Electroplatng Pretreatment Standards - Interim Final Rule - … · 2015-10-09 · SUBPART...

Transcript of Electroplatng Pretreatment Standards - Interim Final Rule - … · 2015-10-09 · SUBPART...

35834

the City of Lawrence, and the Towns cAndover, Methuen, and North AndoveiSources in these areas remain subjecto the previously approved requirementof Regulation 5.1, which stipulate thasources are permitted to burn fossil fuehaving a sulfur content not in excess o0.55 pounds per million Btu heatreleaspotential (approximately equivalent t1.0 percent sulfur content residual fueoil by weight).

Haverhill Paperboard CorpbratiorHaverhill, Massachusetts was not approved to implement the provisions othe revision because violations of th,NAAQS for SO2 are predicted if the planwere to burn 2.2 percent sulfur contenfuel oil. However, on December'30, 1971the Massachusetts Department sub.mitted additional conditions and techni.cal information, and an EPA review o:these data shows that the plant coulcburn fossil fuel having a sulfur contennot In excess of 0.75 pounds per milliorBtu heat release potential (approxi-mately equivalent to 1.4 percent sulftucontent residual fuel oil bk weight) with.out violating the NAAQS for SO.. OrApril 13, 1977 (42 FR 19359) the RegionasAdministrator published a Notice of Pro-posed Rulemaking indicating that he wa,considering approval of Haverhill Paper.board Corporation to burn 1.4 percentsulfur content fuel oil. Haverhill Paper-board Corporation is required to appl5for and receive written approval from theMassachusetts Department before burn-ing the specified higher sulfur contentfuel, and will be required to conform tcall other provisions of the revised Regu-lation 5.1.

No comments were received during the30-day comment period.

After evaluation of the State's sub-mittal, the Administrator has deter-mined that the Massachusetts revisionmeets the requirements of the Clean AirAct and 40 CFR Part 51. Accordingly, thisrevision Is approved as a revision to theMassachusetts Implementation Plan.(See. 110(a) of the Clean Air Act, asamended, 42 U.S.C. § 18576-5(a).)

Dated: July 5, 1977.DOUGLAS M. COSTLE,

Administrator.Part 52 of Chapter I, Title 40, Code of

Federal Regulations, is amended as fol-lows:

SUBPART W-MASSACHUSETTS1. Section 52.1120(c), paragraph (8) is

revised to read as follows:§ 52.1120 Identification of Plan.

(c) The plan revisions listewere submitted on the dates spec

(8) A revision to Regulation 5.1Content of Fuels and Control'for the Merrimack Valley Air PControl. District, submitted on28, 1976, and additional technicamaton pertinent to the Haverhillboard Corporation, Haverhill, Masetts, submitted on December 3

RULES AND REGULATIONS

f by the Secretary of Environmental Af-r. fairs.

2. In § 52.1126, paragraph (e) is re-s vised to read as follows:1 52.1126 Control strategy: Sulfur ox-f ides. -

. (e) Massachusetts Regulation 5.1 for1 the Merrimack Valley Air Pollution Con-

trol District, excluding the City ofL, Lawrence and the Towns of Andover,- Methuen, and North Andover, submittedf on January 28, 1976, is approved excepte as to the following source which is limitedt to burning fossil fuel having a sulfurt content not in excess of 0.75 lb. per mil-3 lion Btu heat release potential (approxi-- mately equivalent to 1,4 percent sulfur- content residual fuel oil by weight) :

Haverhill Paperboard Corporation, Haverhill,I Massachusetts.I[ [FR Doc.77-19980 Filed 7-11-77;8:45 am]

SUBCHAPTER N-EFFLUENT GUIDELINES ANDSTANDARDS

1 PART 413-ELECTROPLATING POINTIl SOURCE CATEGORY- Pretreatment Standardslor Existing

Sources; Interim Final RegulationsAGENCY: Environmental Protection

. Agency.

ACTION: Interim final regulation.SUMMARY: These regulations limit the

* "concentrations of certain pollutantswhich may be discharged into publiclyowned treatment works by electroplatingoperations. The purpose is to regulatethose Pollutants which interfere with,pass through, or are otherwise incom-patible with the operation of treatmentworks. The Federal Water Pollution Con-trol Act requires these regulations to beissued. The effect of these regulationswill- be to require pretreatment of wastewater by operations which do electro-plating and which discharge waste waterinto publicly owned treatment works.-EFFECTIVE DATE: July 12, 1977.ADIpRESS: Send comments to: En-vironmental Protection Agency, 401 MSt., SW., Washington, D.C. 20460, Atten-tion: Distribution Officer, WH-552.FOR FURTHER INFORMATION CON-TACT:

- Harold B. Coughlin, Effluent GuidelinesDivision, (WH-552) EnvironmentalProtection Agency, 401 M St. SW.,Washington, D.C. 20460. (202) 426-2560.

* * SUPPLEMENTARY - INFORMATION:I belowA-,'l BACKGROUND

*. On March 28, 1974, EPA promulgatedS* a regulation adding Part 413 to Title 401, Sulfur of the Code of Federal Regulations (39Thereof, FR 11510). That regulation (the "Phase'ollution I regulation") with subsequent amend-January ments (the "Phase II regulation") (40 FR1-infor- 18130, April 24, 1975) established effluentPaper- limitations guidelines fbr existing sources

ssachu- in five subcategories and standards of0, 1976, performance and pretreatment stand-

ards for new sources in one subcategory,Proposed revisions and additions settingforth effluent limitations guidelines basedon "best available technology economi-cally achievable" (BAT), pretreatmentstandards for new and existing sources,and standards of performance for newsources were also published for five sub-categories (39 FR 11515, March 28, 1974and 40 FR 18140, April 24, 1975). Thehistory of rulemaking for the category,by the Agency prior to December 1976 isdescribed in greater detail In 41 FR 53018(December 3, 1976).

On December 3, 1976, the Agency sus-pended the promulgated effluent limita.tions guidelines based on "best prac-ticable control technology currentlyavailable" (BPT). The effluent limita-tions guidelines based on "best availabletechnology economically, achievable(BAT), new source performance stand-ards, and pretreatment standards forSubpart A .of the Electroplating PointSource Category (41 FR 53081) were re-voked. The Agency also withdrew its no-tices of proposed rulemaking for thecategory (41 FR 53070). The Agency tookthis action for the purpose of reevaluat-ing the appropriateness of limitationsand standards earlier established in lightof new data and further analysis.

The pretreatment standards for exist-ing sources which were originally pro-posed were based on the data and analy-sis relied upon in promulgating the BPTregulations. The effort to conduct newdata gathering and analyses as a basisfor reevaluation of the BPT regulationswas thus expected to encompass the pro-posed pretreatment regulations as well.The interim final regulations set forthbelow take Into account the additionalstudy which has been conducted over thepast several months.

Pretreatment standards are estab-lished for pollutants discharged Into pub-licly owned treatment works (POTW)from existing sources which fall withinthe following subcategories of the Elec-troplating Point Source Category: Elec-troplating of Common Metals Subcate-gory (Subpart A); Electroplating ofPrecious Metals Subcategory (SubpartB)_Anodlzing Subcategory (SubpartD);Coatings Subcategory (Subpart E),Chemical Etching and Milling Subcate-gory (Subpart F); Electroless Plating,(Subpart G) and Printed Circuit Boards(Subpart H). Subparts G and H are newsubcategories which are established bythis regulation. The content of the stand-ards Is discussed In detail below underSummary of Standards.

LEGAL AuTHORiTY

These regulations are promulgatedpursuant to section 307(b) of the FederalWater Pollution Control Act, as amended(33 U.S.C. 1251, 1317(b); 86 Stat. 816 etseq.; Pub. L. 92-500) (the Act), whichrequires the establishnient of pretreat-ment standards for pollutants introducedinto publicly owned treatment works(POTW).

SUMMARY OF STANDARDS

These regulations establish two setsof pretreatment requirements, for the

FEDERAL REGISTER, VOL 42, NO. 133-TUESDAY, JULY 12, 1977

RULES AND REGULATIONS

subcategories mentioned. The first set,the "prohibited discharge" standards,are designed to prevent'inhibition of, orinterference with, publicly owned treat-ment works, by prohibiting the dischargeof pollutants of a nature or in a quan-tity-that would endanger the mechani-cal or hydraulic integrity of the works.Except for minor changes, these prohib-ited discharge standards are identicalto the prohibitions contained in the gen-eral pretreatment regulation now foundat 40 CFR 128.131.

The second set of standards, known as"categorical" pretreatment standards,-contain -specific numerical limitationsbased, on an evaluation of availabletechnologies in a particular industrialsubcategory. The specific numericallimitations are arrived at separately foreach subcategory, and are imposed onpollutants which may interfere with,pass through, or otherwise be incompat-ible with publicly owned treatmentworks. For plants with an average dailyflow of 40,000 gallons or more, the pres-ent regulations specifically, limit theconcentrations of total cyanide, amena-ble cyanide, hexavalent chromium, andthe pH range for wastes discharged intoa POTW. For plants with an averagedaily process waste water flow of lessthan 40,000 gallons, limitations on onlyamenable cyanide are imposed at thistime, due to preliminary indications thatthese plants might experience relativelysevere economic problems if more strin-gent standards were established. Requir-ing treatment of cyanide is the logicalfirst step, since destruction of cyanideis a prerequisite for any subsequent re-moval of metals.

However, the Agency in the near fu-ture will issue in proposed or interimform additional limitations for some orall portions of the industry, based onfurther analysis. First, the Agency willissue limitations on total cyanide, hex-avalent chromium, and pH for some orall of the plants which will be subjectonly to limitations on amenable cyanideunder the regulations which are cur-rently being promulgated. Secondly, theAgency will issue limitations on metalsfor certain portions of the industry. Asdiscussed below, the reasons for theAgency's decision to issue regulationsin stages are closely related to the on-going effort to develop an accurate eco-nomic picture of this industry. Decisionsregarding the appropriate stringency andscope of the additional standards willdepend upon the outcome of currentefforts to characterize the most vulner-able parts of the industry and to deter-mine the possible economic impacts ofvarious levels of regulations.

Because the present interim final reg-tilations provide for up to three yearsfor compliance (see Compliance Date,below), the issuance of regulations intwo stages should not materially affectthe process of planning for and installingthe necessary treatment technology. Thetime necessary for compliance will again-be considered when new regulations are-promulgated and when existing regula-tions are finalized.

The Agency is also in the process offormulating new BPT regulations as wellas standards of performance and pre-treatment standards for new sources.The Agency expects to issue these regu-lations in the near future.

For the purpose of clarity, the sub-categories affected by the present regula-tions are exempted from 40 CFR Part128. The provisions of the present reg-ulation overlap considerably with thelanguage of 40 CFR Part 128. 40 CFRPart 128 was proposed on July 19, 1973(38 FR 19236). and published in finalform in November 1973 (38 FR 30982).It limits the discharge of pollutantswhich pass through or interfere withthe operation of publicly ownedtreatment works, but it does not set nu-merical limitations or explicitly list par-ticular pollutants to be regulated. Theprovisions of 40 CFR Part 128 have some-times been a source of confusion in thepast. New -general pretreatment regu-lations have been proposed (42 FR 6476.February 2, 1977) which will revoke andreplace 40 CFR Part 128 upon promul-gation. Therefore, the general pretreat-ment requirements set forth in 40 CFRPart 128 are superseded with respect tothe subcategories governed by the pres-ent regulations. All pretreatment re-quirements currently applicable to thesubcategories listed are included in theregulations set forth below. When thenew general pretreatment regulationsare promulgated, these standards will bereviewed for consistency with the newgeneral policies.

TECHNICAL BASIS FOR STANDARDS

The technical analysis upon whichthese regulations are based included anIdentification of the principal waste wa-ter pollutants generated by this industry,a consideration of the extent to whichthese pollutants interfere with or passthrough POTW, and a study of the vari-ous pretreatment technologies which areavailable for controlling the discharge ofsuch pollutants. Information gathered inan ongoing technical study of direct andindirect dischargers for this industry wasused as the primary basis for assessingavailable pretreatment technologies.Additionally, data gathered earlier insupport of the direct discharge limita-tions under sections 301 and 304 as wellas data submitted by the industry wereused. Appendix A summarizes these dataand the analysis used in developing theselimitations. The details of these studiesare set forth in the "Pretreatment Re-port Supplementing the Interim FinalDevelopment Documents for the Electro-plating Point Source Category", the"Development Document for InterimFinal Effluent Limitations Guidelines forthe Common and Precious Metals, andMetal -Finishing Segments of the Elec-troplating Point Source Category", andthe "Development Document for EffluentLimitations Guidelines and New SourcePerformance Standards for the Copper,Nickel. Chromium and Zinc Segment ofthe Electroplating. Point Source Cate-gory". The Agency also relied upon areport entitled "A Survey of Three Ex-

emplary Electroplating Waste Treat-ment Systems".

EcoNomc IMPACT ANALYSIS

In establishing the present regulations,the Agency has studied and taken intoaccount the potential economic impacton the industry of implementing thestandards. The analyses which have beenundertaken are described in Appendix A.The details of the economic studies areset forth in a report entitled "Prelimi-nary Economic Analysis of Interim FinalPretreatment Standards for the Electro-plating Point Source Category, May,1977."

Total investment costs for the metalfinishing Job shops to comply with thestandards are estimated to be 38 milliondollars. Annualized compliance costs areestimated to be 15 million dollars peryear including both capital charges andoperating and maintenance costs. It isestimated that 235 metal finishing jobshops representing 5,900 jobs may closeas a result of the standards. This rep-resents eight percent of the firms andnine percent of the employment in thejob shop sector of the industry.

Executive Orders 11821 and 11949, andOMB Circular A-107 require that majorproposals for legislation and promulga-tion of regulations and rules by agenciesof the executive branch be accompaniedby a statement certifying that the in-flationary impact of the proposal hasbeen evaluated. It is hereby certified thatthe inflationary impact of these stand-ards has been evaluated in the economicImpact analysis.

FUTURE REGULATIONS

The present standards represent aminimal level of control-which leaves un-regulated many harmful pollutantswhich pass through or interfere with theoperation of a POTW or have deleterious.effects on the sludge resulting from theoperation of such treatment works. TheAgency is considering establishing reg-ulations in addition to those which arenow being promulgated. In particular,the Agency has considered the need forlimitations on metals, as well as limita-tions on pH, total cyanide, and hexa-valent chromium for those plants whichare currently subject only to limitationson amendable cyanide. The harmfulnessof such pollutants is known, as is thetechnology for controlling these dis-charges. However, the preliminary re-sults of an economic analysis indicatethat the closure rates for implementa-tion of the full range of limitations by allplants may be high. Consequently,limitations on the full set of parametersare not being promulgated at this time.The Agency, however, will issue furtherlimitations for some or all portions of theindustry in the near future, after addi-tional economic analysis has been com-pleted.

Particular attention s being devoted tothe representativeness of the data base,the accuracy of the financial informa-tion, the feasibility of alternative sourcesof capital, and the appropriateness ofthe compliance cost estimates. TheAgency hopes to have a more accurate

FEDERAL REGISTER, VOL 42, NO. 133-TUESDAY, JULY 12, 1977

35835

35836

economic picture of the industry soon,following further evaluation of the database, review of the costs which wereused, and "reality testing" of the eco-nomic model by comparing results withthe actual experience of municipalitieswhich have enforced regulations similarto those under consideration. In addi-tion, the Agency is currently studyingthe industry in an effort to more pre-cisely characterize the most vulnerableportions of the industry and to definethose groups of plants which are respon-sible for the most significant environ-mental -harm. Specific factors under con-sideration include process mix, flow,sales, number of metal finishing em-ployees, total number of employees, andlocation. Identifiable differences betweencaptive and job shops will also be consid-ered. The Agency will be looking for fac-tors which might provide the basis forformulating a spectrum of standards fordifferent groups of plants, or for estab-lishing variances or exemptions to acentral set of standards.

Comments from the public are partic-ularly solicited. The Agency will issueadditional limitations in approximatelytwo months from the date of thispromulgation.

AVAILABILITY OF DOCUMENTS

The EPA technical and economic re-ports mentioned above are available forinspection at the EPA Public Informa-tion Reference Unit, Room 2922 (EPALibrary), Waterside Mall, 401 M St. SW.,Washington, D.C. 20460, at all EPA Re-gional Offices and at State Water Polu-tion Control Offices.

Copies of the supplemental EPA re-ports described are being sent to personsor institutions affected by the regulationor who have placed themselves on amailing list for this purpose (see EPA'sAdvance Notice of Public Review Pro-ced-ures, 38 FR 21202, August 6, 1973).A limited number of additional copiesare available. Persons wishing to obtaina copy may write the EnvironmentalProtection Agency, Efluent GuidelinesDivision, Washington, D.C. 20460, At-tention: Distribution Officer, WH-552.

When this regulation is promulgatedIn final rather than interim form, re-vised copies of the technica documenta-tion will be available from the Superin-tendent of Documents, GovernmentPrinting Office, Washington, D.C. 20402.Copies of the economic analysis docu-ment will be available through the Na-tional Technical Information Service,Springfield, Virginia 22151.

PUBLIC PARTicnATIONNumerous agencies and groups have

participated at various stages in the de-velopment of pretreatment regulationsfor existing sources in this 'industry.Comments were solicited when proposedpretreatment standards were issued onMarch 28, 1974 (Phase I) and onApril 24, 1975 (Phase I). Many agenciesand groups were also consulted in- thecourse of developing the proposed regu-lations. Similar opportunities f~r publicparticipation were also provided in the

RULES AND REGULATIONS

related development of Phase I andPhase II regulations based upon bestpracticable control technology currentlyavailable. Furthermore, a public hearingon pretreatment standards for the elec-troplating industry was held on June 10,1974. On December 3, 1976, the Agencyannounced that the regulations whichhad been previously proposed or promul-gated would be reevaluated. Since thattime the Agency has reconsidered theformulation of pretreatment standardsand other regulations in light of all com-ments which have been received. TheAgency has also continued to consultwith, and receive comments from, in-terested agencies and groups. Further-more, at the request of the National As-.sociation of Metal Finishers, the Agencyhas- released split samples for duplicateanalysis as well as additional data onthe electroplating plants that were se-lected for sampling and study as a basisfor reevaluating the regulations. A silm-mary'of public participation in this rule-making, public comments, and the Agen-cy's response to major issues which havebeen raised is contained in Appendix Bof this preamble.

EFFECTIVE DATE

The Agency is subject to an order ofthe United States District COurt for theDistrict of Columbia entered in "NaturalResources Defense Coun~il (NRDC) vEPA," 8 E.R.C. 2120 (D.D.C. 1976) whichrequires the promulgation of pretreat-ment standards for this industry cate-gory no later than May 15, 1977. Thecourt order which was entered 'by theUnited States Court for the District ofColumbia on June 8, 1976, following aconsent agreement among the parties tofour lawsuits, placed EPA on rigid time-tables for the preparation and publica-tion of water pollution xegulations for 21broad industry categories and 65 familiesof water pollutants.

It has not been practical to develop.and republish regulations for this cate-

gory in a second proposed form and toprovide a 30-day comment period within,the time conlraints imposed by thecourt order referred to above. Accord-ingly, the Agency has determined pur-suant to 5 U.S.C. 553 (b) that notice andcomment on the interim final regula-tions prior to promulgation would beimpractical and contrary to the publicinterest. The effective date shall there-fore be the date of publication of theseregulations.

COMPLIANCE DATE

Section'301 of the Act anticipates thatpretreatment standards for existingsources would be established and com-pliance would be required before July 1,1977, while section 307(b) specifies "atime for compliance not to exceed threeyears from the date of promulgation" ofthe standard. In view of this conflict ofstatutory language and the fact that thepretreatment standards are only nowbeing promulgated, the Agency believesthat the compliance deadline as set forthin section 307(b) should apply. The timefor compliance with the categorical pre-

treatment standards will be not laterthan three yeazs from the effective date,.However, a Regional Administrator orlocal or state authority should establisha more expeditious compliance date onan individual basis where It Is appropri-ate. Compliance with the prohibited dis-charge standards is required immediatelyupon the effective date of these regula-tions since these standards are essen-tially the same as 40 CFR 128.131 andsince the deadline for compliance with40 CFR 128.131 has passed.

OPPORTUNITY FOR PUBLIc COiMusNTInterested persons are encouraged to

submit written comments. Commentsshould be submitted In triplicate to theEnvironmenal Protection Agency, 401 MSt., SW., Washington, D.C. 20460, At-tention: Distribution Officer, WH-552,Comments on all aspects of the regula-tion are solicited. In the event commentsare in the nature of criticisms as to theadequacy of data which are available,or which may be relied upon by theAgency, comments should Identify and,if possible, provide any additional datawhich may be available and should In-dicate why such data suggest amend-ment or modification of the regulation.In the event comments address the ap-proach taken by the Agency In establish-ing pretreatment standards, EPA solicitssuggestions as to what alternative ap-proach should be taken and why and howthis alternative better satisfies the de-tailed requirements of section 307(b) ofthe Act. The Agency particularly solicitscomments on other technologies fortreating metal finishing effluents. Allcomments received on or before Septem-ber 12, 1977, will be considered.

A copy of all public comments will beavailable for inspection and copying atthe EPA Public Information ReferenceUnit, Room 2922 (EPA Library), Water-side Mall, 401 M St. SW., Washington,D.C. 20460. A copy of the technical stud-ies and economic studies referred toabove, and certain supplementary mate-rials will be maintained at this locationfor public review and copying. The EPAinformation regulation, 40 CFR Part 2,provides that a reasonable fee may becharged for copying.

An opportunity for public hearing willbe provided shortly after the close of thecomment period. The place and time willbe announced in a later notice.

SMALL Busxi]ss ADMINISTRATIONLOANS

Section 8 of the FWPCA authorizesthe Small Business Administration,through Its economic disaster loan pro-gram, to make loans to assist any smallbusiness. concern in effecting additionsto or alteration in equipment, facilities,

-or methods of operation so as to meetwater pollution control requirements un-der the F WPCA, if the concern Is likelyto suffer a substantial economic injurywithout such assistance.

For further details on this Federalloan program write to EPA, Office ofAnalysis and Evaluation, WH-586, 401 M.St. SW., Washington, D.C. 20460.

FEDERAL REGISTER, VOL 42, NO. 133-TUESDAY, JULY 12, 1977

In consideration of the foregoing, 40CFR Part 413 is hereby amended as setforth below.

Dated: June 30. 1977.

" " 'BARBARA. BLUM,Acting Administrator.

APPExDIx A-TEnNIcAL SummARY ArmBASIS FOR PEGu-ATIOIS

This Appendix summarizes the basis forinterim final pretreatment standards for ex-isting -sources in the electroplating pointsource category.

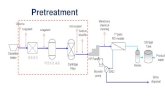

(1) General methocdology. The pretreat-ment standards set forth herein were devel-oped in the following manner: The pointsource category was first studied for the pur-pose of determining whether separate stand-ards-are appropriate for different segmentswithin the category. The raw waste charac-teristics for each such segment were thenidentified. This included an analysis of thesource, flow and volume of water used In theprocess employed, the sources of waste andwaste waters in the operation and the con-stituents of all waste water. The compatibil-ity of each raw waste characteristic with'municipal treatment works was then con-sidered. Waste water constituents posingpass-through or interference problems forPOTW were identified.

The control and treatment technologiesexisting within each segment were identified.This included Identification of each distinctcontrol and treatment technology, includingboth in-plant and end-of-process technol-ogies, which exist or are capable of being de-signed for each segment. It also includedidentification of the effluent level resultingfrom the application of each of the technol-ogies in terms of the amount of constitu-ents and the chemical, physical, andbiological characteristics of pollutants. Theproblems, limitations, and reliability of eachtreatment and control technology were alsoidentified. In addition, the nonwater qualityenvironmental impact, such as the effects ofthe application of such technologies .uponother pollution problems, including air. solidwaste, noise, and radiation were identified.The energy requirements of each control andtreatment technology, were determined aswell as the cost of the application of suchtechnologies.

The information, as outlined above, wasthen evaluated in order to determine whatlevels of technology reflected the applica-tion of appropriate pretreatment technolo-gies. In identifying such technologies, vari-ous factors were considered. These includedthe total cost of application of technology.the age of equipment and facilities involved.the process employed, the engineering as-pects of the application of various types ofcontrol techniques, process changes, non-water quality environmental Impact (includ-ing energy requirements) and other factors.

The data upon Which the above analysiswas performed included EPA permit appli-cations, EPA sampling and inspections, con-sultant reports, and industry submissions.

(2) Summary of technical analyses-(i)Categorization. Previous regulations for theelectroplating point source category weresubcategorized on the basis of process con-,siderations. Electroplating was separatedfrom metal finishing processes because elec-troplating always requires the action of anelectrical current to deposit a metallic coat-Ing on the basis material acting as an elec-trode. Metal finishing processes may or maynot require a current and may or may notdeposit a metallic coat on the basis mate-rial. The processes of anodizing, coatings,chemical etching and milling are sufficientlydifferent so as to warrant separate subcate-

RULES AND REGULATIONS

gories. Anodizing, usually performed on alu-minium, converts the surface of the ob-ject to the metal oxide The object servesas the anode. Coatings refer principally tochromating, phosphating, and Immersionplating. Each of tfeze processe applies athin protective coat on the treated object.An electrical current may or may not beapplied. Chemical etching and milling in-volve the dissolution of the basis material.

In restudying the industry for the purposeof establishing pretreatment regulations, itwas decided that printed circuit board man-ufacturing and electroless plating alzo war-rant separate subcategorlzaton becauce ofthe unique mixture of electrolytic and elec-troless plating operations found in thceprocesses. Additionally, these processes pro-duce pollutants which may render normalwaste treatment techniques ineffective ifproper safeguards are Ignored.

Finally, the foregoing subcategorization isconsistent with the existing rtructure of theindustry, each subcategory tending to beoriented toward individual markets which donot overlap significantly.

(it) Origins and echaracteristics of wastewater pollutants. Waste water from this In-dustry comes from the pretreatment and posttreatment operations as well as the actualmetal finishing and electroplating steps. Theknown significant pollutants and pollutantproperties from theze operations include pH,total suspended solids, oil and grease, cy-anide, chromium, copper. nickel, zinc, cad-mium, lead, tin, Iron, aluminum, fluoride,phosphorus, silver, palladium, and variousprecious metals and organic compounds. Thepresent study indicates'that many of thesepollutants may occur together and that theirindividual concentrations may exceed 100mg/l•

Waste water results from the following op-erations in this industry: (1) Rinsing to re-move films of processing solution from thesurface of work pieces at the site of each op-eration, (2) rinsing away spills (3) washingthe air that passes through ventilation ductsso as to remove spray from the air before Itis exhausted, (4) dumps of spent solutions.(5) washing of equipment, and (6) ccOliilgwater used in heat exchangers to cool colu-tions in metal finishing proceses. Approxi-mately 90 percent of the water consumed isin rinsing. That used as cooling water isusually recycled for rinsing. Operating solu-tions to be dumped are slowly trickled intothe rinse waters prior to treatment

Many of the pollutants which are gen-erated pose significant interference or pathrough problems at POTW. The problemsposed by the parameters affected by the pres-eat regulations are as follows:

(a) Cyanide. Cyanides are widely used inthe electroplating industry and are amongthe most toxic of pollutants commonly dis-charged In industrial waste waters. Cyanidemay exist as free cyanide as hydrocyanicacid, or In a complex, bound in varying de-gree to metals which are also present Inwastes from this Industry.

Of these three forms, hydrogen cyanide(HCN) is probably the most acutely lethalcompound. HCN dissociates In water to hy-drogen Ions and cyanide Ions in a pH de-pendent reaction. The cyanide Ion Is lesacutely lethal than HCN. The relationship ofpH to HCN shows that as the pH is loweredto below 7 there is less than 1 percent of thecyanide molecules in the form of the CN Ionand the rest is present as HCN. When the pHis increased to 8. 9, and 10. the percentage ofcyanide present as ON ions Is 0.7, 42. and 87percent, respectively. The toxicity of cya-nides is increased by increases in tempera-ture and reductions in oxygen tensions. Atemperature rise of 101C produces a two to

35837

threefold ncrea-e in the rate of the lethalaction of cyanide.

In the body. the CN ion, except for a smallportion exhaled, is rapidly changed into arelatively non-toxlc complex (thlcyanate)in the liver and eliminated in the urine. Thesafo ingested limit of cyanide has been esti-mated at amounts lecs than 18 mgday, partof which comes from normal environmentaland industrial exposure. The average fataldo: of HCN by ngestion by man is 50 to 60mg. The US. Public Health Service recom-mended limit for drinking water was 0.1mg/l. with a mandatory maximum of 0.2mg/I; however, the National Interim PrimaryDrinking Water Regulations do not limitcyanide.

Cyanides are more toxic to fish than tolower aquatic organisms such as midge lar-val. crustaceans, and mussels. Toxicity tofish is a function of chemical form and con-centration, and is influenced by the rate ofmetabolism (temperature), the level of dis-solved oxygen, and pH. In the laboratory freecyanide concentrations ranging from 0.05 to0.15 mg/i have been proven to be fatal tocensItive flh species including trout, bluegills, and fathead minnows. Levels above 02mg/i are rapidly fatal for many species. Longterm sublethal concentrations of cyanide aslow as 0.01 mgJI have been shown to affectthe ability of fish to function normally, e.g,reproduce, grow, move freely.

Cyanide forms complexes with metal ionspre=t In waste water. All these complexesexist in equilibrium with HCN. Therefore,the concentration of free cyanide present isdependent on the pH of the waste and therelative strength of the metal-cyanide com-plex. The cyanide complexes of zinc, cad-mium, and copper may dissc late to releasefree cyanide. Also, where these complexes oc-cur together, synergistic effects have beendemonstrated. Zinc, copper, and cadmiumcyanide are more toxic than an equal concen-tration of sodium cyanide.

Iron cyanides are tightly bound complexesand are not extremely toxic. However, ironcyanide readily dissociates when exposed tosunlight. This poes. problems for cyanidedischarges into a POTW. Ferric chloride iscommonly added in a POT7 as part of thetreatment system. Cyanide in the waste wa-ter will readily complex with the iron, re-main diczolved, pass through the POTW, andsubzequently photodecompose, releasing cy-anide to the ambient waters.

A recond pa--through problem related tocyanide is caused by chlorination of wastewaters by the POTV for the purpose of dis-Infection. Chlorination has been found toconvert residual cyanide into highly toxiccyanogen chloride, which is subsequentlyreleased to the environment.

Finally, cyanide can also interfere withthe operation of a POTW. Threshold inhibit-ing concentrations for POTW range from 0.1-5.0 mg/I. Inhibition of activated sludge unitshs been reported between 05-6.0 mg/lSlug discharges of cyanide have caused com-plete failure of some POTW.

At lower concentrations, cyanide s par-tinlly blodegradeable. However, POTW treat-ment efflciency is highly variable, with someplants reporting less than 30 percent removal.

(b) Hexaral et chromium. Chromium ex-Ists in two states, CrIII and Cr.VI. and itis the latter form that is more toxic. Hexa-valent chromium is an Irritant, and corro-sive, and may be absorbed by inhalation, in-geItlon, and through the skin. It causes skinulcers, is a skin sensitizer, can have corro-sive effects on, the intestinal tract and causeinflammation of the kidneys.

For fish, the range of 98-hour LC50 valuesis 10-300 mg/l, including 17.6 mg/I for fat-head mnnos.. and 118 mg/i for bluegill.Alevin and Juvenile chinook salmon, and

FEDERAL REGISTER, VOL 42, NO. 133-TUESDAY, JULY 12, 1977

RULES AND REGULATIONS

rainbow trout are more sensitive to chro-mium than adults. Concentrations of 0.01-0.20 mg/l Cr,VI increase alevin mortalityand retard growth temporarily. Chromiumstress during maturation and spawning issuspected of causing susceptibility to infec-tions. Freshwater zooplankton studies haveshown the water flea to be the most sensi-tive invertebrate to CrVI, with a 48-hourLC50 of 0.022 m/I. It appears that adult fishare relatively tolerant of Cr,VI, but thatboth freshwater and marine Invertebratesare quite sensitive. A CrVI level of 0.001-0.002 mg/l is a safe level for invertebratesand fish. The National Interim PrimaryDrinking Water Regulations limit chromiumin drinking water -to not more- than 0.05mg/l.

Cr.,VI is toxic to activated sludge. Thresh-old inhibitory concentrations range from 1-10 mg/il. Inhibition of activated sludge unitshas been reported between 5-10 mg/l. Inmany large cities industrial sources are re-sponsible for 72-100 percent of Influent chro-mium concentrations. Current local sewerordinance limitations range from 0.05-10mg/l.

Chromium is moderately removed byPOTW. There is a great deal of variabilityamong POTW; the average is around 5opercent removal, but for some systems it Isas low as 14 percent.

The chromium which does not passthrough a POTW is deposited in the POTWsludge. Concentrations of chromium in sludgevaried in one study from 20-10,000 mg/kg,with over half of the measurements less than100 mg/kg. Sludge in Buffalo, New Yorkhad concentrations of 2540 mg/kg 'before im-plementation of pretreatment standards, and1040 mg/kg after the regulations were putinto effect. The chromium content in munici-pal sludge can limit the use of the sludgeas a soil conditioner. Chromium is mobilein soil, and may readily leach from landfill, or filter into a water supply. This is asignificant problem since a large portion ofthe Nation's water supply comes from under-ground sources. One Canadian study com-pared levels of chromium in soil, and vegeta-tion, before and after application of sludge,and found that the concentrations In thesoil and the plants increased 50 percent afterthe sludge use. In some agricultural cropschromium can cause reduced growth or deathof the crop. Adverse effects of low concen-trations of chromium on corn, tobacco andsugar 'beets have been documented.

(c) pH. Extremes of pH or rapid pH changescan exert stress conditions or kill biologicallife outright. At a pH greater than 10,disruption of a biological treatment systemis likely. At a low pH, corrosion of sewerpipes may be caused. Furthermore, at a pHbelow 7.5, only small amounts of metals areconverted to hydroxide form. Since solublemetals tend to pass through POTW untreated,whereas metal hydroxides will tend to beremoved in primary clarifiers, pH levels havean Important Indirect effect on the signifi-cance of metal pass-through problems.

(iv) Treatment and control technology.Waste water treatment and control tech-nologies have been studied for this indus-try to determine the best practicable pre-treatment technologies. This study showedthat although there are differences betweensubcategories in the types and quantitiesof wastes generated, the same general treat-ment technologies are available to this entireindustrial segment.

Electroplating wastes are typically treatedby a number of sequential control tech-niques. General practice includes segregationand Individual treatment of the wastes con-taining cyanide and chrome followed by theremoval of metals by pH adjustment andclarification or filtration in a common treat-ment system. As discussed elsewhere in the

preamble, this regulation does not requireremoval of the metals. Therefore, the presentpretreatment limitations for this industryare based on th e following control tech-niques: The reduction of hexavalent chro-mium to Trivalent chromium, (2) oxidationof cyanides, and (3) pH-adjustment to therange of 7.5 to 10. The use of the technologiesdiscussed below formed the basis of the pre-treatment standards which are lVeing estab-lished. However, this does not preclude theuse of other waste water treatment tech-niques which provide equivalent or betterlevels of treatment. Alternate treatmenttechnologies are discussed in the develop-ment document.

(a). Chrome reduction. Reduction of hexa-valent chrome to trivalent chrome is widelypracticed within the industry and is typi-cally done using sulfur dioxide at a pHof approximately 2.

Seventy-three plants sampled by theAgency had operating chrome reduction fa-cilities. The number of data points from eachplant varied from one to one hundred andthirty-three. The data from each plant were'averaged Into a single number so that allplants were considered equally. Approxi-mately 60 percent of these plants alreadymeet the limitations specified by this regula-"tion.

(b) Cyanide destruction. Cyanide must betreated before treatment for metals removalmay take place. If this is-not done solublemetal cyanide complexes rather tl~an Insolu-ble metal hydroxides will be formed.

Cyanide destruction is generally done in atwo-stage oxidation treatment system usingchorine or hypochlorlte. The first stage ofthe reaction oxidizes cyanide to cyanate, andthe second, cyanate to nitrogen and carbondioxide. The amenable cyanide limitationsset by this regulation may be achieved by asingle stage treatment system that com-pletes the first step in this reaction. I

The total cyanide limitation set by thisregulation is based on two stage treatmentand careful separation of iron, nickel, andcertain other metal bearing wastes from the-cyanide wastes in order to avoid formationof metal cyanide complexes that are untreat-able by established .waste treatment tech-nologies. This latter segregation practice isstandard good housekeeping procedure andis well established within the industry.

Eighty-five plants sampled during thisstudy had cyanide oxidation facilities. Thedata from each plant were treated In thesame manner as the data on chrome reduc-tion. The limitations set by this regulationbased on cyanide oxidation are currentlyachieved by approximately 60 percent of thedata base.

(c) pH adjustment. pH control is an es-tablished and readily available control. tech-nique which was practiced by all of theplants sampled In this study. Typically, the.pH is adjusted by adding an acid, such ashydrochloric or sulfuric, or base (lime orcaustic) to the waste stream in an agitatedtank. pH control is achieved by mixing suf-ficient amounts of acid or base to the wasteto maintain the pH in the desired range.

(iv) Cost estimates for control of wastewater pollutants. Cost information was ob-tained from industry, from engineeringfirms, equipment suppliers, governmentsources, and available literature wheneverpossible. Costs based on actual industrialinstallations or engineering estimates forprojected facilities as supplied by contribut-ing companies were also used.

The foregoing cost information was used todevelop and verify a costing program whichwas then used to cost treatment plants forelectroplating establishments of varioussizes and compositions. Eighty-one modelplants were used.to characterize the treat-ment costs associated with this Industry.

These models and a summary of the costingmethodology are available for public Inspec-tion at the EPA Public Information Refer-ence Unit, Room 2922, (EPA Library), Water-side Mall, 401 Zvi Street SW., Washington,D.C. 20460.

(v) Energy requirements and nonwatcrquality environment impacts. The energycosts related to the implementation of theseregulations are generally limited to electric-.ity required for liquid" transfer pumps andagitator motors.

The major nonwater quality considerationwhich may be associated with those pretreat-ment standards is the generation and releaseto the POTW of metal bearing solid wastes,Use of pH adjustment without metals re-moval by the Industrial user generally resultIn incidental removal of some fraction of themetals at the POTW. Contamination of thesludge from the POTW with these wastes canlimit the sludge disposal alternatives avail-able to the POTW, increase the cost of ade-quate sludge disposal facilities and preventthe use of the sludge for beneficial purposessuch as agriculture. For- these reasons, asdiscussed elsewhere in the preamble, theAgency s currently considering additionallimitations which would require removal ofthese wastes by the Industrial user.

Under the present regulations, sludge dis-posal by the Industrial user should not posea problem.

No significant increase in noise, radiation,air pollution or thermal pollution will resultfrom the implementation of these pretreat-ment standards.

(3) Economic summary. This section sum-marizes the economic and Inflationary Im-pacts of the pretreatment standards for theElectroplating Point Source Category. Execu-tive Orders 11821 and 11949, and OMB Cir-cular A-107 require that major proposals forlegislation and promulgation of regulationsand rules by agencies of the executive branchbe accompanied by a statment certifying thatthe inflationary Impact of the proposal hasbeen evaluated. The Inflationary Impact ofthese standards has been evaluated In aneconomic Impact analysis, the results ofwhioh are summarized below.

The standards directly affect two kinds offirms: (1) Independent establishments per-forming processes covered by these standardsas their primary line of business, and (2)captive establishments performing regulatedprocesses as part of the manufacture of someother product.

The standards are expected to have ad-verse economic impacts on some Independentoperations. Although captive establishmentswere not analyzed in great detail, It Is an-ticipated that the impact on them will beless than on independent operations. The ad-verse impacts on Independent shops are pri-marily due to capital availability problemsthat the captives are expected to have to amuch lesser degree. In 'addition, the com-pliance cost a captive tends to be a muchsmall fraction of production cost since it isbeing spread over more production operations,The specifics of the following discussion referonly to metal finishing job shops.

Total investment costs for the metal finish-ing job shops to comply with the standardsare estimated to be 38 million dollars. Thisestimate allows for the fact that some jobshave treatment facilities already in place,Annualized compliance costs are estimated tobe 15 million dollars per year. This includesboth capital charges and .operations andmaintenance costs.

An estimated 235 job shops representing5,900 jobs may close as a result of the pre-treatment standards. This represents eightpercent of the job shops and nine percentof the workers in the job shop sector of theindustry.

FEDERAL REGISTER; VOL 42, NO. 133-TUESDAY, JULY 12, 1977

35838

Prices are expected to rise to account feiincreased compliance costs. The price of theregulated metal finishing services is expectedto rise by an average of between L2 and 4.2percent. Profitability and owners' compensa-tion are expected. to drop slightly in the shortrun for those firms that remain open, butare expected to return to .their original levelswithin a few years of compliance as the in-dustry adjusts to the new abatement require-ments.

APEIX B.- SUZR xvOF PUBLICPARTICIPATION

The following are *the principal agenciesand groups consulted in the developmentof regulations: (1) Effluent Standards andWater Quality Information Advisory Com-mittee (established under section 515 ofthe Act); (2) all .State and US. TerritoryPollution Control Agencie ; (3) Departmentof Interior (4) Department of Commerce;(5y Department of Defense; (6) Departmentof the Treasury, (7) Water Resources Coun-cil; (8) Atomic Energy CommiSion; (9)Office of Management and Budget; (10) Na-tional Association of Metal Finishers; (11)Metal Finishers Suppliers Association; (12)American Electroplating Society; (13) In-stitute of Printed Circuits; (14) AlbertsPlating Works, Inc4 (15) American Hot DipGalvanizer, (16) - American Society ofMeceanical Engineers; (17) Hudson RiverSloop Restoration, Inc.; (18) The Conserva-tion Foundation; (19) Environmental De-fense Fund. Inc.; (20) Natural ResourcesDefense Council; (21) The American Societyof Civil Engineers; (22) Water Pollution Cqn-trol Federation; (23) National Wildlife Fed-eration; (24) American Institute of ChemicalEngineers; (25) New England Interstate Water Pollution Control Commission.

The following responded with commentsfollowing publication of the Phase I andPhase II regulations: California State WaterResources Control Board; Delaware RiverBasin CommiIon; State of New York De-partment of Environmental Conservation;Commonwealth of Kentucky Department ofNatural Resources and Environmental Pro-tection; State of Ohio Environmental Pro-tection Agency; Tlie Commonwealth of Mas-sachusetts Water Resources Commission;State of Michigan Department of NaturalResources; State of Georgia Department of.Natural Resources; City of Philadelphia;Colorado Department of. Public Health;Municipality of-Metropolitan Seattle; DallasWater Utilities; State of Connecticut Depart-ment of Environmental Protection, Depart-ment of Commerce; Department of Defense;Department of Health, Education and Wel-fare; United States Department of the In-terior; API Industries; State of NebraskaState of Wisconsin; State of Virginia; Stateof North Carolina; State of Illinois; State ofIndiana; Izasir Walton League of America;,Environmental Resources Defense Council;General Electric; Ford Motor Company;,Hewlett Packard; R. 0. Hull and Company;Macerd, Inc.; Institute of Printed Cir-cuits; Kalamus and Associates, Inc.; Ber-linger Plating Inc.; Chromium Inc.; Honey-well; Alco Cad-Nickel Plating Corporation;Frank G Pallard and Associates; Tri-Coun-try Hard Chrome, Inc.; National Associa-tion of Metal Finishers; Bell and Howell;Western Electric; Digital Equipment Cor-poration; The Plate-All Metal Company;American Electroplaters' Society, Inc4 MetalFinishing Suppliers Association, Inc.; Barn-ard and Maybeck; Hay Company;, HarshawChemical Company;, Alcoa Company; Fred-erich Gumn Chemical Company;, ScientificControl Laboratories; Milwaukee PlatingCompany; Raytheon Company;, GTE Syl-vania; Eastman Kodak Company; Chrome-

RULES AND REGULATIONS

Rite Company; Graham Plating: WelchAllyn; Bendix Corporation; Gould Corpora-tion; H.I.G., Incorporated; Luster-On Prod-ucts, Inc.; The Ansul Company; Olin Brass;Photo-Chemical Mhchining Institute; Whirl-pool Corporation; Reynolds Metals Company;Monet-Monocraft; American Iron and SteelInstitute; Optic-Gage. Inc.; Sperry Univac;

" Teledyne CAE; Andes. Inc.; Baker Brothers;- Rockwell International; Industrial Filter and

Pump Manufacturing Company; Rogers Cor-poration; Control Data Corporation; NRCCorporation; Litton Industry; C. E. MangeDevelopment Laboratory; Platers SupplyCompany; SybronCorporation; VanDerHoratCorporation of America; Pratt and Whitney

* Division of United Aircraft; Columbus In-dustrial Association; Keeler Bra-s Company;Lancy Laboratories; Xvasters-ElectroplatingAssociation; Association or Home ApplianceManufacturers; Oxy Metal Finishing Cor-poration; E. I. DuPont de INemours. Inc.;Electronic Industries Assoclation; TRW, Inc.;Burndy Corporation; Jamestown Electroplat-ing Works, Inc.; Douglas and Lomazon Com-pany; Revere Copper and Bra, Inc.; Sargentand Company; AMP. Inc.; Products Finish-ing; Wald Manufacturing Company; UnitedStates Water Resource Council; S. X. Wil-liams Company; Manufacturing Jewelers andSilversmith of 4merlca, Inc.; True TemperCorporation; Tecas Instruments, Inc.; Ca-terpillar Tractor Company; BASF WyandotteCorporation; Lea-Ronal, Inc.; AutomaticPlating Corporation; American Institute ofChemical Engineers; Aircraft Radio and,Control.,

The major Issues raised by commentersduring the development or these regulationsand the subsequent resolution of these issuesare as follows:

1. Numerous commenters questioned theneed for pretreatment except in cas wherethe POTW fails to meet its permit limits

By requiring pretreatment only whenPOTW permit conditions are violated., tlleAgency would be Ignoring serious pollutantproblems. Incompatible toxic pollutants In-troduced Into a POTV by an Industrial usermay pass through the POTW nubstantallyuntreated into the receiving water withoutcausing the POTW to violate Its BOD, TSS,or pH permit limitations. Pass-through oftoxic pollutants can result in accumulationsin receiving water sediments with subcequentdamage to benthic blots, bloaccumulationsof toxic pollutant to unacceptable levels infish, and other water quality problem.

The Agency believes that the requirementsfor industrial users of P0TW eztabl-hedpursuant to section 307 (b) and (o) of theAct and the standards for POTW lursuant tosecti6ns 301 and 301 are separate require-ments designed to be achieved concurrently.The pollutant parameters governed by thepresent standards pass through or Interferewith the operation of P1OTW. These stand-ards, accordingly, apply whether or not aparticular POTW Is already In compliancewith secondary treatment standards or other

-limitations established in Its permit. Con-versely a POTW must comply with applicablestandards and limitations even though In-dustries discharging to It have not met pre-treatment standards.

2. Many commenters stated that the pro-treatment limitations should be expres=ed interms of concentration rather than as masslimitations. /

The limitations specfiled in this regulationare expressed In terms of concentration al-thougiroptional mass-based linitations maybe developed later which will allow local en-forcement authorities to choo30 between thetwo. The Agency has decided to uzo concen-tration limits in this regulation because ofthe ease of enforcing such limit- and becauseof the need to implement the pretreatment

35839

program as quickly as possible. However, di-lution may be a problem in some instances.Whero dilution Is encountered and is o co=-cern local authorities should consider theneed for prohibitIons on dilution, inspectionof pretreatnent and industrial facilities andenforcement of mass limitations.

3. Numerical limitations different thantho:o e=blilshed by this regulation wereproposed by come commenters. The com-ments focused on the technical feasibility ofattaining certain limitations by means ofgiven treatment technologies. The commentsalso focused on the economic impact ofestablishing various levels of standards.

The standards cet forth in these regula-tions are ba ed on a careful assessment bythe Agency of data concerning the levels ofcontrol which can be attaine'i by use ofavailable treatment technologies. 1sta sup-plied by the commenters as well as data col-lected by the Agency was used in developingthe standards. Furthermore, the Agency hasgiven careful attention to the possible eco-nomic impact of c-tablishing various stand.ards. As discussed elsewhere in the preamble.the decision to develop regulations in twostages is closely related to the Agency'sefforts to fully conolder the economic situa-tion of different. cements of the industry inestablishing pretreatment standards. Theformulation of the present standards isdescribrd In more detail in Appendix A.

Part 413, Chapter 1, Subchapter N.Title 40 of the Code of Federal Regula-tions is amended as follows:

Subpart A-Electroplating Point SourceCategory

Subpart A, § 413.11 Is amended by re-vising paragraph (d) and adding para-graphs (e), (D, and (g) as follows:§ 413.11 Specialized definitions.

(d) The term "CNA" shall mean cya-nide amenable to chlorination.

(e) The term "CNT" shall meancyanide, total.

(D The term "CrVr" shall mean hexa-valent chromium.

(g) The term "electroplating processwaste water" shall mean process wastewater generated in operations which are -subject to regulations for the electro-Plating point source category.

Subpart A Is amended by adding§ 413.14 as follows:

§ 413.14 Pretreatment standards for existing sources.

For the purpose of establishing pre-treatment standards under-section 307(b) of the Act for a source within theelectroplating of common metals sub-category, the provisions of Part 128 ofthis chapter shall not apply. The pre-treatment standards for an e-istingsource within the electroplating of com-mon metals subcategory are set forthbelow.

(a) No pollutant (or pollutant prop-ertY) introduced into apublicly ownedtreatment works shall interfere with theoperation or performance of the -works.Specifically, the following wastes shallnot be introduced into the publicly ownedtreatment works:

(1) Pollutants which create a. fire orexplos ion hazard in the publicly ownedtreatment works.

-FEDERAL REGISTER, VOL 42, NO. 133-TUESDAY, JULY 12, 1977

35840

(2) Pollutants which will cause cor.rosive structural damage to treatmentworks, but in no case pollutants with apH lower than 5 unless the works isdesigned to accommodate such pollut-ants.

(3) Solid or viscous pollutants inamounts which would cause obstructionto the flow in sewers, or other inter-ference with the proper operation of thepublicly owned treatment works.

(4) Pollutants at either a hydraulicflow rate or pollutant flow rate which Isexcessive over relatively short time pe-riods so that there is a treatment processupset and subsequent loss of treatmentefficiency.

(b). In addition to the general pro-hibitions set forth in paragraph (a) ofthis section, the following pretreatmentstandards establish the quality or quan-tity of pollutants or pollutant propertiescontrolled by this section which may beintroduced into a publicly owned treat-ment works by a source subject to theprbvisions of this subpart.

(1) For plants discharging less than40,000 gallons per day of electroplatingprocess waste water the following limita-tions shall apply:

Pretreatment standard

Pollutant or Average of dailypollutant property Maximum for values for So

any 1 day consecutive daysshall not exceed-

Milligrams per liter

CN, A ----------- 0.20 ------------ 0.0

(2) For plants discharging 40,000 gal-lons per day or more of electroplatingprocess waste water the following limita-tions shall upply:

Pretreatment standard

Pollutant or " Average of dailypollutant property Maximum for . values for 30

any 1 day consecutive daysshall not exceed-

Mliligrams per liter

CN, A ---- 0.20 ---------- 0.08CN T-- O-- ..---...... 0.24Cr ;VI.---- 0.25 -- - 0.09

--------- Within the range -.............7.5 to 10.0.

Subpart B-Electroplating of PreciousMetals Stibcategory

Subpart B, § 413.21 is amended by re-vising paragraph (d) and adding para-graphs (e), (f), and (g) as follows:§ 413.21 Specialized definitions.

(d) The term "CN,A" shall meancyanide amenable to chlorination.

(e) The term "CN,T" shall meancyanide, total.

(f The term "CrVI" shall mean hex-avalent chromium.

(g) The term "electroplating processwaste water" shall mean process wastewater generated in operations which aresubject to regulations for the electroplat-ing point source category. -

Subpart B is amended by adding§ 413.24 as follows:

"RULES AND- REGULATIONS

§ 413.24 Pretreatment standards for ex-isting sources.

For the purpose of establishing pre-treatment standards under Section 307(b) of the Act for a source within theelectroplating of precious metals sub-category, the provisions of Part 128 ofthis chapter shall not apply. The pre-treatment -standards for an existingsource within the electroplating of pre-cious metals subcategory are set forthbelow:

(a) No pollutant (or pollutant prop-erty) introduced into a publicly ownedtreatment works shall interfere with theoperation or performance of the works.Specifically, the following wastes shallnot be introduced into the publiclyowned treatment works:

(1) Pollutants which create a fire orexplosion hazard in the publicly ownedtreatment works.

(2) Pollutants which will cause corro-sive structural damage to treatmentworks, but in no case pollutants with apH lower than 5, unless the works is de-signed to accommodate such pollutants.

(3) Solid or viscous pollutants Inamounts which would cause obstructionto the flow in sewers, or other interfer-ence with the proper operation of'thepublicly owned treatment works.

(4) Pollutants at either a hydraulicflow rate or pollutant flow rate which isexcessive over relatively short time pe-riods so that there is a treatment processupset and subsequent loss of treatmentefficiency.

(b) In addition to the general prohi-bitions set forth in paragraph (a) of thissection, the following -pretreatmentstandards establish the quality or quan-

Jtity of pollutants or pollutant propertiescontrolled by this section which may beintroduced into a publicly owned treat-ment works by a source subject to theprovisions of this subpart.

(1) For plants discharging less than40,000 gallons per day of electroplatingprocess waste water the folloring limita-tions shall apply:

Pretreatment standard

Pollutant or Average of dailypollutant property Maximum for values for 30

any 1 day consecutive daysshall not exceed-

Milligrams per liter

CN, A ---- / -..... 0.20 ------------ 0.08

(2) For plants discharging 40,000 gal-lons per day or more of electroplatingprocess waste water the following limita-tions shall apply:

Pretreatment standard

Pollutant or Average of dailypollutant property Maximum for values for 30

any 1 day consecutive daysshall not exce d-

Milligrams per liter

CN, A ----------- 0.20- 0.03CN T ------- 0.64 -- 0.24CrI .. .------ 0.25 ------------- 0.09p ----------------- Within the range. ...........

7.5 to 10.0.

Subpart D-Anodizing SubcategorySubpart D, § 413.41 Is amended by re-

vising paragraph (d) and adding para-graphs (e), (f), and (g) as follows:§ 413.41 Specialized definitions.

(d) The term "CN,A" shall mean cya-nide amendable to chlorination.

(e) The term "CN,T" shall mean cya-nide, total.

(f) The term "Cr,VI" shall mean hex-avalent chromium.

(g) The term "electroplating processwaste water" shall mean process wastowater generated in operations which aresubject to regulations for the electro--plating point source category.

Subpart D is amended by adding sec-tion 413.44 as follows:§ 413.44 Pretreatment standards for ex-

isting sources.For the purpose of establishing pre-

treatment standards under section 307(b) of the Act for a source within theanodizing subcategory, the provisions ofPart 128 of this chapter shall not apply.The pretreatment standards for an eX-isting source within the anodizing sub-category are set forth below.

(a) No pollutant (or polldtant proper-ty) introduced into a publicly ownedtreatment works shall interfere with theoperation or performance of the works.Specifically, the following wastes shallnot be introduced into the publiclyowned treatment works:

(1) Pollutants which create a fire orexplosion hazard in the publicly ownedtreatment works.

(2) Pollutants which will cause corro-sive structural damage to treatmentworks, but in no case pollutants with apH lower than 5, unless the works is de-signed to accommodate such pollutants.

(3) Solid or viscous pollutants Inamounts which would cause obstructionto the flow in sewers, or other interfer-ence with the* proper operation of thepublicly owned treatment works.

(4) Pollutants at either a hydraulicflow rate or pollutant flow rate whichis excessive over relatively short timeperiods so that there is a treatment proc-ess upset and subsequent loss of treat-ment efficiency.(b) In addition to the general prohibi-

tions set forth in paragraph (a) of thissection, the following pretreatmentstandards establish the quality or quan-tity of pollutants or pollutant propertiescontrolled by this section which may beintroduced into a publicly owned treat-ment works by a source subject to theprovisions of this subpart..

(1) For plants discharging less than40,000 gallons per day of electroplatingpromess waste water the following limita-tions shall apply:

Pretreatment standard

Pollutant or Average of dailypollutant property Maximum for values for 30

any I day consecutive daysshall riOt exceed-

Milligrams per liter

CN, A ------------ 0.20 ............. 0.08

FEDERAL REGISTER. VOL 42, NO. 133-TUESDAY, JULY 12, 1977

RULES AND REGULATIONS

- (2) For plants discharging 40,000 gal-lons per day or more of electroplatingprocess waste water the following limita-tions shall apply:

Pretreat3nent standard

Pollutant or Aveage of dailypollutant property vrnrimum-for values for 30

any I day cOnscutive daysshall not erased-

AUilligrams per liter

N,A 0.20 0.03CrV.. .0.25 .0.09

p Within therange 7.5to 10.0.

Subpart E-Coatings SubcategorySubpart E, § 413.51 is amended by re-

vising paragraph (d) and adding para-graphs (e), (f), and (g) as folfows:§ 413.51 .Specialized definitions.

(d) The term "CNA" shall mean cy-anide amenable to chlorination.

(e) The term "CN,T" shall mean cya-nide, total.

(f) The term "CrVI" shall mean hexa-valent chromium.

(g) The term "electroplating processwaste water" shall mean process wastewater generated in operations which aresubject to regulations for the electro-plating point source category.

Subpart E is amended by adding § 413.-54 as follows:§ 413.54 Pretreatment standards for e-x-

isting sources.For the purpose of establishing pre-

treatment standards under section 307(b) of the Act for a source within thecoatings subcategory, the provisions ofPart 128 of this chapter shall not apply.The pretreatment standards for an exist-ing source within the coatings subcate-gory are set forth below.

(a) No pollutant (or pollutant prop-erty) introduced into a publicly ownedtreatment works shall interfere with theoperation or performance of the works.Specifically, the following wastes shallnot be introduced into the publicly ownedtreatment works:

(1) Pollutants which create a fire orexplosion hazard in the publicly ownedtreatment works.

(2) Pollutants which will cause corro-sive structural damage to treatmentworks, but in no case pollutants with apH lower than 5, unless the works isdesigned to accommodate such pollut-ants.

(3) Solid or viscous pollutants inamounts which would cause obstructionto the flow in sewers, or other infer-ference with the proper operation of thepublicly owned treatment works.

(4) Pollutants at either a hydraulicflow rate or pollutant flow rate which isexcessive over relatively short timeperiods so that there -is a treatmentprocess upset and subsequent loss oftreatment efficiency.

(b) In addition to the general prohibi-tions set forth in paragraph (a) of thissection, the following pretreatmentstandards establish the quality or quan-tity of pollutants or pollutant propertiescontrolled lhy this section which may beintroduced into a publicly owned treat-ment works by a source subject to theprovisions of this subpart.

(1) For plants discharging less than40,000 gallons per day of electroplatingprocess waste water the following limita-tions shall apply:

Pretrcatmcnt standard

Pollutant or Avcao of dailypollutant property MIaximum far v far W.

any I day con:=utive dayshall not c=acu.

lWgras lprlltcr

OZ - --- . . .. . .0.03

(2) For plants discharging 40,000 gal-lons per day or more of electroplatingprocess waste water the following limi-tations shall apply:

Pretreatment standard

Pollutant or Averag of dailypollutant propcrty Muaxlmum Lcr values far50

any I day cennucutive da3jthall not cx-"-

111111gran= per liter

CN,A . O . 0.03N, T . 0.... 0.21Cr I . . ... 00.09pit-------------Within the

rango 7.5to 10.0.

Subpart F-Chemical Etching and MillingSubcategory

Subpart F, § 413.61 is amended by re-vising paragraph (d) and adding para-graphs (e), (f) and (g) as follows:§ 413.61 Spcciallzcd defnitions.

(d) The term "CNA" shall mean cya-nide amenable to chlorination.

(e) The term "CNT" shall mean cya- 9nide, total.(f) The term "CrVI" shall mean hex-

avalent chromium.(g) The term "electroplating process

waste water" shall mean process wastewater generated in operations which aresubject to regulations for the electro-plating point source category.

Subpart F is amended by adding§ 413.64 as follows:§ 413.64 Pretreatment standards for cx-

isting sources.For the purpose of establishing pre-

treatment standards under section 307(b) of the Act for a source Within the

-chemical etching and milling subcate-gory, the provisions of Part 128 of thischapter shall not apply. The pretreat-ment standards for an existing sourcewithin the'chemical etching and millingsubcategory are set forth below.

35841

(a) No pollutant (or pollutant prop-erty) introduced into a publicly ownedtreatment works shall interfere with theoperation or performance of the works.Specifically, the following wastes shallnot be introduced into the publicly ownedtreatment works:

(1) Pollutants which create a fire orexplosion hazard in the publicly ownedtreatment works.

(2) Pollutants which will cause corro-sive structural damage to treatmentworks, but In no case pollutants with apH lower than 5.0, unless the works isdesigned to accommodate such pollu-tants.

(3) Solid or viscous pollutants inamounts which would cause obstructionto the flow in sewers, or other interfer-ence with the proper operation of thepublicly owned treatment works.

(4) Pollutants at either a hydraulicflow rate or pollutant flow rate which isexcessive over relatively short time pe-riods so that there is a treatment proc-ess upset and subsequent loss of treat-ment efficiency.

(b) In addition to the general prohibi-tions set forth in paragraph (a) ofthis chapter, the following pretreatmentstandards establish the quality or quan-tity of pollutants or pollutant propertiescontrolled by this section which may beintroduced into a publicly owned treat-ment works by a source subject to theprovisions of this subpart-

(1) For plants discharging less than40,000 gallons per day of electroplatingprocess waste water the following limita-tions shall apply:

Pollutant or Average ofdaiypolluant 4.cg:rtr Maximum faz vr r 30

any I day cacLtiva da3-shall not exceed-

Ml~lgam pzrilter

(2) For plants discharging 40,000 gal-lons per day or more of electroplatingprocess waste water the following limi-tations shall apply:

Prctramtmantsan1d

PMlutant cr Ava - zoffdaiyutEn~an pzrt'Y Maximum fa valu. fcrOanyI day co=n-scutlv days

sllnot exmedi-

Xairnraxna per litcr

cN, A ... . ..... 0.sCNT .. . 0.2

Or. Vl .. 0-..... 0. 09pIL........Withn therag7.5 to10.0.

40 CER Part 413 is amended by addinga new Subpart G as follows:

Subpart G-EMectroless PlatingSec.413.70 Applicabllty; description of the

ele-ctroleas plating subcategory-.

FEDERAL REGISTER, VOL 42, NO. 133-TUESDAY, JULY 12, 1977

35842

413.71 Specialized definitions.413.72-413.73 [Reserved]413.74 Pretreatment standards for existing

Gources.AuTOHmosT: Sec. 307(b), Federal Water

Pollution Control Act, as amended (33 U.S.C.1251, 1317(b); 86 Stat. 816 et seq.; Pub. L.92-5Q0 (the Act).

Subpart G-Electroless Plating§ 413.70 Applicability; description of

the electroless plating subcategory.The provisions of this subpart are ap-

plicable to discharges resulting from theelectroless plating of a metallic layer on ametallic or nonmetallic substrate.§ 413.7r Specialized definitions.

For the purpose of this subpart:(a) Except as provided below, the gen-

eral definitions, abbreviatlons and meth-ods of analysis set forth in Part 401 ofthis chapter shall apply to this subpart.

(b) The term "electroless plating" shallmean the deposition of conductive ma-terial from an autocatalytic plating solu-tion without application of electricalcurrent.

(c) The term "sq in" ("sq ft")'shallmean the area plated expressed in squaremeters (square feet).

(d) The term "operation" shall meanany step in the electroless plate proc-ess which Is followed by a rinse and in

,which a metal is deposited on a basismaterial.

(e) The term "CN,A" shall meancyanide amenable to chlorination.

(f) The term "CN,T" shall meancyanide, total.

(g) the term "Cr, VI" shall mean hex-avalent chromium.

(h) The term "electroplating processwaste water" shall mean process wastewater generated in operations which aresubject to regulations for the electro-plating point source category."§ 413.72, [Reserved]§ 413.73 [Reserved]§ 413.74 Pretreatment standards for ex-

isting sources.

For the purpose of establishing pre-treatment standards inder section 307(b) of, the Act for a source within the,electroless plating, subcategory, the pro-visions of part 128 of this chapter shallnot apply. The pretreatment standardsfor an existing source within the electro-less plating subcategory are set .orthbelow.

(a) No pollutant (or pollutant prop-erty) introduced into a publicly ownedtreatment works shall interfere with the.operation or performance of the works.Specifically, the following wastes shallnot be introduced into the publicly ownedtreatment works:

(1) Pollutants which create a fire orexplosion hazard in the publicly ownedtreatment works.

(2) Polluftmts which will cause cor- ~

Iroslve structural damage to treatmentworks, but in no case pollutants with apH lower than 5.0, unless the works isdesigned to accommodate such pol-lutants.

RULES AND REGULATIONS

(3) Solid or viscous pollutants inamounts which would -cause obstructionto the flow in sewers, or other interfer-ence with the proper operation of thepublicly owned treatment works.

(4) Pollutants at either a hydraulicflow rate or pollutant rate which is ex-cessive over relatively short time periodsso that there Is a treatment process up-set and subsequent loss of treatment ef-ficiency.

(b) In addition to the general prohibi-tions set forth in paragraph (a) of thissection, the following pretreatmentstandards establish the quality or quan-

* tity of pollutants or pollutant propertiescontrolled by this section which may beintroduced into a publicly owned treat-ment works by a source subject to theprovisions of this subpart.

(1) For plants discharging less than40,000 gallons per day of electroplatingprocess waste water the following limita-tions shall apply:

Pretreatment standard

Pollutant or Average of dailypollutant property Maximum for values for 30

any I day consecutive daysshall not exceed-

Milligrams per liter

CN, A --------- 0.20 0............ - O 08

(2) For plants discharging 40,000 gal-lons per day or more of electroplatingprocess waste water the following limita-tions shall apply:

Pretreatment standard

Pollutant or Average of dailypollutant property Maximum for values for 30

any 1 day consecutive daysshall not exceed-

Milligrams per liter

-CN, A ....... 0.20 ------------- 0.08CN T --- 0.64 ------------- 0.24Cr, VI ............ 0.25 ------------- 0.09pH ---------------- Withintherange

7.5 to 10.0.

- ,Subpart H-Printed Circuit BoardSec.413.80 Applicability; description of the

printed circuit board subcategory.413.81 Specialized definitions.413.82-413.83 [Reserved].413.84 Pretreatment standards for existing

sources.AuTHoRrrY.--Sec. 307(b), Federal Water

Pollution Control Act, as amended (33 U.S.C.1251, 1317(b)); 86 Stat. 816 et seq.; Pub. L.92-500 (the Act).

Subpart H-Printed Circuit Board§ 413.80 Applicability; description of

the printed circuit board subcategory.,The provisions of this subpart are ap-

plicable to "the manufacture of printedcircuit boards including all manufactur-ing operations required or used to con-vert an insulating substrate to a finishedprinted circuit board. The provisions setforth in other subparts of this categoryare not applicable to the manufacture ofprinted circuit boards.

§ 413.81 Specialized definitions.For the purpose of this subpart:(a) Except as provided below, the gen-

eral definitions, abbreviations and meth-ods of analy1s set forth In Part 401 ofthis chapter shall apply to this subpart,.

(b) The term "printed circuit board"shall mean any insulating carrier whichhas circdltry adhered thereto or encap-sulated therein primarily for the pur-pose of interconnecting electric and elec-,tronic components.

(c) The term "sq m" ("sq ft") shallmean the area of the printed circuitboard immersed in an aqueous processbath.

(d) The term "operation" shall meanany step in the printed circuit boardmanufacturing process wherein theboard is immersed in an aqueous processbath which is followed by a rinse.

(e) The term. "CNA" shall mean cya-nide amenable to chlorination.

(f) The term "CN,T" shall mean cya-nide, total.

(g) The term "Cr, VI" shall mean hoX-avalent chromium.

(h) The term "electroplating processwaste water" shall mean process wastewater generated in operations which aresubject to regulations for the electroplat-ing point source category.§ 413.82 [Reserved]§ 413.83 [Reserved]§ 413.84 Pretreatment standards for ex-

isting sources.For the purpose of establishing pre-

treatment standards under section 307(b) of the Act for a source within theprinted circuit board subcategory, theprovisions of Part 128 of this chaptershall not apply. The pretreatment stand-ards for an existing source within theprinted circuit board subcategory areset forth below.

(a) No pollutant (or pollutant prop-erty) introduced into a publicly ownedtreatment works shall Interfere with theoperation or performance of the works,Specifically, the following wastes shallnot be introduced into the publicly ownedtreatment works:

(1) Pollutants which create a fire orexplosion hazard in the publicly ownedtreatment works.

(2) Pollutants which will cause corro-sive structural damage to treatmentworks, but in no case pollutants with apH lower than 5.0, unless the works is de-signed to accommodate such pollutants.

(3) Solid or viscous pollutants inamounts which would cause obstructionto the flow in sewers, or other interfer-ence with the proper operation of thepublicly owned treatment works.

(4) Pollutants at either a hydraulicflow rate or pollutant flow rate which Isexcessive over relatively short time pe-riods so that there is a treatment processupset and subsequent loss of treatmente]fciency.

(b) In additiorto the general prohibi-tions set forth in paragraph (a) of thissection, the following pretreatmentstandards establish the quality or quan-tity of pollutants or pollutant properties