EFFECT OF LIME STABILISATION ON SINGLE PILE PULLOUT …igs/ldh/conf/2009/articles/T07_35.pdf ·...

Transcript of EFFECT OF LIME STABILISATION ON SINGLE PILE PULLOUT …igs/ldh/conf/2009/articles/T07_35.pdf ·...

Effect of Lime Stabilisation on Single Pile Pullout Capacity

476

EFFECT OF LIME STABILISATION ON SINGLE PILE PULLOUT CAPACITY

Denzil Fernandez M. Tech Student, Department of Civil Engineering, National Institute of Technology, Tiruchirapalli–620 015, India. K. Muthukkumaran Assistant Professor, Department of Civil Engineering, National Institute of Technology, Tiruchirapalli–620 015, India. E-mail: [email protected]

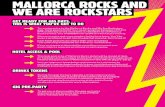

ABSTRACT: Piles are used extensively for supporting heavy buildings, transmission lines, rail and road bridges, offshore platform, berthing structures etc. Many of these structures may be subjected to heavy overturning moments which will in turn cause tension in the supporting pile foundation. The present investigation is to study the effect of lime stabilisation on piles subjected to tensile load. The properties of the materials used, the model pile and soil, are studied by conducting various laboratory tests. The effect of soil stabilisation with different quantities of lime contents of 1%, 2%, 3%, 4%, 6% and 8% and the variation in UCC strength at 1 day, 5 days and 7 days are studied. A hollow aluminum pile having an outer diameter of 25.4 mm and wall thickness of 1 mm is used for the model study. For the experimental study, two layers of different soil are arranged with the top thinner layer composed of clay and the bottom layer of clear river sand. The pile pullout test is then done on the stabilised and unstabilised samples and the pullout capacity in each case is derived and compared. 1. INTRODUCTION

1.1 Piles in Tension

When the surface soil conditions are not strong enough, we will need to adopt pile foundations so that the load of the structure is transferred to hard strata at a greater depth. Pile foundation also provides additional frictional resistance along their length which supplements the resistance to vertical loads. Lateral load is another important load which may be acting on a pile foundation. Pullout load is also a major load which may act upon pile foundations due to heavy winds, waves, ocean currents etc.

Piles are normally designed for the compressive load or lateral load or both. But some time, the same piles may be subjected to tensile loads under particular loading conditions. The tensile capacity of the pile only depends on the skin friction between the pile surface and soil and the cohesive action of the soil. The end bearing does not contribute to the pullout capacity and hence if the pile is likely to be subjected to any tensile loads, special consideration must be given to the design. A typical schematic view of tension piles are shown in Figure 1.

Fig. 1: Case of Pile Subjected to Tensile Load

1.2 Soil Stabilisation

Soil stabilisation is the process of improving the engineering properties of soil and thus making it more stable. Soil stabilisation is required to increase the bearing capacity of foundation soils where the natural soil condition is not fit enough for carrying out the construction works.

1.3 Lime Stabilisation

It is one among the soil stabilisation methods. Lime stabilisation is done by adding adequate quantity of lime to the soil. It is useful for stabilisation of cohesive soils. When lime is added to soil, it reacts with soil with an exchange of cations in the adsorbed water layer and a decrease in plasticity of the soil occurs. The resulting material is therefore more friable than the original soil. The amount of lime required for stabilisation varies between 2 to 10% of the soil. However, if the lime is used only to modify some of the physic-chemical characteristics of the soil, the amount of lime is about 1 to 3%. Lime stabilisation is not effective for sandy soils. However, these soils can be stabilized in combination with clay, fly-ash or other puzzolanic materials, which serve as hydraulically reactive ingredients.

1.4 Literature Review

Ahmed (2005) derived the uplift load–displacement response of long driven piles in cohesionless soils, taking into account the effects of the friction fatigue processes during pile driving and the existence of locked-in residual stresses at the end of pile driving before commencing the pile load test. Chow et al. (1995) suggested that the down drag load on

IGC 2009, Guntur, INDIA

Dock empty Dock flooded Ship under construction

All piles in tension All piles in

CompressingPiles acting neutrally

Ground-water level Piles in bending and compression

Effect of Lime Stabilisation on Single Pile Pullout Capacity

477

individual piles in a group is smaller than that on an isolated single pile. Distribution of down drag loads among the group piles is such that the inner piles experience the smallest load, followed by the perimeter piles and the corner piles experience the largest load. Emilios & Spyridoula (2004) evaluated the influence of negative skin friction in pile foundations. As a result of fill placement or even lowering of phreatic surface, the soil surrounding the piles of pile foundations in soft ground settles more than the piles. El Sawwaf & Nazir (2005) studied the behavior of vertical anchor plates embedded in reinforced and non-reinforced cohesion less soil with the help of small-scale model tests. The test results indicate that the steel rod reinforcement significantly increases the stiffness of the soil and the pullout resistance of shallow anchor plates.

2. EXPERIMENTAL WORKS

2.1 Material Properties

An aluminum pile of length 762 mm and having an outer diameter of 25.4 mm with 1mm thick wall is used as a test pile. Two layers of soil are used for embedding the pile for the pullout test. The top layer will be a cohesive soil and the bottom layer will be a non cohesive one. The engineering and the index properties of these soils are also studied by means of laboratory tests. These tests will give the key properties of soil which will govern its behaviour to different applied load configurations.

The properties of the soil are,

Cu = 2.435, CC = 1.18, Specific gravity of cohesive soil = 2.17, Specific gravity of cohesion less soil = 2.68, Liquid Limit = 61%, Plastic Limit = 24.97 %, IP = 36.13, OMC = 15.1 %, Maximum dry density = 1.90 g/cc, Unconfined Compressive Strength = 7.92 N/cm2, Cohesion = 3.96 N/cm2, Percentage Swelling = 21.33%.

2.2 Pile Pullout Test

The guidelines for conducting pullout test on piles is given in IS 2911 (Part 4) – 1985. A steel wire is used to transfer the load from the loading motor to the pile. The load transferred from the loading motor through the steel wires which run through the pulley is transferred to the pile by connecting the steel wire to a central rod connected to the pile. The schematic view of the experimental set-up is shown in Figure 2.

The pullout load increments and consequent displacement readings shall be read as in the case of a vertical load test. The safe load shall be taken as the least of the following: (1) Two–thirds of the load at which the displacement is 12

mm or the load corresponding to a specified permissible uplift.

(2) Half of the load at which the load displacement curve shows a clear break (downward trend)

Fig. 2: Experimental Setup (Schematic Diagram)

3. EFFECT OF LIME STABILISATION ON UCC STRENGTH

To study the effect of lime stabilization in cohesion of the soil, various samples of the soil is taken and is stabilised by different quantities of lime. The soil is stabilised with 2%, 4%, 6% and 8% of lime by weight of the soil. The sample is then kept at undisturbed and is tested after specific days of curing. Here, the sample is tested after 1 day, 5 days and 7 days of curing. The load deflection curves from samples with different percentage of lime are combined and is compared and interpreted, which is shown from Figures 3 to 5.

Fig. 3: Load Deformation Curves (1 Day Curing)

Fig. 4: Load Deformation Curves (5 Day Curing)

Pile

Pulley

Cohesive Soil

Cohesion less Soil

Loading

1000

500

Load-Deformation

Deformation (mm)

Deformation (mm)

Load-Deformation (5 days)

Load

(N)

Load

(N)

Effect of Lime Stabilisation on Single Pile Pullout Capacity

478

Fig. 5: Load Deformation Curves (7 Days Curing)

3.1 Variation of Unconfined Compressive Strength

Figures 6 & 7 shows the variation of unconfined compressive strength with respect to the curing period. From the figure, it is observed that there is significant increase in the UCC strength capacity till 5 day curing for sample with 4% lime and further increase is almost negligible. From figure 7, we can infer that noted that the sample with 4% lime is having a higher UCC strength than all other samples.

Fig. 6: Variation of UCC Strength with Curing

Fig. 7: Variation of UCC Strength with Lime Content

3.2 Variation of Cohesion

Figures 8 & 9 shows the variation of cohesion with respect to lime content. The variation in cohesion for the various days curing after lime stabilisation is given in Figure 8. It can be noted that the sample stabilized with 4% lime is having substantial positive difference from other samples and the gain in strength after 7 days is likely to be minimal. From Figure 9, which shows the variation of cohesion with lime content, we can confirm that the highest cohesive strength is shown by the 4% lime stabilized sample. The variation of soil properties (UCC strength and cohesion) with respect to lime content is presented in Table 1.

Fig. 8: Variation of Cohesion with Curing

Fig. 9: Variation of Cohesion with Lime Content

Table 1: Variation of Soil Properties by Lime Stabilization Lime

content (%)

Time of curing (Days)

Maximum load (N)

UCC strength N/cm2

Cohesion N/cm2

0 - 92.65 7.92 3.96 1 348.33 30.34 15.17 5 401.64 34.35 17.18 2 7 403.44 34.79 17.39 1 412.55 35.83 17.91 5 482.12 41.29 20.65 4 7 494.83 42.73 21.37 1 291.32 25.27 12.63 5 330.76 28.32 14.16 6 7 343.87 29.67 14.83 1 278.45 24.17 12.08 5 301.24 25.82 12.91 8 7 311.92 26.94 13.47

Deformation (mm)

Load

(N)

Load-Deformation (7 days)

Days of Curing

Lime Content

Lime Content

Days of Curing

qu (N/cm2)

qu (N/cm2)

Cu (N/cm2)

Cu (N/cm2)

Effect of Lime Stabilisation on Single Pile Pullout Capacity

479

3.3 Variation in Pile Pullout Capacity

The pile pullout test is conducted for stabilised and unstabilised samples and the load deflection curve is plotted. The results are obtained and the load deflection curve is plotted and is shown in Figure 10. Safe load for unstabilized soil is given as the half of 78.45 N = 39.225 N

Safe load for stabilized soil is the least of 2/3rd of 120 N or half of 127.48N. Hence, Safe load for stabilized soil is = 63.74 N (Fig. 11).

Fig. 10: Combined Load Deflection Curves

Fig. 11: Maximum and Safe Pullout Loads

4. CONCLUSIONS

The optimum lime content for the soil considered is inferred as around 3.8%. The increase of UCC strength at for the sample stabilised with optimum lime content is found to be increased by 440%. It is inferred that the soil must be cured for 5 to 7 days after mixing with lime is done to facilitate the attainment of expected strength. The maximum pullout load is increased by 62.5% upon stabilizing the given soil with the optimum lime content. The safe load is increased by 62.5% upon stabilizing the soil with optimum lime content.

REFERENCES

Ahmed Shlash Alawned (2005). “Modeling Load–Displacement Response of Driven Piles in Cohesion Less Soils Under Tensile Loading”, Journal of Computer and Geotechnics, 32, 578–586.

E.S.B. Reddy, M.O. Reilly and D. Chapman (1995). “A Software to Predict the Behaviour of Tension Piles”, Journal of Computers and Structures, 62, 653–658.

Emilos M. Comodromos and Spyridoula V. Bareka (2005). “Evaluation of Negative Skin Friction Effects in Pile Foundations using 3D Nonlinear Analysis”, Journal of computer and Geotechnics, 32, 210–221.

K. Ilamparuthi and E.A. Dickin (2001). “Predictions of the Uplift Response of Model Belled Piled in Geogrid Cell Reinforced Sand”, Journal of Geotextiles and Geomembranes, 19, 89–109.

K.R. Arora (2004). “Soil Mechanics and Foundation Engineering”, 6th Edition, New Delhi: Standard Publishers, 380–382.

M. El Sawwaf and A. Nazir (2005). “Effect of Soil Reinforcement on Pullout Resistance of an Existing Vertical Anchor Plate in Sand”, Journal of Computer and Geotechnics, 33, 167–176.

S. Narasimha Rao, K. Hema Latha, B. Pallavi and S. Surendran (2006). “Studies on Pullout Capacity of Anchors in Marine Clays for Mooring Systems”, Journal of Applied Ocean Research, 28, 103–111.

Y.K. Chow, C.H. Lim and G.P. Karunaratne (1995). “Numerical Modelling of Negative Skin Friction on Pile Groups”, Journal of Computer and Geotechnics, 18, 201–224.

Deformation (mm)

Load (N)

Load (N)

Unstabilised

Stabilised

Unstabilised

Stabilised