Electrostatic Discharge Ignition of Energetic Materials

Transcript of Electrostatic Discharge Ignition of Energetic Materials

-

Summary

Electrostatic discharge (ESD) ignition of explosives, pyrotechnics,or propellants is often considered to be mainly dependent upon variousphysical characteristics of the energetic material. This work shows thatESD ignition of secondary explosives tested in powdered form isprimarily dependent upon the chemical characteristics of the energeticmaterial (i.e., the decomposition rate kinetics of the materials). Wepropose that ignition occurs when a spark raises the temperature of theexplosive particles to the point where thermal runaway occurs. ESDsensitivities of a diverse series of explosives were measured using atraveling needle test apparatus with the powders slightly confined byMylar tape to prevent formation and ignition of a dust cloud.

Using global thermal decomposition rate coefficient expressions,two parameters were calculated for each explosive: (1) the criticaltemperatures according to the Frank-Kamenetskii formula for 20 mmparticles of each explosive and (2) the temperatures at which the ratecoefficient equaled 103 s1. These two sets of data were correlatedwith the observed ESD sensitivities for 50 percent probability ofignition, E50. Excellent correlations resulted, indicating that for ESDignition under these conditions the spark discharge is primarily athermal source.

1. Introduction

The role of safety testing is to determine whether there is

an unacceptably large probability that energy from likely

sources (i.e., impact, friction, spark discharge, etc.) will

ignite an energetic material. Such a determination is con-

venient when a safety test is mainly controlled by a single

characteristic of an energetic material. The test data will, in

this case, be highly correlated with that material property,

and thus that property can be used to predict the safety

performance of the material to that particular hazard. The

usual situation, however, is that a safety test which is nor-

mally defined to simulate some specific hazard, such as

ignition by impact, will be controlled by several char-

acteristics of the explosive. In these cases the test data will

not be well correlated with any characteristics of the

material. For example, in addition to the thermal stability of

an explosive, impact ignition probability also depends on

how much heat is generated by deformation of the explosive

during the impact which, in turn, is strongly affected by the

explosives mechanical strength characteristics.

Electrostatic discharge (ESD) sensitivity is an important

parameter in the safe handling of energetic materials since

electric sparks may develop in many handling situations.

Initiation of explosives can be generally categorized as due to

conversion of mechanical, chemical, electrical, or other

energy into thermal energy, followed by exothermic chemical

decomposition of the explosive which generates additional

heat and, thereby, accelerates the decomposition reaction rate.

If a sufficiently high temperature is attained within a suffi-

ciently large volume of the explosive, the chemical reaction

and heat release processes will continue to accelerate and an

ignition or other thermal runaway event will occur.

Electrostatic Discharge Ignition of Energetic Materials

Darin Skinner, Douglas Olson, and Andrew Block-Bolten

Research Center for Energetic Materials, New Mexico Institute of Mining and Technology, Socorro, NM 87801 (USA)

Zundung energetischer Materialien durch eine elektrische Entla-dung

Die Zundung von Explosivstoffen, Pyrotechnika oder Treibstoffendurch elektrostatische Entladung (ESD) wird oftmals als abhangigvon den verschiedenen physikalischen Eigenschaften angesehen. Dievorliegende Arbeit zeigt, da die ESD-Zundung von Sekundar-sprengstoffen in Pulverform in erster Linie von den chemischenEigenschaften der Energietrager abhangt (d.h. von der Kinetik derZersetzungsgeschwindigkeit der Materialien). Es wird die These auf-gestellt, da Zundung dann eintritt, wenn ein Funken die Temperaturder Explosivstoffteilchen auf einen Punkt ansteigen lat, wo dieReaktion thermisch weiterlauft. Die Sensibilisierung der ESD beiverschiedenen Explosivstoff-Serien wurde gemessen unter Verwen-dung eines beweglichen Nadeltest-Apparates bei leichter Abdeckungder Pulver mit einem Mylarband, um die Bildung und Zundung einerStaubwolke zu verhindern. Fur jeden Explosivstoff wurden zweiParameter berechnet unter Verwendung eines allgemein gultigenthermischen Zersetzungsgeschwindigkeits-Koeffizienten: (1) die kri-tischen Temperaturen nach der Frank-Kamenetskii-Formel fur 20 mm-Partikel jedes Explosivstoffs (2) die Temperaturen bei denen derGeschwindigkeitskoeffizient in etwa 103 s1 erreicht. Diese beidenDatensatze wurden korreliert mit den Werten der beobachteten ESD-Empfindlichkeit mit 50% Zundwahrscheinlichkeit, E50. Ausgezeich-nete Korrelationen wurden erhalten, die zeigten, da fur die ESD-Zundung unter diesen Bedingungen die Funkenentladung in ersterLinie eine Warmequelle ist.

Allumage de materiaux energetiques par une decharge electriqueLallumage de substances explosives, pyrotechniques ou de prop-

ergols par decharge electrique (ESD) est souvent considere en fonctionde differentes caracteristiques physiques des materiaux energetiques.La presente etude montre que lallumage ESD dexplosifs secondairessous forme de poudre depend au premier chef des proprietes chimiquesdu materiau energetique (cest-a`-dire de la cinetique de la vitesse dedecomposition des substances). Nous posons que lallumage a lieulorsquune etincelle porte la temperature des particules explosives aupoint au` la reaction se poursuit thermiquement. La sensibilisation ESDde differentes series dexplosifs a ete mesuree en utilisant un appareilde test a` aiguille mobile avec une poudre lege`rement confinee par unruban Mylar, afin dempecher la formation et lallumage dun nuage depoussiere.

Pour chaque substance explosive, on a calcule deux parame`tres enutilisant un coefficient de vitesse de decomposition thermique global:(1) les temperatures critiques suivant la formule de Frank-Kamenetskiipour les particules de 20 mm de chaque explosif, et (2) les temperaturespour lesquelles le coefficient de vitesse est egal a` 103 s71. Ces deuxensembles de donnees ont ete correles avec les valeurs de la sensibi-lisation ESD observees pour une probabilite de 50%, E50. On a obtenudexcellentes correlations indiquant que, pour lallumage ESD dansces conditions, la decharge de letincelle est en premier lieu une sourcethermique.

# WILEY-VCH Verlag GmbH, D-69451 Weinheim, 1998 0721-3115/98/01020034 $17.50:50=0

34 Propellants, Explosives, Pyrotechnics 23, 3442 (1997)

-

2. Background

During the early 1940s the Explosives Division of the

U.S. Bureau of Mines investigated the hazards associated

with explosives for electrostatic discharge ignition. In the

late 1940s the ESD test apparatus was redesigned and in

1953 a revised report was issued(1). That work determined

that the best single criterion of the ESD sensitivity of a

material was to subject the material to a spark from a

capacitive discharge. The total energy initially stored on the

capacitor was used as a measure of the energy discharged

into the explosive sample. To eliminate energy losses in an

apparatus which rapidly switched the high voltage, the

charged capacitor was switched into contact with a needle

electrode when the sample-to-electrode spacing was wide,

and then the electrode was rapidly moved toward the

sample to a position where its distance from the other

electrode was closer than necessary for spontaneous

breakdown.

Samples were tested in two configurations: Unconfined

samples were placed in a shallow depression in the top of a

steel block; partially confined samples were placed inside a

glass tube with a grounded steel plug at one end and the

moving needle entering the tube from the opposite end.

Significant differences were measured between unconfined

and partially confined 50 mg samples. Steel phonograph

needles were used for electrodes. Generally, to vary the

discharge energy, capacitors of different values were used

with the charging voltage held constant at 5000 volt. No

series resistance was used in the discharge circuit. A tabu-

lation of the highest ESD energy at 5000 volt for zero

ignition probability was given for several explosive mate-

rials both unconfined and partially confined.

Several trends in ESD sensitivities were observed from

the tests:

Large particles ignited less readily than small particles. Except for primary explosives, the degree of confine-

ment usually had a marked effect on the ease of ignition

and completeness of burning.

The ignition energies for unconfined samples of finelyground secondary high explosives were invariably less

than for the same samples tested under confinement.

The ignition of unconfined secondary high explosiveswas apparently due to explosions of fine dust dispersed

in the air by the spark.

Metal powders were more sensitive when testedunconfined.

Black powder was much more sensitive when testedunder confinement.

An estimate of the magnitude of electrostatic discharge

that might arise from the human body was made. Capaci-

tance values between 0.0001 and 0.0004 mF were measuredfor various personnel. A value of 10000 volt was arbitrarily

selected as the likely personnel charging potential, giving a

stored energy value of 0.015 J from the total energy for-

mula, Energy 0.5 CV2, where C is the capacitance valuein farads and V is the charging voltage.

The next main development of the Bureau of Mines tra-

veling needle ESD test apparatus was made by Kirshenbaum

and co-workers(2) at the US Army Picatinny Arsenal during

the 1970s where an improved version of the approaching

needle electrode apparatus was developed. Their test proce-

dure(3) was divided into two parts: a screening test to distin-

guish between primary and secondary main-charge

explosives, and a test to rank or compare energetic materials in

the primary explosive category. In the screening test, a

material was assessed using a discharge with no series resis-

tance at a fixed energy of 0.020 J. Materials that ignited at this

level were considered very sensitive and placed in the primary

explosives category. This work was mainly concerned with

primary explosives. Samples were usually unconfined and

placed in a depression in a metal grounded electrode. The

effects of discharge parameters on the minimum ignition

energy were studied extensively.

At Los Alamos National Laboratory, Larson and co-

workers(4) subsequently continued development of the ESD

test, mainly in establishing an improved sample confine-

ment configuration using lead foil and performing addi-

tional studies on secondary explosives. The following

variables were systematically studied: particle size, sample

weight, electrode material, series resistance, sample tem-

perature, voltage, free volume in the sample holder, and

degree of confinement. The Los Alamos system of confin-

ing the samples eliminated subjectivity in operator judge-

ment of go/no-go in testing and provided information on the

sensitivity and explosivity of the sample.

Recently, Fisher at Sandia National Laboratories devel-

oped(5) an improved model and apparatus for simulating a

worst case scenario for spark discharge from a static charge

buildup on a person. Briefly, Fisher determined that a person

could have a very short duration but high current discharge

combined with a slower discharge. The test apparatus for

simulating this situation gives a very brief high current

transient followed by a longer duration discharge which is

achieved by combining the discharges of two energy storage

capacitors through circuits with different time constants. ESD

testing using this type of discharge is more likely to ignite

some materials and is also more likely to damage electro-

explosive components (mainly due to the high current in the

initial spike) than the single pulse test.

3. Experimental

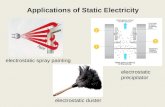

A schematic diagram of the approaching needle ESD test

apparatus as used in this work is shown in Figure 1. The

spring-loaded arm is cocked and held in place by a latch.

The sample material is placed in a holder which is secured

to the grounded base electrode. The minimum spacing

between the needle and base electrode is adjusted prior to

testing to a gap that is less than the anticipated breakdown

gap. Typically, spacing of about 0.020 cm (0.008 inch) was

used in this work. The test energy, E, was taken to be the

total energy stored on the charged capacitor which was

calculated from the capacitance value in farads (C), and the

charge voltage (V) according to the formula E 0.5 CV2.

Propellants, Explosives, Pyrotechnics 23, 3442 (1998) Electrostatic Discharge Ignition of Energetic Materials 35

-

Relatively small variations in discharge energy were

obtained by varying the charging voltage of a given capa-

citor, generally in the range from 2000 to 4000 volt (a factor

of four variation in energy). To vary the test energy by

larger amounts, capacitors of different values were sub-

stituted. Capacitors with 30 kV rating (Plastic Capacitors,

Inc.) were used where available, but some of the larger

value capacitors had lower voltage ratings (8 kV). The

charging voltage was always restricted for these capacitors

to less than the given operating range. Adequate time was

allowed for charging of the storage capacitor through a

16108 ohm resistor. For example, a 0.1 mF capacitorwould exhibit a time constant (63 percent charged) of ten

seconds, but a 1.0 mF capacitor with a time constant of 100seconds would require a longer charging time.

Building on a design described(6) in USAF MIL-STD-

1751, a highly versatile sample holder was developed in

which the explosive powder was loaded prior to testing of

the ESD apparatus. A set of these sample holders could be

loaded and stored in a desiccator until ready for testing.

These sample holders consisted of a No. 10 flat Nylon

washer affixed to a 1.27 cm (0.5 inch) diameter disk of

stainless steel shim stock [0.013 cm (0.005 inch) thick]

using an annulus of double-sided adhesive tape. The

cylindrical cavity in each sample holder, 0.48 cm inside

diameter by 0.165 cm high (0.030 cm3), was loosely filled

with the sample material to be tested and covered with

Scotch type 810 Magic Tape (approximately 0.005 cm thick

Mylar tape). At an apparent density of 1 g/cm3, for exam-

ple, each sample would weigh 30 mg. Many loose pow-

dered explosives have apparent densities less than 1 g/cm3.

This constant sample volume method avoids complications

encountered with a variable air space inside the sample

holder that would be present if a constant weight of various

density materials was used.

Early workers used steel phonograph needles as a con-

venient source of sharp electrodes. Larson and coworkers(4)

used nickel-coated brass pins (No. 20 bank pins), but

these are no longer commercially available. Similar nickel-

coated brass pins (No. 20 dressmaker pins, William Prym

Inc., Dayville, CT) used for this work differed slightly in

shank thickness (bank pins 0.091 cm, dressmakerpins 0.080 cm diameter) from the bank pins. Tests per-formed in our work with both types of pins showed no

detectable difference in results. The points of used pin

electrodes examined under the microscope showed the

points were often melted. At the higher energies, brass was

observed at the point, indicating that the nickel coating had

been vaporized or burned off. The pin electrode was

therefore changed after each ESD trial. Since it would be

difficult to repeatedly cut pins to precisely the same length,

they were cut to an approximate length, to remove the head

of the pin, and then inserted using a holder to position the

cut pin in the apparatus to a repeatable position. The set

screw was then tightened on the pin shank to hold the pin in

place. In this way, the electrode gap spacing was repro-

duced from test to test.

To use the ESD tester, the arm was cocked, a powdered

sample in a holder was inserted into place, the chamber

door was closed, the power supply was energized, the

capacitor was charged to the selected voltage, and the two

firing buttons were simultaneously pressed. One button

released the mechanical arm to initiate the needle electrode

travel and the other button switched a vacuum relay to

electrically connect the charged capacitor to the electrode.

Figure 1. Schematic of the traveling needle ESD test apparatus.

Figure 2. Detailed schematic of the sample holder.

36 D. Skinner, D. Olson, and A. Block-Bolten Propellants, Explosives, Pyrotechnics 23, 3442 (1998)

-

The needle then pierced the tape and sample (as shown in

Figure 2), discharged its energy in a spark, and retracted.

The total time that the needle spent in the sample volume

was measured as 15 ms.

The operator had to judge whether or not an ignition

occurred after each trial. In this testing, the needle punc-

tured the tape, discharged through the sample to the

grounded steel disk, and retracted. A simple puncture

resulted when there was no reaction from the sample. With

increasing chemical reaction, the tape tore; with nearly

complete reaction, a hole was blown in the tape the size of

the opening of the washer. Thus, the tape provided an

excellent witness for determining whether ignition had

occurred, since it was difficult for the operator to visually

judge the results during the test. (The electric spark alone

produced a bright flash and sharp sound, so an ignition may

not have been apparent.) When highly insensitive explo-

sives were tested at discharge energies of greater than

1.25 J, three layers of Mylar tape were used to confine the

sample. (It was found that a 1.5 J discharge into air (no

sample) would tear one layer of tape but hat 1.25 J would

not.) A discharge of 3.0 J into air did not tear three layers of

Mylar tape. Only the explosive TATB was tested using

three layers of tape.

A series of 2530 samples was tested using the up/down

method(7) for each material, and the ESD sensitivity for 50

percent probability of ignition was calculated according to

the usual Bruceton formula.

4. Results

Table 1 shows the results obtained in this work for the

ESD sensitivity of a series of powdered secondary explo-

sives. The materials were dried, coarsely ground if neces-

sary, and sieved using a No. 80 screen (180 mm openings) toremove large particles and to disperse agglomerates. Fine

powders were used as received. The HMX was finer

(nominal 11 mm particle size) than the other materials. Noprimary explosives were investigated. The explosives are

seen to rank in a graded manner, with TATB by far the most

insensitive material to ESD ignition.

Table 2 shows a comparison between the ESD sensitiv-

ities from this work and those of Larson et al.(4) who used

0.008 cm thick lead foil confinement. The agreement is

good for almost all of the explosives studied, with a con-

siderable difference for PYX.

5. Discussion

What are the chemical properties of the various explo-

sives that determine their ESD sensitivities? Just as in

friction and drop weight sensitivity testing, one would like

to correlate some property of the explosive to the experi-

mental results, especially since this may allow predictions

of the sensitivity of new compounds or new mixtures. In

Table 1. ESD Sensitivity Data from this Work

Material Energy for 50% Ignitions (J) Chemical Name

1. PETN 0.19(a) Pentaerythritol tetranitrate2. RDX 0.15 0.03 Hexahydro-1,3,5-trinitro-1,3,5-triazine

0.12 0.033. HMX 0.21 0.09 Octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine

0.17 0.024. AP (90 mm) 0.41 0.02 Ammonium perchlorate5. PYX 0.45 0.06 2,6-Bis(picrylamino)-3,5-dinitropyridine

0.49 0.126. NTO 0.47 0.04 3-Nitro-1,2,4-triazole-5-one

0.43 0.057. DINGU 0.48 0.05 1,4-Dinitroglycolurile8. AP (200 mm) 0.53 0.05 Ammonium perchlorate9. TNT 0.57 0.13 2,4,6-Trinitrotoluene

10. AN 0.58 0.10 Ammonium nitrate11. NQ 0.60 0.10 Nitroguanidine

0.80 0.1312. EDD 0.64 0.06 Ethylene diamine dinitrate13. HNS 0.66 0.04 2,20,4,40,6,60-Hexanitrostilbene14. APic 0.76 0.08 Ammonium picrate15. TATB(b) 2.56 0.07 1,3,5-Triamino-2,4,6,-trinitrobenzene(a) Reference 4 data.(b) For E> 1.5 J, three layers of tape were used.

Table 2. ESD Data Comparison

Explosive ESD Sensitivity, J

This Work LANL(a)

RDX 0.15 0.21HMX 0.21 0.23PYX 0.45 1.18TNT 0.57 0.46APic 0.76 0.73 (KPic)(b)

TATB 2.56 4.25

(a) Reference 4 data obtained using 0.008 cm lead foil confinement.(b) Potassium picrate.

Propellants, Explosives, Pyrotechnics 23, 3442 (1998) Electrostatic Discharge Ignition of Energetic Materials 37

-

ESD testing, some physical properties are expected to be

more or less important (e.g., thermal conductivity, particle

size, moisture content, bulk density, and bulk resistivity).

However, we propose that the ESD spark energy is con-

verted into thermal energy without being greatly affected by

the physical properties of the sample, and that whether there

is an ignition or not is a function of a thermal process

controlled by the heat transfer to the particles and the

chemical kinetics of the explosive decomposition.

To investigate this hypothesis, we evaluated four different

correlations between the decomposition kinetic parameters of

several explosives with the experimental ESD sensitivity

results.Most of the decompositionkineticswereobtained from

Rogers data which were obtained using DSC techniques(8).

We assume that ignition occurs for individual particles

when their temperature reaches some critical temperature,

at which point the particles will undergo thermal run-

away.(9). This process will be mainly controlled by three

factors: the particle size, the thermal conductivity, and the

decomposition rate coefficient for the explosive. The heat of

reaction and particle shape will have smaller effects. For

powders of approximately similar particle sizes, the rate

coefficient will be the controlling factor, and thermal run-

away will occur when the decomposition rate reaches a

minimum value, which is generally the same for all

explosives. The temperature required to produce this reac-

tion rate will vary widely for different explosives. The

discharge energy was assumed to determine the particle

temperature and thus the reaction rate.

5.1 Correlation 1

An approximate analysis of ESD ignition follows. We

assume that the decomposition can be described using first

order kinetics. This is written

Reaction Rate Rate Coefficient; ks1 Mass of Explosivesx;

where x 1 for a first order process. If the reaction rate isdM/dt (negative for disappearance of explosive,M amount of explosive at time t), we can integrate therate law and obtain the expression

M=M0 expkt;where M0 is the initial amount of explosive. Experience

with cook-off testing of small samples has shown that

thermal runaway typically occurs when 110 percent of the

sample has been decomposed. If 5 percent reaction is nee-

ded to initiate ignition, M/M0 0.95, and we can solve toget kt 0.05. Now if t 50 ms,

k 0:05=50 106 103 s1:Thus, ignition will occur when the temperature is raised

to the point where the rate coefficient reaches about 103 s1.If the reaction time were shorter or longer, say 5 or 500 ms,the corresponding values of the rate constant would be 104

and 102 s1, respectively. The reaction duration may bedifferent from 50 ms, but it should be roughly constant forthe various samples tested.

What temperatures are necessary to satisfy this condition

for the explosives for which we have ESD sensitivities? The

rate coefficient expression,

k A expEa=RT;was solved to obtain T for k 103 s1 using the values of Aand Ea for each material. Figure 3 shows an Arrhenius plot

for several explosives with k 103 s1 indicated. Table 3lists the kinetic parameters that were used in the analysis. It

is seen that for this group of explosives, PETN is the least

thermally stable, reaching k 103 s1 at about 1/T 1.656103 K1 or at about 610 K, whereas HNSreaches the same rate coefficient value at about 1/T

0.96103 K1, a much higher temperature (1110 K).Table 4 lists the temperatures for k 103 s1 for eachexplosive where we have both ESD sensitivity and

decomposition rate coefficient data. These values are plot-

ted in Figure 4, which shows that a good linear fit was

obtained, with correlation coefficient r 0.894. TATB, not

Table 3 Decomposition Kinetics Data

Explosive A Ea Kinetics Reference Thermal Conductivity

(s1) (kJ/mol) (kcal/mol) (W/(cm K))

PETN 6.3061019 196.6 47.0 4 0.25RDX 2.0261018 197.1 47.1 4 0.11HMX 5.0061019 220.5 52.7 4 0.42AP 2.096109 126.4 30.2 13 0.40PYX 1.2061024 293.9 74.4 13 0.5(b)

NTO 2.361021 251.0 60.0 (c) 0.5TNT 2.5161011 143.9 34.4 4 0.26AN 5.0161012 169.4 40.5 4 0.24NQ 2.846107 87.4 20.9 4 0.42EDD 1.2561013 169.4 40.5 15 0.25(b)

HNS 1.536109 126.8 30.3 4 0.21TATB 3.1861019 250.6 59.9 4 0.50

(a) Reference 14.(b) Estimate.(c) Kinetic data from a preliminary best fit to literature values.

38 D. Skinner, D. Olson, and A. Block-Bolten Propellants, Explosives, Pyrotechnics 23, 3442 (1998)

-

shown, appears to be an exception to this analysis and was

not included in the figure.

Since the trend line intercepts zero ESD sensitivity at

about 300C, a plot of log ESD sensitivity versus 1/T is

given in Figure 5. This plot allows us to predict ESD sen-

sitivities over a wide range of temperatures. For example,

an ESD sensitivity of about 0.03 J would be predicted for a

material with T for k 103 s1 of 150C.In the Arrhenius plot (Figure 3), most of the kinetic

expressions have been extrapolated over a large temperature

range from the region where the experiments were per-

formed. Differential scanning calorimetry (DSC) measure-

ments are typically obtained where k 104 to 102 s1,over five decades lower than used in this analysis. TATB is

seen to be highly stable at low temperature (i.e., below

about 400C), but with a large activation energy (highslope). Extrapolating the rate constant expression for TATB

beyond the temperature region of the experimental data

probably gives erroneous values at high temperatures. In

reality, the activation energy at high temperatures may be

much less than the value measured at low temperatures

(e.g., 250 kJ/mol), leading to an erroneous estimate for the

temperature where k 103 s1. TATB, which required ESDenergies five to ten times larger than any other explosive

tested and which did not fit the correlation method, was

excluded from the analysis.

Nitroguanidine (NQ) is notable for its especially low

activation energy. At relatively low temperatures, NQ is not

very thermally stable (second to PETN in decomposition

rate at 1/T 2.06103 K1). However, the Los Alamosdata give NQ a low activation energy (87 kJ/mol), which

indicates that at higher temperatures it is relatively more

stable when compared to the other explosives shown in

Figure 3. This discussion is supported by the low ESD

sensitivity (high E50) experimentally found, 0.60 J, com-

pared, for example, to 0.57 J for TNT which is generally

considered to be much more stable than NQ. Thus we have

NQ indicated by the ESD results to be nearly as stable as

HNS and TNT when tested at high temperatures.

The explosive PYX exhibits the opposite trend because it

has the high activation energy of 294 kJ/mol. PYX is very

stable at low temperatures but only moderately stable

about the same as NTOin the high temperature region of

the ESD test.

Table 4. Critical Temperature Data(a)

Explosive T for k 103 Critical Temperature k(Tc)

(K) C K s1

PETN 611 296 569 54RDX 673 328 601 15HMX 690 369 642 57AP 1044 641 914 304PYX 771 464 737 110NTO 714 406 679 113TNT 895 547 820 170AN 913 569 841 157NQ 1026 707 980 622EDD 877 538 811 153HNS 1071 656 929 114TATB 793 467 740 66

(a) See text for details

Figure 3. Arrhenius graph of decomposition rate coefficients forseveral explosives (see Table 3 for references).

Figure 4. Correlation of ESD sensitivities with inverse temperaturewhere the decomposition rate coefficient is equal to 103 s1. Under-lying assumptions are that the sample ignites when about 5% is reactedand that the duration of the heating is approximately 50 ms. The datafor TATB do not agree with the correlation and were not included inthe fit of the data.

Propellants, Explosives, Pyrotechnics 23, 3442 (1998) Electrostatic Discharge Ignition of Energetic Materials 39

-

5.2 Correlation 2

The second correlation analysis was performed by cal-

culating the minimum thermal runaway temperature (i.e.,

the critical temperature) for each explosive using available

data for its kinetics, thermal conductivity, and density. The

particles were assumed to be spherical in shape with a

diameter of 20 mm. This particle size assumption can besomewhat justified for these samples which contained a

broad mixture of particle sizes, including many larger par-

ticles, since the fine particles are expected to be easier to

heat to ignition. The Frank-Kamenetskii solution(10) to the

problem of heat losses by conduction with heat generation

by chemical reaction was used to calculate the critical

temperatures (Tc, K) as

Tc Ea=Rln

r2rQAEaTc2lShR

;where

TcCritical temperature, KEaActivation energy, J/molA Preexponential factor, s1RGas constant, 8.314 J/KmolrRadius or half-thickness, cmrDensity, g/cm3QHeat of decomposition reaction, J/glThermal conductivity, W/(cm K)

Sh Shape factor, 3.32 for a sphere.Table 3 shows the decomposition kinetics and thermal

conductivity parameter values used to calculate the critical

temperatures shown in Table 4 for the explosives that were

experimentally tested (except for ammonium picrate, where

no kinetic data were found in the literature). These critical

temperatures are correlated with the observed ESD sensi-

tivities in Figure 6. Again, TATB did not fit the correlation

and was not included. A good linear fit was obtained with a

correlation coefficient, r 0.925.By solving the Arrhenius expression using the calculated

critical temperature, an estimate of the minimum rate con-

stant for runaway reaction was made for each material,

including the effects of various densities, thermal con-

ductivities, and heats of reactions. These rate constant

values, also shown in Table 4, ranged from 15 s1 for RDXto 620 s1 for NQ, with an average value of about 160 s1

(or 120 s1 if NQ was not included). These rate constantsare slightly lower than the fixed value of k 103 s1assumed in correlation 1, and demonstrate the effects of the

parameters other than the kinetics constants in the Frank-

Kamenetskii calculations. However, as can be seen in

Figure 3, the rank ordering of the various explosives is

little affected (except for NQ) by selecting for correlation

a different value of the rate constant in the k 101 to106 s1 range.

5.3 Correlation 3

Roux et al.(11) recently presented a good correlation of

ESD sensitivities with inverse activation energies for a

series of five nitroarenes. The ESD data from our work,

which included a much broader range of types of explo-

sives, are shown in this correlation form in Figure 7.

Although a general trend is seen, as predicted by Roux et

al., the quality of the fit (r 0.63) is much poorer than whenplotted against inverse temperature for k 103 s1(r 0.89) or against the critical temperature for 20 mmparticles (r 0.92).

Also shown in Figure 7 is a dashed line representing the

normalized Roux et al. fit to their ESD data. Since Roux et

al. measured an ESD sensitivity of 0.57 J for HMX

(hemispherical electrode) compared with 0.21 J measured

in this work, their fitted expression was normalized for

comparison with our data in Figure 7 by dividing by a factor

of 2.7. The general agreement between the two trend lines is

very good.

5.4 Correlation 4

Storm et al.(12) discussed the relationships between shock

sensitivities, impact sensitivities, and properties of the

Figure 5. ESD sensitivities correlated with temperature for k103 s1 in semi-logarithmic form.

Figure 6. Correlation of ESD sensitivities with critical temperaturesfor 20 mm particles of each explosive calculated using the Frank-Kamenetskii formula.

40 D. Skinner, D. Olson, and A. Block-Bolten Propellants, Explosives, Pyrotechnics 23, 3442 (1998)

-

explosive materials. They found that the gap test results

from the shock sensitivities at ninety percent of theoretical

maximum density were very highly correlated with the

impact sensitivity of a variety of common explosives. When

the data for three compounds were removed from con-

sideration, the quality of fit (r 0.99) was excellent foreighteen explosives.

In an effort to perform correlations of sensitivity with

only the structural information about a compound, Storm et

al. proposed the use of a Sensitivity Index (SI) defined as:

SI 100 d a bn2 Ncon5a b c dfor a material of composition CaHbNcOd with Nco as the

number of carbonyl groups. Good correlations were

obtained with impact sensitivities of explosives grouped by

chemical structure.

SI values were calculated for the explosives in Table 1

and correlated against the measured ESD sensitivities.

Figure 8 shows that the ESD data was only poorly corre-

lated (r 0.45) by the Sensitivity Index.

6. Conclusions

The traveling needle-to-plane electrode capacitive dis-

charge, electrostatic discharge sensitivity test procedures,

and the test apparatus have been described. A set of baseline

experimental data on common explosives is reported and a

successful correlation has been made between the observed

ESD sensitivity and the critical temperature for thermal

runaway of 20 mm particles as calculated using the Frank-Kamenetskii equation. The ESD sensitivities were also well

correlated against the temperature at which the thermal

decomposition rate coefficient of each explosive reaches a

given value (k 103 s1 was used here but the conclusionswould not be significantly affected if k 102 or 104 s1 hadbeen used instead.) The explosives in the correlation

included a broad range of chemical types: nitrate esters,

nitramines, nitroarenes, and others (AP, AN, etc.). Potential

difficulties were pointed out that could be encountered

when experimental Arrhenius rate coefficient expressions

are extrapolated far out of the temperature range where the

data were measured, particularly for explosives with com-

plicated reaction mechanisms such as TATB.

The ESD sensitivities were only poorly correlated with

the value of the decomposition activation energy or a

Sensitivity Index similar to the oxygen balance of the

compounds. The electrostatic discharge sensitivity test is an

important tool in determining safe handling characteristics

of energetic materials. Experimentation suggests that igni-

tion of secondary explosive powders is primarily a thermal

event controlled by the decomposition rate kinetics.

7. References

(1) F. W. Brown, D. J. Kusler, and F. C. Gibson, Sensitivity ofExplosives to Initiation by Electrostatic Discharges, Report ofInvestigations 5002, US Bureau of Mines, Pittsburgh, PA, Sep-tember 1953.

(2) M. S. Kirshenbaum, Electrostatic Sensitivity, in EnergeticMaterials, H. D. Fair and R. F. Walker (Eds.), Vol. 2, Chapter 5,Plenum, New York, NY, 1977.

(3) M. S. Kirshenbaum, Response of Primary Explosives to Gas-eous Discharges in an Improved Approaching-Electrode Elec-trostatic Sensitivity Apparatus, Picatinny Arsenal, Dover, NJ,Technical Report 4955, October 1976, NTIS AD-A033118.

(4) T. E. Larson, P. Dimas, and C. E. Hannaford, ElectrostaticSensitivity Testing of Explosives at Los Alamos, Proceedings,9th (International) Symposium on Detonation, Portland, OR,August 28September 1, 1989, Vol. II, pp. 10761083.

(5) R. J. Fisher, A Severe Human ESD Model for Safety and HighReliability System Qualification Testing, EOS/ESD NewOrleans, September 1989.

(6) MIL-STD-1751 (USAF), Military Standard. Safety and Per-formance Tests for Qualification of Explosives. Method 4.Response of Primary Explosives to Gaseous Discharges in anImproved Approaching-Electrode Electrostatic SensitivityApparatus, August 1982.

(7) W. J. Dixon and A. M. Mood, J. American Stat. Assoc., 43, 109(1948).

(8) R. N. Rogers, Thermochemistry of Explosives, Thermo-chimica Acta 11, 131 (1975).

(9) J. Zinn and R. Rogers, Thermal Initiation of Explosives,J. Phys. Chem. 66, 2646 (1962).

(10) D. A. Frank-Kamenetskii, Diffusion and Heat Exchange inChemical Kinetics, Princeton University Press, Princeton, NJ,1955.

(11) M. Roux, M. Auzanneau, and C. Brassy, Electric Spark andESD Sensitivity of Reactive Solids (Primary or SecondaryExplosives, Propellant, Pyrotechnics). Part One: ExperimentalResults and Reflection Factors for Sensitivity Test

Figure 7. ESD sensitivity data correlated with inverse activationenergies. The solid line is a fit to the data. The dashed line representsthe fit found by Roux et al.(10) normalized using HMX data.

Figure 8. ESD sensitivity data correlated with sensitivity indexdefined by Ref. 12.

Propellants, Explosives, Pyrotechnics 23, 3442 (1998) Electrostatic Discharge Ignition of Energetic Materials 41

-

Optimization, Propellants, Explosives, Pyrotechnics, 18, 317324 (1993).

(12) C. B. Storm, J. R. Stine, and J. F. Kramer, Sensitivity Rela-tionships in Energetic Materials, in: Chemistry and Physics ofEnergetic Materials (Kluwer Academic Press, Boston), 1990, p.605639.

(13) D. Olson, Research Center for Energetic Materials, unpublishedresults, April 1992.

(14) A. Block-Bolten, M. Grant, and D. Olson, Thermal Conductivityof Energetic Materials, Research Center for EnergeticMaterials Report A-02-93, New Mexico Tech, Socorro, NM,April 1993.

(15) E. K. Rideal and A. J. B. Robertson, The Sensitiveness of SolidHigh Explosives to Impact, Proc. Roy. Soc., A195, 135150(1948).

AcknowledgementsThs work was funded by the Research Center for Energetic Mate-

rials, an NSF-sponsored Industry/University Cooperative ResearchCenter at New Mexico Tech.

(Received June 26, 1996; Ms 53/96)

42 D. Skinner, D. Olson, and A. Block-Bolten Propellants, Explosives, Pyrotechnics 23, 3442 (1998)