ELGIN AREA WATER TREATMENT PLANT DESIGN OF A … · The Elgin Area Water Treatment Plant (EAWTP) is...

Transcript of ELGIN AREA WATER TREATMENT PLANT DESIGN OF A … · The Elgin Area Water Treatment Plant (EAWTP) is...

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

1

ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTY FOR VARYING

RAW WATER CONDTIONS

Neil Awde, AECOM Canada Inc.*

Zirui Yu, AECOM Canada Inc. Joe Gemin, AECOM Canada Inc.

Simon Breese, AECOM Canada Inc. Brian Lima, Regional Water Supply

* AECOM Canada Inc.,

250 York Street, Citi Plaza, Suite 410 London, Ontario N6A 6K2

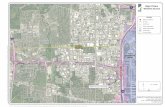

INTRODUCTION This summary paper presents the strategy for sizing of a new residuals management facility (RMF) for the Elgin Area Water Treatment Plant (EAWTP). The EAWTP is an existing conventional water treatment plant, constructed in 1969, which was originally designed in such a way that all wastes produced by the plant, including solids from the sedimentation basins, backwash wastes from the filters, and miscellaneous roof drains and floor drains are collected in a unified waste discharge header, and discharged back to Lake Erie with no treatment. The new RMF will address the issue of waste discharges to the natural environment by allowing for the capture and treatment of process wastes (sedimentation basin sludge and filter backwash waste), thereby significantly reducing the historical waste loads back to the Lake. The key topic of this paper is the establishment of suitable design criteria given the highly variable raw water conditions. A summary of the selected equipment technology and treatment processes will also be provided. BACKGROUND The Elgin Area Water Treatment Plant (EAWTP) is a conventional water treatment plant located at 43665 Dexter Line, approximately 2 km east of the community of Port Stanley in the Municipality of Central Elgin. The EAWTP provides potable water to the communities of London, St. Thomas, Aylmer, Bayham, Central Elgin, Malahide and Southwold which forms the Elgin Area Water Supply System (EAWSS). The EAWSS is owned by a Joint Board of Management with the City of London (City) acting in its’ capacity as the administering municipality on their behalf. The EAWTP has a rated capacity of 91,000 m3/d and is comprised of the following:

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

2

A 1,500 mm diameter raw water intake, extending 737 m into Lake Erie, with

an intake capacity of 182,000 m3/d; A low lift pump station consisting of a wet well, surge well, two pump wells,

and four low lift pumps with a firm capacity of 91,000 m3/d; Two parallel coagulation/flocculation trains, each including mechanical flash

mixing and mechanical flocculation basins, Two parallel conventional gravity sedimentation trains, each rated 45,500

m3/d; Coagulant, polymer, and powdered activated carbon (PAC) storage and

dosing systems; Four granular media filters, using conventional anthracite over sand media

design; One filter backwash system equipped with one surface wash pump and two

backwash pumps; Four UV disinfection reactors, one per filter, mounted within the filter effluent

piping; One clearwell and one reservoir; Chlorine gas for primary disinfection; A high lift pump station primarily consisting of four high lift pumps with a

firm capacity of 82,000 m3/d; Other chemical storage and feed systems including carbon dioxide system and

caustic soda system for pH adjustment, fluoridation system, and sodium hypochlorite feed system for Zebra mussel control;

One 900 mm diameter plant drain. Figure 1 presents a schematic diagram of the existing water treatment plant.

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

3

Figure 1: Elgin Area Water Treatment Plant Schematic

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

4

As stated previously, the plant presently does not treat residuals produced by the water treatment process. All non-sanitary wastes are discharged back into Lake Erie. The plant currently applies the following measures to handle the process residuals: The sedimentation tanks are operated in batch mode with respect to solids

removal. Solids are allowed to settle and accumulate/thicken within the sedimentation tanks. Periodically (every 2 to 4 months, depending upon the solids loading to the plant) one of the basins is taken off-line, and manually drained and washed down to remove the accumulated sludge. The sludge and wash water are directed to the existing 900 mm diameter drain pipe, which discharges wastes back to the Lake approximately 130 m off shore.

The granular media filters are backwashed periodically. Backwash waste is also discharged directly to the Lake, through the same 900 mm plant drain pipe;

In 2011, AECOM completed a Schedule B Municipal Class Environmental Assessment to evaluate several alternates to address the residuals management issues at the plant. The alternatives evaluated included; do nothing, treatment of residuals off-site, treatment of residuals on-site and, limit growth. Through the evaluation process, treatment of residuals on-site with landfill disposal was selected as the preferred alternative. The project was selected as part of the HELP Clean Water initiative, a regional infrastructure project which will supply safe, clean drinking water to over 500,000 residents as well as various businesses in Southwestern Ontario for generations to come. ESTABLISHMENT OF DESIGN CRITERIA As identified in the introduction, the key topic of this paper is the establishment of suitable design criteria given the varying raw water conditions. Given the shallow depth of Lake Erie and its sandy lake bottom, significant raw water turbidity spikes are frequent during storm events and during seasonal lake turnover periods. In considering the approach to design of the RMF, it was important to consider the characteristics of the waste streams being treated. Inherently, sedimentation sludge is significantly more concentrated than backwash waste, and it did not make sense to blend these wastes, and treat them as a blended stream, but to treat them individually to equalize their characteristics before combining them. Figure 2 illustrates a process flow diagram of the selected treatment process.

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

5

Figure 2: Process Flow Diagram

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

6

Backwash Waste (BWW) Historic plant data was used to develop the BWW flow projections. Unit Filter Run Volume (UFRV), a measurement of the volume of water produced per unit area of a filter, per filter run, and a predictor of the “health” of a filter, was found in the range of 170 m3/m2 to 480 m3/m2 with an average at 350 m3/m2. It was determined that total BWW volume per backwash was approximately 1,300 m3. A waste minimization audit was performed during the preliminary design phase, and recommended a series of filter optimization measures to reduce the BWW generation and improve the overall filter health. It was estimated that an average UFRV of 400 m3/m2 could be achieved under “normal” conditions following completion of the filter optimization recommendations. Under worst case conditions, i.e. high sedimentation basin effluent turbidity and cold water, the UFRV would decrease to 200 m3/m2. It was also estimated that, with the improvements to the filter backwash sequence, the BWW could be reduced to 970 m3 per wash. In addition, it is estimated that 3 and 5 total backwashes per day would be required under normal conditions for existing plant capacity, and future plant capacity, respectively. Under peak scenarios, 5 and 10 total backwashes per day would be required at existing plant capacity, and future plant capacity, respectively. Table 1 summarizes the filter backwash waste for existing plant capacity, and future plant capacity. Table 1: Projected Backwash Waste Volumes Flow Condition Existing Plant Capacity

(m3/d) Future Plant Capacity

(m3/d) Average 2,917 4,861 Peak 4,861 9,722

The estimated BWW volume represents from 3.3 – 5.4 % of the total WTP production, which is within typical limits but slightly high for a well operated and maintained water treatment plant. Solid Production Projection

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

7

Historical raw water turbidity is co-presented with the plant flow data in Figure 3.

Figure 3: Turbidity and Plant Flow It is evident that raw water turbidity is typically low in the summer months (less than 50 NTU), but peaks visibly during two discrete spells in the winter months, first in the months of September through January, and again between March and May, presumably when the ice cover on the Lake breaks up. During these periods, peak turbidities in the hundreds of NTU are commonly seen, and over the period tracked in the figure, a peak raw water turbidity of really 800 NTU was found entering the plant. Sampling of the raw water was conducted from 2010 to 2012, to investigate raw water total suspended solid (TSS)-to-Turbidity ratio. The lab testing results are demonstrated in Figure 4. A wide variation in TSS-to-turbidity ratio can be observed, ranging from 0.24 to 31, with an average of approximately 1.57 over the entire period. Error! Reference source not found. 4 also illustrates that TSS-to-turbidity ratios are typically less than 2 during the high turbidity (higher than 150 NTU) spiking events, except for one observed event with a TSS-to-turbidity ratio of approximately 3. Based on these observations, a TSS-to-turbidity ratio of 2 was used for the RMF design.

0

100

200

300

400

500

600

700

800

900

0

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

Raw

Wat

er T

urb

idit

y, N

TU

Raw

Wat

er F

low

, m3 /

d

Date

RW Flow

RW Turbidity

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

8

Figure 4: TSS to Turbidity In addition to the flow and turbidity data, historical chemical data and true colour were used to develop a daily estimate of solids production. The calculated daily solid productions are presented as Figure 5.

Figure 5: Calculated Total Daily Solid Productions

0

200

400

600

800

1000

1200

1400

1600

1800

2000

0 200 400 600 800 1000

Raw

Water TSS (m

g/L)

Raw Water Turbidity (NTU)

Turbidity (NTU)

TSS‐to‐Turbidity = 1:1

TSS‐to‐Turbidity = 1.5:1

TSS‐to‐Turbidity = 2:1

0

10,000

20,000

30,000

40,000

50,000

60,000

70,000

To

tal

So

lids

Pro

du

ctio

n,

kg/d

Date

Total Solid Production @ 2-1 TSS/Turbidity Ratio

Total Solid Production @ 1-1 TSS/Turbidity Ratio

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

9

Figure 5 demonstrates the seasonal variation in solids loading to the plant. The data shows estimated daily solids load to range between 0.2 metric tonnes dry solids per day (MTDS/d) and 75.3 MTDS/d. This significant range in the estimated solids production provided challenges for establishing the capacity of the RMF and sizing of the equipment while balancing treatment objectives and the project capital cost. The historical daily solid productions were also presented in cumulative frequencies, as shown in Figure 6. Figure 6 illustrates that the estimated solids production is less than 17 MTDS/d 95% of the time at the TSS-to-Turbidity ratio of 2. If a TSS-to-Turbidity ratio of 1 was applied, the solid production of 17 MTDS/d would account for 99% of events.

Figure 6: Total Daily Solid Production - Cumulative Frequency Based on the analyses of the historical plant operation and raw water quality data, solid productions were projected for the existing plant design capacity and for the future, when the plant capacity is doubled (using the TSS-to-Turbidity ratio of 2). The solids projections are shown in Table 2. Table 2: Projected Total Solid Production Flow Condition Existing Plant Capacity

(kg DS/d) Future Plant Capacity

(kg DS/d) Normal 9,221 18,423 Peak 110,061 219,880 95th percentile 23,168 46,286

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

0 10,000 20,000 30,000 40,000 50,000 60,000 70,000

Cumulative Frequency

Daily Solid Production (kg/d)

Total Solid Production @ 2‐1 TSS/TurbidityRatioTotal Solid Production @ 1‐1 TSS/TurbidityRatio

Note: Total Solid Production includessolids from turbidity, colour, algea, coagulant, polymer, PAC, etc.

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

10

Settled Sludge (SS) Flow Projection SS flows from the sedimentation basins were calculated based on the total solid production projections in Table 2. Table 3 presents projections of SS flows for the existing plant capacity, and future plant capacity, respectively. Table 3: Projected Settled Sludge Volumes Flow Condition Expected Sludge

Solid Content (%)

Existing Plant Capacity

(m3/d)

Future Plant Capacity (m3/d)

Normal 0.6 1,471 2,939 Worst 1.5 7,258 14,499 95th percentile 0.8 2,848 5,690

The projected SS flows range from 1.6% of plant flow under normal conditions to 10.9% under worst conditions of the total WTP production. This represents a significant fraction of total plant throughput under worst case conditions, but is indicative of the high solids load entering the plant at that time. In combination with the BWW flows, it can be expected that, under normal conditions, the total waste streams to the RMF would represent 4.9% of the main plant production under normal conditions, while under worst conditions, the total waste flow would represent over 16% of the plant production, as it is assumed that the peak sludge volume would be concurrent with a period of the lowest filter productions. Design Flows The BWW treatment capacity was designed to accommodate the BWW volume generated under the peak flow conditions when the WTP reaches its current design capacity. The design of SS thickening process considered the significant range of potential SS flow. Over-sizing thickeners to accommodate the worst scenario events can potentially lead to septic conditions formed within the thickeners, which would cause the re-suspension of settled solids, and thus deteriorate supernatant quality. However, undersized thickeners based on normal flows would lead to the upset of entire thickening process. Discussions with the Owner led to the following design approach: It is technically and financially difficult to size the thickening capacity to treat

the SS flow generated under the worst case scenario; The firm design flow for SS thickening is based on the SS flow generated

under the events of 95th percentile high solid loading level; Total installed SS treatment capacity will be over double the normal design

capacity, but less than the peak SS flow;

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

11

Flexibility to take a portion of the SS thickening capacity out of service under the conditions of solid loading less than 95th percentile level, to avoid septic conditions due to excessive capacity;

The overall residuals management processes are designed to provide buffering capability to attenuate the peak SS flow during extreme turbidity spiking events, (above 95 percentile condition).

Overflow of SS stream from the RMF during the extreme turbidity spiking events.

Pre-consultation meetings held with the MOE confirmed that the above design approach was acceptable. Table 4 summarizes the design flows for the RMF. Table 4: RMF Design Flows Waste Stream Design Treatment Capacity

(m3/d) Filter Backwash Waste 4,861 Settled Sludge 5,696

Effluent Criteria The RMF was designed such that only the supernatant from the BWW clarification and thickening process is permitted to discharge to Lake Erie under normal conditions (solid loading less than 95th percentile). The MOE does not have a specific guideline or policy for the discharge of water treatment plant waste stream clarified effluent. The following discharge criteria were established in consultation with representatives of the MOE: Monthly average TSS concentration of 25 mg/L based on similar criteria for

industrial waste and stormwater discharges, and No parameters other than TSS would require a specific criterion in the

Environmental Certificate of Approval.

Sludge Cake Generation Rates Table 5 provides a summary of the anticipated final sludge cake production from the RMF. Table 5: Calculated Sludge Cake Production Rates Flow Conditions Expected Sludge

Cake Solid Content (%)

Dewatered Sludge (kg/d)

Existing Plant Capacity

Dewatered Sludge (kg/d)

Future Plant Capacity Normal 24 38,422 76,761 95th percentile 24 96,535 192,859 Peak 20 550,303 1,099,399

The sludge cake solid content is dependent on the solid loading rate to the dewatering equipment and the pre-condition of the thickened sludge before

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

12

dewatering. Dewatering centrifuges produce alum sludge typically ranging from 18 – 25 % solids. Table 5 illustrates that the dewatered sludge cake varies greatly over the year. It is estimated that a maximum of 490 m3/day of sludge cake will be generated under the worst scenario when the WTP reaches its design capacity, if all solids loaded to the WTP are captured, treated and dewatered. Although it is not anticipated to be an issue to dispose of the final sludge cake under normal conditions, it will certainly be very challenging to handle and dispose of dewatered sludge under conditions upwards of, or beyond, the 95th percentile solid loading events. TECHNOLOGY ALTERNATIVES & EVALUATION A brief summary of the technologies and equipment considered and evaluated through Preliminary Design of the RMF is provided below. Additional information pertaining to the evaluation and selection process is available by contacting the Author.

Sedimentation Basin Sludge Removal Technologies Evaluated Selected

Chain & Flight Scrapers X Travelling Bridge Scrapers X

Reciprocating Scrapers Vacuum Sludge Removal Devices X

Sludge Thickening Processes

Evaluated Selected Crude (Batch) Sedimentation X

Gravity Sedimentation / Thickening X Lamella Sedimentation / Thickening

Dissolved Air Flotation (DAF) X ActiFlo Clarification / Thickening X

Rotary Drum Thickening X Belt Thickener X

Sludge Dewatering Processes

Evaluated Selected Sand Drying Bed X

Solar Drying X Dewatering Lagoon X

Centrifuge Belt Filter Press X

Plate and Frame Filter Press X Geotextile Tube X

OWWA/OMWA Joint Annual Conference 2014 ELGIN AREA WATER TREATMENT PLANT DESIGN OF A RESIDUALS MANAGEMENT FACILTIY FOR VARYING RAW WATER CONDTIONS

13

FACILITY LAYOUT The following model clips provide 3-dimentional illustrations of the final RMF layout.

Exterior View

Thickening Area

\ Thickening Area Dewatering Area PROJECT STATUS Tendering of the RMF was completed in the fall of 2013 with contract award in December 2013. Construction commenced in mid-January 2014 and is scheduled for completion in December 2015.