EE Policy Opportunities for EM-Driven Systems Paul_Waide

Transcript of EE Policy Opportunities for EM-Driven Systems Paul_Waide

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

1/132

Energy-EfficiencyPolicy Opportunities

for ElectricMotor-Driven Systems

INTERNATIONALENERGYAGENCY

PAULWAIDEANDCONRADU. BRUNNER

W O R K IN G PA PE R

Energy

Efficiency

Series

2011

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

2/132

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

3/132

Energy-EfficiencyPolicy Opportunities

for ElectricMotor-Driven Systems

INTERNATIONALENERGYAGENCY

PAULWAIDEANDCONRADU. BRUNNER

W O R K IN G PA PE R

2011

The views expressed in this working paper are those of the

authors and do not necessarily reflect the views or policy

of the International Energy Agency (IEA) Secretariat or of

its individual member countries. This paper is a work in

progress, designed to elicit comments and further debate;

thus, comments are welcome, directed to the authors of the

Energy Efficiency and Environment Division at: [email protected]

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

4/132

INTERNATIONAL ENERGY AGENCY

The International Energy Agency (IEA), an autonomous agency, was established in November 1974.Its primary mandate was and is two-fold: to promote energy security amongst its membercountries through collective response to physical disruptions in oil supply, and provide authoritative

research and analysis on ways to ensure reliable, affordable and clean energy for its 28 membercountries and beyond. The IEA carries out a comprehensive programme of energy co-operation amongits member countries, each of which is obliged to hold oil stocks equivalent to 90 days of its net imports.The Agencys aims include the following objectives:

Secure member countries access to reliable and ample supplies of all forms of energy; in particular,through maintaining effective emergency response capabilities in case of oil supply disruptions.

Promote sustainable energy policies that spur economic growth and environmental protectionin a global context particularly in terms of reducing greenhouse-gas emissions that contributeto climate change.

Improve transparency of international markets through collection and analysis ofenergy data.

Support global collaboration on energy technology to secure future energy supplies

and mitigate their environmental impact, including through improved energyefficiency and development and deployment of low-carbon technologies.

Find solutions to global energy challenges through engagement anddialogue with non-member countries, industry, international

organisations and other stakeholders.IEA member countries:

Australia

Austria

Belgium

Canada

Czech Republic

Denmark

Finland

France

Germany

Greece

Hungary

Ireland

Italy

Japan

Korea (Republic of)

Luxembourg

NetherlandsNew Zealand

Norway

Poland

Portugal

Slovak Republic

Spain

Sweden

Switzerland

Turkey

United Kingdom

United States

The European Commission

also participates in

the work of the IEA.

Please note that this publication

is subject to specific restrictions

that limit its use and distribution.

The terms and conditions are available

online at www.iea.org/about/copyright.asp

OECD/IEA, 2011

International Energy Agency9 rue de la Fdration

75739 Paris Cedex 15, France

www.iea.org

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

5/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|3

TableofContents

Acknowledgments............................................................................................................................9

ExecutiveSummary........................................................................................................................11

Theglobalassessment.............................................................................................................11

Motorsystemsusedwidelyacrossallsectors.........................................................................11

Policyinterventioncanstimulatesignificantsavings..............................................................13

Policiesneededforoptimisingpackagedsystems..................................................................14

Comprehensiveintegratedpolicypackage.............................................................................15

Regulatorypolicymeasures.............................................................................................15

Nonregulatorypolicymeasures......................................................................................16

Puttingideasintopractice.......................................................................................................16

1.Introduction...............................................................................................................................18

2. ElectricMotorDrivenSystemsandApplications.....................................................................20

Motorsystemtypesanddefinitions........................................................................................20

EMDSApplications...................................................................................................................20

Motormarketdata..................................................................................................................21

Marketvolumesbyapplication...............................................................................................22

Marketsharebyefficiency......................................................................................................23

MarketpenetrationofVFDtechnology...........................................................................27

3.Global

Electricity

Consumption

and

CO2

Emissions

of

Electric

Motor

Driven

Systems..........29

Scopeandmethodology..........................................................................................................29

Scopeanddefinitions.......................................................................................................30

Methodology....................................................................................................................32

Topdownestimatesofelectricityuse....................................................................................32

Demandbyenduse.........................................................................................................32

Demandbymotorsector.................................................................................................33

Demandbymotorsize.....................................................................................................37

Demandbymotorapplication.........................................................................................37

Conclusionsfromtopdownestimates............................................................................39

Bottomupmodelofmotorelectricityuse..............................................................................41

Methodology....................................................................................................................41

Themotorstockmodel....................................................................................................41

Estimatesfrombottomupmodel...................................................................................42

Consolidatedtopdownandbottomupestimatesofelectricityconsumption

andCO2emissions...................................................................................................................43

Causesofuncertainty..............................................................................................................45

Topdownestimates........................................................................................................45

Bottomupestimates.......................................................................................................45

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

6/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|4

4. EnergySavingsTechnologiesandSavingsPotentialsApplicabletoElectric

MotorDrivenSystems..............................................................................................................46

Improvingcomponentefficiency.............................................................................................46

StandardACsquirrelcageinductionmotor............................................................................46

Othermotortechnologies...............................................................................................48

Newmotortechnologies.................................................................................................49

Gearsandtransmissions..................................................................................................51

Motorcontroltechnologies.....................................................................................................53

VariableloadsandVFDsorASDs.............................................................................................53

Efficiencyopportunitiesindifferentmotorapplications........................................................56

Pumps..............................................................................................................................56

Fans..................................................................................................................................62

Compressors....................................................................................................................66

Otherapplications...........................................................................................................67

Relatedenergysavingsopportunities.....................................................................................68

Engineeringpracticeimprovement.........................................................................................68

Integratedmachinedesign..............................................................................................69

Packagedproductsascoremotorsystems.....................................................................70

Adequatesizing................................................................................................................70

Efficientoperation...........................................................................................................70

5. TheEconomicsofEnergySavingsinElectricMotorDrivenSystems......................................72

FactorsthatinfluenceEMDSeconomics.................................................................................72

Engineeringdecisionmaking...........................................................................................73

Leastlifecyclecost..........................................................................................................73

Repairversusreplacement..............................................................................................75

Upgradingexistingsystems.............................................................................................75

Payingforabettermotorbybuyingasmallermotor.....................................................76

Tappingcostbenefitsfrommotorsystemoptimisation.........................................................76

6.BarrierstoOptimisationofEfficientElectricMotorDrivenSystems.......................................78

Conceptsofbarriers................................................................................................................78Missedcostreductionsformassproducedproducts.....................................................78

Barrierstointernationaltrade.................................................................................................80

Technicalbarriersinelectricitysupply............................................................................80

Barriersinnonharmonisedstandards............................................................................81

Barriersatsectorandbusinesslevels.....................................................................................82

BarriersatthelevelofmanufacturersandOEMs...........................................................82

Barriersinwholesale,planningandengineering.............................................................84

Barriersatthelevelofinvestorsandenergymanagers..................................................85

Paybackperiodandinternalrateofreturn:riskandprofitabilityanalysis...........................87

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

7/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|5

Externalitiesofelectricityusebyelectricmotorsandmotorsystems...................................88

Conclusionsonremovingbarriers...........................................................................................89

6. EnergyEfficiencyPolicyExperienceforElectricMotorDrivenSystems.................................90

Regulationsandlabellingforintegratedequipmentandcomponents..................................90Electricmotors.................................................................................................................90

Pumps..............................................................................................................................96

Fans................................................................................................................................101

Compressors..................................................................................................................102

Systemsperformancespecifications.....................................................................................103

Electricmotors...............................................................................................................103

Pumps............................................................................................................................103

Fans................................................................................................................................104

Aircompressors.............................................................................................................104

Toolstoencourageadoptionofenhancedmotordrivensystems.......................................105

UnitedStates:pumpmotorsystems.............................................................................105

UnitedStates:fanmotorsystems.................................................................................106

UnitedStates:aircompressorsystems.........................................................................106

Awarenessraisingefforts......................................................................................................107

EuropeanUnion:pumps................................................................................................107

Economicincentives..............................................................................................................107

NorthAmerica................................................................................................................107

China..............................................................................................................................108

Industrialsectorenergyservicecompanies..........................................................................108

Industrialenergyefficiencyprogrammesandcapacitybuilding.............................................108

EuropeanUnion.............................................................................................................108

China..............................................................................................................................109

Linkswithmacropolicyinitiatives.................................................................................109

Evaluationandimpacts..................................................................................................109

7. OptionsandRecommendationsforNewPoliciesonElectricMotorDrivenSystems..........111

Policycontext........................................................................................................................111

Policyrecommendations.......................................................................................................112

Regulatorypolicymeasures...........................................................................................112

Nonregulatorypolicymeasures....................................................................................114

Potentialpolicyimpacts........................................................................................................116

Comprehensiveintegratedpolicypackage...........................................................................117

Regulatory......................................................................................................................118

Nonregulatory...............................................................................................................118

Puttingideasintopractice.....................................................................................................119

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

8/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|6

AnnexA.TechnicalStandardsforEMDS......................................................................................121

Abbreviations................................................................................................................................123

References....................................................................................................................................125

Listoffigures

Figure1: Projectedglobalelectricmotorsystemelectricityconsumption.................................14

Figure2: Electricmotorcategories..............................................................................................20

Figure3: EfficiencyclassesforfourpolemotorsofstandardIE3,IE2andIE1classes,

andthenewIE4class....................................................................................................23

Figure4: MarketshareofefficiencyclassesintheUnitedStates(200106)...............................25

Figure5: MotorefficienciesinCanadabeforeandafterintroductionin1997ofEnergy

EfficiencyRegulationsforGeneralPurposeIndustrialMotors.....................................26

Figure6: MarketshareofefficiencyclassesinEuropeunderthe

CEMEPvoluntaryagreement........................................................................................27

Figure7: Totalmotorsystem,coremotorsystemandelectricmotor........................................29

Figure8: Maintypesofelectricmotorsasafunctionofpowerand

associatedcharacteristics.............................................................................................31

Figure9: Estimatedshareofglobalelectricitydemandbyenduse(2006).................................33

Figure10: Assumedshareofmotorelectricityusebyendusersector........................................35

Figure11: Estimatedelectricitydemandforallelectricmotorsbysector....................................37

Figure12: Estimatedshareofglobalmotorelectricitydemandbyapplication(2009).................40

Figure13: Estimatedoverallefficiencyandelectricityuseforalltypesofelectric

motorsystems...............................................................................................................40

Figure14: PartialloadefficiencyofIE3andIE1motors(4pole)...................................................47

Figure15: Impactofpossibleareasofimprovementforinductionmotorperformance..............48

Figure16: IE3PremiumEfficiencymotor......................................................................................50

Figure17: HighefficiencyECmotorsfrom0.1kWto10kWforfans...........................................51

Figure18: Twotransmissionsystems:rollerchainsandsynchronousbelts.................................52

Figure19: Schematicvariablefrequencydrive..............................................................................53

Figure20: Typicalefficiencyoflowvoltage,pulsewidthmodulatedfrequency

convertersatfullload...................................................................................................55

Figure21: Variablefrequencydriveefficiencyatfullandpartialload..........................................56

Figure22: Fivemajorpumptypes(typicalpumpconfigurations).................................................57

Figure23: Efficiencyofsinglestagepumpsaccordingtovariationofheadandflow...................57

Figure24: Energysavingswithspeedcontrolforacentrifugalpumpwithout

staticpressurehead......................................................................................................58

Figure25: Highefficiencyelectronicallycommutatedmotorforpumps......................................58

Figure26: GlandlesscirculationpumpwithECmotorandautomaticpoweradjustment............59

Figure27: Electricitysavingsofcirculatorpumpinheatingsystem..............................................59

Figure28: Reducedelectricpoweruseinindustrialsizepumpsystem........................................60

Figure29: ECmotorsforfans.........................................................................................................62

Figure30: FutureEUminimumenergyperformancestandards(MEPS)forfans/ventilation.......63

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

9/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|7

Figure31: Centrifugalfans:energysavingswithdifferentmethodsofairflowcontrol...............64

Figure32: Fanefficiencypotential reducedspecificpower......................................................66

Figure33: Fanefficiencypotential reducedannualelectricityuse...........................................66

Figure34: Systematiceliminationoflossesinanoptimaldrivesystem........................................69

Figure35:

Life

cycle

cost

of11

kW

IE3

motor

with

4000

operating

hours

per

year

.....................

72

Figure36: Relativepricesofelectricmotorswithhigherefficiencyand

variablefrequencydrives,Switzerland,2008...............................................................74

Figure37: Systemlifecyclecostanalysisofan11kWmotor.......................................................74

Figure38: Exampleofhowdownsizingcanpayforamoreefficientmotor.................................76

Figure39: Policyinstrumentstoreduceobstaclestodiffusionofhighefficiency

electricmotorsandmotorsystemsalongtheproductcycle........................................82

Figure40: Conventional(static)paybackperiodandIRRofhighefficiencymotors

comparedtonormalmotorsatdifferentyearlyoperatinghours................................88

Figure41: Projectedglobalelectricmotorsystemelectricityconsumption...............................117

Listoftables

Table1: EDMSelectricityconsumptionbysector......................................................................11

Table2: Proposedtimetableforimplementationofrecommendations....................................17

Table3: EMDSapplicationsshowingrelationshipsbetweensystemsandservice....................21

Table4: MotorsystemssalesintheUnitedStates(2003).........................................................22

Table5: MotorsystemssalesintheEuropeanUnion(2005).....................................................22

Table6: DistributionofmotorapplicationsintheUSindustrysector(1997)............................22

Table7:Stock

data

for

three

applications

inthe

European

Union

(2005)

.................................

22

Table8: Motorefficiencyclassesindifferentcountriesandthecorresponding

internationalstandard..................................................................................................24

Table9: Timelineforelectricmotorefficiencyclasses,testingstandardsandminimum

energyperformancestandards.....................................................................................24

Table10: ShareofmotorefficiencyclassIE3salesintheUnitedStates(200106)

andCanada(2007)........................................................................................................26

Table11: ShareofefficiencyclassIE3inelectricmotorsalesbysize,UnitedStates(2003).......26

Table12: Estimateofglobalelectricitydemand(TWh)bysectorandenduse(2006)................33

Table13: Estimatedglobalelectricityconsumptionbysectorin2006........................................34

Table14: Electricityendusebysector,countryandestimateddemandforall

electricmotors(2006)...................................................................................................36

Table15: Estimatedelectricitydemandforthethreemajorgroupsofelectricmotors(2009)..38

Table16: Applicationsofallkindsofelectricmotors...................................................................38

Table17: Estimatedglobalmotorelectricitydemandbysectorandapplication(2006).............39

Table18: Estimatedmotorelectricitydemandwithparticularfactorsfromthe

bottomupmodelfor13countrieswithhighestelectricityconsumption....................43

Table19: Comparisonofmotorelectricitydemandinbottomupandtopdownmodels

andfiguresfromtheliteratureof12economies..........................................................44

Table20:

Nominal

load

efficiencies

inIE3

Premium

Efficiency

AC

induction

motors

..................

47

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

10/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|8

Table21: TypicallossesinanACinductionmotor........................................................................48

Table22: Gearefficiency...............................................................................................................52

Table23: Comparisonofannualelectricityuseincirculatorpumpsystems...............................60

Table24: Comparisonofannualelectricityuseinindustrialsizepumpsystems........................61

Table25: Majorfanproductcategoriesandcharacteristics........................................................62

Table26: Measuresandpotentialsforreducingtheenergydemandoffans..............................64

Table27: Optimisationstudyofafan...........................................................................................65

Table28: Exampleoflossesinacompressedairsystem.............................................................67

Table29: Areasofenergyefficiencyinelectricmotorsystems...................................................68

Table30: Classificationofbarrierstoenergyefficiency...............................................................79

Table31: Internalrateofreturnandpaybackperioddifferencebetweenrisk

andprofitabilityanalysis...............................................................................................87

Table32: Nominalminimumefficiencies()forelectricmotorsinEurope(50Hz)....................91

Table33: MotortypessubjecttoMEPSintheUnitedStates

1.....................................................93

Table34: NominalminimumfullloadefficienciesforSubtypeIelectricmotors

intheUnitedStates(60Hz)1.........................................................................................93

Table35: Regulationsforelectricmotorsinsomeothercountries.............................................95

Table36: EnergylabellingefficiencythresholdsforcirculatorpumpsintheEuropeanUnion....98

Table37: Regulationsforpumpmotorsystemsinsomeothercountries.................................100

Table38: Proposedtimetableforimplementationofrecommendations..................................119

Table39: Keyinternationalstandards........................................................................................122

Table40: Otherregionalstandards............................................................................................122

Listofequations

Equation1........................................................................................................................................34

Equation2........................................................................................................................................41

Equation3........................................................................................................................................42

Equation4........................................................................................................................................63

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

11/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|9

Acknowledgments

ThispaperwaswrittenbyPaulWaide(formerlywiththeIEAandnowwithNavigantConsulting)

and Conrad U. Brunner of A+B International in collaboration withMartin Jakob andMartin

Meyer,TEPEnergy,Zurich,SwitzerlandaswellasEberhardJochem,BSRSustainability,Karlsruhe,Germany.ParticularthanksgotothefollowingIEAstaffandoutsidecolleaguesforthetimespent

in reviewing and providing comments: Nigel Jollands, Shane Holt, Jungwook Park and Hugh

Falkner.TheauthorswouldalsoliketoacknowledgeEditaZlaticforheradministrativeassistance,

MarilynSmith,SusanCopelandandAurlienSaussayforeditorialassistance.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

12/132

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

13/132

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

14/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|12

The largestproportionofmotorelectricityconsumption isattributabletomidsizemotorswith

outputpowerof0.75kW to375kW.Manydifferentmotor technologiesanddesign typesare

available,butasynchronousalternatingcurrent(AC) inductionmotorsaremostfrequentlyused

and consume the most energy. These motors are either sold to original equipment

manufacturers (OEMs) and integrated into prepackaged electromechanical products (such as

pumps,fans,compressors,etc.)orsoldasstandalonemotorsthatfinalcustomersthenintegrate

into a specific application on site. Such standalonemotors are produced in large volumes,

accordingtostandardised inputpowerandsizespecifications,withvaryingchannels tomarket

and integration into electromechanical systems. This has a significant impact on the type of

barrierstoadoptionofenergyefficientsolutionsforEMDSand,hence,onthemostappropriate

policypackagestoovercomesuchbarriers.

Motors inthemidsize rangearemostcommonly found in industrialapplications,buttheyare

also widely used in commercial applications, infrastructure systems and, less often, in the

residential sector. Ingeneral, theirmainapplicationsaremechanicalmovement, compressors,

pumpsandfans,which inturnhavemanytypesofsubapplication.Atpresent,mostOECDand

manynonOECDeconomiesimposeMEPSonasynchronousmidsizeACmotorssoldasseparatecomponents.Veryfewcountrieshavesetsuchrequirementsforothertypesofelectricmotors,

andtherequirementsarerarelyappliedspecificallytomotorsintegrateddirectlyintoapackaged

systempriortosale.

Largeelectricmotorswithmorethan375kWoutputpowerareusuallyhighvoltageACmotors

thatarecustomdesigned,builttoorderandassembledwithinanelectromechanicalsystemon

site.Theycomprisejust0.03%oftheelectricmotorstock intermsofnumbers,butaccountfor

about23%ofallmotorpowerconsumption,makingthemverysignificantconsumersofglobal

power(about10.4%).ThesemotorsarenotcurrentlysubjecttoMEPSinanypartoftheworld.

Inelectricmotordrivensystems,someenergylossesoccurinthemotoritself,butenergylosses

are greater in the rest of the mechanical system to which themotor is coupled. A typical

electromechanicalsystem involvesamotor,anelectricalcontrolsystem,avariablespeeddrive

(VSD)andamechanicalload.Themagnitudeofenergylossesdependsontheapplicationandthe

degree towhichanadvancedtechnicalsolution isused.Foranygivenpower rating, there isa

differenceofonlyafewpercentagepointsinenergyefficiencybetweenaveragemotorsandthe

mostefficientmotorsonthemarket.

Smallmotors are less efficient than higherpoweredmotors. Large losses can occur due to

mismatches between the output power of fixedspeed motors and the mechanical power

demands of the electromechanical system. This is especially true whenmotors are used in

mechanicalapplicationswithvariablemechanicalpowerneeds,whichhaveahighlynonlinear

relationshipbetween inputpowerandmechanical load (torqueandspeed)andanexponential

relationshipbetweeninputpowerandmechanicalpower(e.g.pumps,fansandcompressors).In

thiscase,therecanbeverysignificantsavingsfromusingvariablefrequencydrives(VFDs)with

intelligent control, which regulate the output torque and speed of themotor tomatch the

systemmechanicalloads.However,suchcontrolsystemsneedasignificantamountofpowerto

operateandshouldnotbeusedinfixedoutputpowerapplications.Insuchapplications,theywill

incurmoreenergylossesandimposehighercoststhanaproperlysizedfixedspeedsystem.

Foranygivenoutputpower rating, there is currentlya spreadof severalpercent inefficiency

betweenthemostandleastefficientmotorsonthemarket.Despitebeingslightlymorecostlyto

purchase than standard motors, higherefficiency motors (HEMs) with over 1000hours of

operationperyeararemorecosteffectiveoverthesystem lifeforendusers inallapplications,

becausemotorenergy costs typically account for over 95% of amotors lifecycle cost. The

internalrateofreturn(IRR)fromtheuseofaHEMcomparedtoastandardmotor isoftenwell

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

15/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|13

over 100%,but endusers rarelydemandHEM applications,due to ahostofmarketbarriers.

Mandatory regulations are usually the best way to ensure significant and timely market

penetrationofHEMs.

Policyintervention

can

stimulate

significant

savings

Overall,thisanalysisfindsthatusingthebestavailablemotorswilltypicallysaveabout4%to5%

ofallelectricmotorenergyconsumption.Linkingthesemotorswithelectromechanicalsolutions

thatare costoptimised for theenduserwill typically saveanother15%to25%.Thepotential

exists to costeffectively improve energy efficiency ofmotor systems by roughly 20% to30%,

whichwouldreducetotalglobalelectricitydemandbyabout10%.

Thethreemajorroutestoachievingthesesavingsare:

Useofproperlysizedandenergyefficientmotors.

Useofadjustablespeeddrives(ASDs)2,whereappropriate,tomatchmotorspeedandtorque

to the systemmechanical load requirements. Thismakes it possible to replace inefficientthrottling devices and, in some cases with directdrive, to avoid wasteful mechanical

transmissionsandgears.

Optimisation of the complete system, including correctly sized motor, pipes and ducts,efficient gears and transmissions, and efficient enduse equipment (fans, pumps,

compressors,traction,andindustrialhandlingandprocessingsystems)todelivertherequired

energyservicewithminimalenergylosses.

Withoutpolicyintervention,manybarriersmakeitdifficultorimpossibletorealisethesesavings

in thecurrentmarketenvironment. Inunregulatedmarkets,purchasers tend tounderinvest in

higherefficiencyoptionsandchooseelectricmotorsystemswithalowfirstcost.Thisoccursfora

varietyofreasons,including:

Lackofawarenessamongmotorpurchasersof thepotential forenergyandcostsavingsbyusingmoreefficientmotorswithinenergyefficientEMDS.

Company organisational structures that manage their equipment procurement budgetseparatelyfromoperationsandmaintenancebudgets.

The factthatmotorsareoften integrated intoequipmentproducedbyOEMsbeforesaletothefinalenduser.

To overcome these barriers,many countries (now comprising over onethird of the worlds

population)haveadoptedMEPSforthemainclassof industrialelectricmotors.Morecountries

areintheprocessofdevelopingsuchrequirements.Thispolicyinstrumenthasbeenshowntobe

practicable to implement and a costeffective means of saving energy. The average energy

efficiencyofnewmotorsincountriesapplyingMEPSisnotablyhigherthanincountrieswithout

suchrequirements.ItisestimatedthatifallcountriesadoptedbestpracticeMEPSforindustrial

electricmotors,by2030approximately322TWhofannualelectricitydemandwouldbesaved,

givingrisetocorrespondingsavingsof206MtofCO2emissions.

2 Anadjustablespeeddrive(ASD)orvariablespeeddrive(VSD)isequipmentusedtocontrolthespeedofmachinery.Many

industrial processes such as assembly lines must operate at different speeds for different products.Where process

conditionsdemandadjustmentofflowfromapumporfan,varyingthespeedofthedrivemaysaveenergycomparedwith

othertechniquesforflowcontrol.Wherespeedsmaybeselectedfromseveraldifferentpresetranges,usuallythedriveis

saidtobe"adjustable"speed.Iftheoutputspeedcanbechangedwithoutstepsoverarange,thedriveisusuallyreferred

toas"variablespeed".Avariablefrequency

drive

(VFD) isasystemforcontrollingtherotationalspeedofanalternating

current(AC)electricmotorbycontrollingthefrequencyoftheelectricalpowersuppliedtothemotor.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

16/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|14

Policiesneededforoptimisingpackagedsystems

Important as these savings are, much larger savings would accrue if all EMDS were properly

optimised.Realisingthisobjectiveislessstraightforwardfromapolicyperspective,butitispossible

tomakeheadwayinthemorecomplexdomainofEMDSbycarefullysegmentingtheapplicationsin

whichmotorsareused,andbytargetingregulatorypoliciesatpackagedmotorsystemsapplications

withlargesavingspotentials(e.g.certainkindsofpumps,fansandcompressors).Itispracticable

to set MEPS and energy labelling requirements for a range of core motordriven systems,

including fans,pumpsand compressors. In some cases, similarMEPS canbeapplied toentire

motordrivensystemapplications(e.g.formunicipalwaterpumping,elevatorsandescalators).

Regulatorymeasuresshouldnotnecessarilybeconfinedtodevicesandcomponentsthatdirectly

consume power;policies could also eventually target the large potential energy savings from

improvedenergyperformanceofmechanicalcomponents(suchasgearsanddrivebelts).Certain

commontechnologies(suchaswormdrivesandVbelts)arefundamentallyinefficientandcould

potentiallyberegulatedoutofthemarketinfavourofmoreefficientoptions.

As some aspects of motorsystem energy use do not lend themselves to simple regulatory

approaches, softer policymeasures can be beneficial. It is especially important to strengthen

marketawareness througheducationalefforts targetingmultipledecisionmaking levels (OEM,

system specifier, plant manager, energymanager and senior manager/executive level). This

would includeuserfriendly technicalassistance throughenhanced technical standards, system

specificationandoperational/energymanagementtoolsandservices.Thereisalsoaneedtobetter

alignfiscalandfinancialincentivesthroughoutthevaluechain,whichcouldbecomplementedby

welltargetedeconomicassistancetoencouragetheuptakeofenergyefficientEMDS.

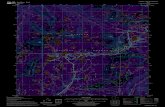

Figure1:Projectedglobalelectricmotorsystemelectricityconsumption

Abbreviation:LLCC=leastlifecyclecost.

Notes:

Referencescenario:whenthecurrentsituationismaintainedwithoutadditionalpolicymeasures.

Policyscenario:whenallcountriesadoptabroadbasedandrigorouspolicypackageonEMDS.

LLCCscenario:whenallEMDSaremovedtowardtheleastlifecyclecostlevel.Source: IEAestimate.

0

2000

4000

6000

8000

10000

12000

14000

16000

2005 2010 2015 2020 2025 2030

Motorsystem

electricityconsumption(TWh)

Policyscenario

LLCCscenarioMotor

sys

tem

electricity

consumption

Reference

scenario

20%

30%

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

17/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|15

Aboveall,itisessentialtoscaleuptheoperationsandresourcescommittedtorealisingthevast

savingspotentialofoptimisedEMDS.Bycomparisonwithothersustainableenergyopportunities,

the energy efficiency of EDMS has been relatively neglected, and nowhere do such systems

currentlybenefit from the scale of support that isoffered to sustainable supplysideoptions.

While governments are starting to become more proactive on this issue, and many have

implemented someusefulpolicymeasures,nonehas yetput inplace the resourcesorpolicy

processeslikelytorealisesubstantialsavings.

Ifabroadbasedandrigorouspolicypackagewereput inplace, it isestimatedthatglobally,by

2030,itwouldsavesome24000TWhinelectricitydemand,avoidsome16GtofCO2emissions,

andgeneratecostsavingsofaboutUSD1.7trillion(Figure1).Thesesavingswouldcomeat less

costthansupplying thisenergy.Annualsavings in2030wouldbe in theorderof2800TWh in

electricitydemand,1790MtofCO2emissionsandUSD190billioninelectricitycosts.

IfitwerepossibletomoveallEMDStowardstheleastlifecyclecostlevelasrapidlyastechnically

possible,itisestimatedthatsome42000TWhofelectricitydemand,29GtofCO2emissionsand

USD2.8trillioninelectricitycostswouldbesavedgloballyby2030.Annualsavingsin2030would

be of the order of 3890TWh in electricity demand, 2490Mtof CO2 emissions and

USD264billioninelectricitycosts.

Comprehensiveintegratedpolicypackage

To help realise the tremendous potential for costeffective energy savings in electric

motordriven systems, governments should consider, as a firstmeasure, adoptingmandatory

MEPSforelectricmotors,inlinewithinternationalbestpractice,subjecttodueprocessandcost

effectivenessanalysis.

These standards shouldapply toasmany typesand sizesofelectricmotor as it is feasible to

address and should not be confined to midsize asynchronous AC motors sold as separatecomponents.Thelevelofthesestandardsshouldbesetatnolowerthantheleastlifecyclecost,

which isgenerallyat IE33orhigherformidsizeasynchronousAC inductionmotors.Even larger

energy savings canbeachievedbyusingVFDs,whichdynamicallymatch theoutputpowerof

motor systems to thepowerdemandedby thedrive train.Furthersavingscanbeachievedby

using efficient transmission and gear systems, and through better sizing andmanagement of

electricmotordrivensystems.

Overallitisestimatedthatitiscosteffectivetosaveabout20%to30%oftotalglobalelectricmotor

demand (i.e.roughly 10%of all globalelectricity consumption) through theuseofmore efficient

electricmotorsanddrives.Achievingsuchsavingswillrequireindividualandconcertedactiononthe

partofallplayers,includingregulators,policymakersandstandardsdevelopmentagencies.

It is proposed that IEA member countries and nonmember economies apply a market

transformation package based on the portfolio of energy performance policies set out in the

followingpackageofpolicyrecommendations:

Regulatorypolicymeasures

1. MEPSshouldbe introduced in IEAmembercountries in linewith internationalbestpractice

for allmajor classes of electricmotors. They should not be set at levels less than IE3 for

asynchronous motors. These requirements should apply to motors sold individually or

integratedintoprepackagedelectricmotordrivensystems,andshouldapplytomotorswith

aswidearangeofoutputpowerasispracticable(100Wto1000kW).

3PremiumefficiencylevelasdefinedwithinIEC6003430andIEC6003431.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

18/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|16

2. Regulatorymeasures,suchasMEPSandenergylabelling,shouldbeintroducedforpackaged

integrated motordriven energy enduses between 100W and 1000kW, including fans,

pumps,circulationpumpsandcompressorsthatareproducedinsufficientlylargevolumesto

havesignificantenergyconsumption.

3. Regulators, policymakers and standardsdevelopment agencies should ensure that energy

performancetestproceduresaredevelopedforallmotortypesthatusesignificantamounts

ofelectricityandarenotcoveredbyexistinginternationallyagreedtestprocedures.

4. Regulators, policy makers and standards development agencies should commission the

development and application of energyperformance test procedures to cover other

essential components of electricmotordriven systems, including transmissions, gears and

system controldevices (e.g.VFDs). In addition,efforts should bemade todevelop energy

performance test procedures and guidelines that apply to whole electric motor system

applications,suchasutilitywaterpumping,lifts(elevators),escalators,conveyors,etc.

5. Regulators should explore the feasibility of developing minimum energy performance

standardsforcertainclassesofgearsandtransmissionstodiscourage(andlaterprohibit)the

useofinefficientsolutionssuchaswormgearsandVbelts.

Nonregulatorypolicymeasures

6. Largescaleawarenessprogrammesshouldbedevelopedandputinplacetoinformindustrial

andcommercialelectricityusersofthesignificantsavingspotentialspossiblethroughtheuse

ofefficientelectricmotordrivensystems.Theseprogrammesshouldtargetthoseresponsible

for procurement of electric motors and motordriven systems, including operations and

maintenance managers, production and plant managers, and company executives and

decisionmakersresponsibleforoverallcompanypolicyonenergy,carbonandcostreduction.

7. Incentiveschemesshouldbedevelopedandappliedtoencourageadoptionanduseofbest

practicemotor sizing,managementand integration, including theappropriateuseofVFDs.

These shouldbe targetedat the systemsproducing thehighestbenefit,namely forpumps,

fansandotherapplicationswithvariablemechanicalloads(wheretorqueincreasesnearlyas

thesquareoftherotationalspeedofthemotor).Inmostcases,costeffectivesavingscanalso

be achievedwhenVFDs are used for conveyors, hoists, escalators and similar applications

(wheretorque ismoreor less independentofthemotorspeed). Incentiveschemesarealso

likelytobebeneficialfortheseapplications.

8. Internationalcapacitybuildingeffortsshouldbesubstantiallyexpandedtocreatepermanent

support structures,ata scale sufficient to supportongoingneeds in thedomainofenergy

efficientelectricmotordrivensystems.

9. Globalmarket

monitoring should be established at defined intervals, to support national

regulationandincentiveprogrammeswithmarkettransformationdata.

Puttingideasintopractice

Realising these savings opportunities by 2030 will require a clear a plan of action and rapid

implementationofaneffectivesetofstructuralandconsensusbuildingendeavours.Itisproposed

that IEA member countries establish a timetable for implementation of the nine policy

recommendations.Toaidthatprocess,theauthorshaveidentifiedtimelinesforcompletionofthe

stepsnecessarytoprogressEMDStowardtheidentifiedenergysavingsgoalsby2030(Table2).

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

19/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|17

Table2:Proposedtimetableforimplementationofrecommendations

RecommendationsPhase 1In 2011

Phase 22012-15

Phase 32016-20

Phase 42021-25

Phase 52026-30

Regulatory policy measures

Implementation of MEPSfor all major classes ofelectric motors.

COMMENCE COMPLETED

Regulatory measures forpackaged integratedmotor-driven energyend-uses.

COMMENCE COMPLETED

Development ofinternational testprocedures for otherelectric motor types.

COMMENCE CONTINUE COMPLETED

Development of

international testprocedures for otherelectric motor systemcomponents.

COMMENCE COMPLETED

Regulatory measures forgears andtransmissions.

COMMENCE COMPLETED

Non-regulatory policy measures

Development of large-scale awarenessprogrammes.

DEVELOP ROLL-OUT ROLL-OUT ROLL-OUT

Development ofincentive schemes.

DEVELOP IMPLEMENT

International capacity-building efforts andcreation of a permanentsupport structure.

COMMENCE COMPLETE ROLL-OUT ROLL-OUT ROLL-OUT

Global marketmonitoring (to supportnational regulation andincentive programmeswith market-transformational data).

COMMENCE REPORT 2015 REPORT 2020REPORT2025

REPORT 2030

To support theunderpinning recommendation regarding theadoptionofmandatoryminimum

energy performance standards for electricmotors, it is proposed that IEAmember countriesadoptapolicypositionasquicklyaspossible,withanIEAreportonitbefore2015.IEAmember

countries can then bepositioned as lead actors in apush for globally coordinated actionon

motors,withsupportingprojectworktoengagewithmajormotormanufacturingcountries(such

asChina,Brazil,Indiaandothers).

Inaddition,itisproposedthattheIEAimmediatelyundertakeacomprehensivestudy,completed

in 2011, to assistmember countries in their efforts to implement thesemeasureswithin the

proposedtimeframes.AsbindingpolicydecisionsaretakenbyIEAmembercountries,thisstudy

shouldevolveintoaregularupdateonimplementationplans.

TheIEASecretariatshouldalsoworkwiththenonmembereconomiesthatproduceandexport

significantvolumesofelectricmotorsandelectricmotordrivencomponentstoensurethatthis

coordinatedplanwillgaintheirsupport.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

20/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|18

1.Introduction

Thisreportexploresthecomplexandchallengingworldofelectricmotordrivensystems(EDMS)

andmakesrecommendationsforfuturepolicysettingstoreduceelectricitydemandforEMDSin

atimelyandcosteffectivemanner.

Electricmotors areused in awide rangeof industrial applications,but also inmany typesof

applications in the commercial, residential, agricultural and transportation sectors. Typically

electricmotorsareacomponent inamotorsystem,responsibleforconvertingelectricalpower

intomechanicalpower.Consumptionofamotorsystemcorrespondstoelectricityconsumption

ofitsmotorsplusasmalladditionalquantitytopowersystemcontrols.

Priortotheanalysispresentedinthisreport,therehavebeenveryfewattemptstoestimatethe

overallelectricityconsumptionofelectricmotorsandnosystematicattempt toproduceglobal

estimates.However, backoftheenvelope calculations have typically estimated thatmotors

useover40%ofallelectricity(in2005,morethan6000TWhatthegloballevel).Infact,electric

motordriven systemsappear tobe the largestsourceofelectricityuse, farexceeding lighting,thenextlargestenduse(about19%ofglobalelectricitydemand).

It issurprisinghow fewconcertedstudieshavebeendirectedatquantifyingtheenergyuseof

EMDS.Thisreportattemptstoprovideasounderbasisfortheseestimates,usingbothtopdown

andbottomupanalysestoincreaseconfidenceinthefindings.Itbuildsuponimportantregional

studies such as the EuropeanUnions Lot 11 studies for the EcodesignDirective (DeAlmeida

etal.,2008a[motors];Falkner,2008a[pumps];Falkner,2008b[circulatorpumps];Radgen,2008

[fans]),USDepartmentofEnergysponsored investigations (DOE,2002),otherNorthAmerican

sources(Elliot,2007;Boteler,2007;NRCan,2009),Japanesestudies(JWG,2007),Chinesestudies

(Zhao,2007)andotherregionaldatasources.

Electricmotorsarefoundintheindustrial,commercial,residential,agriculturalandtransportation

sectors.

In the residential sector, motors are used for compression (in refrigerators and airconditioners), ventilation (to power fans); pumping (to power central heating system

circulation andhot and coldwater pumps); cooking appliances (foodmixers,whisks,oven

fans, extractorhoods); laundry; cleaning; ICT (hard disks and fans) and garden appliances.

Somelesswidespreadresidentialapplications(suchasautomaticgatesandshutters)alsouse

motors.

In the commercial building sector, motors are used for heating, ventilating and airconditioning (HVAC); pumping; ICT (hard drives and fans); escalators; lifts (elevators) and

hoists;laundry;cleaningandcooking.

Intheagriculturalsector,motorsareusedforpumpingandconveyanceactivities.

Intransportation,motorsareusedformotivepowerforelectrictrains,trucks,carsandmotorbikesandrelatedcooling;ventilationandauxiliarydevices;fluidpumping invehiclesshippingand

planes;HVACapplications;servomechanismsinaviationandseveralotherapplications.

Yetitisinindustrythatelectricmotorsdominateandaccountforthelargestamountoftotalelectricityconsumption.Inindustrialapplications,motorsareusedforpumping;fans;airand

liquid compression; conveyance; and other forms ofmechanical handling and processing.

Electricmotordrivensystems (EMDS)areby farthemost important typeofelectric load in

industry.IntheEuropeanUnion,forexample,theyareestimatedtoaccountforabout70%of

allindustrialelectricityconsumption.

Ineachof theapplicationsmentionedabove, theelectricmotor isonlyonepartof thewholeelectromechanical system. Themotor (togetherwith the controller) is theonlypart thatuses

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

21/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|19

electricity, but the amount of electricity required to fulfil its function is determined by the

amountofmechanicalpowerrequiredandthemagnitudeofthelossesthatoccurinthedelivery

ofthatpower.Those lossesoccurnotonlywithinthemotor itselfbutalsoandusuallymore

significantly in themechanical system that distributes power from themotor to the final

mechanicalapplication.

This report examinesmarkets and use of electricmotordriven systems and estimates their

electricityconsumptionbysector,applicationandcountryaswellasataglobal level.Itreviews

the types of EDMS and analyses the different technologies in use and the potential to save

energy through better design, configuration and operation. It presents estimates of potential

energysavingsandreductionofCO2emissionsandexplorescostefficiencyissuesassociatedwith

differentmotorsystem choices. It also examines barriers to the adoption and use ofmore

efficientEMDSand the various standards thathavebeendeveloped tomeasureand improve

motorsystemelectricitydemand.Itreviewsexistingandpendingpolicysettingsformotorsand

motordrivensystemsandmakesrecommendationsforfuturepolicysettings.

The findings of the report are consistentwith and buildupon the findings of earlier regional

studies.Bydrawingattentionto thewidevarietyofmeans to increaseefficiencyofEMDS,the

study attempts to set out practicable pathways to increase energy savings and exploit

opportunitiesmoreeffectivelythanundercurrentpolicysettings.Itproposespolicymeasuresto

stimulateenergyefficiencyimprovementsinmotorsystemcomponents,coremotorsystemsand

dedicated motorsystem applications and future activities to build international capacity to

identifyandaccesssignificantsavingsinEDMS.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

22/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|20

2.ElectricMotorDrivenSystemsandApplications

This chapterdescribes technologiesandapplicationsofelectricmotordriven systems (EMDS),

summarises availablemarket data (including information on sales and stocks ofmotors and

motordrivensystemsasafunctionoftheirefficiency),andexplorestheadoptionofcontrollersthatmatchoutputtoload,suchasvariablespeeddrives(VSDs).

Motorsystemtypesanddefinitions

Anelectricmotorisadevicethatconvertselectricalenergyintomechanicalenergy.Motorscome

inoutputpower ranging froma fewwattsuptomanyhundredsofkilowatts. IntherecentEU

studyundertheDirectiveonEcodesignofEnergyUsingProducts,theproductgroupisdescribed

aselectricmotorsintheoutputpowerrangeof1kWto150kW.However,thestudyconsidered

a lowerboundof0.75kWandanupperboundof200kWtotake intoaccountstandardpower

sizesandthenewproposedInternationalElectrotechnicalCommission(IEC)6003430efficiency

classification standard onmotor efficiency.Almost allmotors in this power range are of lowvoltage.Mediumvoltagemotorsaretypicallyused inveryhighpowerapplicationsof>500kW;

astheyareofnonstandarddesign,theyaresoldinverysmallnumbersandarenotyetincluded

in any targeted energyefficiency policies. Electricmotors are classified according to type of

powersupplyandothercriteria(DeAlmeidaetal.,2008a)(Figure2).

Figure2:Electricmotorcategories

Abbreviations:ACalternatingcurrent;DCdirectcurrent;ECelectronicallycommutated;

PMpermanentmagnet.Source:DeAlmeidaetal.,2008a.

EMDSApplications

Motorsareusedinamyriadofapplications,whicharebroadlycategorisedasfollows:

Industrialapplications:pumps, fans, compressedairdelivery, conveyors,motivepower forothermachinery,etc.

Buildingapplications:pumps, fans,conveyors, lifts,compressors inheating,ventilationandairconditioningsystems,etc.

Appliance

applications: refrigerators, air conditioners, personal computer and laptop fans,harddrives,cookingappliances,ovenfans,extractorfans,gardenappliances,poolpumps,etc.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

23/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|21

Table3:EMDSapplicationsshowingrelationshipsbetweensystemsandservice

Electric motors

Application

Pumps Drinking water Water/refrigerant Sewage Oil

Rotatingmachines

Closedloop

Closed watersupply system

Heating, coolingand chilling

system

Pressure sewagesystem

Hydraulicpumps

Openpipe Water supplysystem Irrigation, coolingtower Sewage system Pipeline

Fans Air Gas

Room air supplyand exhaust,

blowers

Natural gassystems

Compressors Refrigerant Air Gas

Coolingmachines for airconditioning and

commercialfreezers,

refrigerators andfreezers

Compressed-airstorage anddistribution

system, pneumaticsystems

Liquificationsystems

Rotating/mix/stir

Roller, rotors Extruder Textile handlingMixers,stirring

SolidMetal, stone,

plasticsAluminium,

plasticsWeaving, washing,

dryingFood, colour,

plastics

LiquidFood colour,

plastics

Transport People Goods Vehicles

VerticalPassenger

elevatorGoods elevator,cranes, hoists

Inclined Escalator ConveyorCog wheel train,

cable car, ropeway

Horizontal

Conveyor Conveyor

Train, tram, trolley,cars, buses,

electric cars, bikes

and bicycles

Linear motors Open/close Sort Grab and place

Back and forthmovement

Valve Robot

Stepper motor Open/close Position

Angular position Valve Servo

Source:A+BInternational,2009.

Motor

market

data

Following a reviewofdataonmotor sales, efficiency and stocks, this report considersmotor

usage by enduse system applications and examinesmarket penetration of adjustablespeed

drives (ASD) and variablefrequency drives (VFD). Although few sources are available to

determinedistributionofelectricmotorsbyenduseapplication,datafromtheUnitedStatesand

the European Union on differentmotor applications are included. Literature about different

applications is rarely available for other countries, except for some sales data for Japan and

Taiwan.Regionaldatasetsarenoteasilycomparable,astheyhavedifferentscopesofstudyand

applydifferentdefinitions(forexample,definitionsmayvaryregardingwhetheracompressoris

usedforcoolingorcompressedairapplications).

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

24/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|22

Marketvolumesbyapplication

TheshareofmotorsalesbyenduseapplicationintheUnitedStatesappearsquitedifferentfrom

the situation in theEuropeanUnion (Tables4and 5). Figures forUSpump sales includeonly

pumps and vacuumpumpsused in industry, anddonot cover pumps used in commercial or

buildingsectors.Compressordataappliesonlytostationarycompressors.Thetotalisthesumof

thesethreeapplications.Nodataforanyotherapplicationsispresented.

Table4:MotorsystemssalesintheUnitedStates(2003)

Pumps Vacuum pumps Compressors Total

No. of units (thousands) 12 143 200 1 301 13 645

Sales value(USD millions)

2 637 103 1 534 4 275

Note:Numbersmaynotsumtototalduetorounding.

Source:USCensusBureau.

Table5:

MotorsystemssalesintheEuropeanUnion(2005)4

Pumps Circulators Fans Total

No. of units (millions) 1 800 14 000 8 927 24 727

Market share 7% 57% 36% 100%

Sources:Falkner,2008a(pumps);Falkner,2008b(circulatorpumps);Radgen,2008(fans).

In theUnited States,more than 40% of generalpurpose industrialmotors are used to drive

materialprocesses,representingthelargestshareofmotorapplications.Otherlargegroupsare

pumpsandmaterialhandlingapplications;compressors(compressedair,refrigeration)andfans

representonlyminorshares(Table7).

Table6:DistributionofmotorapplicationsintheUSindustrysector(1997)

Pumps FansCompressed

airRefrigeration

Material

handling

Material

processOther All

Share of stock 19.7% 11.2% 5.1% 0.8% 16.8% 42.2% 4.2% 100.0%

Source:DOE,2002.

Table7:StockdataforthreeapplicationsintheEuropeanUnion(2005)

Pumps Fans Circulators Total

No. of units (millions) 17 104 10 131

Share of stock 13% 79% 8% 100%

Sources:Falkner,2008a(pumps);Falkner,2008b(circulatorpumps);Radgen,2008(fans).

In the case of the EuropeanUnion, the figure for circulators includes only large standalone

circulators, and the figure for fans includes only building ventilation (no fans for process

ventilationetc.areincluded).Inthislimitedcontext,fansaccountforthelargestsharealmost

80%oftheinstalledmotorbase(Table7).Significantdifferencesinthescopeofavailablestock

data onmotor applicationsmake it difficult to draw direct comparisons between theUnited

StatesandtheEuropeanUnion.

4 On1January2007,theEuropeanUnionexpandedfrom25to27memberstates.Dataupto2006isforEU25;startingin

2007,dataisforEU27.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

25/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|23

Marketsharebyefficiency

Electricmotorefficiency istheratioofmechanicaloutputpowertoelectrical inputpower.The

weightedaverageefficiencyoftherunningelectricmotorstockdependson:

sizedistributionofthemotorstock;

relativesharesofenergyefficiencyclasses;

mandatory energy performance standards (MEPS) and other policy measures in place(e.g.voluntaryagreements)andtheirperiodofintroduction/reinforcement.

Figure3:EfficiencyclassesforfourpolemotorsofstandardIE3,IE2andIE1classes,andthenewIE4class

Electric motors efficiency classes (4-pole 50 Hz)

70

75

80

85

90

95

100

0.1 1 10 100 1000

Motor output in log scale (kW)

Nominalefficiency(%)

IE3

IE2

IE1

IEC 60034-31:2009

IEC 60034-30:2008

IE3

IE2

IE1

IE4

Source:IEC6003430andIEC6003431,draft2009.

Theefficiencyofmotorsdependsbothon their sizeand theirefficiencyquality,which canbe

characterised by efficiency classes. For small motors, size is the most important factor in

determiningefficiency;forlargemotors,efficiencyclassesarerelativelymoreimportant.In2008,

inIEC6003430,theInternationalElectrotechnicalCommissionintroducedthepreciselydefined

andopenended internationalefficiencyclassificationschemeusing IE1, IE2, IE3and IE45asthe

classificationsystem(Figure3).

In recentyears,market shareofmoreefficientmotorshasbeen increasing inmany regionsand

countries(BorgandBrunner,2009).ThiswasparticularlythecasefortheUnitedStates,Chinaand

other countries, and, to a certain extent, for Europe. Tounderstand thisdiffusion pattern, it is

usefultorelatedifferentefficiencyclassificationsystemstoeachother,andtorelatediffusionto

MEPS andother policymeasures. Four standardised efficiency classes are currently recognised,

althoughdefinitionsandclassificationschemesvaryslightlyfromcountrytocountry(Table8).

5SuperpremiumefficiencylevelasdefinedwithinIEC6003430andIEC6003431.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

26/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|24

Table8:Motorefficiencyclassesindifferentcountriesandthecorrespondinginternational standard

Motorefficiencyclass

InternationalUnitedStates

EuropeanUnion(old system1998

1)

EuropeanUnion(new system2009)

China Australia

Premium IE3NEMA

Premium IE3

High IE2 EPAct Eff1 IE2Grade 1 (underconsideration)

AU2006MEPS

Standard IE1 Eff2 IE1 Grade 2AU2002

MEPS

Belowstandard

IE0 (used onlyin this paper)

Eff3 Grade 3 (current

minimum)

Abbreviations:EPActUSEnergyPolicyAct,1992;MEPSminimumenergyperformancestandard;

NEMAUSNationalElectricalManufacturersAssociation.

Source:A+BInternational,2009.

Note:1.With thebackingof theEuropeanCommission,manufacturers representing80%of theEuropeanproductionof standard

motors,agreedtoestablishthreeefficiencybandsorclassesdesignatedEFF1,EFF2,andEFF3,withEFF1beingthehighestband.

Whenanewandhighermotorefficiencyclass is introduced, itdiffusesslowly intothenational

market.Therateofdiffusiondependsonnationalmotorproducers,additionalprice,electricity

cost,financialincentives,MEPS,etc.

Table9:Timelineforelectricmotorefficiencyclasses,testingstandardsandminimumenergyperformance

standards

Efficiency levels Efficiency classes Testing standard Performance standard

IEC 60034-30 IEC 60034-2-1 Mandatory MEPS

Global definition of motorefficiency classes, IEC, 2008

Including stray load losses 2007 Policy goal

Premium efficiency* IE3Low uncertainty United States 2001

Europe 2011

High efficiency IE2

United States

Canada

Mexico

Australia

New Zealand

Korea

Brazil

China 2011

Switzerland 2011

Europe 2011 with VSD

Standard efficiency IE1

Medium uncertainty China

Brazil

Costa Rica

Israel

Taiwan

Switzerland 2010

Below standard

Source:A+BInternational,2009.

The United States and Canada are international leaders in terms of setting motor energy

efficiency standards, as they introduced regulations formotors in the late 1990s.As early as

2002,ChinadefinedMEPSforelectricmotors.TheEuropeanUnionpassedMEPS legislationforelectricmotors in2009asan implementingmeasureundertheEcodesignDirective;thesewill

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

27/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|25

replacethepreviousindustrialvoluntaryagreement.Australia,Korea,Brazil,Mexico,Taiwanand

some other countries with large electricity consumption frommotors have already adopted

MEPS,ashave some smallereconomies suchasCostaRica, IsraelandNew Zealand (Table9).

However, some largemotorusing economies, such as India, Japan and Russia, have not yet

adoptedMEPS(suchmeasuresareunderstoodtobeunderconsideration).

IntheUnitedStates,marketpenetrationofenergyefficientmotorshasbeenincreasingsincethe

late 1990s particularly since 1998 when MEPS were enforced. In 2001, EPAct motors

(equivalent to IE2) reached amarket share of about twothirds; this figure has since steadily

declined, as the US National Electrical Manufacturers Association (NEMA) Premium motors

startedgainingmarketshare(Figure4).

Figure4:MarketshareofefficiencyclassesintheUnitedStates(200106)

Source:Boteler,2007.

In Canada, the energy efficiency of motors is the responsibility of the ministry of Natural

Resources Canada (NRCan). In 1994, the Energy Efficiency Actwas implemented and in 1997

Canadas EnergyEfficiencyRegulations forGeneral Purpose IndustrialMotors came into effect

(Figure5).In1999,explosionproofandintegralgearmotors(whicharenotcoveredintheUnited

States)were also included. Formotors in the range of 0.75 kW to 150kW (1hp to 200hp),

regulationinCanadacorrespondsinprincipletotheMEPSofEPActoftheUnitedStates.However,

Canadaalsohassomespecificregulations,suchasallowingtheuseof75%loadtopassMEPS.

IntheUnitedStates,marketintroductionofthemostefficientclassIE3(NEMAPremium)started

in2002andmarketsharehasgrownsteadily(Table10).Itwasintroducedasavoluntaryproduct

but has been supported since 2006 by a federal procurement decision (the Federal Energy

ManagementProgram[FEMP]).

Market penetration of different efficiency classes varies considerably between countries. The

shareofthemostefficientclass(IE3)hasreached20%intheUnitedStates,butitisvirtuallyzero

intheEuropeanUnion. IntheUnitedStates, theshareofefficiencyclassesgenerally increases

withmotorsize(Table11).Theshareofthemostefficientclass(IE3)reached75%ofsalesforthe

largestmotorclass;itwasonlyabout10%forsmallermotors.Thediffusionofmotorswithhigher

efficiencystartsearlierforlargermotorsthanforsmallerones,sincemoreengineeringtimeand

money isusually spent in the search for thebestmatchingmotorwhena largemotorhas to

berenewed.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

28/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|26

Figure5:MotorefficienciesinCanadabeforeandafterintroductionin1997ofEnergyEfficiencyRegulations

forGeneralPurposeIndustrialMotors

Table10:

ShareofmotorefficiencyclassIE3salesintheUnitedStates(200106)andCanada(2007)

2001 2002 2003 2004 2005 2006 2007

United States 10% 13% 20% 21% 24% 27%

Canada 39%

Sources:Boteler,2007;NRCan,2009.

InEurope,electricmotorsbetween1.1kWand 90kWare included in a voluntaryagreement

between the European Committee of Manufacturers of Electrical Machines and Power

Electronics (CEMEP)and the EuropeanUnion. Since thisagreementwas initiated in1999, the

marketshareoftheclassEff3hasbeenfallingduetoincreasingmarketpenetrationofthemore

efficientclassEff2(IE1)(Figure6).TheevenmoreefficientclassEff1(IE2)hasalsobeengaining

marketshare,albeitatamuchslowerrate.

Table11:ShareofefficiencyclassIE3inelectricmotorsalesbysize,UnitedStates(2003)

Motor size (kW) Horsepower Sales (thousands) Market share of IE3 (%)

0.75 - 3.75 1 - 5 932 9.8

4.5 - 15.0 6 - 20 410 27.6

15.0 - 37.5 21 - 50 116 48.1

37.5 - 75.0 51 - 100 41 55.1

75 - 150 101 - 200 22 69.2

150 - 375 201 - 500 11 75.0

Total 1 532 20.0

Source:USCensusBureauascitedbyElliott,2007.

InAustralia sinceOctober 2001,manufactured or imported threephase electricmotors from

0.73kW to

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

29/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|27

Figure6:MarketshareofefficiencyclassesinEuropeundertheCEMEPvoluntaryagreement

Source:CEMEP,2008.

BrazillauncheditsfirstregulationoftheEnergyEfficientActforelectricmotorsin2002.Thisact

establishedtwosetsofMEPS,forstandard (mandatory)andhighefficiency (voluntary)motors.

Anupdated regulation from theendof2005 (Edict 553/2005), established theprevioushigh

efficiencyMEPSasmandatoryforallmotors intheBrazilianmarket.ThesenewBrazilianMEPS

arecompatiblewith those implemented inothercountries.Brazilianmotormanufacturershad

already set a highefficiency line in 2006, accounting for about 10% of total production.

Nevertheless,itisexpectedthattheexpansionofthisshareto100%wouldhavealargeimpact

onmanufacturersandtheirpresuppliers,mainlyfortechnicalreasons(Garciaetal.,2007).

South Korean data on themarket share of highly efficientmotorswere reported byHuseok

(2007).Aftercrosscheckingwithrelevantexperts,ithasbeendeterminedthatthetermhighly

efficientwasusedtorefertomotorsattheIE2efficiencylevel.

MarketpenetrationofVFDtechnology

Motorsaresometimessoldtogetheror latermatchedwithavariablefrequencydrive (VFD) to

enablegreaterefficiencywhenoperatingatpartialloads.ThefractionofmotorssoldwithaVFD

isincreasing,but isnotclearlyreportedbecausemotorsandVFDsareoftenmanufactured,and

mostlysold,bydifferentmanufacturers,andare integratedafterpurchaseat theplaceofuse.

DataonVFDuseisverysparse.

AmarketoverviewofVFDuseinEU15in1998estimatedthat1.3millionVFDsweresold,witha

market valueofEUR1.05billion (DeAlmeida etal.,2000), TheVFDsweremainly0.75kW to

4kWinoutputsize.MorerecentindustrybasedestimatesinGermanyshowthat30%ofelectric

motorsarenow sold togetherwithaVFD. Smallpumpsand fansarealso increasingly sold in

integratedpackagesthatincludeaVFD.

EuropeandJapanarethemajorcentresofmotorproductionintheOECD.Japanproducesover

15millionelectricmotorsperyearofwhichabout8millionareintheintegralmotorpowerrange

(the rest are very smallmotors). The energy efficiency of the Japanese newmotormarket is

slightly lowerthan intheEuropeanUnion,andsignificantly lowerthan intheUnitedStatesand

Canada.However,Japanisthegloballeaderinproductionanduseofinverters(VSDs/VFDs),andthusmay well be using electromotive power more efficiently on average than other OECD

Eff3

Eff2 = IE1

Eff1 = IE2

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

30/132

Energyefficiencypolicyopportunitiesforelectricmotordrivensystems OECD/IEA2011

Page|28

economies.Salesof inverters inJapanbegan inthe1980sandbythemid1990saccounted for

about 75% of the sales volume of electricmotors, which implies that a high proportion of

applicationswereusing inverters.Pricesof invertersdroppedby60%from1990to2002.Japan

hasbeenusingtax incentives toencourage theuptakeof inverterssince the late1980s; ithas

beenestimatedthatthesemayhaveledtopowersavingsof>1GW,i.e.theoutputofanuclear

powerplant(JWG,2007).

InnonOECDeconomies,VSD/VFD (inverter)use is thought tobequite lowdue to thehigher

initialcostofinverterbasedtechnologies.

-

7/26/2019 EE Policy Opportunities for EM-Driven Systems Paul_Waide

31/132

OECD/IEA2011 Energyefficiencypolicyopportunitiesforelectricmotordrivensystems

Page|29

3.GlobalElectricityConsumptionandCO2Emissions

ofElectricMotorDrivenSystems

Theglobalelectricityconsumptionbyelectricmotordrivensystems (EMDS)hasnotpreviouslybeenmeasuredorestimated inaconsistentway,and few reliabledataexistonwhich tobase

suchestimates.Theauthorsusedalternatetopdownandbottomupmethodologicalapproaches

to develop estimates of global electricity consumption and CO2 emissions from EMDS. These

analysesdrawondispersedand inconsistentdataonstockandsalesofelectricmotors,electric

motor power and electricity demand, and attempt to organise the available data within a

consistent analytical framework.A comparison of the estimates of energy and CO2 emissions

produced by these two methodologies determines the degree of agreement between the