Effect of entanglement density, temperature, and rate

Transcript of Effect of entanglement density, temperature, and rate

Strain Hardening of Polymer Glasses: Effect of EntanglementDensity, Temperature, and Rate

ROBERT S. HOY, MARK O. ROBBINS

Department of Physics and Astronomy, Johns Hopkins University, Baltimore, MD 21218

Received 24 May 2006; revised 28 July 2006; accepted 23 August 2006DOI: 10.1002/polb.21012Published online in Wiley InterScience (www.interscience.wiley.com).

ABSTRACT: The strain hardening behavior of model polymer glasses is studied with sim-ulations over a wide range of entanglement densities, temperatures, strain rates, andchain lengths. Entangled polymers deform affinely at scales larger than the entangle-ment length as assumed in entropic network models of strain hardening.The dependenceof strain hardening on strain and entanglement density is also consistent with thesemodels, but the temperature dependence has the opposite trend. The dependence on tem-perature, rate, and interaction strength can instead be understood as reflecting changesin the flow stress. Microscopic analysis of local rearrangements and the primitive pathsbetween entanglements is used to test models of strain hardening. © 2006 Wiley Periodicals,Inc. J Polym Sci Part B: Polym Phys 44: 3487–3500, 2006Keywords: compression; computer modeling; glass; mechanical properties; modulus;molecular dynamics; relaxation; rubber; simulations; stiffness; strain hardening

INTRODUCTION

Mechanical deformation of polymer glasses hasbeen studied for many decades, and the basic fea-tures of the stress–strain curves are well known.1At very small strains the response is elastic. Atslightly larger strains, yielding occurs when inter-molecular barriers to segmental rearrangementsare overcome. Following yield, the material mayexhibit strain softening, a reduction in stress toa level corresponding to plastic flow. At higherstrains, the stress increases again as the chainmolecules orient, in a process known as “strainhardening.” The balance of strain softening andstrain hardening is critical in determining mate-rial properties such as toughness. Polymers thatexhibit greater strain hardening, such as polycar-bonate, are tougher and tend to undergo ductilerather than brittle deformation, because strainlocalization is suppressed.

Correspondence to: R. S. Hoy (E-mail: [email protected])Journal of Polymer Science: Part B: Polymer Physics, Vol. 44, 3487–3500 (2006)© 2006 Wiley Periodicals, Inc.

The complex stress–strain behavior of polymerglasses has often been modeled using rubber elas-ticity theory.2 Glasses are assumed3 to behavelike a crosslinked rubber, with the number ofmonomers between crosslinks equal to the entan-glement length Ne. The contribution of strainhardening to the stress is then associated withchanges in the entropy of the entanglement net-work under macroscopic deformation. For uniaxialstress with a longitudinal stretch λ, this contribu-tion is given by

σ (λ) = −λT(

∂s∂λ

)

T, (1)

where σ (λ) is the true stress, s is the entropyper unit volume, and T is the temperature. Inthe simplest case, known as “Gaussian” harden-ing, eq 1 yields σ (λ) = GR(λ2 − 1/λ), with GR

the “strain hardening” modulus. GR is predictedto be linearly proportional to both T and theentanglement density ρe: GR = ρekBT.

It is not clear why an entropic argumentshould apply in the glassy state where chains

3487

3488 HOY AND ROBBINS

cannot move freely to sample the configurationalentropy,4 but the network model of strain hard-ening has had much success in describing exper-imental results on polymer glasses. For exam-ple, Gaussian hardening has been observed inmany uncrosslinked glasses.5,6 More recently, vanMelick et al. performed experiments7 that showedGR has the predicted linear dependence on ρe.However, in contrast with the entropic predic-tion, GR was not proportional to T but insteaddecreased linearly with increasing T. Also, GR wasfound7 to be about 100 times larger than ρekBT,even near the glass transition temperature Tg.The higher modulus can be attributed8 to “fric-tional forces” or to the greater energy necessary toplastically deform a material below Tg, but quan-titatively little is known. Other open questionsabout glassy strain hardening remain as well, assummarized recently by Kramer.4

In this paper we examine the effect of entan-glement density, temperature, chain length, andstrain rate on the strain hardening behavior ofmodel polymer glasses. Several previous simula-tion studies have considered strain hardening,9–14

but none have examined the factors controllingGR over a wide parameter space. This is desir-able to understand the results of van Melick et al.and other recent experiments.7,15,16 To examinechemistry-independent factors controlling GR, weuse a generic coarse-grained bead-spring model.17

The lower computational cost of this model allowsus to simulate a wide variety of relatively largesystems, allowing for good statistics and precisemeasurements of GR.

We find that the functional form of the stress–strain curves at fixed temperature and strain rateis consistent with entropic elasticity as definedby eq 1. Both Gaussian hardening and the moredramatic “Langevin” hardening2 are observed.Moreover, the transition between these two formsis consistent with rubber-elastic predictions.2 Inaddition,we reproduce the key result of van Melicket al., GR ∝ ρe, over a comparable range of en-tanglement densities.

Other simulation results reveal dramatic incon-sistencies with the entropic network model. As inthe experiments of van Melick et al.,7 GR dropslinearly with increasing T. This drop extendsto the T → 0 limit, which is clearly inconsis-tent with eq 1. The ratio of GR to ρekBT is alsocomparable to experiment, remaining of order100 even near Tg. Our results for the variationof GR with T, intermolecular interactions, andthe rate of deformation can be understood if GR

scales with the plastic flow stress σflow rather thana network entropy. Indeed entire stress–straincurves at different strain rates and interactionstrengths collapse onto a universal curve whenscaled by σflow.

It is known that GR decreases with decreasingmolecular weight, and this has been attributedto greater relaxation of the entanglement net-work.15 We study the entire range of molecularweights from the N $ Ne to N % Ne limits, with Nthe degree of polymerization. We find significantstrain hardening even in unentangled systems. Atsmall strains the chains deform affinely, and theirincreased length and alignment leads to strainhardening that is very similar to that of entan-gled chains. Only at large strains do the alignmentand strain hardening begin to drop below thosein entangled systems. The chain length depen-dence combined with the rate dependence dis-cussed above suggests that strain hardening canbe expressed as a product of the flow stress and afactor that represents the amount of local plasticdeformation required to maintain connectivity ofthe chains.

Our simulations also allow us to examine micro-scopic quantities that are not easily accessible inexperiments. Entangled chains deform affinely atlarge scales, as expected if entanglements act likecrosslinks, and there is little entanglement lossthrough slippage at chain ends. The underlyingentanglement structure is studied using primitivepath analysis.18 A primitive path is the shortestpath a chain fixed at its ends can take withoutcrossing any other chains.19 The scaling of prim-itive path lengths with increasing strain is welldescribed by a model assuming affine stretchingof paths, and also by the nonaffine tube model ofRubinstein and Panyukov.20 The degree of plasticdeformation is studied by examining the nonaffinecomponent of deformation at low temperatures.Results for different entanglement densities fallon a universal curve for low strains, but increasemore rapidly for higher entanglement densitiesat large strains. Strain hardening is related tomicroscopic plastic events, which are required tomaintain chain connectivity. As the stress riseswith increasing strain, both the number of eventsand the energy dissipated per event increase.

In the following section we describe the polymermodel used in our simulations, and the protocolsused to strain the system and identify primi-tive paths and entanglement lengths.18 Next wedescribe the effect of entanglement density, tem-perature, interaction strength, strain rate, and the

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

STRAIN HARDENING OF POLYMER GLASSES 3489

microscopic rearrangements of monomers, chains,and primitive paths. The final section containsconclusions.

POLYMER MODEL AND METHODS

We employ a coarse-grained bead-spring polymermodel17 that incorporates key physical featuresof linear homopolymers such as covalent back-bone bonds, excluded-volume and adhesive inter-actions, chain stiffness, and the topological restric-tion that chains may not cross. All monomers havemass m and interact via the truncated and shiftedLennard-Jones potential:

ULJ(r) = 4u0

(((ar

)12−

(arc

)12)

−((a

r

)6−

(arc

)6))

, (2)

where rc is the potential cutoff radius and ULJ(r) =0 for r > rc. Unless noted, rc = 1.5a. We expressall quantities in terms of the molecular diame-ter a, binding energy u0, and characteristic timeτLJ =

√ma2/u0.

Covalent bonds between adjacent monomers ona chain are modeled using the finitely extensiblenonlinear elastic (FENE) potential

UFENE(r) = −kR20

2ln

(1 − (r/R0)

2), (3)

with the canonical parameter choices17 R0 = 1.5aand k = 30u0/a2. N monomers are bound togetherto make a linear chain, with equilibrium bondlength l0 & 0.96a. As a means of varying entangle-ment density, we introduce chain stiffness usingthe bending potential

Ubend(r) = kbend(1 − cos θ), (4)

where θ is the angle betweeen consecutive cova-lent bond vectors along a chain. Stiffer chains(higher kbend) produce higher entanglement den-sities, as discussed below.

The values of N employed in this paper rangefrom 4 to 3500, but most simulations have N =350, which is long enough for the systems to bein the highly entangled (N > 8Ne) limit. The ini-tial simulation cell is a cube of side length L0,which is chosen to be greater than the typical

Table 1. System Parameters and Values of Ne

from PPAkbend C∞ N Ntot f Ne

2.0 3.2 350 70,000 0 221.5 2.6 350 70,000 0 262.0 3.2 350 70,000 0.25 282.0 3.2 350 70,000 0.33 291.5 2.6 350 70,000 0.25 360.75 2.0 350 70,000 0 392.0 3.2 350 70,000 0.5 450 1.7 500 250,000 0 710.75 2.0 350 70,000 0.5 770 1.7 3500 280,000 0.5 165

Values of the entanglement length Ne and chain stiffnessconstant C∞ are given as a function of kbend and the fraction fof monomers in short chains of five beads. The total number ofmonomers Ntot in the simulation, and length N of long chainsare also given.

end–end distance of the chains. Nch chains areplaced in the cell, with periodic boundary condi-tions applied in all three directions. Nch is chosenso that the total number of monomers Ntot = NNch

is 30,000–280000, and typically 70000 (Table 1).The monomer number density is ρ = 0.85a−3.

Each initial chain configuration is a randomwalk of N − 1 steps with the bond angles chosento give the desired large-scale chain structure

C∞ = lK

l0= 1 + 〈cos(θ)〉

1 − 〈cos(θ)〉 , (5)

where C∞ is the chain stiffness constant and lK

is the Kuhn length. In melt studies, C∞ increasesfrom 1.8 to 3.34 as kbend is increased from 0to 2.0u0.21 Larger values of kbend produce localnematic order,22 which is undesirable since wewish to simulate amorphous systems.

After the chains are placed in the cell, weperform molecular dynamics (MD) simulations.Newton’s equations of motion are integrated withthe velocity-Verlet method23 and timestep δt =0.007τLJ − 0.012τLJ. The system is coupled to aheat bath at temperature T using a Langevinthermostat24 with damping rate 1.0/τLJ.

We equilibrate the systems thoroughly at T =1.0u0/kB, which is well above the glass transi-tion25 temperature Tg & 0.35u0/kB. For short,poorly entangled chains, we use the “fast pushoff”method.21 The cutoff radius rc is set to 21/6a, asis standard in melt simulations.17 The chains areallowed to diffuse several times their end–endlength before the system is considered equili-brated. For longer chains, the time required for

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

3490 HOY AND ROBBINS

diffusive equilibration is prohibitively large, so weuse the double-bridging-MD hybrid algorithm.21

In addition to standard MD, Monte Carlo movesthat alter the connectivity of chain subsections areperiodically performed, allowing the chain config-urations to relax far more rapidly.26 In some cases,to reduce the entanglement density, we cut a frac-tion f of the long chains into pieces with N =5 after the initial equilibration. Additional MDequilibration is then performed until the newlycreated short chains have diffused several timestheir length.

Glassy states are obtained by performing arapid temperature quench at a cooling rate ofT = −2 × 10−3u0/kBτLJ. We increase rc to its finalvalue and cool at constant density until the pres-sure is zero. The quench is then continued at zeropressure using a Nose-Hoover barostat.23 Unlessnoted, the final temperature is 0.2u0/kB, whichis about 3/5 of Tg. This temperature is chosenbecause it is high enough to observe significantthermal relaxation and strain rate effects, but stillwell below Tg. The resulting glasses have den-sity ρ & 1.00a−3. We have checked that resultsfrom other quench protocols are consistent withthe conclusions presented below.

To examine trends in GR with entanglementdensity, it is necessary to measure ρe = ρ/2Ne.Melt entanglement lengths have been obtained forundiluted18 systems and vary from about 70 forfully flexible chains (kbend = 0) to 20 for semiflexi-ble chains with kbend = 2.0u0. Measurements havenot been made for diluted systems. Also, althoughquenching a melt into a glass has little effect27 onNe, we still measure ρe at the various tempera-tures employed. The changes in ρe upon coolingare primarily due to changes in ρ. Values of ρe

are measured by performing primitive path analy-ses (PPA)18,28 on systems with N % Ne. We alsoapply PPA to deformed states to examine how theprimitive paths evolve with increasing strain.

In PPA,all chain ends are fixed in space and sev-eral changes are made to the interaction potential.Intrachain excluded-volume interactions are deac-tivated, while interchain excluded-volume inter-actions are retained. Turning off intrachain inter-actions means that self-entanglements are notpreserved, but their number is negligibly smallfor the systems considered here.29 The covalentbonds are strengthened by setting k = 100u0, andthe bond lengths are capped at 1.2a to preventchains from crossing one another.29 The FENEpotential is linearized for r < 0.75a so the lengthminimization takes place at constant tension.28

For semiflexible chains, the bond-bending poten-tial is deactivated by setting kbend = 0. For sys-tems diluted with short chains, the short chainsare removed. This is justifiable because the shortchains’ contour length is smaller than the tubediameter.

In the final stage of the PPA the system is cou-pled to a heat bath at T = 0.001u0/kB so that ther-mal fluctuations are negligible, and the equationsof motion are integrated until the chains minimizetheir length. This typically requires 1000τLJ. Oncethe chain contour lengths have been minimized,we calculate the primitive path lengths Lpp. Forundeformed systems, we use the formula given inref. 18 to calculate the entanglement length:

Ne = 〈R2ee〉

L2pp/(N − 1)

, (6)

where 〈R2ee〉 is the average squared end–end dis-

tance. The primitive paths have Gaussian ran-dom walk statistics, with Ne monomers per Kuhnsegment.18,29 Results for different systems aresummarized in Table 1.

Several atomistic simulation studies have cov-ered various aspects of strain hardening, but mosthave been for tensile deformation.9–12 For fun-damental studies of strain hardening, compres-sive rather than tensile deformation is preferredbecause it suppresses strain localization. Thisallows the stress to be measured in uniformlystrained systems. Previous atomistic simulationsof strain hardening in compression13,14 usedunited-atom models of polyethylene, and focusedon dihedral (trans/gauche) transition physicsrather than quantitative measurement of GR.

A plurality of the experiments7,15,16,30,31 mostrelevant to the present study have employed uni-axial compression; we therefore do the same. Thesystems are compressed along one direction, z,while maintaining zero stresses along the trans-verse (x, y) directions.32 The rapidity of the quenchminimizes strain softening, which in turn yieldsductile, homogeneous deformation even at the low-est temperatures and highest strains consideredhere.

The uniaxial stretch λ is defined as Lz/L0z , where

L0z is the cube side length at the end of the quench.

Since we consider compression, λ is less thanone. Compression is performed at constant truestrain rate ε = λ/λ, which is the favored proto-col for strain hardening experiments.8 We use ε

of between −3.16 · 10−5/τLJ and −10−3/τLJ. Theserates are significantly lower than those employed

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

STRAIN HARDENING OF POLYMER GLASSES 3491

in some previous simulations.11,12 The systemsare compressed to true (logarithmic) strains up toεfinal = −1.5, corresponding to λfinal = exp(−1.5) &0.223.

RESULTS

Variation of Stress with Strain and Ne

As noted in the introduction, the entropic networkmodel of strain hardening reproduces the mea-sured variation of stress with strain and Ne. Itassumes that the polymer glass acts like a networkwith chains of Ne beads between crosslinks, andthat the stress is proportional to the derivativeof entropy with strain (eq 1). Many experimentscan be fit to the simplest Gaussian strain harden-ing model where the chains are assumed to obeyGaussian statistics. For volume-conserving uni-axial compression, the Gaussian strain-hardeningmodel predicts

−σ = σ0 + GRg(λ), (7)

where GR is the hardening modulus, g(λ) ≡ 1/λ −λ2 describes the functional form of the hardening,and a constant offset σ0 must be added to fit the ini-tial yield stress. Note that we consider −σ so thatcompression gives positive values in subsequentplots.

The Gaussian approximation breaks down asthe root-mean-squared (rms) distance betweenentanglements

√〈R2(Ne)〉 approaches the contour

length Nel0. The “Langevin” hardening modelincludes the change in configurational entropyas the ratio h ≡

√〈R2(Ne)〉/Nel0 increases.33 For

uniaxial compression at constant volume,

−σ = σ0 + GRg(λ)L−1(h)/3h, (8)

where L−1(x) = 3x + 9x3/5 + 297x5/175 + · · ·is the inverse Langevin function and h =√

(λ2 + 2/λ)C∞/3Ne for an affine strain.34 Forsmall h the ratio of Langevin to Gaussian harden-ing is 1 + 3h2/5, and the Gaussian approximationis usually considered adequate2 for h < 1/3.

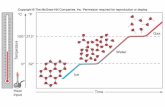

Figure 1 illustrates how the strain hardeningvaries with Ne in our simulations. The four casesshown span the range of Ne studied below. Allsimulations were done at ε = −10−3/τLJ, andother parameters are listed in Table 1. As in manyexperiments,the stress is plotted against g(λ) sothat Gaussian strain hardening corresponds to astraight line.

Figure 1. Strain hardening for various degrees ofentanglement. The strain rate is ε = −10−3/τLJ andT = 0.2u0/kB. Successive curves from bottom to top arefor Ne = 165, Ne = 71, Ne = 26, and Ne = 22 andother parameters are provided in Table 1. Solid blacklines indicate linear fits used to determine GR. A dashedcurve shows a fit to eq 8, with the fit value of Ne = 14.25.[Color figure can be viewed in the online issue, which isavailable at www.interscience.wiley.com.]

The behavior at small g is nearly independentof Ne. In this limit, g is proportional to strain.An initial elastic response is followed by yield-ing at a stress σy and nearly ideal plastic flow ata stress σflow. For the results shown in Figure 1,σy & σflow, but postyield strain softening occurs atlower temperatures and slower quench rates.

The strain hardening at g > 0.5 dependsstrongly on Ne. For large Ne, the entire curveshows linear Gaussian strain-hardening. As Ne

decreases, nonlinear Langevin strain-hardeningsets in at smaller g. The nonlinearity becomes pro-nounced when h exceeds 1/3, as expected fromthe Langevin expression (eq 8). For Ne = 22,h = 0.4 in the unstrained state, and the resultsshow pronounced curvature at all g. We find thatsuch strongly nonlinear curves cannot be fit to theLangevin expression unless Ne is taken as a fittingparameter. The quality of such fits is illustratedby the dashed line in Figure 1. The fit value ofNe = 14.25 is about 2/3 of the value of Ne = 22obtained from the PPA and plateau modulus.18

Experimental fits to Langevin strain harden-ing also produce smaller entanglement lengthsthan those determined from the plateau modu-lus.30,35 This might be interpreted as a shift inthe length between the effective crosslinks pro-duced by entanglements, but may also reflect thelimitations of the entropic network model. One isthe assumption of constant volume. While volumechanges less than 1% for the two systems that

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

3492 HOY AND ROBBINS

Figure 2. Plot showing proportionality of hardeningmodulus GR and entanglement density ρe. As shownin Figure 1, GR is obtained from linear fits for 0.5 ≤g(λ) ≤ 3. Filled (empty) squares indicate the undiluted(diluted) systems from Table 1; the fractions f of shortchains are indicated in this table. Error bars are of orderthe symbol size. Results for Ne = 22 are not shownsince Langevin hardening extends to low strains, butLangevin fits to this and other Ne are consistent withthe line drawn through the data.

show Gaussian hardening, systems with Ne = 26and 22 contracted by 3.2 and 5.5% respectively.Much of this contraction occurred at large g andcould affect the fit to Langevin hardening.

The network model also predicts that GR shouldincrease linearly with entanglement density, andthis prediction was verified in the recent experi-mental work of van Melick et al.7 Following theirwork, we obtain GR from linear fits to the stressover the range 0.5 ≤ g(λ) ≤ 3. Except for the mostentangled system, Ne = 22, the behavior is nearlyGaussian over this range, and linear and Langevinfits to GR differ by less than 10%. Results for GR

are plotted against ρe in Figure 2 over a slightlywider range (26 ≤ Ne ≤ 165) than consideredin the experiments.7 As predicted by the networkmodel, the results are well fit by a line passingthrough the origin. In the following sections wewill consider whether GR/ρe scales with the tem-perature or the flow stress. The results in Figure 2do not distinguish between these interpretationsbecause T is constant and σflow only varies by±10%.

Some authors have suggested that the Kuhnlength lK , or more properly the chain stiffness con-stant C∞, plays a critical role in determining GR.They argue that the reason that GR is observedto be higher for polymers with larger C∞ is thatstraight chains are harder to deform.8,9 However,these tests were performed on undiluted systems,

in which C∞ and ρe cannot be varied indepen-dently. The data in Figure 2 show that systemsof very different C∞ have similar GR if they arediluted so that they have the same entanglementdensity. We find that diluting gives an approxi-mately linear decrease in both GR and the entan-glement density from PPA. In particular, GR ≈(1− f )G0

R where G0R is the undiluted value. Thus it

appears that straighter chains have larger GR pri-marily because they are more densely entangled.

To our knowledge, all previous simulation stud-ies of strain hardening have employed dihedral(trans/gauche) interactions. Since dihedral inter-actions are absent from the model employedhere, our results show that these interactionsare not essential for strain hardening. Angularinteractions apparently affect strain hardeningonly because they control the entanglement den-sity through the equilibrium Kuhn length, andbecause of their less important effects on densityand yield stress.

Effect of Temperature

While both the form of the stress–strain curvesshown in Figure 1 and the proportionality betweenGR and ρe are consistent with entropic elastic-ity, the temperature dependence is not. Figure 3shows stress–strain curves for temperatures rang-ing from near zero to slightly below Tg. At highertemperatures, stress increases monotonically withstrain, and exhibits a smooth transition to plas-tic flow. At low temperatures, the initial elasticresponse is followed by a clear peak and strain

Figure 3. Strain hardening at kBT/u0 = 0.01, 0.1, 0.2,and 0.3 from top to bottom. Simulations are done atstrain rate −3.16 · 10−4/τLJ with Ne = 39, Nch = 200,and N = 350. Lines are fits to Gaussian hardening.[Color figure can be viewed in the online issue, whichis available at www.interscience.wiley.com.]

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

STRAIN HARDENING OF POLYMER GLASSES 3493

Table 2. Temperature Dependence of the StrainHardening Modulus GR, Entanglement Density ρe,and the Ratios of GR to the Network Model Predictionand the Flow Stress σflow

kBT/u0 GRa3/u0 ρea3 GR/ρekBT GR/σflow

0.01 0.51 0.0134 3800 0.350.1 0.44 0.0131 340 0.390.2 0.38 0.0129 150 0.410.3 0.32 0.0125 85 0.51

Data are for Ne = 39 and ε = −3.16 · 10−4/τLJ.

softening. In all cases, Gaussian hardening ensuesat g(λ) & 0.5. Again, values of GR are deter-mined by linear fits to the stress over the range0.5 ≤ g(λ) ≤ 3 and are reported in Table 2.

Our results for GR show a linear decrease overthe entire range of T from 0 to ∼Tg. A lineardecrease was also seen in van Melick et al.’s exper-iments7 on increasing T from about 0.6Tg to 0.9Tg.The main difference from our observations is thata greater fractional change in GR was observed inexperiments.7,15,30 This is due to the high strainrate employed in our simulations. The yield stressand GR only vanish at Tg in the low strain ratelimit. Previous studies in similar systems showthat σy drops linearly with temperature at allshear rates.25 At the strain rate used here, σy onlydecreases by about a factor of two as T changesfrom 0 to Tg. As the strain rate is decreased, σy

goes to zero at Tg and the fractional change withtemperature diverges. The relatively small changein GR with temperature in Table 2 is consistentwith these observations, and rate dependence isdiscussed further below.

The decrease in GR with T in experiment7 andour simulations is inconsistent with entropic net-work models derived from eq 1. In the simplestform these predict GR = ρekBT. Experimental andsimulation values for both GR and GR/ρe (Table 2)decrease linearly with increasing T rather thanrising linearly. It has been suggested30,34,36–38 thata drop in effective entanglement density withincreasing T could explain a decrease in GR nearTg. However, in order for a network model toexplain the observed monotonic drop in GR fromT = 0, the entropy would have to diverge fasterthan 1/T as T → 0, an unlikely proposition.Another difficulty with the network model is thateven near Tg the values of GR are much larger thanρekBT. We find GR/ρekBT is of order 100 for T = 0.2and T = 0.3, which is similar to the experimentalratios7 in the same range of T/Tg.

Refs. 15,16 argue that thermally assisted relax-ation of the entanglement network is the primarysource of the drop in GR with increasing T. Prim-itive path analysis does not support this hypothe-sis. The stretching of primitive paths with strain,Lpp(λ)/L0

pp, is the same for T = 0.3u0/kB as itis for T = 0.01u0/kB (∼1.47 at ε = −1.5). Also,measurements of the nonaffine displacement ofatoms as a function of chemical distance from thechain ends indicate that chain end slippage doesnot occur. Therefore, entanglement loss is negligi-ble, at least at the large strain rate (ε = −3.16 ·10−4/τLJ) used in these simulations. Instead, itseems that thermally assisted rearrangement atscales below the entanglement mesh is the pri-mary source of the drop in GR with increasing T.

Local rearrangements are required to maintainchain connectivity during deformation of the glass.The local stresses required for these rearrange-ments must be of order of the flow stress. Thisdecreases with increasing T due to thermal activa-tion over local energy barriers (Fig. 3).25,39,40 Thefinal column in Table 2 gives GR/σflow, with σflow

measured at the onset of the strain hardeningregime, g(λ) = 0.5. The ratio of hardening mod-ulus to flow stress changes relatively little overthe entire range of T, while GR/ρekBT changesdramatically. In the next section we examine thecorrelation between GR and σflow in more detail.

Scaling of GR with Flow Stress

The most direct way to vary the flow stress is bychanging the intermolecular interactions. Chang-ing the strength of the potential u0 will of courseproduce proportional increases in GR and σflow

because all energies scale with u0. The flow stressalso increases when the form of the potentialis altered by increasing the cutoff rc, because alarger region contributes to the energy barrierspreventing chains from sliding past each other.Table 3 shows that increasing rc produces compa-rable increases in both GR and σflow. Their ratiodoes not change within our numerical uncertain-ties as they increase by more than 50%. Note thatthe network model would not predict any changein the configurational entropy or GR with rc.

Studies of the strain-rate dependence of thestress also reveal a correlation between GR andσflow. Figure 4 shows stress–strain curves for anNe = 39 system at four different strain rates rang-ing from −3.16 · 10−5/τLJ to −10−3/τLJ. The lowestthree strain rates show a continuous transitionbetween the elastic regime and plastic flow, while

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

3494 HOY AND ROBBINS

Table 3. Variation of Strain Hardening ModulusGR and Flow Stress σflow with the Range of AdhesiveInteractions rc for ε = 3.16 · 10−4/τLJ, N = 350,and Ne = 39

rc/a GRa3/u0 σflowa3/u0 GR/σflow

1.5 0.38 0.92 0.411.8 0.45 0.97 0.462.2 0.56 1.25 0.452.6 0.60 1.44 0.42

the highest rate shows a slight postyield strain-softening. At all strain rates Gaussian strain hard-ening is observed for 0.5 ≤ g(λ) ! 3. Both GR andσflow increase by about 35% with strain rate. Theincrease in GR is not accounted for in standard the-ories of strain hardening,30,34,36 where GR dependsonly on ρe and T. However, if GR scales with σflow,its rate dependence can be explained in terms ofthermally activated local rearrangements.

Experimental6,41 and theoretical1,25,40 studiesof the yield and flow stresses generally find alogarithmic dependence on deformation rate. Thesimplest explanation is provided by the Eyringtheory of thermal activation over an energy bar-rier that decreases linearly with stress.42 Asthe rate increases, there is less time for ther-mal activation, and the stress required for flowincreases as

σflow(ε) = σflow(ε0) + b ln(ε/ε0), (9)

where ε0 is a reference rate, b ≡ kBT/V ∗, and V ∗

is a constant with dimensions of volume. Whilestudies25,40,43 show that b has a more complexdependence on temperature, the basic logarithmic

Figure 4. Strain hardening at ε = −3.16 · 10−5/τLJ,−10−4/τLJ, −3.16 · 10−4/τLJ, and −10−3/τLJ from bottomto top. Here kBT/u0 = 0.2 and Ne = 39.

dependence on rate is quite general. The varia-tions in the flow stress observed in Figure 4 areconsistent with these studies.

If the hardening modulus is proportional to theflow stress, then the stress–strain curves shouldscale as

σ (λ, ε) = F(λ)σflow(ε), (10)

where F is a dimensionless function of strain. Thestress–strain curves for all rates should collapseonto a universal curve, F(λ), when normalized byσflow. As shown in Figure 5, this approach providesan excellent collapse of our data, particularly forg(λ) ! 3. There is a small deviation near the yieldstress for the highest strain rate that is not sur-prising because σy is known to vary with aging aswell as rate, while σflow only depends on rate.40,44

We found that data for different rc could also be col-lapsed onto the same universal curve. The dashedline in Figure 5 illustrates this for rc = 2.6a andε = 10−3. The total change in σflow is a factor of twofor the curves collapsed in Figure 5.

We also examined the rate dependence of strainhardening for Ne = 22 where the hardening ishighly nonlinear. The stress–strain curves at dif-ferent rates also collapsed when scaled by theflow stress, but on a more nonlinear F(λ) becauseof the greater entanglement. Thus the correla-tion between strain hardening and the stressrequired for local rearrangements applies for bothGaussian and Langevin hardening regimes.

Glassy strain hardening has been the subjectof many constitutive models.3,6,15,16,30,34,36,41,45 Inall of these, the strain and rate dependence is

Figure 5. Ratio F(λ) of stress to flow stress for thedata from Figure 4 with ε = −3.16 · 10−5/τLJ (black),−10−4/τLJ (blue), −3.16·10−4/τLJ (green), and −10−3/τLJ

(red) with rc = 1.5a. A dashed purple line shows theratio of stress to flow stress for rc = 2.6a with ε =10−3/τLJ.

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

STRAIN HARDENING OF POLYMER GLASSES 3495

assumed to be additive rather than multiplicative:

σ (λ, ε) = σ1(λ) + σ2(ε), (11)

where σ1 and σ2 represent the nondissipativerubber-elastic stress and viscous stress, respec-tively. If the stress had this form, the curves inFigure 4 would be shifted vertically by constantoffsets and GR would be independent of defor-mation rate. The rate dependence of GR and thecollapse of stresses in Figure 5 from the rescalingof eq 10 clearly show that rate-dependent correc-tions to the stress are multiplicative rather thanadditive. Note that the correlation of GR to the flowstress is particularly hard to interpret in rubberelasticity models. These models do not naturallyproduce a flow stress, and the offset σ0 in eqs 7and 8 must be added as an ad hoc fitting parame-ter rather than the central quantity that scales allstresses.

Values of GR/σflow in Table 2 increase slightlywith temperature, showing a bigger variation thanthe changes with rc and rate discussed in thissection.This shows that thermally activated relax-ation processes reduce σflow by more than theyreduce GR. One possible explanation is that GR

reflects the local rather than global flow stress,because local rearrangements must occur aroundeach chain to maintain its connectivity duringdeformation. Studies of the global yield stressshow that it decreases with increasing system sizebecause there are more possible sites for fluctua-tions to nucleate yield.46 This effect should becomemore pronounced with increasing temperature,leading to a greater reduction of the large scaleflow stress relative to the local flow stress. The risein GR/σflow with increasing T in Table 2 would bereduced if GR was normalized by a larger local flowstress at higher T.

Chain Length Dependence

Our simulations allow us to test aspects ofthe microscopic picture underlying the networkmodel. If the effective crosslinks come from entan-glements, strain hardening should disappear forN < Ne and saturate for N % Ne. In addition,the system should deform affinely at scales largerthan

√〈R2(Ne)〉, something that is difficult to test

in experiments.Figure 6 shows stress–strain curves for undi-

luted systems with Ne = 39 and chain lengthsbetween 4 and 350. The initial elastic responseand yield is fairly independent of N, although for

Figure 6. Variation of strain hardening with N forsystems with Ne = 39 at kBT/u0 = 0.2 and ε = −10−3/τLJ.From bottom to top, N = 4, 7, 10, 16, 25, 40, 70, 175and 350. [Color figure can be viewed in the online issue,which is available at www.interscience.wiley.com.]

large N the yield stress is slightly larger and thereis some strain softening. For the N = 4 system,yield is followed by perfect-plastic flow, with nostrain hardening. All other systems show strainhardening that increases monotonically with N.As expected from the network model, the stressappears to saturate for N % Ne, and simulationsat N = 500 showed no further change. Note how-ever that there is a surprisingly large amount ofstrain hardening even for chains much shorterthan the entanglement length. For example, thedata for N = 25 show linear Gaussian hardeningover the entire range of g.

Strain hardening can occur as long as there issome order parameter that continues to evolvewith increasing strain. We find a correlationbetween strain hardening and any measure oflarge scale chain orientation and deformation. Aparticularly simple one is the rms end to endlength as a function of strain R(λ) normalized byits value in the initial state (λ = 1). Figure 7plots R(λ)/R(1) for the systems whose stress–strain curves are depicted in Figure 6. A dashedline shows the prediction for an affine uniax-ial deformation at constant volume, R(λ)/R(1) =√

λ2/3 + 2/3λ, that is assumed to apply in theLangevin strain hardening model (eq 8).34 Resultsfor highly entangled chains lie very close to thisaffine prediction, providing strong evidence thatentanglements act like permanent crosslinks dur-ing deformation of these glassy systems. The smalldeviation (∼3% for N = 350) can be explainedby noting that the entanglements will not beat the very ends of the chains and that thesegments past the last entanglement need not

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

3496 HOY AND ROBBINS

Figure 7. Ratio of total rms length R(λ) to unstrainedvalue R(1) as a function of g(λ) for N = 4, 7, 10, 16,25, 40, 70, and 350 from bottom to top. A dashed lineshows the predicted increase for an affine uniaxial com-pression at constant volume. Data for N = 175 lie ontop of the N = 350 results and are not shown. Resultsare for Ne = 39 at ε = −10−3/τLJ. [Color figure canbe viewed in the online issue, which is available atwww.interscience.wiley.com.]

deform affinely.* Note that neutron scatteringexperiments on deformed glasses also show thatlong chains deform nearly affinely on the scale ofthe radius of gyration, but short chains do not.47

There is a clear correlation between the degreeof strain hardening (Fig. 6) and that of chainstretching (Fig. 7). The magnitude of the changesin both quantities increases monotonically withN and saturates above 5 to 10Ne. In this largeN limit the chains deform affinely at large scalesand their total length becomes irrelevant. Resultsfor shorter chains follow the asymptotic large Nbehavior at small strains, and then cross over to aless rapid rise at a g that decreases with decreas-ing N. This suggests that the deformation involvesstraightening segments of increasing length as gincreases. Only when this length becomes compa-rable to the chain length or Ne do the stress andR(λ) begin to saturate or follow the asymptoticbehavior.

While chains of length 25 are only 60% ofthe entanglement length, they remain close tothe asymptotic behavior up to g ≈ 2. Thus forthis chain stiffness, entanglements only appear toaffect strain hardening for g > 2. We expect thatthe degree of elongation in unentangled systems

*Indeed this would predict an error of order Ne/N if theends did not deform at all. The smaller error observed indi-cates that the ends also deform substantially. There is also asmall correction associated with the change in volume duringdeformation (∼1.3%).

depends on a competition between the friction pre-venting relaxation of stretched configurations, andthe decreasing number of configurations with agiven degree of elongation. Thus the monomer fric-tion, temperature, and strain rate may all affectthe value of g where entanglements become impor-tant. For example, the higher shear rates usedin the simulations of Lyulin et al.12 may haveprevented nonaffine relaxation of short chains,explaining why GR was essentially the same forentangled and unentangled systems.

The very shortest chains in Figures 6 and 7,N ≤ 10, lie below the asymptotic curves at allg. The value of R(1) for these chains is alreadynear the completely stretched limit Nl0 and theycannot align significantly under strain. For exam-ple, chains with N = 4 (about two Kuhn lengths)start at 80% of their fully extended length andshow no strain hardening. For N = 7, R(1)/Nl0 =0.6 and chains only stretch about 10% at thelargest g studied.

A recent experimental result48 is consistentwith our observation of strain hardening forchains with N < Ne. Wendlandt et al. found thatthe level of segmental orientation during plasticstrain well below Tg is indicative of an effectiveconstraint density much higher than the entangle-ment density in the melt. In addition to topologicalentanglements, they postulate the existence offrictional constraints, which cannot relax on thetime scale of the experiment. Friction clearly pre-vents relaxation of the stretching in short chainsin our simulations.

Plasticity and Nonaffine Displacements

One measure of the amount of plasticity is thedeviation of monomer displacements from anaffine deformation:†

D2na ≡ 〈(0r − F0r0)

2〉, (12)

where F is the macroscopic deformation tensor, 0ris the current position of a given monomer, 0r0 is itsinitial position at zero strain, and the average istaken over all monomers. To minimize the contri-butions to D2

na from thermally activated diffusion,we present results for a very low temperature,kBT/u0 = 0.01. Previous studies have focused ondeformation-enhanced mobility at higher temper-atures.11–14

†Small nonaffine deformations accompany elastic defor-mations in disordered media,49 but we consider strains wellbeyond the elastic regime.

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

STRAIN HARDENING OF POLYMER GLASSES 3497

Figure 8. Nonaffine displacement D2na as a function

of g(λ) = 1/λ − λ2. Successive curves from bottom totop are for Ne = 71, Ne = 39, Ne = 26, and Ne = 22.Solid lines indicate linear fits to the data for g(λ) ≥ 3.The system parameters are given in Table 1 andthe strain rate is −3.16 · 10−4/τLJ. [Color figure canbe viewed in the online issue, which is available atwww.interscience.wiley.com.]

Figure 8 shows data for D2na plotted against g(λ)

for four different entanglement densities. As notedabove, we have also calculated D2

na as a functionof the position of atoms along highly entangledchains (N > 5Ne). There is no statistically signifi-cant variation with position, indicating that chainend slippage does not play an important role.

For strains up to g(λ) & 1 (λ & 0.7), the D2na data

fall on a Ne-independent curve, showing that plas-tic deformation occurs on length scales below thescale of the entanglement mesh. At larger strains,well into the strain hardening regime, the rateof increase of D2

na with g(λ) gradually increases,becoming linear in g(λ) at large strains. As in plotsof stress and other quantities, the increase in theslope of D2

na occurs sooner for lower Ne.Remarkably, the slopes of D2

na at large strains(g(λ) ≥ 3) are proportional to ρe. Table 4 shows val-ues of (∂D2

na/∂g(λ)) obtained from linear fits to D2na

for g(λ) ≥ 3. The fit lines are also shown in Figure8. Values of Ne(∂D2

na/∂g(λ)) vary by only about5%. This result is very surprising, especially sincethe more densely entangled samples are undergo-ing Langevin hardening at these strains while thehardening in the less entangled samples remainsnearly Gaussian. The scaling of D2

na with N−1e at

large g suggests a simple picture in which theamount of plastic deformation is proportional tothe density of entanglements.

The increase in stress associated with strainhardening implies that more work must be doneto produce each increment in strain. We observe asmall increase in energy during deformation that

is not expected from the network model, but ismuch smaller than the work performed. For thesystems considered in Figure 8, the percentage ofthe work that goes into potential energy increasesfrom 8 to 18%, with decreasing Ne. The entropiccontribution to the change in free energy is alsosmall, particularly, at the low temperature con-sidered in this section. As a result, most of thework is dissipated as heat following local plasticrearrangements. The rate of work is proportionalto the stress and should scale as the rate of plas-tic rearrangements times the energy dissipated ineach.

One way of quantifying the rate of plasticity isto examine the nonaffine deformation δD2

na overa small strain interval δε = 0.025. Another is tocount the number of atoms that undergo the largenonaffine displacements associated with plasticevents. We find that the two measures are cor-related because δD2

na is dominated by the atomsundergoing large displacements with typical sizegreater than 0.2a. Both show an increase in plas-tic deformation with increasing g. There is a rapidrise as the strain approaches the yield point, andthen a slower rise in the strain hardening regime.Thus one factor in strain hardening is the increasein the amount of plastic deformation needed tomaintain the connectivity of chains as g increasesor the degree of entanglement increases. However,it appears that the stress rises more rapidly thanthe rate of plastic events at large g, particularly forNe = 22. This implies that the energy dissipatedin the events is increasing with g. Further studiesof plastic deformation are underway.

Primitive Path Statistics

For the systems considered here, the deformationof chains is nearly perfectly affine on the end–end scale and there is negligible disentanglementthrough chain-end slipping. The network model ofentanglements then suggests that the entangle-ment points and the primitive path between them

Table 4. Slope of Nonaffine Deformation(∂D2

na/∂g(λ)) versus ρe

Ne (∂D2na/∂g(λ)) Ne(∂D2

na/∂g(λ))

71 1.41 10039 2.42 9426 3.52 9222 4.29 94

Strain rate is ε = −3.16 · 10−4/τLJ.

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

3498 HOY AND ROBBINS

Figure 9. Variation of Lpp(λ)/L0pp−1 with λ for Ne = 22

(bottom) and Ne = 39 (top). Solid lines are fits toc(Y(λ) − 1) with c=0.58 and 0.70, respectively. [Colorfigure can be viewed in the online issue, which isavailable at www.interscience.wiley.com.]

will deform affinely. One way of testing this is tocompare the increase in the contour length of theprimitive path Lpp to the network model. Figure 9shows Lpp(λ)/L0

pp − 1 for Ne = 22 and Ne = 39. Wenow show that these results can be described bytwo seemingly different models.

Affine deformation of the entanglement net-work implies that the primitive paths shoulddeform affinely at all length scales. We calcu-late the change in Lpp by considering an initialGaussian path and applying a volume conservinguniaxial compression. Then averaging the changein length over steps with all initial orientationsyields:

Y(λ) ≡Laffine

pp (λ)

L0pp

= 12

(

λ + sin−1(√

1 − λ3)√λ − λ4

)

.

(13)

The solid lines in Figure 9 are fits to c(Y(λ) − 1),where c = .58 for Ne = 22 and c = .70 for Ne = 39.The agreement is excellent, although it is not clearwhy c is reduced from unity. It appears that thereare deviations from affine deformation on the scaleof a few monomer spacings. This is insignificant atthe scale of an entire chain, but not at the separa-tion of individual entanglements (∼8a), allowingthe primitive path length to stretch less thanpredicted.

An alternative approach is to calculate theexpected evolution of Lpp(λ) from the nonaffinetube model of Rubinstein and Panyukov.20 Lpp(λ)

is related to 〈R2ee(λ)〉 and the strain-dependent

tube diameter a(λ) by Lpp(λ) = 〈R2ee(λ)〉/a(λ).

For volume-conserving compression the nonaffine

tube model predicts

a(λ) = a0√3

√

λ + 2√λ

, (14)

where a0 is the tube diameter in the undeformedstate. The affinity of the deformation at the end–end scale gives 〈R2

ee(λ)〉 = (λ2+2/λ)〈R20〉. Replacing

〈R20〉 with L0

ppa0, a0 drops out after some algebra,and the prediction is

Z(λ) = Lpp(λ)

L0pp

= 1√3

λ2 + 2λ−1

√λ + 2λ−1/2

. (15)

The data in Figure 9 are equally well fit byd(Z(λ) − 1), where d = 0.27 for Ne = 22 and d =0.33 for Ne = 39. The reason is that Z(λ)−1 = (35/

16)(Y(λ)−1) to within a few percent over the entirerange of λ explored here. The correspondenceof Y(λ) and Z(λ) is somewhat surprising, giventhe different approaches to their calculation, onecoming from a purely mathematical single-chaintreatment and the other from a physically moti-vated mean-field tube model. To the best of ourknowledge this has not been previously reported.

CONCLUSIONS

Simulations of strain hardening were carried outfor glassy polymer systems with a wide rangeof entanglement densities. At fixed temperatureand strain rate, the results are consistent withthe entropic network model. The strain harden-ing modulus GR is linearly proportional to theentanglement density ρe and does not correlatewith chain stiffness alone.8,9 Both Gaussian andLangevin hardening are observed and the transi-tion between them occurs at the expected entan-glement density.

The effect of temperature on strain harden-ing is in dramatic disagreement with the entropicmodel. Both GR and GR/ρe decrease linearly withincreasing T rather than being proportional to T.This behavior extends between the T → 0 andT → Tg limits. To accomodate this behavior, anentropic description would require that S divergefaster than 1/T as T → 0. In addition, values of GR

at all temperatures considered were much largerthan the entropic prediction GR = ρekBT. Near Tg

the ratio GR/ρekBT is of order 100 in both our sim-ulations and recent experiments.7 The decreasein GR with increasing T is similar to the corre-sponding decrease in the flow stress, suggesting

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

STRAIN HARDENING OF POLYMER GLASSES 3499

that thermally assisted local rearrangements mayreduce both quantities at higher temperatures.

The correlation between GR and the flow stressextended to variations with interaction parame-ters and rate. While both GR and σflow increase withthe strength and range of adhesive interactions,the ratio GR/σflow remains essentially constant.Correlated increases with strain rate were alsoobserved. Indeed the stress–strain curves for dif-ferent rates and interactions collapsed onto auniversal curve when normalized by σflow. Theobserved multiplicative dependence on strain andstrain rate (eq 10) is very different than theadditive dependence commonly assumed in con-stitutive laws (eq 11). The experimental literatureoffers conflicting results on the rate dependenceof strain hardening. Some experiments6,16,39 showrate-dependent hardening, while others37,50 donot. Most experiments are fit to additive consti-tutive laws like eq 11, but a multiplicative formlike eq 10 has also been employed.41 In many casesthe flow stress may not change by a large enoughfactor to distinguish between the two forms, butit would be interesting to test the multiplicativerelation on a wider set of experimental data.

The effect of chain length on strain harden-ing was examined over the entire range of chainlengths from unentangled to fully entangled. Sig-nificant strain hardening was found in systemswith chains much shorter than the topologicalentanglement length Ne. Hardening occurs as longas chains are able to continuously orient withincreasing strain.

The evolution of microscopic quantities inac-cessible to experiment was studied. The nonaffinepart of the deformation was observed to fall on anNe-independent curve at strains up to the earlypart of the strain hardening regime (g(λ) ≈ 1).This suggests that the deformation is restricted tochain segments shorter than Ne at small strains.The onset of a more rapid rise in the deformationmoves to lower strains as Ne decreases and at highstrains the rise in deformation is proportional toρe. This is consistent with a simple model in whichthe amount of nonaffine (or plastic) deformationis proportional to the entanglement density. Stud-ies of local plastic rearrangements indicate thatstrain hardening results from an increase in theamount of local plastic deformation with increas-ing strain and ρe, as well as an increase in theenergy scale of rearrangements. Finally, the scal-ing of the increase in primitive path lengths wasfound to be consistent with both an affine primi-tive chain model and a nonaffine tube model, but

the absolute values of the increases were smallerthan those predicted.

We hope that the connections we have shownbetween GR and flow stress provide additionalinsight into the physics controlling GR. The flowstress is related to small scale structure and thereis a growing understanding of the factors thatcontrol it.25,40,44,46 The success of the network mod-els in explaining the form of strain hardeningsuggests that entropic arguments may be ableto predict the amount of deformation required tomaintain chain connectivity, and thus the func-tion F(λ) that multiplies σflow. Combining thisapproach with models for σflow may allow strainhardening to be predicted directly from knowledgeof the microsopic interchain interactions.

Edward J. Kramer provided the inspiration for thiswork. Jorg Röttler and Kenneth S. Schweizer pro-vided useful discussions. Gary S. Grest provided theDBH-equilibrated initial states. The simulations in thispaper were carried out using the LAMMPS moleculardynamics software (http://www.cs.sandia.gov/∼sjplimp/lammps.html). This material is based upon work sup-ported by the National Science Foundation underGrants No. DMR-0454947 and PHY-99-07949.

REFERENCES AND NOTES

1. The Physics of Glassy Polymers, 2nd ed.; Haward,R. N.; Young, R. J. eds.; Chapman and Hall: London,1997.

2. Treloar, L. R. G. The Physics of Rubber Elasticity;Clarendon Press: Oxford, 1975.

3. Haward, R. N.; Thackray, G. Proc Roy Soc LondonSer A 1968, 302, 453.

4. Kramer, E. J. J Polym Sci Part B: Polym Phys 2005,43, 3369.

5. Cross, A.; Haward, R. N. Polymer 1978, 19, 677.6. G’Sell, C.; Jonas, J. J. J Mater Sci 1981, 16, 1956.7. van Melick, H. G. H.; Govaert, L. E.; Meijer, H. E. H.

Polymer 2003, 44, 2493.8. Haward, R. N. Macromolecules 1993, 26, 5860.9. Mckechnie, J. I.; Haward, R. N.; Brown, D.; Clarke,

J. H. R. Macromolecules 1993, 26, 198.10. Yashiro, K.; Ito, T.; Tomita, Y. Int J Mech Sci 2003,

45, 1863.11. Lyulin, A. V.; Balabaev, N. K.; Mazo, M. A.; Michels,

M. A. J. Macromolecules 2004, 37, 8785.12. Lyulin, A. V.; Vorselaars, B.; Mazo, M. A.; Balabaev,

N. K.; Michels, M. A. J. Europhys Lett 2005, 71, 618.13. Capaldi, F. M.; Boyce, M. C.; Rutledge, G. C. Phys

Rev Lett 2002, 89, 175505.14. Capaldi, F. M.; Boyce, M. C.; Rutledge, G. C. Polymer

2004, 45, 1391.

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb

3500 HOY AND ROBBINS

15. Govaert, L. E.; Tervoort, T. A. J Polym Sci Part B:Polym Phys 2004, 42, 2041.

16. Wendlandt, M.; Tervoort, T. A.; Suter, U. W. Polymer2005, 46, 11786.

17. Kremer, K.; Grest, G. S. J Chem Phys 1990, 92, 5057.18. Everaers, R.; Sukumaran, S. K.; Grest, G. S.;

Svaneborg, C.; Sivasubramanian, A.; Kremer, K.Science 2004, 303, 823.

19. Doi, M.; Edwards, S. F. The Theory of PolymerDynamics; Clarendon Press: Oxford, 1988.

20. Rubinstein, M.; Panyukov, S. Macromolecules 1997,30, 8036.

21. Auhl, R.; Everarers, R.; Grest, G. S.; Kremer, K.;Plimpton, S. J. J Chem Phys 2003, 119, 12718.

22. Faller, R.; Kolb, A.; Müller-Plathe, F. Phys ChemChem Phys 1999, 1, 2071.

23. Frenkel, D.; Smit, B. Understanding Molecular Sim-ulations, 2nd ed.; Academic Press: San Diego, 2002.

24. Schneider, T.; Stoll, E. Phys Rev B 1978, 17, 1302.25. Rottler, J.; Robbins, M. O. Phys Rev E 2003, 68,

011507.26. Karayiannis, N. C.; Mavrantzas, V. G.; Theodorou,

D. N. Phys Rev Lett 2002, 88, 105503.27. Hoy, R. S.; Robbins, M. O. Phys Rev E 2005, 72,

061802.28. Zhou, Q.; Larson, R. G. Macromolecules 2005, 38,

5761.29. Sukumaran, S. K.; Grest, G. S.; Kremer, K.; Ever-

aers, R. J Polym Sci Part B: Polym Phys 2005, 43,917.

30. Arruda, E. M.; Boyce, M. C.; Jayachandran, R. MechMat 1995, 19, 193.

31. Bartczak, Z. Macromolecules 2005, 38, 7702.32. Yang, L.; Srolovitz, D. J.; Yee, A. F. J Chem Phys

1997, 107, 4396.

33. Wang, M. C.; Guth, E. J Chem Phys 1952, 20,1144.

34. Arruda,E. M.;Boyce,M. C. J Mech Phys Solids 1993,41, 389.

35. Tervoort, T. A.; Govaert, L. E. J Rheology 2000, 44,1263.

36. Boyce, M. C.; Parks, D. M.; Argon, A. S. Mech Mat1988, 7, 15.

37. Boyce, M. C.; Arruda, E. M. Polym Eng Sci 1990, 30,1288.

38. Arruda, E. M.; Boyce, M. C. Int J Plasticity 1993, 9,697.

39. Hope, P. S.; Ward, I. M.; Gibson, A. G. J Mater Sci1980, 15, 2207.

40. Rottler, J.; Robbins, M. O. Phys Rev Lett 2005, 95,225504.

41. G’sell C.; Jonas, J. J. J Mater Sci 1979, 14, 583.42. Eyring, H. J Chem Phys 1936, 4, 283.43. Cook, W. D.; Mayr, A. E.; Edward, G. H. Polymer

1998, 39, 3725.44. Varnik, F.; Bocquet, L.; Barrat, J.-L. J Chem Phys

2004, 120, 2788.45. Klompen, E. T. J.; Engels, T. A. P.; Govaert, L. E.;

Meijer, H. E. H. Macromolecules 2006, 38, 6997.46. Rottler, J.; Robbins, M. O. Phys Rev E 2001, 64,

051801.47. Dettenmaier, M.; Maconnachie, A.; Higgins, J. S.;

Kaush, H. H.; Nguyen, T. Q. Macromolecules 1986,19, 773.

48. Wendlandt, M.;Tervoort,T. A.; van Beek, J. D.; Suter,U. W. J Mech Phys Solids 2006, 54, 589.

49. Tanguy, A.; Wittmer, J. P.; Leonforte, F.; Barrat, J.-L.Phys Rev B 2002, 66, 174205.

50. G’Sell, C.; Hiver, J. M.; Dahoun, A.; Souahi, A.;J Mater Sci 1992, 27, 5031.

Journal of Polymer Science: Part B: Polymer PhysicsDOI 10.1002/polb