P R 320 King StreetAlexandria, VA 22314

RECORD OF REVISIONS

Calculation No. Prepared By Checked By Page: 2

0102-0135-07 . .. . C1&s')

Revision Affected Pages Description

0 All Initial Issue

Note: The revision number found on each individual page of the calculation carries the revision

level of the calculation in effect at the time that page was last revised.

MPR QA Form QA-3.1-2, Rev. 0

MPR Associates, Inc.0M P R 320 King Street

Alexandria, VA 22314

Calculation No. Prepared By Checked By Page: 3

0102-0135-07 .1 . Revision: 0

Table of Contents

1.0 Purpose ................................... ..................................................................... 4

2.0 Sum m ary ..................................................................................................... 4

3.0 Background ...................................................................................................... 5

4.0 Approach ..................................................................................................... 5

5.0 Assum ptions ...................................................................................................... 7

5.1 Unverified Assumptions ......................................................................................... 7

5.2 Other Assumptions ................................................................................................. 7

6.0 Calculation ....................................................................................................... 8

6 .1 D ata ............................................................................................................................... 8

6.2 Rebar Distance to Compression Face and Rebar Area ......................................... 13

6.3 Interaction Diagram Functions ............................................................................ 14

6.4 Interaction Diagrams for Sections ................................. 18

7.0 References ..................................................................................................... 30

MPR QA Form: QA-3.1-3, Rev. 0

Calculation No.:7AW M P R Prepared By: S .'. 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King Street Ch ckd/yAlexandria VA 22314 Checked By: Page No.: 4

1.0 PURPOSE

This calculation provides interaction diagrams for selected sections of the Crystal River Unit 3containment. These results will be used in subsequent calculations to determine the acceptability ofcontainment locations that have high stress. The sections were selected based on preliminary finiteelement model results.

2.0 SUMMARY

Interaction diagrams are calculated for selected sections of the Crystal River Unit 3 containment. Thefigure below shows the interaction diagram for all the sections. Individual interaction diagrams andnumerical results are in Section 6.4.

-Section 1-Section 2

m 0• o Section 3

- -- Section 4

* * @*Section 5

... - Section 6• 0 0 oSection 7

1000

6

.4

Notes:1. These results are applicable

to uniaxial bending andtension/compression.

2. See Section 6.4, Section 4 fora limitation on use of theSection 4 interaction diagram.

3. Section 6 applies betweenButtresses 1&2, 2&3, 4&5,and 5&6.

S 4. Section 7 applies betweenButtresses 3&4.

Failure

laI)jI . - _________________ -

- 1000 0 1000 2000

Moment (fi*kip/ft)

("Section" "Location" "Tension" "Rebar"

1

2

"Buttress"

"Buttress"

Td = 3 "Ring Girder"

4 "Ring Girder"

5 "Containment"

6 "Containment"

"Surface" "Orientation"

"OD" ".vertical"

"OD" "vertical"

" O D .... "h o o p "

"OD" "vertical"

"OD" "vertical"

"OD" ".vertical"

"OD" "vertical"

"Elevation"

I1(ft)Il

"93 to 103"

"230 to 250")

"250 to 256""250 to 256"

"230 to 250"

"93 to 103"

"93 to 103"7 "Under Eq. Hatch"

Calculation No.:7iM Prepared By: S . • 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King Street Checked By:Alexandria VA 22314 CekdB:Page No.: 5

3.0 BACKGROUND

A project is underway at Progress Energy's Crystal River Unit 3 site to replace the steam generators.As part of that project, an opening has been cut into the concrete containment above the equipmenthatch. As this opening was being cut, cracking in the concrete containment wall was identified. Thecrack is around the full periphery of the opening and is in the plane of the wall. The cracking is located atthe radius of the circumferential tensioning tendons, and is indicative of a delaminated condition.

4.0 APPROACH

This calculation develops interaction diagrams for selected sections of the Crystal River Unit 3containment. The approach used is that provided in Reference 4, which is a explicit approach consistentwith ACI criteria and methodology (Reference 1.2, Sections 10.2 and 10.3). A comparison ofrequirements from ACI 318-63 to those in a later edition of the code is provided on the following page.

This analysis evaluates the capacity of the containment concrete plus reinforcement without the effect ofprestressing forces. Prestress loads, deadweight load, and other loads can be evaluated with thecalculated interaction diagrams.

The approach in Reference 4 is based on application of axial load and bending to a column. Thisapproach is adapted to sections of interest in the Crystal River containment. The sections of interest canbe simplified to rectangular beams similar to a column. The loading on the beam is uniaxialtension/compression and bending. For example, the ring girder in the hoop direction is treated as astraight column with bending and tension/compression loads. Ultimate strength tensile loads andmoments are calculated per unit width of the beam. The width of the beam, b, is arbitrary and is selectedfor convenience in determining the reinforcement cross section area.

Reference 4, Equation 11-8b gives a limit on axial compression to account for accidental moments, suchas might occur in columns supporting a building. Since the results of this calculation are applied to thecontainment and to moments calculated with ANSYS there are no accidental moments. Accordingly,this limit is not included.

spColumn is commercial software for calculating interaction diagrams. spColumn was used to calculatean interaction diagram for Section 1, the buttress. The results of the calculation with spColumn and theresults below in Section 6.4 are nearly identical. This was done to confirm the calculation method.spColumn results are not included in this calculation because spColumn is not QA software.

Calculation No.:Prepared By: • . 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street Cc B: / 7/Alexandria VA 22314 Checked By: Page No.: 6

As stated above, the approach used in this calculation is consistent with a later edition of the ACI Code.Reference 4 does not specify the ACI 318 Code year used, but it is later than 2002 (Reference 4, p.492). For the purpose of a comparison, the 2005 edition of ACI 318 was used below.A comparison was made of the requirements in ACI 318-63 to ACI 318-2005. Results of thecomparison are as follows:

The following sections of ACI 318-63 and ACI 318-2005 are equivalent:

ACI 318-631503(c)1503(d)1503(f)1503(g)

1602(e)1604(a)

ACI 318-200510.2.310.2.410.2.610.2.7 (except that there is a lower limit of 0.65 for concrete with compressive

strengths greater than 8,000 psi, which is not a factor for this analysis)10.3.210.3.1

The reinforcing steel strain limits of ACI 318-2005 in 10.3.4 and 10.3.5 are not addressed in ACI318-63.

The capacity reduction factors in ACI 318-2005, 9.3.2 are equivalent to or more conservative than inACI 318-63, 1504.

Based on the above, it was concluded that the approach in this calculation is consistent with and suppliesresults at least as conservative as that in ACI 318-63.

Calculation No.:RIM P R Prepared By: • *_.-,• 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King Street Chce y 7/•Alexandria VA 22314 Checked By: Page No.: 7

5.0 ASSUMPTIONS

5.1 Unverified Assumptions

None.

5.2 Other Assumptions

1. It is assumed that the rebar cover depth for vertical rebar at the OD face of the ring girder(Ref. 2.3) is dovor = 2.25.in . This is a reasonable assumption because the same rebar cover

depth is used at other locations as shown on Reference 2.2.

IMPRMPR Associates, Inc.320 King StreetAlexandria VA 22314

Calculation No.:Prepared By: ,L,, • 0102-0135-07

Cheke ByRevision No.: 0Checked By: EPage No.: 8

6.0 CALCULATION

6.1 Data

This calculation determines the moment capacity of the concrete at the locations specified in the followingtable. Data for the calculation is input into arrays that contain entries, each of which corresponds to theSection number in the table below.

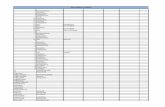

"Section" "Location" "Tension" "Rebar" "Elevation"

"M Surface" "Orientation" "Y(f)"

1 "Buttress" "OD" "vertical" "93 to 103"

2 "Buttress" "OD" ".vertical" "230 to 250"

Td := 3 "Ring Girder" "OD" "hoop" "250 to 256"

4 "Ring Girder" "OD" "vertical" "250 to 256"

5 "Containment" "OD" "vertical" "230 to 250"

6 "Containment" "OD" . " vertical" "93 to 103"

7 "Under Eq. Hatch" "OD" "vertical" "93 to 103"

tcont =- 42 in

tb =-tont + (2. ft + 4. in)

trg - 6nt + (2. ft + 4. in)

R., 65.ft + 0.375.in + 42.in

Ro.rg= Re.,+ (2.ft + 4.in)

fy := 40ksi

fc':= 5000.psi

tb =70.in

trg 70.in

Ro., = 68.53 ft

Ro.rg n

Containment wall thickness; Ref. 2.1

Buttress thickness; Ref. 2.1

Ring girderthickness at approximately the 250 ftelevation; Ref. 2.1

Outside radius of containment; Ref. 2.1

Outside radius of ring girder; Ref. 2.1

Rebar minimum yield strength; Ref. 3 Section 5.2.2

Concrete specified compressive strength; Ref. 7, p. 2

Calculation No.:PN M Prepared By: * ,'_,. , 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King Street Cheicked/ByAlexandria VA 22314 Checked By: Page No.: 9

Standard rebar diameters from Reference 5, Table 12.3.1 are (rebar diameter is in inches):

Odrebar '=34

5

6

7

8

9

10

11

14

18

0.3750.5

0.625

0.75

0.875

1

1.128

1.27

1.41

1.693

2.257

Define a function to return rebar diameter.

dr(n) := vlookup(n,fOdrebar,2)1.in

For example,

dr(18) = 2.257.in

tc b=

b :=

70

70

70

70

42

42

K42,

in bOc =

12.ft

12.ft

(255.ft + 10.5 .in) - (250.f

30.deg.Ro.rg

(11 + 15 ÷ 60).deg.Ro.,

48.in

144. in

"Buttress"

"Buttress"

"Ring Girder"

"Ring Girder"

"Containment"

"Containment"

"Under Eq. Hatch"

")

"Buttress"

"Buttress"

"Ring Girder"

"Ring Girder"

"Containment"

"Containment"

"Under Eq. Hatch"

Concrete thickness-Ref. 2.1-Ref. 2.1-Ref. 2.1; conservative thickness-Ref. 2.1; conservative thickness-Ref. 2.1-Ref. 2.1; conservative thickness for Elev. = 93 ft-Ref. 2.1

Width of section considered (see discussion inSection 4); this is an arbitrary dimension, butreferences are provided to show the dimension-Ref. 2.1-Ref. 2.1-Ref. 2.1-Ref. 2.3, 00 to 3300-Ref. 2.2, Section 2-2, 11 *-15' section-Ref. 2.2, this width was chosen to give an integernumber of rebar for each layer

-Ref. 2.2, this width was chosen to give an integernumber of rebar for each layer

144

144

70.5

445.26

161.47

48

144

-in Ioc =

Calculation No.:Prepared By: A- *._. . 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street Checked By:Alexandria VA 22314 Checked By Page No.: 10

There are several layers of rebar through the depth of the sections. The data for the layers is input with 1by x arrays below, with x being the number of layers. For example, the first entry in the array below is a1 x 3 array with the three entries corresponding to the three layers of rebar in the buttress (one layer of#11 at the OD face and two layers of #18 near the ID face).

(dr(11) dr(18) dr(18))

(dr(11) dr(18))

(dr(9) dr(9) dr(9) dr(9))

odr:= (dr(9) dr(9) dr(11) dr(11) dr(18))

Re bar diameter-Ref. 2.2, Section 1-1 and Ref. 2.5, Section 1-1-Ref. 2.2, Sections 2-2 and 3-3-Ref. 2.3, Section 1-1-Ref. 2.3, Section 1-1-Ref. 2.2, Section 3-3-Ref. 2.2, Section 3-3 and Ref. 2.5, Section 1-1-Ref. 2.2, Section 3-3, Ref. 2.5, Section 1-1, and Ref.2.4

(dr(18) dr(18) )

(dr(11) dr(18) dr(18))

(dr(11) dr(18) dr(18))

(1.41 2.257 2.257)

(1.41 2.257)

(1.128 1.128 1.128 1.128)

"Buttress"

"Buttress"

"Ring Girder"

"Ring Girder"

"Containment"

"Containment"

odr= (1.128 1.128 1.41 1.41 2.257) Iin bOc =

(2.257 2.257)

(1.41 2.257 2.257)

(1.41 2.257 2.257) ý"Under Eq. Hatch"j

nr :=I

(12 8 16)

(12 13)

(5 2 2 8)

(59 59 33 33 59)

(11 17)

(4 3 6)

(16 9 18)

bOc =

"Buttress"

"Buttress"

"Ring Girder"

"Ring Girder"

"Containment"

"Containment"

"Under Eq. Hatch"

Number of rebar in section width, b-Ref. 2.2, Section 1-1-Ref. 2.2, Sections 2-2 and 3-3, and Ref. 2.6-Ref. 2.3, Section 1-1 (there are four rebar inthe angle section of which two are creditedand assumed to align with the above rebarfor ease of calculation)

-Ref. 2.3, 00 to 3300 with spacing at mid-bayused over buttress for Layer 1

-Ref. 2.2, Section 2-2-Ref. 2.2, Section 1-1-Ref. 2.2, Section 1-1, Ref. 2.5, Section 1-1,and Ref. 2.4

dcover =- 2.25.in

a:= atan(2-52

Cover depth for OD face rebar; Ref. 2.2, Sections 1-1and 3-3

Angle with respect to vertical of ID face rebar at aboutElevation 93 feet; Ref. 2.5, Section 1-1a= 15.15.deg

MR ,Calculation No.:& IM P R Prepared By: A .-- --- 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King Street cke B:7/,Alexandria VA 22314 Checked By: Page No.: 11

Radial distance of rebar layer from OD face-Ref. 2.2, Section 1-1 and Ref. 2.5, Section 1-1-Ref. 2.2, Sections 1-1, 2-2, and 3-3-Ref. 2.3, Section 1-1, scaling for Layers 2 and 3, and Assumption 5.2.1-Ref. 2.3, Section 1-1, scaling for Layers 2, 3, and 4, and Assumption 5.2.1-Ref. 2.2, Section 3-3-Ref. 2.2, Section 3-3 and Ref. 2.5 Section 1-1-Ref. 2.2, Section 3-3, Ref. 2.5, Section 1-1, and Ref. 2.4

rr:=

dcover + 1.5-dr(11) 70.375.in - (7.5 + 2.5).in n0.37.5. 5in

_ cos(a) cos(a)

[dcover + 1.5.dr(11) 70.in - (7.in + dr(11) + 0.5.dr(18))]

[dcover + 0.5.dr(9) 12.5.in 22.in (70- 8.25).in- 0.5.dr(18) - 0.5.dr(9)]

[dcover+1.5.dr(9) 35in 47.in 51in (70-8.25).in]

[dcover + dr(11) + 0.5.dr(18) 42.in - (7.in + dr(11) + 0.5.dr(18))]

S(7.5 + 2.5).in 7.5.-in1

L4.25in 42.375.in- cos(a) 42.375.in cos(a)

[425-i1 42.375*in- (7.5+ 2.5).in 7 7.5.in

4I cos(a) cos(a)

I(4.365 60.015 62.605)

(4.365 60.462 )

rr =

(2.814 12.5 22 60.057)

(3.942 35 47 51 61.75)

(4.788 32.462 )

(4.25 32.015 34.605)

(4.25 32.015 34.605)

-in bOc =

"Buttress"

"Buttress"

"Ring Girder"

"Ring Girder"

"Containment"

"Containment"

K"Under Eq. Hatch")

Calculation No.:• Prepared By: Ž *_. . L sQ. .-.,9 . 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King StreetAlexandria VA 22314 Checked By: Page No.: 12

Misc.

ec:= 0.003 Concrete compressive strain limit; Ref. 4, Page 496

Steel modulus of elasticity; Ref. 1.1, Section 1100ES.:= 29.106.psi

0.65 if -0.002 < £s <_0.003

2500.65+ - 0.002).- if -0.005 < e, -0.002

0.9 if es _-0.005

S 0.8..... .... .... ...

" 0.7

0.6'

Capacity reduction factor; Ref. 4, Table 11-1

The sign convention in this calculation ispositive is compressive and negative istensile, consistent with the sign convention inReference 4.

0.8 -0.6 -0.4 -0.2 0 0.2 0.4

Steel Strain (%)

Calculation No.:Prepared By: • .- . 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street CheckAedByAlexandria VA 22314 Checked By Page No.: 13

6.2 Rebar Distance to Compression Face and Rebar Area

The radial distance of the rebar layer center to the extreme compression fiber is:

d :=( - rr

(65.635 9.985 7395)

(65.635 9.538)

(67186 57.5 48 9.943)

(66.058 35 23 19 8.25)

(37212 9.538)

(37.75 9.985 7395)

(37.75 9.985 7395)

-in Rebar center to extremecompression fiber

The area of rebar in each layer is:

A,. := [nri'[ '(Odr.)2]

(18.74 32.01 64.01)

(18.74 5201 )

(5 2 2 799)

(58.96 58.96 51.53 51.53

(44.01 68.01 )

(6.25 12 24.01)

(24.98 36.01 72.02)

?36. 05) .in2 Re bar area

1M P R Calculation No.:1,vA Prepared By: A- -'.. , 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street CheckedAlexandria VA 22314 By.kedBy:Page No.: 14

6.3 Interaction Diagram Functions

The interaction diagram is calculated with the approach in Reference 4. In Reference 4 and in thiscalculation, compressive strain, compressive load, and compressive stress are positive.

The concrete compressive strain limit is:

= 0.003

The reinforcement strain at yield strength is:

= yS5 : .

e/= 0.1379.%

The distance from the compression face to the neutral axis is a function of arbitrary parameter Z.

d1C

(Z ) E -Y(iRef. 4, Equation 11-9

The strain in the reinforcement is:

c(Z,' - (di) lj.Es(Z,i,j) :"Co

c (Z, 1

The stress in the reinforcement is:

fs(Z,i,j):= *-Es-es(Z,ij)

-fy if f, < -fyIi y if f, > fy

Ref. 4, Equation 11-10

Ref. 4, Equation 11-11

The factor P1 used to calculate the size of the stress block is:

,31 := 0.85 if fc <-4000.psi

fc,- 4000.psi0.85 - 0.05. if 4000.psi < f. <- 8000.psi

1 000 .psi0.65 if f0. > 8000.psi

Ref. 4, Equation 4-14a, b, and c

01 = 0.8

Calculation No.:P re p a red B y : * .L .. bo.-i,- 0 10 2-0 135-07

MPR Associates, Inc. Revision No.: 0320 King Street Checked ByAlexandria VA 22314 Cek ByPage No.: 15

The depth of the concrete stress block is:

a(Z,i) /,31-C(Z,f)Ref. 4, Paragraph below Equation 11-11, andFigure 11-14(c)

The compressive force in the concrete per unit width is:

Cc(ZJ):= 0.85-fc-a(Zi) Ref. 4, Equation 11-12

The force in the reinforcement per unit width is:1

Fs(Z,i,j): -. fs(Z,i,j).(As)' if a(Z,i)bi - 0j

(fs(Z, i,j ) - O.85"fc')'(A.ijj

(d')l,j

otherwise

Ref. 4, Equations 11-13a and 11-13b

The axial load capacity per unit width of the beam including the capacity reduction factor is providedbelow. Reference 4, Eq. 11-8b gives a limit on the axial compression to account for accidentalmoments. Since the results of this calculation are applied to the containment and to moments calculatedwith ANSYS there are no accidental moments. Accordingly, this limit is not included.

cols( di)

P,,(Z,I): q5(eS(Z~i,1)) .rC,(Z,i) + FZ~~ Ref. 4, Equation 11-14

The moment capacity per unit width of the beam including the capacity reduction factor is:

Mn(Z,I)= tAeZi1)rc(Z' i){ - a(Zi)~ +

cols( d1) IZ [Fs(Zl i~I) L [2 - (di)1 J'j

j =

Ref. 4, Equation11-15a

The pure axial tension capacity including the capacity reduction factor is:

Pnt(Z, i) -(E, (Ii,1 1)) cols(d,)j=l

Ref. 4, Equation 11-16

Calculation No.:Prepared By: S 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street ChceAlexandria VA 22314 Checked By: Page No.: 16

The unbalanced moment for pure axial tension is calculated based on the discussion in Reference4, the paragraphs above and below Equation 11-16. The concrete section is cracked completelythrough. Equation 11-15a from Reference 4 is modified to account for the steel only and to use asteel stress of minus yield strength (-ty) in the tension layer.

1 col•d,) [ Ft0. 1]gnt(l) := b-I . ] cofY'(ASi)l,j'J .'c - (di),,

j =I

Define a function to calculate the value Z for the case of pure bending, i.e., the tension is 0.

Zbend(•) Zg - -10

Iroot(Pn (zg, i), zg)

Define a function to calculate the values of Z for the case of pure bending and pure tension. The value ofZ for the case of pure tension is arbitrary since the interaction curve between these two cases will bedetermined from linear interpolation.

ZS(I := Zb <- Zbend(i)

Zb Zb -2)

Calculation No.:Prepared By: • *_.. , 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street Checked By: Page No.: 17Alexandria VA 22314 'PgNo:1

The interaction diagram in the tension region is approximately linear as shown in Reference 4, Figure11-18. The interaction diagram will be calculated with a linear interpolation in the tension region of theinteraction diagram. This is a conervative approach.

Define functions to calculate the axial load capacity and the moment capacity.

Pn 2 (Z,i):= Ze -- ZS(I)

Pn(Z,') if Z>Ze

linterpfz:2j I' ,1 i) , 7] otherwise

Mn2 (Z,I):= Ze--zS(i)

Mn(Z,i) if Z>Ze

linterp rz 2, ,"rZ otherwiseE' Il gn(zel '

Calculation No.:7dMPRPrepared By: * A.- . 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street e&b 7,Alexandria VA 22314 Checked By: Page No.: 18

6.4 Interaction Diagrams for Sections

Section i:= 1L !i Section"

"Location" "Tension"

I'l "Surface"

"Buttress" "OD"

"Rebar"

"Orientation"

"vertical"

"Elevation" >"(ft)"

"93 to 103"

9/I/1(}

1500

1000

500

0

-500

7 IIt[t)

-•1000- 500 0 500 1000 1500 2000 2500 3000

Moment (ft*kip/ft)

Calculation No.:AW M PR Prepared By: S . 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King Street Checked/ByAlexandria VA 22314 Checked By: Page No.: 19

"Z " "P.nt"I'll. "kip/if'

"M.n"

"'kip"

I'l

"iFs"

"kip/ft"

I'll

"C. c"

"kip/ft"I'l

"in"

Tchk () =

(00 1926.6 1683 95.35

1.190.71,

-31.23'

-0.5 1580.9 2076.5 95.35

Y190.71)

-62.46

-1 13377 2208.7 95.35

Y.190. 71 )

(-62.46

-3 11173 2521.5 95.35

.190.71)

-62.46

-20.69 0 387.1 -106.69

-85.59

(-62.46

-22.69 -344.3 -553.8 -106.69

-

2677.9 52.51

21774 42.69

1834.5 35.97

1125.5 22.07

If 111

0

40

40,

40

40S40)40

40

40

40

"e.s"

0

0.25

0.27)L-0.07'0.24

0.26 )-0.14)

0.23

0.25 )-0.410.19

0.22 J

"in"

65.64

53.37

44.96

27.59

6.24

5.74

1" -40 -28254.7 4.99 -40 -0.18

-16.05 ) -0.06,

40 (-3.13234.3 4.59 -40 -0.6 2

-25.06 : -0-09)

Notes:1.

2.

3.

Positive P, are compressive forces.

Positive M, are compressive at the ID face.

Entries that are arrays provide results for each of the layers of reinforcement. Thefirst entry in the array is for the layer nearest the OD, the second for the secondlayer, and so on.

IMPRMPR Associates, Inc.320 King StreetAlexandria VA 22314

Calculation No.:Prepared By: S _. k 0102-0135-07

Revision No.: 0Checked By: (E /4J•7/A/ Page No.: 20

Section i:= 2 L(O=L 2'

"Buttress"

"Tension" "Rebar" "Elevation"

"Surface" "Orientation" ".(ft)"

"OD" "vertical" "230 to 250"

I~nnJ~

1506

1006

506

6

- 1000- 500 0 500 1000 1500 2000 2500

Moment (ft*kip/fit)

Tchk () =

liZIt

0

-0.5

-1

-3

-22.52

-24.52

",P.n"

"kip/ftl"

1841.4

1495.7

1252.5

1008.7

0

-212.2

"Mn"

1482.3

1875.8

2008.1

2265.8

390.6

-208.4

"F.s"

"kipftl"

15 4.9 5 )

5-31.23)

154.95)

-62.46

154.95)

-62.46)

(154.95)C-62. 46-173.37)

-62.46

-173.37)

IC.cc

"kip/ft"

2677.9

2177.4

1834.5

1125.5

235.8

218.2

"a"

"in"

52.51

42.69

35.97

22.07

4.62

4.28

"ksi"

0°)4C20D40

C -2040

40

(40

ý-40

(-40

"~e.s"I

C.-0.07(0.25)C-0. 14(0.24)C-0. 41

0.26

-3.11)

C-0.2)-3.38

-0.24)

"in"

65.64

53.37

44.96

27.59

5.78

5.35

Calculation No.:Olk M P R Prepared By: -ý A- - 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street ed eAlexandria VA 22314 Checked By: Page No.: 21

Section i:= 3

2000

1500

1000

L~500

""Section"

3

"Location" "Tension" "Rebar"

.... ."Surface" "Orientation"

"Ring Girder" "OD" "hoop"

"Elevation"

"2(ft)"

"1250 to 256")

2500

Moment (ft*kip/ft)

Calculation No.:

Prepared By: S *_. . 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King Street ,J6.4)"'Alexandria VA 22314 Checked By: Page No.: 22

1711 IIP.n"

I'll Xiplftlf

I'll "it

"Est,

"kiplft"

III,

"C.¢"~

"kip/ft"

III

"a"

Tchk (i) =

(0

4.270 1820.7 1262.4 I I

7.01

.48.65),

-17.01

-1.56-0.5 1470.6 1682.5 | 3

3.59

K 48.65

(-34.02

-7.38-1 1224.5 1822.7 -12

-1.27

K 48.65

(-34.02'

-13.61-3 943.7 2077.8 -1 I

-13.61

K 48.65 )(-34.02'

-13.619.37 0 309.8 _13 I-13.61

,-54.43)

(-34.02

-13.611.37 -104.1 178 -16

-13.61

K-54.43)

2741.2 53.75

2228.8 43.7

1877.8 36.82

1152.1 22.59

115.7 2.27

111.3 2.18

0

12.54

24.84

40 )L-20-4.57

10.56

40)

-40L-21.69-3.73

40)

"-40'L-40-40

,40)L-40,-40

-40

-40)L-40-40

-40

-40)

Ie.sl

0

0.04

0.09

,.0.26)L-0.07-0.02

0.04

0.25 )-0.14

-0.07

-0.01

0.24 )-0.41

-0.31

-0.21

0.19L-6.81-5.78

-4.78

-0.75)

-7.09

-6.02

-4.98

-0.79

"C"

"in"

6719

54.63

46.03

28.24

2.83

2.73

-4

-5

Calculation No.:Prepared By: 'ý A\-. •-4boa-- 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street Cekdya &Alexandria VA 22314 Checked By Page No.: 23

Section i:= 4 "Section"L(J) toll

4

"Location" "Tension"

I'll "Surface"

"Ring Girder" "OD"

"Rebar"

"Orientation"

"vertical"

"Elevation"

"250 to 256"

zUUU•

150t

1006

506

6

- 506

............... ..........

................................. ................. ............................

- 1000- 500 0 500 1000 1500 2000 2500 3000

Moment (ft*kip/ft)

Note:The rebar configuration shown in Section 1-1 of Reference 2.3 was used tocalculate the interaction diagram for the ring girdervertical rebar in thiscalculation. As shown in Section 1-1 of Reference 2.3, there is no verticalrebar at the OD face of the ring girder that spans the construction joint atElevation 255 ft -10.5 in. This above interaction diagram does not applyabove above the construction joint at Elevation 255 ft - 10.5".

Calculation No.:M M P R Prepared By: • *-. . 0102-0135-07MPR Associates, Inc. Revision No.: 0"320 King Street C e dB /lAlexandria VA 22314 Checked By: Page No.: 24

IIZI1 "Ent'

"It "kiplft"

fill I'll

WWI"

"kip"

Tchk () =

0 2001.2 1656.9

-0.5 1643 2062.6

-1 13871 2201.8

-3 1087.8 2476.8

-17.24 0 629.1

-19.24 -443.4 -532.4

"kipift"

0

5681

49.65

49.65

\22743

-31.78

41.41

49.65

49.65

122743J

-63.56

24.57

49.65

49.65

,227.43

-63.56

-36.03

20.73

32.23

,22743)

-63.56'

-63.56

-55.55

-55.55

,-63.66)

-63.56

-63.56

-55.55

-55.55

-12722

"kipIft"I'll

2695.2 52.85

2191.4 42.97

1846.3 36.2

1132.8 22.21

301.9 5.92

,273.7 5.37

0

40

40

40

,40J

-20

30.31

40

40

40

-40

19.71

40

40

40

-40

-22.68

14.93

2746

40

-40

-40

-40

-40

,-10.01

-40

-40

-40

-40

,-20)

"in"

0

0.14

0.2

0.21

(0.26

-0.07,

0.1

0.17

0.19

,0.25

-0.14

0.07

0.15

0.17

(0.25

-0.41

-0.08

0.05

0.09

0.21

-2.38

-1.12

-0.63

-0.47

-0.03,

-2.65

-1.27

-0.73

-0.55

-0.07)

66.06

53.71

45.25

27.76

74

6.71

C.

"in"

Calculation No.:7 Prepared By: • 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King Street Checked B,Alexandria VA 22314 C Page No.: 25

Section i:= 5 "Section"

"Location"

"Containment"

I JtU.

1006

0

506

"Tension"

"Surface"

"OD"

"ksi"

III,

"Rebar"

"Orientation"

"vertical"

"Elevation"II (ft)II

6

.1U)-500 0 500

Moment (ft *kip/fi)

"Z7. "P.n"

I'll V'kip/lft

,I'l I'll

"Mn"

"tki"

"iFs"

"Xip/ft"I'll

"IC.cI"

"W•p/ft"' Ila"'in"l

I'l

Tchk () =

0 1104.3 615.1 (180.7)

-0.5 877.3 764.6 -1 5.47 )

(-130.82

-1 708.5 835.7 130.7 I

K180.7)C -130.82-3 544.4 914.4 130.82)

(150.07)(-130.82

-9.33 0 416.3 -1 56.3

K-156.3)(9-130.82)-11.33 -299.7 -16.4 I.221

1518.2 29.77 I00K0 40)

1234.4 24.2 (-204

1040 20.39 (4040

638.1 12.51 -40

K33.94)

287.1 5.63 (-0.

K -30.92)

244.6 4.8 -0

"le.s",

C 0.072)

0.21 )-0.14

0.19)

-0.41)

0.12 )

-1.56(-O0.18

"'in''

mll

37.21

30.26

25.49

15.64

7.04

5.99

Calculation No.:Prepared By: ' 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street edBy:Alexandria VA 22314 Checked By: Page No.: 26

Section i:= 6

cation" "Tension"

lilt "Surface"

ainment" "OD"

"Rebar"

"Orientation"

"vertical"

"Elevation"

"9(ft)1"

"93 to 103"16 "Conti

I JUU

1000

0

500

0

- JLUL-500 0 500 1000 1500

Moment (ft*kip/ft)

Calculation No.:Prepared By: • . , 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King StreetAlexandria VA 22314 Checked By: Page No.: 27

"Z71 "Pn"IM. ."kip/if'

I'll IMw

"M. n"

"kip"

" F.s""VP/ff"

III,

Tchk (1) =

(0

0 1210.3 714.3 107.27

,214.55)

-31.23

-0.5 1002.9 842.1 107.27

,214.55)

-62.46

-1 854.4 887.8 107.27

t,214.55

(-62.46

-3 731.6 992.1 84.01

p214.55)

(-62.46

-10.62 0 260.3 -120.03

-79.41

-62.46

-12.62 -380.3 -295.1 -120.03

Y,-173.46)•

"Cc" "a" "f.s"

"kiplft" "into "ksi"

(0

1540.2 30.2 40

,40,

(-20o

1252.3 24.56 40

40

-40

1055.1 20.69 40

40

(-40

647.3 12.69 32.25

40 )

"e.s"

L0 N0.22

0.24)(-0.07 N0.2

0.23)L-0.14 N0.18

0.21)

-0.41 NL0.16)

ICl

"in"

37.75

30.69

25.86

15.87

6.42

5.55

1-40 146261.9 5.14 -40 -0.17

,-13.23, -0.05

226.5 4.44 -40 -0.24

\-28.9 k,-0.1 )

Calculation No.:O M P R Prepared By: S .- - 0102-0135-07

MPR Associates, Inc. Revision No.: 03 2 0 K in g S tre e t C e k B yP g,. 2Alexandria VA 22314 Checked By: Page No.: 28

Section i:= 7"Section"

"Location" "Tension" "Rebar" "Elevation"

..... "Surface" "Orientation" . .(fi)"

"Under Eq. Hatch" "OD" "vertical" "93 to 103"

S1J00

1 000

ZI 500

0

- 500 0 500

Moment (ft*kip/ft)

1000 1500

Prepred y: kk--Calculation No.:TVMPR °'°-°Prepared By: P R k, 0102-0135-07

MPR Associates, Inc. Revision No.: 0320 King Street e OJ6Pg .Alexandria VA 22314 Checked By: Page No.: 29

1"71 IPn"... .kip/if'

"Mn"

"kip"t

"F.st

"kipift'I'll

Tchk () =

(0

0 1210.3 714.3 107.27

,214.55)

(-41.64'

-0.5 996.1 851.6 107.27

1,214.55)

(-83.28

-1 840.9 906.7 10727

Y214.55)

(-83.28

-3 714.4 1016.2 84.01

Y,214.55s)

-83.28

-10.31 0 308.8 -120.03

-65.01

-83.28

-12.31 -399 -266.1 -120.03

-159.06)

"C1c"l "all I"fs1""tkip/fl" "..in" .. .. si"

(0

1540.2 30.2 40

,40,

1252.3 24.56 40

40

(-40

1055.1 20.69 40

40

(-40

647.3 12.69 32.25

0 40

268.3 5.26 -40

K-10.83)(-40

231.3 4.53 -40

-26.5)

"e.s"

0

S0.22

-0.07

S0.2

0.23)L-0.140.18

0.21)L-0.41'01.11

0.16)L-1.42'-0.16

-0.204

(-1.7

-0.23

-0.09)

lClIVn"in"l

I'lll

37.75

30.69

25.86

15.87

6.58

5.67

Calculation No.:YR Prepared By: Ž• .'_.. i-,-.• 0102-0135-07MPR Associates, Inc. Revision No.: 0320 King Street ed By:Alexandria VA 22314 Checked By: Page No.: 30

7.0 REFERENCES

1. ACI 318, "Building Code Requirements for Reinforced Concrete"

1.1 ACI-631.2 ACI-83

2. Progress Energy Drawings:

2.1 No. SC-421-031, "Reactor Building Exterior Wall Concrete Outline," Revision 4.2.2 No. SC-421-036, "Reactor Building External Wall Sections and Details," Revision 10.2.3 No. SC-421-301, "Reactor Building Ring Girder Plan & Sections," Revision 8.2.4 No. SC-421-039, "Reactor Building Exterior Wall Equipment Access Opening, Reinforcement

Placing," Revision 5.2.5 No. SC-421-006, "Reactor Building Foundation Mat Anchor Bolt and Dowels," Revision 4.2.6 No. SC-421-032, "Reactor Building Stretch-out of Exterior Buttress #2, #3, #4, and #5,"

Revision 8.

3. Florida Power FSAR, Containment System & Other Special Structures, Revision 31.3.

4. J. Wight and J. MacGregor, Reinforced Concrete Mechanics and Design, Pearson Education,Inc., 5th Edition.

5. E. Avallone & T. Baumeister, "Marks' Standard Handbook for Mechanical Engineers,"McGraw-Hill Book Company, 9th Edition.

6. Florida Power Corporation Document Identification No. S-00-0047, As-built ConcreteStrength for Class 1 Structures, Revision 0.

7. Progress Energy, "Design Basis Document for the Containment," Revision 6.

MPR Associates, Inc.

&I*M PR 320 King StreetAlexandria, VA 22314

CALCULATION TITLE PAGE

Client:

Progress Energy Page 1 of 23plus Attachment

Project: Task No.CR3 Containment Calculations

0102-0906-0135

Title: Calculation No.Seismic, Wind, and Tornado Evaluation and Delamination Depth 0102-0135-08Evaluation for Detensioned State

Preparer / Date Checker / Date Reviewer & Approver / Date Rev. No.

0J. L. Hibbard M. Oghbaei E. Bird

1-23-2010 1-23-2010 1-23-2010

QUALITY ASSURANCE DOCUMENTThis document has been prepared, checked, and reviewed/approved in accordance with the Quality Assurance

requirements of 1 OCFR50 Appendix B, as specified in the MPR Quality Assurance Manual.

MPR-QA Form QA-3.1-1, Rev. 1

MPR Associates, Inc.

*M P R 320 King StreetAlexandria, VA 22314

RECORD OF REVISIONS

Calculation No. Prepared By Checked Bv Page: 2

0102-0135-08n_[__Afecte Page Dsrtion

Revision Affected Pages Description

0 All Initial Issue

Note: The revision number found on each individual page of the calculation carries the revision

level of the calculation in effect at the time that page was last revised.

MPR QA Form QA-3.1-2, Rev. 0

MPR Associates, Inc.Q0 M PR 320 King Street

Alexandria, VA 22314

Calculation No. Prepared By Checked By Page: 3

0102-0135-08 , ,1 f h~z.- Revision: 0

Table of Contents

1.0 Purpose ......................................................................................................... 4

2.0 Sum m ary ....................................................................................................... 4

3.0 Background ...................................................................................................... 9

4.0 Assum ptions .................................................................................................... 9

4.1 Unverified Assumptions ........................................................................................ 9

4.2 Other Assumptions ................................................................................................. 9

5.0 Approach ........................................................................................................ 10

6.0 Calculation ..................................................................................................... 12

6.1 Design Inputs ......................................................................................................... 12

6.2 Deadweight Stress 1..................................................................................................... 15

6.3 Seismic and Deadweight Stress .............................................................................. 17

6.4 Tornado and Deadweight Stress .......................................................................... 21

7.0 References ..................................................................................................... 23

Attachm ent .................................................................................................................. 24

MPR QA Form: QA-3.1-3, Rev. 0

Calculation No.:60 Prepared By: A -.. . 0102-0135-08MPR Associates, Inc. Revision No.: 0320 King Street C kAlexandria VA 22314 Checked By:. Page No.: 4

1.0 PURPOSE

This calculation evaluates the containment building for three design basis loads due to naturalphenomena that might occur while the containment building is detensioned for repair. The load casesare: 1) deadweight and Safe Shutdown Earthquake (SSE), 2) deadweight and wind, and 3) deadweightand tornado. The containment is evaluated for membrane plus bending stress at two sections throughthe containment: 1) the bottom of the containment at Elevation 93 ft, and 2) at the bottom of the SGR(Steam Generator Replacement) opening at Elevation 183 ft. For the evaluation at the bottom of theSGR opening, the containment is assumed to have no concrete between Buttresses 3 and 4 betweenElevations 183 feet and 210 feet. These are the bottom and top elevations respectively, of the SGRopening.

2.0 SUMMARY

Membrane plus bending stress in the containment shell at two sections for two load cases are providedin the table below. The deadweight plus wind load case is bounded by the results for the deadweightplus tornado load case.

"Load" "Section" "M + B"t "Stress" "Result"

"Case ." "Stress" "Limit"

liltof tl oni" 139 lt Failure"

Ts "Deadweight & SSE" "Bottom of Cont.i" 19 600 ("No Failure"( "Bottom of Cont." )(-103 ("No Failure"

"Deadweight& Tornado" 'Bottom of SGR O " -103) 600 ("No Failure"\.."Bot'tom of SGR Opnng (~-95) "No Failure")

Notes:1. Column with heading M + B is the membrane plus bending stress. Plus is tensile and

minus is compressive.2. SSE is Safe Shutdown Earthquake.3. SGR is Steam Generator Replacement4. The stress limit prevents a tensile failure per Reference 4. It is conservative to

compare a compressive stress to a tensile stress limit.5. The section at the bottom of containment is at Elev. Esect = 93 ft . The section at the

bottom of the SGR opening is at Elev. Esect2 = 183ft .

Calculation No.:

ON M Prepared By: • A-.. • 0102-0135-08MPR Associates, Inc. Revision No.: 0320 King Street C d.P.N :Alexandria VA 22314 Checked By: /'. Page No.: 5

Conclusions from these evaluations are:

* The containment building is not expected to fail catastrophically while the building is detensioned forrepairs due to the following load combinations: 1) deadweight and SSE, 2) deadweight and wind,and 3) deadweight and tornado.

* Delamination depths greater than nominal will not result in a catastrophic failure of the containmentbuilding for the load cases listed above. The basis for this conclusion is the analysis result at thesection at the bottom of the SGR opening. This section is assumed to have no concrete betweenButtresses 3 and 4 for the height of the SGR opening. This configuration bounds a case in which thedelamination depth is greater than nominal. Delamination depths greater than nominal above andbelow the SGR opening are considered acceptable based onjudgement. The basis is that the SGRopening with a width of 25 feet and extending the full thickness of the containment wall will boundany thinned sections above or below the opening.

Calculation No.:Prepared By: A .- , 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street Checked By:Alexandria VA 22314 Checked By: A(. ,yr Page No.: 6

-~ 41

I.

at Bottom of SGR Opening(Elev. 183 ft)

~1-

-F

a •.... .. . L..:• •. .: , .. • .. ,

-L

Section at Bottom of Containment(Elev. 93 ft)

Figure 1. Containment Building

Calculation No.:1 M P R Prepared By: * . 0102-0135-08MPR Associates, Inc. Revision No.: 0320 King Street Ch ck dyAlexandria VA 22314 Checked By: H1. Page No.: 7

I

N

'~1

Ii~...

/

///

/

"7

Section at Bottom of Containment (Approximate)

... ...... ; £•• . : " • . . .

"-'7

I!

/y

'I'

i/>

Section at Bottom of SGR Opening (Approximate)

Figure 2. Sections

Calculation No.:Prepared By: Žý A--. 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street C e dB HAlexandria VA 22314 Checked By: /41. Page No.: 8

4. BU~tTT•ES8

• Configuration for this-r - Calculation I

,, SGR Opening

Figure 3. Configuration of Containment for Section at SGR Opening

Calculation No.:I M R Prepared By: • . L--,-. 0102-0135-08MPR Associates, Inc. Revision No.: 0320 King StreetAlexandria VA 22314 Checked By: A(. Page No.: 9

3.0 BACKGROUND

A project is underway at Progress Energy's Crystal River Unit 3 site to replace the steam generators.As part of that project, an opening has been cut into the concrete containment above the equipmenthatch. As this opening was being cut, cracking in the concrete containment wall was identified. Thecrack is around the full periphery of the opening and is in the plane of the wall. The cracking is located atthe radius of the circumferential tensioning tendons, and is indicative of a delaminated condition.

4.0 ASSUMPTIONS

4.1 Unverified Assumptions

None.

4.2 Other Assumptions

1. It is assumed that the thickness of the ring girder is trg = 8.83 ft . This is a reasonable

estimate of the concrete in the ring girder considered as an equivalent rectangular section(see Ref. 2.1). The thickness is used to calculate the mass of the ring girder. A comparisonwas made of the mass of the ring girder and dome determined in this calculation to themass calculated by the finite element model used in this project. There was goodagreement between the mass calculation in this calculation with that from the finiteelement model.

SM PR Calculation No.:Prepared By: • .. . 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King StreetAlexandria VA 22314 Checked By: Page No.: 10

5.0 APPROACH

This calculation is an approximate evaluation to assess the potential for a catastrophic failure ofthe containment when the containment is detensioned for repair. Approximate analysistechniques are used. The analysis considers effects that are considered to be important to theassessment. This is a bounding evaluation rather than a comprehensive evaluation. Effects thatare considered to have less than a 20% effect on the final answer are not considered. This isjustified based on the large margin to failure in the results.

This calculation considers three load cases: 1) deadweight and SSE, 2) deadweight and wind,and 3) deadweight and tornado. A best estimate is used for the deadweight load. The SSE,wind, and tomado loads are the design basis loads as defined by the FSAR (Reference 3). Noload factors are used in the analysis. This is appropriate for a catastrophic failure assessment.

The static coefficient method for seismic analysis specified in Reference 7, Section 6.3 is used.The static coefficient method applies a factor of 1.5 to peak response acceleration to account forpotential closely spaced modes. The peak seismic response is from the ground accelerationspectrum from Reference 1. The seismic assessment considers horizontal acceleration and asimultaneous vertical acceleration in the up direction. The vertical up acceleration increases thetensile stress due to the horizontal acceleration, which is a conservative approach.

The analysis calculates the mass of the containment for deadweight and for seismic using theintact configuration of the containment. The effects of removing concrete for the delaminationand removing the concrete for the SGR opening are not significant within the framework of thisapproximate analysis. The mass is based on cylinders and does not include the mass of thebuttresses (the buttress mass is less than 1% of the total mass).

The acceptance criterion is that the containment wall membrane plus bending stress be less thanthe tensile failure stress criterion established in Reference 4 (oten = 600psi ). The containmentwall membrane plus bending stress is a near uniform tensile stress across the containment wallthickness at the extreme tension fiber. Use of a tensile stress criterion is appropriate.

The analysis calculates membrane plus bending stress at two sections through the containmentas shown on Figures 1 and 2.

The first section is at the bottom of the containment at elevation 93 feet. The nominalcontainment wall thickness is 3.5 feet. At elevation 93 feet, the containment wall is thickerthan the nominal thickness. For conservatism and simplicity, the nominal containment wallthickness is used for the evaluation at this section.

Calculation No.:

AA M P R Prepared By: • A.- - 0102-0135-08MPR Associates, Inc. Revision No.: 0320 K ing S treet C c- . a qg N 1Alexandria VA 22314 Checked By. All V Page No.: 11

The second section is at the bottom of the SGR opening at Elevation ESGR.b = 183ft . TheSGR opening dimensions are hSGR = 27 ft high by WSGR = 25 ft wide (Reference 2.2). Theanalysis assumes a configuration for the containment in which there is no concrete for anangular extent of a = 60.deg for the height of the SGR opening. Figure 3 shows theconfiguration used for the analysis. For reference, the angular extent of the SGR opening isaSGR = 20.9. deg.

Some vertical and hoop tendons will be detensioned for the repair. Detensioning vertical tendonsreduces the containment resistance to an overturning moment such as might occur in a seismic,wind, or tornado event. The vertical tendons strengthen the containment in the longitudinaldirection and keep the containment concrete in longitudinal compression. Without all the verticaltendons, the capacity of the containment to resist an overturning moment is reduced. Thiscalculation uses the conservative approach that all vertical tendons are detensioned.

The containment building is reinforced with a significant amount of vertical rebar at the 93 footelevation. This rebar connects the containment shell to the basemat. This calculation takes nocredit for this rebar.

The center of gravity of the dome and ring girder are offset from the neutral axis for the analysisat the section at the SGR opening. The moment created by the offset increases the compressivestress due to deadweight at the SGR opening. No credit is taken for this effect in the analysis.

Calculation No.:Prepared By: • 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street Cc BAlexandria VA 22314 Checked By: /1, Page No.: 12

6.0 CALCULATION

6.1 Design Inputs

Containment Cylinder

tcyl=- 42 in

tb =- 2.ft+ 4.in

tliner 0.3 75.in

idyI, 2.(65. ft + tiner)

o dcyI= idcyl + 2. tcy

Ecyl.b 93.ft

Ecyl.t =250.ft

a =- 60.deg

SGR Opening

ESGR.b 183.ft

ESGR.t- 210.ft

WSGR 25"ft

WSGRoaSGR =

odcyl + 2

hSGR ESGRt - ESGR.b

tb 28.in

idcyj = 130.06 ft

Odyt =137.06 ft

qSGR = 20.9. deg

hsGR = 2 7 ft

Containment wall thickness; Ref. 2.1

Buttress additional thickness beyond thickness ofcylinder; Ref. 2.1

Liner thickness; Ref. 2.1

Inside diameter of containment concrete wall;Ref. 2.1

Outside diameter of containment; Ref. 2.1

Elevation of bottom of containment cylinder; Ref. 2.1

Elevation of top of containment cylinder; Ref. 2.1

Angle between Buttresses 3 and 4; Ref. 2.1 anddiscussion in Section 5.0

Elevation of bottom of SGR opening; Ref. 2.2

Elevation of top of SGR opening; Ref. 2.2

Width of SGR opening; Ref. 2.2

Angular extent of SRG opening

Height of SGR opening

Calculation No.:

Prepared By: S *'_. , 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King StreetAlexandria VA 22314 Checked By: P7. Page No.: 13

Ring Girder

odrg := od0y + 2. tb odrg = 141.73 ft Outside diameter of ring girder; Ref. 2.1

trg = tcyl + tb + 3. ft

idrg := Odrg - 2 .trg

trg = 106.inEstimate of ring girder thickness for mass calculation;Ref. 2.1 and Assumption 4.2.1

idrg = 124.06 ft Inside diameter of ring girder

Height of ring girder; Ref. 2.1Lrg:= 17.5.ft

Dome

tdome := 3ftDome thickness; Ref. 2.1

Height of dome; Ref. 2.1Ldome := (35.ft + 4.5.in) - Lrg Ldome = 17.88 ft

Concrete

lbpc:= 144-.

f' 0

O-tn =-600.psi

Concrete density; Ref. 6

Concrete tensile strength; Ref. 4

Seismic

ah:= 1.5.2.0.135.g ah = 0.405.gSSE static equivalent acceleration; the peak in theOBE ground response spectra is from Pages 97 and98 of Attachment E to Ref. 1 at 2% damping;damping for the reactor building shell is from Ref. 3,Section 5.2.4.1.2, Page 36; SSE is a factor of 2 timesOBE based on Ref. 3, Section 5.2.1.2.9; the 1.5factor accounts for potential closely spaced modesper Ref. 7, Section 6.3

SSE vertical ground acceleration; Ref. 3, Section5.2.1.2.9

2av:= - ah

3av = 0.27.g

Calculation No.:Prepared By: • . 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street Checked By:Alexandria VA 22314 Page No.: 14

Wind

Vwinld:= 179.mph Wind speed fordesign basis accident; Ref. 3,Section 5.2.1.2.5

Tornado

Vtornado:= 300.mph

Pext:= 3.psi

Tornado wind speed for design basis accident; Ref.3, Section 5.2.1.2.6

Tornado internal to external pressure drop for designbasis accident; Ref. 3, Section 5.2.1.2.6

Air

lbPair: 0.071.-

P-air := 1.285.107 5 lb

ft.sec

Misc.

Cd.E6:= 0.38

Cd.E5:= 1.2

Density of air; the air temperature to obtain density is10OF for simplicity; Ref. 9, Table A-3

Viscosity of air; the air temperature to obtain viscosityis 10OF for simplicity; Ref. 9, Table A-3

Drag coefficient for a cylinder at Reynolds Number

greater than 10 6; Ref. 8, Figure 5-78

Drag coefficient for a cylinder at Reynolds Number of

105; Ref. 8, Figure 5-78

Calculation No.:Prepared By: • . 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street Checked By:Alexandria VA 22314 C Page No.: 15

6.2 Deadweight Stress

Stress will be calculated at two sections at elevations:

Ecyl.bEsect:= ESGR.b Esect • ft1

The length of the containment cylinder above each section for the analysis is:

Lcyl := Ecy t - Esect

L 157"fL/ •67) Esect ý ( 93 ) ft183

The mass of dome, ring girder, and cylinder are:

mass1, i:= Pc"

tdome-1 dcy

Lrg (odrrg- Idrg2)

4

Lcy.. 7r(od cY,2 -idcyl2)

id:= 2 The mass of the dome iscalculated with a simplifiedapproach in which the dome is acircular plate.

TEsect = (93 183 ) ft

5.74xx610 5.74x 106

mass=!9.29 x 0 6 9.29x 106 lb

L\3.32 x 107 Y.1.42 x 107

id = 2The total mass is:

masstot := I mass,' ip4.82 x 107

masstot = lb<2.92 x 107)

=93 )fEsect= C183)

Calculation No.:Prepared By: S . 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street Ch.cke ..ByAlexandria VA 22314 Checked By: .€.* Q Page No.: 16

The cross section area at the two sections is:

A, l -. (od y'2 - id0yl2)4

odcyl + idcylrmean :-

Ac2 := AI - aormean-tcyI

2.11 x 1051 2

Ac = .in

\1.76 x 105

The compressive stress is:

rmean = 66. 78 ft

(93>E sect = 183)ft183

masst0 t-1 g'7dw := - A

S-228.1)O'W -165.7 )ps

Esect C 1893 ) ft

Calculation No.:Prepared By: S *\._ , 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street Checked By: Pg N .Alexandria VA 22314 C. Page No.: 17

6.3 Seismic and Deadweight Stress

Horizontal

The length from the mass cg to the elevation for the section is:

SLcyl, + Lrg + Ldome + 2 ]

L Lcgl, i :=j TLcg1 Lcyl. + rg 2

Lcyl1 i + 2

TEsect = (93 183) ft

L 183.441 (93.441] "dome"

Log = 165.75 75.75 ft = "ring girder"

L 78.5 ) Y. 33.5)] "cylinder" )

The moment due to horizontal seismic is:

3Msi: ahj- Yl [(massl, )i -j(Lcgj,,ijj

44

4

Dome c.g.Ring Girder c.g.

Cylinder c.g.

2.11 x 109Ms = • ft.lbf

k.6.95 x 108)

93 ftEsect C 183)

The moment of inertia for the intact containment is:

cyI = -(odcyl idc) cy = 6.8 x 10olin4

7P Calculation No.:Prepared By: • 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street C e dBAlexandria VA 22314 Checked By: /'. Page No.: 18

The moment of inertia for the C shaped segment of containment about the containment centroid iscalculated below. The neutral axis of the C shaped segment is defined as:

f ydA =0

basic statics, no reference required

Define a function to calculate the integral.

ir a

f(Yna) 2

2

2

where y

dA

rmean'tcy,.(rmean'sin(O) - Yna) d9

=rmean-Sin(O - Yna

=rmean, tcyl, d9

The neutral axis is:

Yna = Yguess +- 0

root( f(Yguess) , Yguess)

Yna = -12. 75 ft

Verify the solution:

f(Yna) = 9.93x 1- 10.in which is approximately zero.

The moment of inertia about the containment centroid is:

cetod= I'y ~2 Ref. 5, Formula j 100

7r a2 2

Icentroid := 2* rmean, tcyl .(rmean. sin (0) 2 dO

2

1centroid = 4. 72 x 10 10.n4

where y = rmean-sin(69

dA = rmean -tcyl -d9

Calculation No.:AU M P R Prepared By: • .... , 0102-0135-08MPR Associates, Inc. Revision No.: 03 2 0 K i n g S t r e e t C e k d B :a e N . 1Alexandria VA 22314 Checked By: /H*., ' Page No.: 19

The moment of inertia about the neutral axis is:

2Ic:'centroid + A02"Yna 10 . 4/c,= 5.14 x10 .ifl Ref. 5, Formula p 19

where Ac2 = 176232.in2

The distance from the neutral axis to the extreme tension fiber is:

- 2 I2 Yna

C C ~m a x = m a x _I(a Y a2d~ .n2i -2)Yn

CC.max = 72.1 ft

where2 Yna 56.ft2 =

S2 f . iV - _Yna =72.1 ft21K 2) 1=

The moments of inertia for the two sections are:

Isect:=cy/.c6.8x 1010 4

Isect = t5.14 x 1010i Esect = (93)1ftC183)The distances to the extreme tension fiber are:

:(°d 0 y'+2"j (68.53"I

Csect := jCCm + Csect = 68.1 ) ftKcc~max ) K72.1)

Esect = (9 Jft183

The bending stress is:

MS. CsectO's.h.=- Isect (~~7 1 4 0.4 2 ps Esect = 9 ft183

Calculation No.:50M PR Prepared By: . 0102-0135-08MPR Associates, Inc. Revision No.: 0320 King Street CcdAlexandria VA 22314 Checked By: Page No.: 20

Vertical

The vertical seismic stress is:

av )61.58O 'S.v : =: - - O 'd w '- _ _'S.V = 4 . 4 p s i

S 1-g} (44.74)

Deadweight and Seismic Stress

The deadweight and seismic stress is:

Esect = ft183

O-dw.s :ýO.h + 0 'S.V + 0~dw -dw's C 139.3 ) psi(19.5)Ps

Esect = ft183

Compare the stress to the concrete tensile strength.

checkI:= if(o-dw.s I .oten, ok, nok)= ("No Failure"

("No Failure"Esect = 83 )ftC183)

Calculation No.:t Prepared By: • 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street C dP oAlexandria VA 22314 Checked By: ,€'. Page No.: 21

6.4 Tornado and Deadweight Stress

The drag on the containment building is (Ref. 8, y-axis of Figure 5-78):

1 2Fd = Cd . "Pair'Ap Vtomado

2

where Cd = drag coefficient

Pair = air density

Ap = projected area

Vtomado = air velocity due to tornado

The projected area of the containment including the projection of the buttresses and ring girder is:

Ap:= [odrg.(Lcyl + Lrg + Ldome) Ap = .09 X9113k\2.09 x 106) Esct= 83), f

The drag coefficient is a function of the Reynolds Number.

Pair" Vtornado "od rg8

Re := Re = 3.45 x 10/1air

The drag coefficient for a cylinder at Reynolds Number greater than 106 is Cd.E6 = 0.38 . For

conservatism, use a drag coefficient of Cd.E5 = 1.2 at a Reynolds Number of about 105. The drag

load is:

1 2 (6.99x10o6> 93"

Fd:= Cd.E5" I "Pair'Ap"Vtomado Fd = I 6 Ibf Esect 93jft23.72 x 10 6,183

The bending moment due to the tornado is:

Mtornado [Fd - (Lyi + Lrg + Ldome)]

Mtomado = x .ft.Ibf Esect =(3)ft

1.9x 8 183

Calculation No.:Prepared By: • *'- , 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King StreetAlexandria VA 22314 Checked By: At'. Page No.: 22

The bending stress is:

Mtomado * Csect

'ornado - sect tornad° 938.49 ) psi(ondo=38.49)s

Esect ( ft183

Coincident with the tornado wind is a local depressurization. The internal to external pressuredrop across the containment wall is Pext = 3 psi . The longitudinal stress in the containment due to

the pressure is:

1?- 2Pext, dy

40-,t: - AC

C27.14)°'ext = 32.57 )psi

Esect = ( 93 fty183j

Deadweight and Tornado Stress

The deadweight and tornado stress is:

Jdwt:= (Ctomado + O7ext + O'dwt -103.3)

d -94.6)Esect = ft

183

Compare the stress to the concrete tensile strength.

cheC" 21 if ( Odwt, •ý O'ten, ok, nok)("No Failure"

check2 ("'No Failure)Esect = ft

183

Calculation No.:Prepared By: '% *"-. , 0102-0135-08

MPR Associates, Inc. Revision No.: 0320 King Street CyAlexandria VA 22314 Checked By: ,'?. Page No.: 23

7.0 REFERENCES

1. Progress Energy Specification SP-5209, "CR-3 Seismic Qualification," Revision 0.

2. Progress Energy Drawings:

2.1 No. SC-421-031, "Reactor Building Exterior Wall Concrete Outline," Revision 4.2.2 No. 421-347, "Reactor Building Temporary Access Opening for SGR Vertical & Horizontal

Tendon Positions," Revision 0.

3. Florida Power FSAR, Containment System & Other Special Structures, Revision 31.3.

4. Letter from WJE (Mr. J. Fraczek) to Progress Energy (Mr. D. Dyksterhouse), Subject: CR3Containment Limiting Tensile Stress, WJE No. 2009.4690, January 11, 2010.

5. K. Gieck, "Engineering Formulas," McGraw-Hill Book Company, 3rd Edition, 1979.

6. Email from Mr. J. Holliday (PE) to Mr. K. Gantz (MPR), 12-30-2009, 10:35 AM, Subject:Concrete Density.

7. Institute of Electrical and Electronics Engineers, Inc. (IEEE) Standard 344-1987,"IEEE Recommended Practice for Seismic Qualification of Class 1E Equipment for NuclearPower Generating Stations."

8. Perry & Chilton, "Chemical Engineers' Handbook," McGraw-Hill, 5th Edition.

9. F. Kreith, "Principles of Heat Transfer," International Textbook Company, 1964.

Calculation No.:7 P R Prepared By: A - 0102-0135-08MPR Associates, Inc. Revision No.: 0320 King Street C e dBAlexandria VA 22314 Checked By: A(. Page No.: 24

ATTACHMENT

Email from Mr. J. Holliday (PE) to Mr. K. Gantz (MPR), 12-30-2009, 10:35 AM, Subject: ConcreteDensity.

Message Page 1 of I

Hibbard, Jim

From: Holliday, John [[email protected]]

Sent: Wednesday, December 30, 2009 10:35 AM

To: Gantz, Kevin; Knott, Ronald

Cc: Hibbard, Jim; Dyksterhouse, Don

Subject: RE: Concrete Density

Kevin,

The reference will be EC 75218, RB Delamination Repair Phase 2- Detensioning

The unit weight is 144 lbs cu ft.

From: Gantz, Kevin [mailto: [email protected]]Sent: Wednesday, December 30, 2009 10:01 AMTo: Knott, Ronald; Holliday, JohnCc: Hibbard, JimSubject: RE: Concrete Density

John and Ron,

I don't think there was ever a follow-up sent to this email. Could you provide us with the reference. I did not see itin SOO-0047.

Kevin

---- -Original Message -----From: Knott, Ronald [mailto: [email protected]]Sent: Wednesday, December 16, 2009 10:15 AMTo: Holliday, JohnCc: Gantz, KevinSubject: FW: Concrete Density

John,Can you direct Kevin to the density reference. I don't know where the original data came from fordensity. I was only quoting what I heard in the meeting. I assumed it was in the 500-0047 attachments.

From: Gantz, Kevin [mailto:[email protected]]Sent: Tuesday, December 15, 2009 6:22 PMTo: Knott, RonaldCc: Dyksterhouse, Don; Holliday, John; Bird, Edward; Butler, PatrickSubject: Concrete Density

Ron,

During our previous meeting you received some original information on the concrete density. I rememberyou saying later that the concrete density was 144 or 145 pcf. Do you have a reference or an actualnumber so that I can make sure I have the correct modulus calculated?

Thanks,

Kevin

12/30/2009

MPR Associates, Inc.

*M PR 320 King StreetAlexandria, VA 22314

CALCULATION TITLE PAGE

Client:

Progress Energy Page 1 of 15

Project: Task No.CR3 Containment Delamination

0102-0906-0135

Title: Calculation No.Conduit Local Stress Analysis 0102-013505

Preparer / Date Checker / Date Reviewer & Approver / Date Rev. No.

1-20-2010 1-20-2010 1-20-2010Edward Bird Erin Tindall Robert Keating 0

QUALITY ASSURANCE DOCUMENT

This document has been prepared, checked, and reviewed/approved in accordance with the Quality Assurance

requirements of IOCFR50 Appendix B, as specified in the MPR Quality Assurance Manual.

MPR-QA Form QA-3.1-1, Rev. 1

MPR Associates, Inc.

*M P R 320 King StreetAlexandria, VA 22314

RECORD OF REVISIONS

Calculation No. Prepared By Checked By Page: 2

0102-0135-05 .-. ' ,- ,

Revision IAffected Pages Description

0 All Initial Issue

Note: The revision number found on each individual page of the calculation "carries the revision

level of the calculation in effect at the time that page was last revised.

MPR QA Form QA-3.1-2, Rev. 0

MPR Associates, Inc.50MPR 320 King Street

Alexandria, VA 22314

Calculation No. Prepared By Checked By Page: 3

0102-0135-05 Revision: C

Table of Contents

1.0 Purpose ........................................................................................................ 4

1.1 Background .......................................................................................................... 4

1.2 P u rp o se ......................................................................................................................... 4

2.0 Sum m ary of Results and Conclusions .......................................................... 5

3.0 Methodology ..................................................................................................... 5

4.0 Design Inputs ................................................................................................... 7

4.1 Geometry ........................................................................................................... 7

4.2 M aterial Properties ................................................................................................. 7

4.3 Boundary Conditions ............................................................................................... 8

5.0 Assumptions ................................................................................................... 10

6.0 Computer Codes ............................................................................................. 11

7.0 Results ................................................................................................................. 11

8.0 References ..................................................................................................... 14

MPR QA Form: QA-3.1-3, Rev. 0

MPR Associates, Inc.FIM PR 320 King StreetAlexandria, VA 22314

Calculation No. Prepared By Checked By Page: 4

0102-0135-05 . , -,,-1c, . Revision: 0

1.0 PURPOSE

1.1 Background

A project is underway at Progress Energy's Crystal River Unit 3 (CR3) site to replace the steamgenerators. As part of that project, 10 vertical and 17 horizontal tendons were detensioned and anopening was cut into the concrete containment above the equipment hatch. As this opening wasbeing cut, cracking in the concrete wall was identified around the full periphery of the opening inthe cylindrical plane of the wall. The cracking is located at the radius of the circumferentialtensioning tendons, and is indicative of a delaminated condition. Progress Energy plans toremove the delaminated concrete and replace it.

1.2 Purpose

The concrete repair and restoration of the steam generator opening may require detensioningadditional tendons. The purpose of this calculation is to determine if the absence of either thevertical or horizontal compressive load results in a more limiting stress condition around thetendon conduits than the case with both vertical and horizontal compression applied. If a morelimiting stress condition is predicted for the case with either vertical load only or hoop load only,this calculation will provide a basis for the detensioning sequence.

A local axisymmetric finite element analysis of the hoop tendon conduits was performed toevaluate the principal stress magnitude and orientation around the hoop conduits for threecombinations of vertical and hoop compression. The three cases are:

* Both vertical and hoop tendons tensioned

* Vertical tendons only tensioned

* Horizontal tendons only tensioned.

MPR QA Form: QA-3.1-3, Rev. 0

MPR Associates, Inc.320 King StreetAlexandria, VA 22314

Calculation No. Prepared By Checked By Page: 4

0102-0135-05 . , lc,-"G, Revision:(

2.0 SUMMARY OF RESULTS AND CONCLUSIONS

Figures 7-1, 7-2 and 7-3 show color contour plots of maximum principal stress (S 1) in theconcrete for the three post-tension loading conditions evaluated. The maximum principal stressfor the three cases is listed below:

* Horizontal + Vertical Tendon Load: 1,041 psi

* Vertical Tendon Load Only: 919 psi

* Horizontal Tendon Load Only: 237 psi

The results show that with either vertical only or horizontal only tendon loads, the maximumprincipal stress is less than the case with both loads applied simultaneously. Therefore, thiscalculation does not provide a basis for the detensioning sequence.

3.0 METHODOLOGY

An axisymmetric finite element model of the local geometry around the hoop tendons wasdeveloped with the Ansys finite element program. The axis of symmetry for the model is thevertical centerline of the containment. The model represents an un-delaminated section of thecontainment wall. Linear-elastic, static structural analyses were performed for three loadingconditions.

Figure 3-1 shows the axisymmetric model developed for the local stress analysis. The modelrepresents a vertical slice through the containment wall between vertical tendons and includesthe liner and two conduits.

MPR QA Form: QA-3.1-3, Rev. 0

MPR Associates, Inc.

*M P R 320 King StreetAlexandria, VA 22314

Calculation No. Prepared By Checked By Page: 6

0102-0135-05 Revision: 0

3/8 inch Thick Liner 5.25 inch OD Conduit

42 inch Thick Concrete Containment Wall

Figure 3-1 Hoop Conduit Axisymmetric Finite Element Model

MPR QA Form: QA-3.1-3, Rev. 0

*MPRMPR Associates, Inc.320 King StreetAlexandria, VA 22314

4.0 DESIGN INPUTS

4.1 Geometry

The basic geometric parameters used for the model are listed in Table 4-1.

Table 4-1. Local Model Dimensions

Dimension Value Reference

Containment Liner Inside Radius 65 ft Reference la and Reference 2, pg 35

Containment Wall Thickness 42 in Reference la

Hoop Conduit OD 5.25 in Reference 2, Page 4

Hoop Conduit ID 5.125 in Assumption 1

Hoop Conduit Spacing 13 in Reference 2, Page 14

Hoop Conduit Placement Radius 67 ft 8.625 in Reference lb

Liner Thickness, Excluding Base 0.375 in Reference l a

The model is 39 inches high, which represents the nominal distance between tendon pairs.

4.2 Material Properties

The linear elastic material properties used in the conduit local stress analysis are elastic modulus,density and Poisson's ratio. The values used for concrete are listed below:

Elastic Modulus:

Density:

Poisson's ratio:

4.03x 106 psi Reference 3, page 4 (uncracked)

150 lb/ft3

0.2

Reference 2, page 3

Reference 2, page 3

The liner is made of ASTM A283 Grade C carbon steel with a yield strength of 30.0 ksi(Reference 2 page 34). Typical values for the elastic modulus, density and Poisson's ratio aretaken from Reference 4, Table 38.

Elastic Modulus:

Density:

Poisson's ratio:

29 x 106 psi

0.283 lb/in3

0.27

MPR QA Form: QA-3.1-3, Rev. 0

MPR Associates, Inc.

*M P R 320 King StreetAlexandria, VA 22314

Calculation No. Prepared By Checked By Page: 8

0102-0135-05 . , •C'1CdG. Revision: 0

4.3 Boundary Conditions

The boundary conditions applied to the model include displacement restraints and applied forcesthat represent post-tension loads only. As shown in Figure 4-1, along the lower edge of themodel, displacements of the concrete and liner normal to the edge are restrained. At the upperedge of the model, the concrete and liner displacements normal to the edge are coupled to oneanother such that all nodes have the same vertical displacement. This condition forces the upperedge of the model to remain horizontal and represents a symmetry condition across the edge. Apressure corresponding to the vertical compression load was applied at the upper edge.

Three hoop tendons, each spanning 120 degrees, form a complete 360 degree circle around thecontainment. In the axisymmetric model, at each tendon conduit, the tendon load is representedby the total (360 degree) radial load. For the case with vertical load only, both hoop tendons inthe model are detensioned. The hoop tendon load and vertical pressure are calculated below.

Note that because the liner is explicitly included in the model with steel material properties, theprestress load is shared between the steel liner and concrete wall.

MPR QA Form: QA-3.1-3, Rev. 0

MPR Associates, Inc.*M PR 320 King Street

Alexandria, VA 22314

Calculation No. Prepared By Checked By Page: 9

0102-0135-05 ,. ,. ,,. - Revision: 0

ri:= 65.ft+-in8

ri= 65.031 ft

ro =ri + 42.in

ro= 68.531 ft

tb := 28.in

Lb 12.ft

Nb:= 6

Nv := 144

dc:= 5.25.in

TV:= 1474000.lbf

Th := 1398000.lbf

Containment concrete inside radius (Reference la)

Containment concrete outside radius (Reference la)

Buttress thickness (Reference 1a)

Buttress length (Reference la)

Number of buttresses (Reference 1 a)

Number of vertical tendons (Reference 2, page 14)

Tendon conduit outside diameter (Reference 2, page 4)

Vertical tendon tension (Reference 5, page 5, unadjusted tendon atthe end of the SGR project, 33 years)

Hoop tendon tension (Reference 5, page 5, unadjusted tendon at theend of the SGR project, 33 years)

The vertical tendon load is reacted by the cross section area of the containment wall andbuttresses less the area of the vertical tendon conduits.

aa :=r.(ro2- ri2)+ Nb.Lb.tb- Nv.4.dc2 aa = 1615 ft2

Nv.TvGa :- aa cra = 913 psi

Each hoop tendon has a tension of Th and exerts a unit radial force of Th / r on thecontainment. The Ansys code requires that the radial load be applied on a 360 degreebasis. The total radial load is then (Th / r) x 2 pi r = 2 pi Th.

Fhoop := 2 .7rTh Fhoop = 8.784 x 106 lbf

MPR QA Form: QA-3.1-3, Rev. 0

MPR Associates, Inc.* M P R 320 King Street

Alexandria, VA 22314

Calculation No. Prepared By Checked By Page: 10

0102-0135-05 . , ý',m f,-.- Revision: 0

A uniform pressure of 913psi is applied to the upperedge representing thevertical tendon load

Along the lower edgedisplacements normal tothe edge are restrained

Along the upper edge,displacements normal to theedge are coupled to oneanother resulting in this lineremaining horizontal

A force equal to2 rr Th is appliedto each conduit

Figure 4-1 Local Conduit Model Boundary Conditions

5.0 ASSUMPTIONS

1. The DBD provides both a minimum wall thickness of 1/16 inch for the hoop conduits andan inside diameter of 5 inch which leads to a thickness of 1/8 inch (Reference 2, page 4).The conduit wall thickness used in the analysis is 1/16 inch.

MPR QA Form: QA-3.1-3, Rev. 0

IMPR

MPR Associates, Inc.320 King StreetAlexandria, VA 22314

11

0102-0135-05 4 ,%•Iý Revision: 0

6.0 COMPUTER CODES