Electrochemical copolymerization of thiophene derivatives; a precursor to photovoltaic devices

-

Upload

prajwal-kumar -

Category

Documents

-

view

213 -

download

0

Transcript of Electrochemical copolymerization of thiophene derivatives; a precursor to photovoltaic devices

Ep

PD

a

ARRAA

KCCIEC

1

(rppmsbrem(aowmt

pi

0d

Electrochimica Acta 56 (2011) 8184– 8191

Contents lists available at ScienceDirect

Electrochimica Acta

j ourna l ho me pag e: www.elsev ier .com/ locate /e lec tac ta

lectrochemical copolymerization of thiophene derivatives; a precursor tohotovoltaic devices

rajwal Kumar, K. Ranjith, Satyajit Gupta, Praveen C. Ramamurthy ∗

epartment of Materials Engineering, Indian Institute of Science, Bangalore 560012, India

r t i c l e i n f o

rticle history:eceived 23 February 2011eceived in revised form 28 April 2011ccepted 5 June 2011vailable online 23 July 2011

eywords:onducting polymer

a b s t r a c t

This work presents an electrochemical technique for the polymerization and copolymeriza-tion of thiophene derivatives like 7,9-dithiophene-2yl-8H-cyclopenta[a]acenaphthalene-8-one and3-hexylthiophene. The structural characterization of chemically synthesized monomers and electro-chemically synthesized polymers was carried out by nuclear magnetic resonance and Fourier transforminfrared spectroscopy. Thermal characterizations indicate that copolymer has increased thermal stabilitythan that of homopolymer. Morphological studies of the polymerized films carried out by scanning elec-tron microscopy shows network structure of copolymer. Optical properties of the homopolymers and

yclic voltammetrympedancelectrochemical depositionopolymer

copolymer were studied by UV–visible spectrometer and it was observed that band gap of copolymeris less than the homopolymers. HOMO and LUMO levels, band gap values of the respective polymerswere also calculated from the cyclic voltammetry technique with various scan rates. By the peak cur-rent obtained from various scan rates shows that all polymerization reactions are diffusion controlledprocess. Charge transfer resistances of polymers were determined using Nyquist plots. Conductivity ofsynthesized polymers shows higher conductivity for copolymer than homopolymers.

. Introduction

Research and development in the field of conducting polymersCPs) is an exciting area. Even though lot of research is being car-ied out, many more issues need to be addressed to make theseolymers useful for a device application. Most of the conductingolymers are difficult to process due to poor solubility in com-on organic solvents. However, low cost and less energy intensive

ynthesis techniques make CPs as a promising material for flexi-le organic electronics [1,2]. Band gap engineering is a challengingesearch area in organic electronics [3]. There have been significantfforts for synthesis and characterization of low band gap poly-ers [4]. Last few decades, various types of conducting polymers

CPs) such as unsaturated carbon atoms in backbone [5], carbontoms with electron rich heteroatom [6] have been synthesized forbtaining low band gap materials. Tailoring a polymer structureith donor (D) and acceptor (A) groups at the backbone resultsultiple intense absorption bands which is one of the approaches

o obtain low band gap materials for photovoltaic applications [7].

Polymerization of thiophene based derivatives is an oxidationrocess and can be achieved by chemically as well as electrochem-cal techniques [8]. The anodic oxidation of monomers is currently

∗ Corresponding author. Tel.: +91 80 2293 2627; fax: +91 80 2360 0472.E-mail address: [email protected] (P.C. Ramamurthy).

013-4686/$ – see front matter © 2011 Elsevier Ltd. All rights reserved.oi:10.1016/j.electacta.2011.06.114

© 2011 Elsevier Ltd. All rights reserved.

the most employed method for electrochemical synthesis of CPs.Monomer 7,9-dithiophene-2yl-8H-cyclopenta[a]acenaphthalene-8-one has an electron accepting acenaphthenequinone (n type)[9] held between two electron donating (p type) thiophenemoieties giving rise to a donor–acceptor–donor (DAD) archi-tecture. Hence this monomer in this work is abbreviatedas DAD. Both thiophene derivatives 7,9-dithiophene-2yl-8H-cyclopenta[a]acenaphthalene-8-one (DAD) and 3-hexylthiophene(3HT) were used for the electrochemical homopolymerization andcopolymerization. Poly(DAD) is insoluble in most common organicsolvent. It has been shown earlier that solubility of CPs could beimproved by introducing various moieties such as alkyl chains tothe backbone [10,11]. Hence, hexyl substituted thiophene (3HT)was copolymerized with DAD, as alkyl substituted thiophene incopolymer backbone will enhance the processability of the poly-mer in addition to decrease the bandgap. It is generally observedthat cyclic voltammetry (CV) method leads to more homogeneousfilms as studied by various optical and structural techniques [12]and deposition generally carried out on an inert metallic workingelectrode such as platinum or gold [13]. However, as depositiontime increases, film thickness goes on increasing leading to het-erogeneous polymer film [14]. In this study polymerizations were

carried out by three electrode system using platinum as a workingelectrode, platinum wire as a counter electrode and nonaqueousAg/Ag+ as reference electrode. Synthesized polymers were furtherevaluated for thermal, optical and morphological properties.mica A

2

2

d3dlSdpb

2

2(

(l(awffic(s

6or(ryTihN77

2

b(ss(oc

beaacrloccaı7

P. Kumar et al. / Electrochi

. Experimental

.1. Materials

Dicyclohexylcarbodiimide (DCC), 2-thiophene-acetic acid,imethylaminopyridine (DMAP) and acenaphthenequinone,-bromothiophene, [1,3-bis (diphenylphosphino) propane]ichloronickel(II) (Ni(dppp)Cl2), 1-bromohexane and tetrabuty-

ammonium hexafluorophosphate (TBAPF6) were purchased fromigma Aldrich and used without further purification. Solventsichloromethane (DCM), ethanol, and acetonitrile (ACN) wereurchased from local suppliers (SD Fine Chem Ltd.) and distilledefore use.

.2. Synthesis

.2.1. Synthesis of 7,9-dithiophen-2-yl)-8H-cyclopenta[a]acenaphthylen-8-one (DAD)

Before synthesizing DAD, the intermediate compound dithiophen-2-yl) propan-2-one was synthesized as reported ear-ier [7]. To a stirred solution of DCC (7.6 g, 0.0368 mol) and DMAP1.23 g, 0.01 mol) in anhydrous DCM (70 mL), 2-thiophene-aceticcid (5 g, 0.0352 mol) in anhydrous DCM (30 mL) was added dropise at 0 ◦C under inert atmosphere. Reaction was carried out

or 12 h at room temperature. Byproduct urea was removed byltration. Purification of the product was carried out by columnhromatography in 100–200 mesh silica gel with petroleum etherPE) and ethyl acetate (EA) as the eluent (1–5% PE/EA). Residualolvent was removed under vacuum.

In a round bottom flask, di (thiophen-2-yl) propan-2-one (1.5 g,.75 mmol) and acenaphthenequinone (1.23 g, 6.75 mmol) in 75 mLf ethanol was added at room temperature and the mixture wasefluxed for 2 h under inert atmosphere. Potassium hydroxide0.1 g) dissolved in 3 mL of ethanol was added drop wise to theeaction mixture. During addition, the reaction mixture turns fromellow to dark green color and was stirred for further 15 min.he mixture was then quenched into an ice bath and precip-tate was filtered. Product was washed with cold ethanol andot hexane, respectively and dried under vacuum. Yield = 82%. 1HMR spectrum (Fig. 3A) (CDCl3, ı in ppm): 8.413–8.431(2H, d),.924–7.935(2H, dd), 7.879–7.899 (2H, d), 7.655–7.694 (2H, t),.494–7.509 (2H, dd), 7.216–7.259 (2H).

.2.2. Synthesis of 3-hexylthiophene (3HT)Synthesis of 3HT was carried out by Grignard reaction using 3-

romo thiophene [15]. In a round bottom flask magnesium turnings0.435 g, 0.178 mol) and 0.1 g of iodine to activate the magne-ium was charged to 20 mL of diethyl ether. Resulting yellow colorolution was kept under stirring for 1 h in ice bath. Bromohexane3 g, 0.01 mol) was added to the mixture and refluxed for 1 h. Thebtained white turbid solution of hexyl magnesium bromide wasooled to room temperature.

In an another flame dried two neck round bottom flask 3-romothiophene and Ni(dppp)Cl2 were mixed with 30 mL diethylther and kept for stirring. Hexyl magnesium bromide in ether wasdded drop wise to the above stirring solution under cold and inerttmosphere. The reaction mixture was refluxed for 6 h and thenooled to room temperature. 2 N hydrochloric acid was added to theeaction mixture until the reaction mixture stops bubbling. Organicayer was separated by extracting with ether (3 × 50 mL). Obtainedrganic layer was dried over anhydrous sodium sulfate and con-entrated under vacuum. The product was purified by column

hromatography using 230–400 mesh silica gel and neat hexane asn eluting solvent. Yield = 85%. 1H NMR spectrum (Fig. 3B) (CDCl3,in ppm), 0.86–0.88 (3H, t), 1.28–1.36 (6H, m), 1.56–1.62 (2H, m),.18–7.20 (1H, m), 6.98–6.99 (1H, dd), 6.87–6.91 (1H, m).

cta 56 (2011) 8184– 8191 8185

2.2.3. Preparation of nonaqueous Ag/Ag+ electrodeSilver nitrate (AgNO3) is insoluble in DCM and completely sol-

uble in acetonitrile (ACN). Hence for the reactions in this worknon aqueous electrode with DCM:ACN mixture was used. 10 mM ofAgNO3 was dissolved in DCM:ACN (1:1) mixture and to this 0.1 MTBAPF6 was added. The resulting solution mixture was poured intoa glass tube and capped with silver wire to form nonaqueous Ag/Ag+

electrode. The solution mixture was filled to 2/3 of glass tubingvolume (Scheme 1).

2.2.4. Electrochemical homopolymerization andcopolymerization of DAD and 3HT

Electrochemical homopolymerization and copolymerization ofDAD and 3HT were carried out at room temperature by using CVtechnique. A platinum foil of area 1.5 cm × 3.5 cm with 0.05 cmthickness as a working electrode, platinum wire as a counter elec-trode, and Ag/Ag+ electrode as reference electrode were used forthe deposition. Deposition was carried out inside Faraday cage con-nected with pico amp booster. Because of insolubility of monomerin aqueous solvent, depositions were carried out in a non aque-ous solvent as electrolytic solution [16]. TBAPF6 0.01 M was usedas supporting electrolyte [17,18]. DCM and acetonitrile were usedas electrolyte for homopolymerization of DAD and 3HT monomers,respectively, while a mixture of DCM and acetonitrile (1:1 ratio)was used for the copolymerization. Before each deposition nitrogengas was purged for 20 min. For the homopolymer poly (DAD) depo-sition, 15 mL of DCM was taken in a reaction cell into which 0.0552 g(0.01 M) of DAD monomer was dissolved. Deposition was carriedout by potentiodynamic technique in a potential range of −0.8 Vto +1.2 V with the scan rate of 100 mV/s. Poly(3HT) depositionwas achieved with acetonitrile as an electrolyte, in which 0.0252 g(0.01 M) of 3HT monomer was dissolved and deposition was car-ried out by potentiodynamic technique of the potential range of0.2 V to +1.4 V with the scan rate of 100 mV/s. Copolymerizationwas carried out by using mixture of solvents DCM and acetonitrilemixture (1:1) as an electrolyte, in which 0.0552 g (0.01 M) of DADand 0.0252 g (0.01 M) 3HT was dissolved. Deposition was carriedby potentiodynamic technique with potential range of −0.8 V to+1.4 V. All polymerization reactions were carried out with a scanrate of 100 mV/s for 20 cycles.

2.3. Equipment and measurements

CHI 660D CV instrument was used for the electrochemical poly-merization, band gap and impedance measurements. Nicolet 5700Fourier transform infrared spectroscopy (FTIR) (KBr pellet method)was used in the wave number range of 4000–400 cm−1 with aresolution of 4 cm−1. Absorption spectrum was analyzed by usingVarian Carry 500 UV–visible spectrophotometer. Conductivity ofhomopolymers and a copolymer were measured using two pointprobe method by Keithley 236 source unit. Differential scanningcalorimetry (DSC) technique was carried out using Mettler Toledo(DSC 822e) instrument at a heating rate of 10 ◦C min−1 in argonatmosphere at a flow rate of 80 mL min−1 using hermitic aluminumpan. Thermal stability of the as synthesized polymers was car-ried out using high-resolution TGA 2950 (NESTEZ-STA 409PC) witha heating rate of 10 ◦C min−1 in an alumina crucible. The mor-phology of the cross-sectional surface of the polymer depositedelectrochemically over platinum foil were observed using scan-ning electron microscopy (SEM), which was carried out using ESEMQuanta. Thickness and surface roughness of the electrochemicallydeposited films were determined by Wyko NT1100 optical pro-

filometer. Bruker ultra shield 400 MHz NMR was used to obtainthe proton NMR of the compounds. Solution of the materials inchlorobenzene was used for UV–visible measurements with spec-troscopy grade chlorobenzene as the reference.8186 P. Kumar et al. / Electrochimica Acta 56 (2011) 8184– 8191

S

O

OH S S

O

S S

OSS

O

KOH/ ethanolacena phthenequinone

DCC /DMAP

DCM

thiophen-2-y lacetic acid1,3-di(thiophen-2-y l)p ropan-2-on e

DAD

n-BrC6H13

n-MgBrC6H13ether

3-bromo thioph ene/Ni (dp pp)C l2ether S

C6H13

3-hexylthi ophene

S S

O

S

C6H13

+S S

O

S

C6H13

nn

n

S S

O

S S

O

CV

-0.8 V to 1.4 V

CV

n

S

C6H13

S

C6H13

n

poly(DAD-c o-3HT)

poly(DA D)

poly(3HT)

CV

-0.8 V to 1.2 V

0.2 V to 1.4 V

Mg/ I2

HT an

3

brccptw

tiCcco

Scheme 1. Reaction scheme for synthesis of monomers DAD, 3

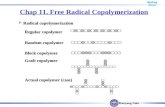

. Results and discussions

Purity of synthesized CP plays major role for conductivity andand gap. Even though chemical polymerization is more familiaroot for synthesis of CPs but many CPs are synthesized by electro-hemical technique. Cyclic voltammogram for homopolymers andopolymer polymerization are as shown in Fig. 1A–C. Change in theeak current on each new segment due to change in working elec-rode environment indicates the polymer deposition on platinumorking electrode.

FTIR spectra of the synthesized materials are shown in Fig. 2. Inhe spectrum of homo polymer poly (DAD), aromatic CH stretch-ng peaks were observed at 3080 cm−1, 3109 cm−1 and 2953 cm−1.

arbonyl stretching peak was observed at 1707 cm−1. The peaksorresponding 1431 cm−1 was due to aromatic ring mode. Theharacteristic peak of thiophene moiety i.e. C–S stretching wasbserved at 835–845 cm−1 and CH out of plane peak was observedd electrochemical synthesis of copolymer poly(DAD-co-3HT).

at 700 cm−1 [19]. FTIR spectrum of homo polymer poly(3HT) showsaromatic CH stretching peak at 2924 cm−1 and aliphatic CH sym-metric stretching at 2854 cm−1 which indicates the hexyl groupof poly(3HT). Aromatic C C peak was observed at 1632 cm−1

and the corresponding aromatic ring mode appears at 1458 cm−1.Characteristic thiophene peak, C–S stretching was observed at839 cm−1. FTIR spectra of copolymer poly(DAD-co-3HT) have aro-matic stretching peak at 3104 cm−1, 3011 cm−1 and aliphatic CH2stretching peak at 2848 cm−1. The aliphatic CH2 stretching peak inthe copolymer indicates the presence of 3HT moiety. The carbonylstretching peak at 1704 cm−1 indicates the presence of DAD moietyin the copolymer. In addition, few common absorption peaks wereobserved in both copolymer and homopolymers FTIR spectrum.

Common peaks observed are at 1632 cm−1, 1480 cm−1, 1420 cm−1of aromatic mode and characteristic peak of thiophene ring C–Sstretching peak at 839 cm−1. These results indicate the electro-chemical copolymerization of DAD and 3HT monomers. The broad

P. Kumar et al. / Electrochimica Acta 56 (2011) 8184– 8191 8187

1.5 1.0 0. 5 0.0 -0. 5 -1. 0

-0.000 04

0.0000 0

0.0000 4

I/A

E/V

A

B

C

poly(DAD )

1.4 1.2 1. 0 0.8 0. 6 0.4 0.2

0.0

2.0x10-5

4.0x10-5

I/A

E/V

poly(3 HT)

1.5 1.0 0. 5 0. 0 -0. 5 -1. 0

0.00000

0.00002

0.00004

I/A

E/V

pol y(D AD-co-3 HT)

Fig. 1. Cyclicvoltammetric curve during electrochemical deposition of homopoly-mers (A) poly (DAD) (potential range −0.8 V to 1.2 V vs nonaqueous Ag/Ag+), (B)p +

pr

ppd

saabsa

3500 3000 2500 2000 1500 1000 500

700

839

Wavenumber (cm-1 )

Poly(3HT)

Poly(DAD-co-3HT)

Poly(DAD)

3080

2953

1707

1431

3011

700

83928

48

1708

1632

839

3104

714

Inte

nsity

(a.u

.)

2924 28

54

1632 14

58

700 nm is due to strong �–� interaction of unsaturated long back-bone of polymer [20]. These humps appear due to the vibroniccoupling of singlet excitons of synthesized material [21]. Thusincorporating two different thiophene derivatives to form the back-

oly(3HT) (potential range 0.2 V to 1.4 V vs nonaqueous Ag/Ag ), and copolymeroly(DAD-co-3HT) (potential range −0.8 V to 1.4 V vs nonaqueous Ag/Ag+), scanate of 100 mV/s; 20 cycles.

eak in the region of 3440 cm−1 is due to adsorbed moisture in KBrellet and peak around 2358 cm−1 in poly(3HT) is due to the carbonioxide (Fig. 2).

UV–visible spectra of homopolymers and copolymer are ashown in Fig. 4. Poly(DAD) shows absorption maximum at 380 nmnd also has a shoulder around 487 nm. An absorption hump

ppears around 740 nm with onset at 750 nm and correspondingand gap is determined to be 1.67 eV. Homopolymer poly(3HT)hows absorption maxima at 435 nm with onset around 524 nmnd corresponding band gap was calculated to be about 2.37 eV.Fig. 2. FTIR characterization of electrochemically synthesized poly(DAD),poly(3HT), and poly(DAD-co-3HT).

The synthesized copolymer shows absorption maxima at 428 nmin addition to a hump appearing at about 760 nm. Onset for theobserved hump is about 796 nm and corresponding band gap wascalculated to be about 1.56 eV. The broad absorption band above

Fig. 3. (A) 1H NMR spectrum of DAD monomer (in CDCl3, tetramethylsilane (TMS)as internal standard). (B) 1H NMR spectrum of 3HT monomer (in CDCl3, TMS asinternal standard).

8188 P. Kumar et al. / Electrochimica Acta 56 (2011) 8184– 8191

300 450 600 750 900

Abs

orba

nce

(a.u

.)

λ/n m

poly(DAD)poly(3HT)poly(DAD-co-3 HT)

380487

750435

524428

796

bit

hmE5fppdc˚Efi[wetdm

aprTrc

npfsidwabbaew1t

Fig. 5. Cyclic voltammetric curves for band gap calculation of: (A) poly(DAD),(B) poly(3HT) and (C) poly(DAD-co-3HT) using platinum disc (of area 0.5 mm),nonaqueous Ag/Ag+ and platinum wire of 1 mm as working electrode, reference

Fig. 4. UV visible spectrum of poly(DAD), poly(3HT) and poly(DAD-co-3HT).

one of a copolymer enhance the degree of conjugation, whichnfluence on electronic transition and results red shifts in absorp-ion spectra [22].

Fig. 5A–C indicates CV plots for various scan rate from whichighest occupied molecular orbital (HOMO), lowest unoccupiedolecular orbital (LUMO) and band gap (Eg) were calculated.

xperiments were carried out with various scan rates of 10, 30,0 and 100 mV/s. HOMO, LUMO and band gap values calculatedrom these measurements are tabulated in Table 1. The onsetotentials of n-doping or reduction potential (˚1

n) and the onsetotential of p-doping or oxidation potential (˚1

p) was used toetermine the LUMO and HOMO energy levels of electrochemi-ally deposited copolymers [23]. Potential difference, �˚1 = ˚1

n −1p was used to estimate the band gap (Eg = �˚1) of the film.

lectrochemical potentials (vs SCE) are obtained by adding workunction of ferrocene system (4.8 eV), which is considered as annternal standard while calculating band gap by CV technique24–26]. Hence EHOMO = −e(˚1

p + 4.8) and ELUMO = −e(˚1n + 4.8)

here EHOMO is the HOMO energy level and ELUMO is the LUMOnergy level all potential values are vs Ag/Ag+ as the reference elec-rode. Obtained band gap value indicate that HOMO–LUMO gapecreases for copolymer (1.59–1.68 eV) as compared to homopoly-ers, poly(DAD) (1.63–1.85 eV) and poly(3HT) (1.87–1.92 eV).Potential shifts were not observed as scan rate changes in either

nodic or cathodic peak indicating that all the three polymerizationrocesses are reversible reactions. Anodic, peak current vs squareoot of scan rate for various scan rates are as shown in Fig. 6 andable 1. Straight line in anodic peak current vs square root of scanate indicates polymerization processes are reversible and diffusionontrolled process [27].

Electrochemical impedance spectroscopy is an important tech-ique, used to characterize the interfacial and charge transferroperties of polymer films. AC impedance scans were per-ormed for all the three electroactive polymers. The impedancetudy of electroactive material was carried out to establish thenfluence of applied potential on charge transfer resistance (Rct)uring electrochemical polymerization process. Impedance resultsere recorded in the frequency range of 1 Hz to 1× E5 Hz at voltage

mplitude of 0.025 V. Charge transfer resistances were measuredy using Nyquist plot. The initial potential of 1.5 V were appliedecause at this anodic potential the polymer starts diffusion ofnions to the film and thus results desirable conducting prop-

rty [28]. The measured charge transfer resistance for poly(DAD)as 18,971 �, poly(3HT) was 1411 � and poly(DAD-co-3HT) was856 � (Fig. 7). The observed high value of charge transfer resis-ance for poly(DAD) could be due to the presence of carbonyl

electrode and counter electrode, respectively, with various scan rate of, 10 mV/s,30 mV/s, 50 mV/s and 100 mV/s.

moiety (electron withdrawing group) that acts as charge traps.Consequently, electron transfer at the interface between film andelectrolyte will reduce. In case of copolymer even though film was

uniform and continuous, due the presence of carbonyl group in thebackbone results the slight enhance in the charge transfer resis-tance as compared to poly(3HT) film.P. Kumar et al. / Electrochimica Acta 56 (2011) 8184– 8191 8189

4 8 12 16

1.0x10-5

2.0x10-5

1.50x10-5

3.00x10-5

4.0x10-5

8.0x10-5

r=0 .994 7

υ

poly(DAD -co-3HT)r=0 .981 7

I pa/

A

poly (3HT )

r=0 .989 8poly (DAD )

mV1/2s-1/2

Fig. 6. Graph of anodic peak current versus square root of scan rate for poly(DAD),poly(3HT) and poly(DAD-co-3HT) of various scan rates 200 mV/s, 100 mV/s, 50 mV/s,30 mV/s and 10 mV/s.

400 80 0 120 0 160 0 200 0 240 0

500

1000 400 80 0 120 0 160 0

400

800 0 800 0 1600 0 2400 00

5000

10000

Z′/oh m

poly(DAD-co-3 HT)

poly(3 HT)

poly(DAD)

- Z″/o

hm

F3

au

�

TE

ig. 7. Impedance measurement curve for poly(DAD), poly(3HT), and poly(DAD-co-HT) at 1.5 V from frequency range of 1–1E5 Hz.

Conductivity of electrochemically synthesized homopolymersnd a copolymer were measured by two point probe method [29]sing a formula:

= I

V

(l

wt

)

able 1lectrochemical parameters obtained by cyclic voltammetry for various scan rates of syn

Polymers Scan rate(mV/s)

Oxidationpotential (V)

Reductionpotential (V)

Poly(DAD) 10 0.55 −1.20

30 0.66 −1.29

50 0.53 −1.10

100 0.68 −1.05

200

Poly(3HT) 10 1.51 −0.81

30 1.28 −0.94

50 1.45 −0.95

100 1.47 −0.99

200

Poly(DAD-co-3HT) 10 0.85 −0.70

30 0.87 −0.70

50 0.88 −0.68

100 0.88 −0.69

200

Fig. 8. Conductivity measurement of synthesized poly(DAD), poly(3HT), andpoly(DAD-co-3HT) by two probe method.

where, � = conductivity, w = width of sample area, l = gap lengthbetween the measuring electrodes, and t = thickness of polymerfilm.

Polymers were dissolved in chlorobenzene by heating at 50 ◦Cand simultaneous sonicating for 2 h. On a cleaned glass plate of1 cm × 1 cm gold was deposited by physical vapor deposition. Anarrow crevice of about 5–10 �m was made on the gold surface asshown in the inset of Fig. 8. Leak current across the split surface wasmeasured to be in pico ampere range. About 100 nm thick polymerfilm was drop casted in between the split surface. I–V characteris-tics of the samples were measured. The conductivity of poly(DAD)was determined to about 4.27 E−4 ± 2.19 E−5 S cm−1, poly(3HT)was about 4.17 E−5 ± 1.01 E−5 S cm−1 and for copolymer obtainedconductivity was 1.284 E−2 ± 2.70 E−4 S cm−1. These data indicatethe after copolymerization conductivity increases by two to threeorder magnitude.

To study the melting and crystallization behavior of bothhomopolymers and copolymers were evaluated by DSC betweentemperature range of 0–300 ◦C. For homo polymer, poly(DAD)(Fig. 9A) no transitions were observed in the thermogram. Whereasin case of the poly(3HT) (Fig. 9B) and copolymer poly(DAD-co-3HT)(Fig. 9C), distinct endothermic peaks were observed. First heating

cycle of all samples were neglected due to possible residual solventand thermal history. In the poly(3HT) heating cycle, melting peakwas observed ∼128 ◦C (4.1 J g−1) and which was observed againthesized polymers.

HOMO (eV) LUMO (eV) Band gap (Eg)(eV)

Anodic peakcurrent Ip/A(E−5)

−5.35 −3.60 1.65 3.43−5.46 −3.51 1.76 4.27−5.33 −3.70 1.69 6.26−5.48 −3.75 1.77 7.37

10.16−6.31 −3.99 2.32 0.49−6.08 −3.86 2.22 0.97−6.25 −3.85 2.40 1.34−6.27 −3.81 2.46 2.29

3.05−5.65 −4.10 1.55 0.92−5.67 −4.10 1.57 1.24−5.68 −4.12 1.56 1.31−5.68 −4.11 1.57 1.56

2.29

8190 P. Kumar et al. / Electrochimica Acta 56 (2011) 8184– 8191

0 50 100 15 0 200-0.3

0.0

-0.4

-0.2

0.0

0.8

T/°C

poly(DAD-c o-3HT )

2nd heating cycle

3rd he ating cyc le

Hea

t flo

w (m

W)

exo

poly(3HT )

poly(DAD)

Fc

iwhtThimcsCcc

aoowc2

fitomc

F

ig. 9. (A) DSC thermogram of synthesized poly(DAD), poly(3HT), and poly(DAD-o-3HT).

n next heating cycle. In case of poly(DAD-co-3HT) melting peaksere observed ∼129 ◦C (7.8 J g−1) and ∼175 ◦C (7.6 J g−1). In the nexteating cycle, the reappearance of the endothermic peaks at abouthe same temperature shows the reversibility in the transitions.he enthalpy of melting observed for copolymer was found to beigher than that of poly(3HT). This increased in enthalpy of melting

ndicate enhancement of crystallinity for the synthesized copoly-er. This increased crystallinity of the copolymer will enhance the

harge transport mechanisms as observed from conductivity mea-urements. The decrease in band gap observed in both UV–vis andV techniques could be due to the increased crystallinity (whichan reduce the defects and increase packing) of the copolymerompared to homopolymers [30].

Thermal stability of both homopolymers and copolymer werenalyzed by TGA (Fig. 10). Up to 260 ◦C 24.8% weight loss wasbserved for poly(DAD) and for poly(3HT) 10.3% weight loss wasbserved, where as for copolymer poly(DAD-co-3HT) only 6.6%eight loss was observed. These results indicate that synthesized

opolymer is thermally more stable than homopolymers up to80 ◦C.

Prior to the SEM analysis, samples were sputter-coated with thinlm of gold using JEOL (JFC-1100E) ion sputtering device. Charac-erization of as synthesized homo polymers and copolymer film

n platinum foil shows morphological changes from homopoly-er to copolymer. The homo polymer poly(DAD) (Fig. 11A) hasircular fibrous morphology. Poly(3HT) (Fig. 11B) images resembles

100 200 300 400 500

0

20

40

60

80

100

Wei

ght l

oss (

%)

T/°C

poly(DAD )poly(3HT)poly(DAD -co-3 HT)

ig. 10. Thermal gravimetric analysis of poly(DAD), poly(3HT), poly(DAD-co-3HT).

Fig. 11. Morphological study of homopolymers poly(DAD), poly(3HT) and copoly-mer poly(DAD-co-3HT).

mica A

s(fimpaar

dwsfma1wifi

4

aaimccmatptcgirttp

A

C

[[

[[

[[

[[[

[[

[

[

[[[

[

[[

[29] M.C. Quiles, T. Ferenczi, T.A. Gostinelli, P.G. Etchegoin, Y. Kim, T.D.

P. Kumar et al. / Electrochi

mall flakes deposited on a smooth film. But in case of copolymerFig. 11C) there is resemblance to the morphology of the poly(DAD)lm. In addition, copolymer a higher density of circular fibrousorphology was observed. From morphological studies of homo

olymers and a copolymer infers that these films could be useds an interpenetrating network of copolymer for both photovoltaicnd sensor applications as there is an increase in surface to volumeatio.

Thickness and surface roughness of the electrochemicallyeposited homopolymer and copolymer films on the platinum foilere measured using Wyko NT1100 optical profilometer. The mea-

ured thickness of the both homopolymer and copolymer wereound to be about 160 ± 10 �m. RMS roughness of poly(DAD) was

easured to be 560.0 ± 185.5 nm and that of poly(3HT) film wasbout 78.9 ± 21.4 nm. Copolymer film RMS roughness was about98.7 ± 54.0 nm. Same thickness for all the three polymer filmsas obtained but RMS roughness for electrochemically polymer-

zed poly(3HT) and poly(DAD-co-3HT) was less than poly(DAD)lms.

. Conclusions

In the present study both homopolymers poly (DAD), poly(3HT)nd copolymer poly(DAD-co-3HT) were electropolymerized. FTIRnalysis indicates the formation of copolymer. Thermal studiesncluding TGA and DSC indicate that copolymer is more ther-

ally stable than homopolymers and also enhanced crystallinity ofopolymer compare to homopolymer was observed. This increasedrystallinity of the copolymer will enhance the charge transportechanisms. Both UV visible and CV technique results indicate

lower band gap of copolymer (1.56 eV and 1.64 eV, respec-ively) than poly(DAD) (1.67 eV and 1.71 eV, respectively) andoly(3HT) (2.37 eV and 1.89 eV, respectively). Measured conduc-ivity of copolymer shows about three order increase in theonductivity compared to homopolymers. This decrease in bandap observed in both UV–visible and CV techniques and increasen the conductivity could be due to the increased crystallinity thateduce the defects and increase packing of the copolymer comparedo homopolymers. These results indicate that the copolymer as syn-hesized by electrochemical technique is a promising material forhotovoltaic applications.

cknowledgements

This study is partially supported by KRCF (Korea Researchouncil of Fundamental Science & Technology) and KIST (Korea

[

cta 56 (2011) 8184– 8191 8191

Institute of Science & Technology) for ‘NAP (National AgendaProject) program’. In addition, authors gratefully acknowl-edge the financial support from DST No. SR/S3/ME/025/2008,technical support from Tribology lab, mechanical engineer-ing department and NMR research centre, IISc. One of theauthor SG would like to acknowledge CSIR for financialsupport.

References

[1] C.J. Brabec, N.S. Sariciftci, J.C. Hummelen, Adv. Funct. Mater. 11 (2001) 15.[2] C.J. Brabec, Sol. Energy Mater. Sol. Cells 83 (2004) 273.[3] D. Sahu, H. Padhy, D. Patra, J. Huang, C. Chu, H. Lin, J. Polym. Sci. Part A: Polym.

Chem. 48 (2010) 5812.[4] I. Jung, H. Kim, M. Park, B. Kim, J. Park, E. Jeong, H.Y. Woo, S. Yoo, H. Shim, J.

Polym. Sci. 48 (2010) 1423.[5] M. Thakur, Macromolecules 21 (1988) 661.[6] Y. Yao, Q.T. Zhang, J.M. Tour, Macromolecules 31 (1998) 8600.[7] K. Ranjith, S.K. Swathi, P. Kumar, P.C. Ramamurthy, J. Mater. Sci. 46 (2011) 2259.[8] J. Roncali, Chem. Rev. 92 (1992) 711.[9] W. Walker, B. Veldman, R. Chiechi, S. Patil, M. Bendikov, Macromolecules 41

(2008) 7278.10] R.L. Elsenbaumer, K.Y. Jen, R. Oboodi, Synth. Met. 15 (1986) 169.11] J.P. Ruiza, B. Melinda, K.N. Gieselmana, D.S. Marynick, J.R. Reynolds, Synth. Met.

28 (1989) 481.12] A. Efremova, A. Regis, L. Arsov, Electrochim. Acta 39 (1994) 839.13] B. Ilic, D. Czaplewski, P. Neuzil, T. Stanczyk, J. Blough, G.J. Maklay, J. Mater. Sci.

35 (2000) 3447.14] A. Walcarius, E. Sibottier, M. Etienne, J. Ghanbaja, Nat. Mater. 6 (2007) 602.15] M. Trznadel, A. Pron, M. Zagorska, R. Chrzaszcz, J. Pielichowski, Macromolecules

31 (1998) 5051.16] W. Simka, D. Puszczyk, G. Nawrat, Electrochim. Acta 54 (2009) 5307.17] A. Baba, W. Knoll, J. Phys. Chem. B 107 (2003) 7733.18] E. Bundgaard, S.E. Shaheen, F.C. Krebs, D.S. Ginley, Sol. Energy Mater. Sol. Cells

91 (2007) 1631.19] O. Papila, L. Toppare, Int. J. Polym. Anal. Charact. 9 (2004) 13.20] G. Zerza, A. Cravino, H. Neugebauer, R. Gómez, J.L. Segura, N. Martín, M. Svens-

son, M.R. Andersson, N.S. Sariciftci, Mater. Res. Soc. Symp. Proc. 660 (2001).21] K. Pakbaz, C.H. Lee, A.J. Heeger, T.W. Hagler, D. McBranch, Synth. Met. 64 (1994)

295.22] B. Chen, Y. Wu, M. Wang, S. Wang, S. Sheng, W. Zhu, R. Sun, H. Tian, Eur. Polym.

J. 40 (2004) 1183.23] Y. Li, Y. Cao, J. Gao, D. Wang, G. Yu, A.J. Heeger, Synth. Met. 99 (1999) 243.24] S. Xiao, H. Zhou, W. You, Macromolecules 41 (2008) 5688.25] Q. Shi, H. Fan, Y. Liu, W. Hu, Y. Li, X. Zhan, J. Phys. Chem. 114 (2010)

16843.26] D.Y.W. Yu, C. Fietzek, W. Weydanz, K. Donoue, T. Inoue, H. Kurokawa, S. Fujita-

nia, J. Electrochem. Soc. 154 (2007) A253.27] A. Sargent, O.A. Sadik, Electrochim. Acta 44 (1999) 4667.28] S.N. Sawant, M. Doble, J.V. Yakhmi, S.K. Kulshreshtha, A. Miyazaki, T. Enoki, J.

Phys. Chem. B 110 (2006) 24530.

Anthopoulos, P.N. Stavrinou, D.D.C. Bradley, J. Nelson, Nat. Mater. 7 (2008)158.

30] K. Vandewal, W.D. Oosterbaan, S. Bertho, V. Vrindts, A. Gadisa, L. Lutsen, D.Vanderzande, J.V. Manca, Appl. Phys. Lett. 95 (2009) 123303.