Effect of process parameters on surface hardness, dimensional accuracy and surface roughness of...

-

Upload

sunpreet-singh -

Category

Documents

-

view

216 -

download

3

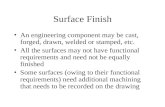

Transcript of Effect of process parameters on surface hardness, dimensional accuracy and surface roughness of...

Journal of Mechanical Science and Technology 27 (1) (2013) 191~197

www.springerlink.com/content/1738-494x

DOI 10.1007/s12206-012-1218-5

Effect of process parameters on surface hardness, dimensional accuracy and

surface roughness of investment cast components†

Rupinder Singh* and Sunpreet Singh

Department of Production Engineering, Guru Nanak Dev Engineering College, Ludhiana, Punjab, India

(Manuscript Received May 13, 2012; Revised August 20, 2012; Accepted August 28, 2012)

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Abstract

This paper deals with investment casting (IC) application for development of spherical disc of ball valve as a case study. Three control-

lable factors of the IC process, namely: volume/surface-area (V/A) ratio of components, slurry layer’s combination (LC) and type of

metal (MT), were studied at three levels by Taguchi’s parametric approach and single-response optimization was conducted to identify

the main factors controlling surface hardness (SH), surface roughness (Ra) and dimensional accuracy (∆d). Ceramic shell moulds were

made on wax plate using primary slurry and fused-silica sand as stucco. Castings were produced using Al, M.S and S.S at recommended

arameters by following Taguchi L9 orthogonal array through ceramic shell IC process. The microstructure analysis has been used to

study the surface morphology.

Keywords: Investment casting; Surface hardness; Surface roughness; Dimensional accuracy; Metal type; Volume/surface-area ratio; Slurry layer’s combi-nation.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Introduction

Spherical disc is the component of the ball valve which con-

trols the flow of fluid through it by rotating at 180° angle. The

mechanical properties of the spherical disc are required of

superior quality in order to avoid any interruption during

working. Investment casting (IC) is a widely used technique

for modern metal casting that provides an economical means

of mass producing shaped metal parts containing complex

features [1-3].

Components are replicated from the precise pattern and

transmitted in turn to the castings. IC allows dimensionally

accurate components to be produced and is a cheaper alterna-

tive than forging and machining since waste material is kept to

a minimum [4-7]. The mold is made by surrounding a wax or

plastic replica of the part with ceramic material [2].

After the ceramic material solidifies, the wax replica is

melted out, and metal is poured into the resulting cavity [3, 9-

12]. A special design of the pattern and the riser has been done

to form the plaster mould. The effect of different parameters

like pouring temperature of the metal alloy, firing temperature,

firing time and silica sand of different grain fineness numbers

have been established in IC process [7, 13-16]. This process is

used for the production of numerous equipments like: dental

tools, electrical equipment electronics, radar, guns, hand tools,

jewelry, machine tools, material handling equipments, metal

working equipment, agricultural equipment, cameras, pneu-

matics/hydraulics components, etc. [2-5].

IC involves 10 steps as shown in Fig. 1. This research work

is aimed at the development of spherical disc of ball valve by

IC process as a case study. The ball valve with spherical disc

is shown in Fig. 2.

The sphere has a port or hole through the middle so that

when the port is in line to the ends of the valve, flow will

occur and rotating the port perpendicular to the ends of valve

will block the flow. The 3D view of sphrical disc is shown in

Fig. 3.

*Corresponding author. Tel.: +91 9872257575

E-mail address: [email protected] † Recommended by Associate Editor Dae-Cheol Ko

© KSME & Springer 2013

Fig. 1. IC Process.

192 R. Singh and S. Singh / Journal of Mechanical Science and Technology 27 (1) (2013) 191~197

The dimensions for the different sizes (that is 2˝, 3˝ and 4˝)

of spherical discs are shown in Figs. 4(a)-4(c) respectively.

2. Design of experiments

Before going for the final experimentation, pilot experi-

ments were conducted in order to analyze the contributing

parameters and their levels. For the present study, three pa-

rameters were studied in pilot experimentation and their

ranges for best outputs were fixed. Basically, in the pilot ex-

perimentation moulds are prepared with 5, 6 and 7 number of

layers. But when the molten metal was poured into the

mould’s cavity, breakdown of the mould occurred. This is due

to the fact that the pouring pressure of the metal is non-

sustainable to the mould. Finally, when the mould was made

with 8 numbers of layers, castings were prepared safely. So, 8

numbers of layers were fixed for the present work. Further in

the three levels of layer combination, primary and secondary

combinations were kept fixed while the tertiary and the quar-

ter layer combination were varied. The primary coating was

made with the finest refractory followed by coarse one. Al,

S.S and M.S metals were used for the present research work.

These three metals were selected for the present work be-

cause the spherical disc is casted commercially with these

metals, and they have industrial applications in marine, petro-

leum industry and distilled water discharge pipe line respec-

tively. Experiments were conducted under the constraint of

processing parameters and their levels (as shown in Table 1)

by following Taguchi L9 O.A.

Fig. 2. Ball valve assembly.

Fig. 3. 3D drawing of spherical disc.

(a)

(b)

(c)

Fig. 4. (a) Dimensions of 2˝ spherical disc; (b) Dimensions of 3˝

spherical disc; (c). Dimensions of 4˝ spherical disc.

R. Singh and S. Singh / Journal of Mechanical Science and Technology 27 (1) (2013) 191~197 193

3. Experimentation

This research work is aimed at the optimization of surface

hardness, surface roughness and dimensional accuracy of the

selected component (spherical disc). Total 27 numbers of

experiments were conducted under the combinations of differ-

ent levels of input parameters. Table 2 shows the control log

for experimentation.

Hardness was measured as Vickers hardness (HV). Surface

roughness of the casted components was measured by operat-

ing a stylus on the surface profile of the cast components. The

high and low limits are detected and reading was obtained by

mean of a digital output. Whereas the dimensions of the wax

replica and that of the final cast components were measured

with the help of CMM (coordinate measuring machine). The

difference in the dimensions of the wax replica and final

casted components gives the ∆d. ∆d was measured in term of

the outer diameter of the spherical disc (the most critical di-

mension of the spherical disc).

4. Result and discussions

4.1 Surface hardness results

Hardness of any metal depends upon the rate of cooling

within the re-crystallization zone. Making the mould by coat-

ing it with more number of thicker refractory tends to slower

the cooling rate and decreases the hardness of the casted

specimen. Hardness test results for the present work are given

in Table 3. Signal to noise (S/N) is used to represent a re-

sponse or quality characteristics and the largest S/N ratio is

required. Table 4 shows the variation of S/N ratio and hard-

ness w. r. t. to V/A ratio. Fig. 5(a) shows the peak values of

the S/N ratio and hardness w. r. t. V/A ratio of spherical disc

for best setting of the as input parameter.

Table 5 shows the variation of S/N ratio and hardness w. r. t.

to LC. Fig. 5(b) shows the peak value of the S/N ratio and

hardness w. r. t. LC and gives the best setting for hardness.

Table 6 shows the variation of S/N ratio and hardness w. r. t. to

MT. Fig. 5(c) shows the peak value of the S/N ratio and hardness

w. r. t. MT gives the best setting of the surface hardness.

Table 1. Different control variable and their level.

Levels

Parameters L1 L2 L3

V/A ratio (mm) 2.74 3.78 4.09

Layer combination (total no.

of layers fixed to 8) 1+1+3+3 1+1+2+4 1+1+4+2

Type of metal Al S.S M.S

[*Note: 1+1+3+3 signifies one primary layer, one secondary layer,

three tertiary layers and three quarter layers. Similarly in case of

1+1+2+4 and 1+1+4+2, tertiary and quarter layer are varied accord-

ingly while primary and secondary layers remains unchanged]

Table 2. Control log for experimentation.

Exp. No. Variable 1

(V/A ratio)

Variable 2

(LC)

Variable 3

(MT)

1 2.74 mm 1+1+3+3 Al, 600°C

2 2.74 mm 1+1+2+4 S.S, 1550°C

3 2.74 mm 1+1+4+2 M.S, 1600°C

4 3.78 mm 1+1+3+3 S.S, 1550°C

5 3.78 mm 1+1+2+4 M.S, 1600°C

6 3.78 mm 1+1+4+2 Al, 600°C

7 4.09 mm 1+1+3+3 M.S, 1600°C

8 4.09 mm 1+1+2+4 Al, 600°C

9 4.09 mm 1+1+4+2 S.S, 1550°C

Table 3. Observation of final experimentation for hardness (HV).

Vickers hardness

(HV) Sr.

No.

V/A

ratio

Layer

combinations

Type of

metal L1 L2 L3

1 2.74 mm 1+1+3+3 Al 42 43 41

2 2.74 mm 1+1+2+4 S.S 239 237 239

3 2.74 mm 1+1+4+2 M.S 185 184 182

4 3.78 mm 1+1+3+3 S.S 239 241 238

5 3.78 mm 1+1+2+4 M.S 163 167 160

6 3.78 mm 1+1+4+2 Al 50 54 51

7 4.09 mm 1+1+3+3 M.S 180 183 178

8 4.09 mm 1+1+2+4 Al 42 45 43

9 4.09 mm 1+1+4+2 S.S 248 250 251

Table 4. Variation of S/N ratio and hardness w. r. t. to V/A ratio.

Sr No. S/N Ratio Vickers hardness

(HV)

V/A ratio

(mm)

1. 41.75308 154.4444 2.74

2. 42.12057 154 3.78

3. 41.91932 157.7222 4.09

Table 5. Variation of S/N ratio and hardness w. r. t. LC.

Sr No. S/N Ratio Vickers hardness

(HV) LC

1 41.81123 156.4444 1+1+3+3

2 41.48929 148.0556 1+1+2+4

3 42.49244 161.6667 1+1+4+2

Fig. 5(a). S/N response and hardness w. r. t. V/A ratio.

194 R. Singh and S. Singh / Journal of Mechanical Science and Technology 27 (1) (2013) 191~197

The microstructure analysis has been done to study the sur-

face morphology and to support the surface hardness data. In

case of stainless steel IC (Ref. Exp. No-9), it has the maximum

hardness (251 HV) because of the dendrite grains of longer size

as shown in Fig. 6. Dendrites are also formed in Exp. No. 4,

but with slightly smaller grain as compared to Exp. No. 9, so

the hardness is relatively less (241 HV). In Exp. No. 2, micro-

uniformly distributed alloy carbides with inter dendrites segre-

gation are formed having hardness value of 239 HV.

In case of mild steel, surface hardness is maximum in Exp.

No. 3 (that is 185 HV), having uniformly distributed pearlitic-

ferritic microstructure with larger grain size shown in Fig. 7.

While in Exp. No. 7 hardness is slightly less (that is 183 HV),

having non-uniformly distributed pearlitic-ferritic microstruc-

ture with variable grain size and inter-dendrite segregation and

further in Exp. No. 5, hardness is minimum (that is 167 HV)

due to smaller grains.

Aluminum has maximum hardness in Exp. No. 6 (that is

54HV) because of larger grains as shown in Fig. 8. In Exp. No.

1 and in Exp. No. 8 hardness is 43 HV and 45 HV.

4.2 Surface roughness results

The result for the surface roughness is shown in Table 7.

Signal to noise (S/N) is used to represent a response or

quality characteristics and the largest S/N ratio is required.

Table 8 shows the variation of S/N ratio and surface

roughness w. r. t. to V/A ratio. Fig. 9(a) shows the peak values

of the S/N ratio and surface roughness w. r. t. V/A ratio of

spherical disc for best setting as input parameter.

Table 9 shows the variation of S/N ratio and surface rough-

ness w. r. t. to LC. Fig. 9(b) shows the peak value of the S/N

ratio and surface roughness w. r. t. LC gives the best setting of

the surface roughness.

Table 10 shows the variation of S/N ratio and surface

roughness w. r. t. to MT. Fig. 9(c) shows the peak value of the

Table 7. Observation of final experimentation for surface roughness.

Surface roughness (um) Sr No. V/A ratio LC MT

L1 L2 L3

1. 2.74 mm 1+1+3+3 Al 1.62 1.65 1.58

2. 2.74 mm 1+1+2+4 S.S 2.42 2.5 2.4

3. 2.74 mm 1+1+4+2 M.S 2.03 2.09 2.12

4. 3.78 mm 1+1+3+3 S.S 2.03 1.95 1.99

5. 3.78 mm 1+1+2+4 M.S 2.7 2.74 2.69

6. 3.78 mm 1+1+4+2 Al 1.55 1.57 1.59

7. 4.09 mm 1+1+3+3 M.S 2.42 2.5 2.4

8. 4.09 mm 1+1+2+4 Al 2.3 2.23 2.27

9. 4.09 mm 1+1+4+2 S.S 2.32 2.35 2.38

(Exp. No-3) (Exp. No-5) (Exp. No-7)

Fig. 7. Microstructures of M.S (X200).

(Exp. No-1) (Exp. No-6) (Exp. No-8)

Fig. 8. Microstructures of Al (X200).

Table 6. Variation of S/N ratio and hardness w. r. t. to MT.

Sr No. S/N Ratio Vickers hardness (HV) MT

1 33.1339 45.61111 Al

2 47.77328 244.7778 S.S

3 44.88578 175.7778 M.S

Fig. 5(b). S/N response and hardness w. r. t LC.

[*Note: Layer combination 1 signifies 1+1+3+3, 2 signify 1+1+2+4

and 3 signifies 1+1+4+2].

Fig. 5(c). S/N response and hardness w. r. t MT.

[*Note: Layer combination 600, 1550 and 1600 signifies pouring tem-

peratures of Al, S.S and M.S in °C]

(Exp. No-2) (Exp. No-9) (Exp. No-4)

Fig. 6. Microstructures of S.S (X200).

R. Singh and S. Singh / Journal of Mechanical Science and Technology 27 (1) (2013) 191~197 195

S/N ratio and surface roughness w. r. t. MT and gives the best

setting of the surface roughness.

4.3 Dimensional accuracy results

The results of dimensional accuracy are shown in Table 11.

Dimensional accuracy has been measured by subtracting the

original dimension of spherical disc (outer diameter) measured

on the wax replica and the dimension of the casted spherical

disc.

Table 12 shows the variation of S/N ratio and dimensional

accuracy w. r. t. to V/A ratio. Fig. 10(a) shows the peak values

of the S/N ratio and dimensional accuracy w. r. t. V/A ratio of

spherical disc for best setting as input parameter.

Table 13 shows the variation of S/N ratio and dimensional

accuracy w. r. t. to LC. Fig. 10(b) shows the peak value of the

S/N ratio and dimensional accuracy w. r. t. LC gives the best

setting of the surface roughness.

Table 14 shows the variation of S/N ratio and ∆d w. r. t. to

MT. Fig. 10(c) shows the highest value of the S/N ratio and

∆d w. r. t. MT and gives the best setting of surface roughness.

Figs. 11-13 shows pie charts of percentage contribution for

surface hardness, surface roughness and dimensional accuracy

in present case study of IC.

Table 8. Variation of S/N ratio and surface roughness w. r. t. to V/A

ratio.

S. No. S/N Ratio Surface roughness

(um)

V/A Ratio

(mm)

1 -6.0952 2.045556 2.74

2 -6.18545 2.09 3.78

3 -7.42648 2.352222 4.09

Table 9. Variation of S/N ratio and surface roughness w. r. t. LC.

S. No S/N Ratio Surface Roughness (um) LC

1 -5.96705 2.0115 1+1+3+3

2 -7.83909 2.4772 1+1+2+4

3 -5.90099 2 1+1+4+2

Table 10. Variation of S/N ratio and surface roughness w. r. t. MT.

S. No S/N Ratio Surface roughness (um) MT

1 -5.0669 0.817778 AL

2 -7.04974 2.26 S.S

3 -7.5905 2.41 M.S

Fig. 9(a). S/N response and surface roughness w.r.t. V/A ratio.

Fig. 9(b). S/N response and surface roughness w.r.t. LC.

[Note: Layer combination 1 signifies 1+1+3+3, 2 signify 1+1+2+4 and

3 signifies 1+1+4+2].

Table 11. Observation of final experimentation for dimensional accu-

racy (∆d).

∆d (mm) Sr No. V/A ratio LC MT

L1 L2 L3

1. 2.74 mm 1+1+3+3 Al 0.00882 0.0088 0.0087

2. 2.74 mm 1+1+2+4 S.S 0.0147 0.015 0.0146

3. 2.74 mm 1+1+4+2 M.S 0.0141 0.0143 0.0139

4. 3.78 mm 1+1+3+3 S.S 0.026 0.03 0.025

5. 3.78 mm 1+1+2+4 M.S 0.0183 0.0185 0.018

6. 3.78 mm 1+1+4+2 Al 0.0104 0.01 0.0103

7. 4.09 mm 1+1+3+3 M.S 0.0122 0.012 0.0123

8. 4.09 mm 1+1+2+4 Al 0.0045 0.0048 0.0045

9. 4.09 mm 1+1+4+2 S.S 0.0171 0.0172 0.0175

Table 12. Variation of S/N ratio and ∆d w. r. t. to V/A ratio.

S. No. S/N Ratio ∆d V/A Ratio (mm)

1 -38.2569 0.012547 2.74

2 -35.341 0.0185 3.78

3 -40.1039 0.011344 4.09

Fig. 9(c). S/N response and surface roughness w.r.t. MT.

[*Note: Layer combination 600, 1550 and 1600 signifies pouring tem-

peratures of Al, S.S and M.S in °C]

196 R. Singh and S. Singh / Journal of Mechanical Science and Technology 27 (1) (2013) 191~197

In the present case study, effort has been made to develop a

macro model, which is actually applicable in industrial envi-

ronment, for IC application by optimizing surface hardness,

surface roughness and dimensional accuracy. The step of

building a mathematical model has been bypassed because

macro modeling gives faster and more efficient results. In the

present study some parameters like pouring time, mould initial

temperature etc. were kept fixed. Further studies may also

focused on optimization of these parameters.

5. Conclusions

The following conclusions can be drawn from the study.

(1) From the present case study it is concluded that MT

plays a very significant role in the hardness and reason behind

the contribution of MT to such a great extent is because of the

selection of the input metals that is S.S, M.S and Al. Further, it

is well known that there is a wide range of differences in the

hardness of S.S, M.S and Al. As the difference in the hardness

values of input metals is large, its contribution is more. The

same results are ought to be valid on other MT. For rest of two

output parameters (surface roughness and dimensional accu-

racy) all three input parameter (MT, LC and V/A ratio) plays a

very significant role.

(2) Surface hardness of Al disc is obtained best at V/A ratio

3.78mm and LC 1+1+4+2. Similarly for S.S, surface hardness

is best at V/A ratio 4.09mm and LC 1+1+4+2. Further for M.S,

best condition for surface hardness is V/A ratio 2.74mm and

Table 13. Variation of S/N ratio and ∆d w.r.t. LC.

S. No S/N Ratio ∆d LC

1 -42.5658 0.007869 1+1+3+3

2 -34.4415 0.019678 1+1+2+4

3 -36.6946 0.014844 1+1+4+2

Table 14. Variation of S/N ratio and ∆d w. r. t. MT.

S. No. S/N Ratio ∆d MT

1 -36.9622 0.007869 Al

2 -39.3804 0.019678 S.S

3 -37.3592 0.014844 M.S

Fig. 10(a). S/N responses and ∆d w.r.t. V/A ratio.

Fig. 10(b). S/N responses and ∆d w.r.t. LC.

[*Note: Layer combination 1 signifies 1+1+3+3, 2 signify 1+1+2+4

and 3 signifies 1+1+4+2]

Fig. 10(c). S/N responses and ∆d w.r.t. MT.

[*Note: Layer combination 600, 1550 and 1600 signifies pouring tem-

peratures of Al, S.S and M.S in °C]

Fig. 11. Pie chart for surface hardness.

Fig. 12. Pie chart for surface roughness.

Fig. 13. Pie chart for dimensional accuracy.

R. Singh and S. Singh / Journal of Mechanical Science and Technology 27 (1) (2013) 191~197 197

LC 1+1+4+2.

(3) Surface roughness of Al disc is produced best at V/A ra-

tio 3.78mm and LC 1+1+4+2. Further for S.S disc, V/A ratio

3.78mm and LC 1+1+3+3. While in case of M.S disc, best

condition for surface roughness is, V/A ratio is 2.74mm and

LC is 1+1+4+2.

(4) In case of dimensional accuracy of Al disc best condi-

tion is V/A ratio 4.09mm and LC 1+1+2+4. For S.S disc, fa-

vorable condition is V/A ratio 2.74mm and LC 1+1+2+4. And

for M.S disc, V/A ratio 4.09mm and LC 1+1+3+3 are favor-

able condition.

(5) The percentage contribution of input parameters in sur-

face hardness is as follows: V/A ratio contributes 0.05%, LC

contributes 0.43% and MT contributes 99.28%. While in the

case of surface roughness, V/A ratio contributes 15.56%, LC

contributes 34.06% and MT is 49.66%. Further, in case of

dimensional accuracy, V/A ratio contributes 23.12%, LC con-

tributes 6.57% and MT contributes 68.38%.

Acknowledgment

The authors are grateful to Saini Precision Casting Pvt. Ltd.

Ludhiana, for providing their facilities and CSIR, Extramural

research division New Delhi for financial support.

Nomenclature------------------------------------------------------------------------

I.C : Investment casting

S.H : Surface hardness

Ra : Surface roughness

S.S : Stainless steel

M.S : Mild steel

∆d : Dimensional accuracy

Al : Aluminum

D.O.E : Design of experiment

References

[1] Y. Dong, K. Bu, Y. Dou and D. Zhang, Determination of

interfacial heat-transfer coefficient during investment-casting

process of single-crystal blades, J. Mater. Processing Tech-

nology, 211 (12) (2011) 2123-1231.

[2] E. R. Dootz, R. G. Craig and F. A. Peyton, Influence of in-

vestments and duplicating procedures on accuracy of partial

denture castings., J. Prosthetic Dentistry, 15 (4) (1965) 679-698.

[3] M. W. Hooker, T. D. Taylor and H. D. Leigh, Non-aqueous

slip casting of YBa2Cu3O7−x ceramics. Applied Super Con-

ductivity Journals, 1 (7-9) (1993) 1303-1311.

[4] C. C. Hung, G. L. Hou, C. C. Tsai and C. C. Huang, Effect

of Zirconia-Modified Magnesia Investment on the Casting of

Pure Titanium. The Kaohsiung Journal of Medical Sciences,

19 (3) (2003) 121-125.

[5] K. M. Ibrahim, M. Mhaede and L. Wanger, Mechanical

characterization of cp-Ti produced by investment casting.

Transactions of Non- ferrous Metal Society of China., 21 (8)

(2011) 1735-1740.

[6] J. Jiang and X. Y. Liu, Dimensional variations of castings

and moulds in the ceramic mould casting process. J. Mater.

Processing Technol., 189 (1-3) (2007) 247-255.

[7] S. Jones and P. M. Marquis, Role of silica binder in invest-

ment casting. British Ceramics Transactions, 2 (2001) 94.

[8] M. T. Jovanovic, S. Tadic, S. Zec, Z. Miskovic and I. Bobic,

The effect of annealing temperatures and cooling rates on mi-

crostructure and mechanical properties of investment cast Ti–

6Al–4V alloy. J. Mater. and Design, 27 (3) (2006) 192-199.

[9] C. H. Konrad, M. Brunner, K. Kyrgzaev, R. Volkil and U.

Glatzel, Determination of heat transfer coefficient and ceramic

mold material parameters for alloy IN738LC investment cast-

ing. J. Mater. Processing Technol., 211 (2) (2011) 181-186.

[10] Q. Liu, G. Sui and M.C. Leu, Experimental study on the ice

pattern fabrication for the investment casting by rapid freeze

prototyping (RFP). J. Computers in Industries, 48 (3) (2002)

181-197.

[11] O. Mahoney and Browne, Use of experiment and an in-

verse method to study interface heat transfer during solidifi-

cation in the investment casting process. J. Experi. and Fluid

Science (2000) 22 (3-4) 111-121.

[12] B. S. Sidhu, P. Kumar and B. K. Mishra, Effect of Slurry

Composition on Plate Weight in Ceramic Shell Investment

Casting. American Society of Microbiological Journal, 17

(4) (2008) 489-498.

[13] P. R. Taylor, An illustrated history of lost wax casting.

Proceedings of the 17th Annual BICTA Conference, Wash-

ington, D.C., (1993).

[14] N. Yadav and D. B. Karunakar, Effect of process parameters

on mechanical properties of the investment castings produced

by using expandable polystyrene pattern. International J. Ad-

vances in Engg. & Technology, 1 (3) (2011) 128-137.

[15] J. Yang, Y. Shi, Q. Shen and C. Yan, Selective laser sinter-

ing of HIPS and investment casting technology. J. Mater.

processing Technol., 209 (2011) 191-198.

[16] X. P. Zhang, S. M. Xiong and Q. Y. Xu, Numerical meth-

ods to improve the computational efficiency of solidification

simulation for the investment casting process. J. Mater.

Processing Technol. 173 (1) (2006) 70-74.

Rupinder Singh is an Associate Profes-

sor in the Department of Production

Engineering at Guru Nanak Dev Engi-

neering College, Ludhiana, India. He

completed his B.Tech in Production

Engineering with Honors’ and M.Tech

in Production Engineering with Gold

Medal from P.T.U. Jalandhar. He ob-

tained a Ph.D (Engineering) from T.I.E.T. Patiala. He is a

member of ASME, ISTE, ISME, MPAS, ISC and AIE. He

has contributed about 185 research papers at the National and

International level and supervised 58 M.Tech theses. His areas

of interest include rapid prototyping, non-traditional machin-

ing, maintenance engineering and welding.