EcoBlendTM - Primary Aggregates Suppliers · This brochure describes EcoBlend™ Type 1 sub-base, a...

Transcript of EcoBlendTM - Primary Aggregates Suppliers · This brochure describes EcoBlend™ Type 1 sub-base, a...

EcoBlendTM

Type 1 Sub-base

SHW 803 November 2009

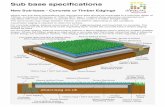

This brochure describes EcoBlend™Type 1 sub-base, amixture of recycled

and primaryaggregates, intendedfor use as a sub-base

under flexible or rigid pavements and footpaths.

EcoBlendTM Type 1 Sub-base

Technical DescriptionEcoBlend™ Type 1 is a mixture oftwo products, both compliant tospecification prior to blending. Theratio of blend is dependent on theneed to produce a product whichperforms to the requirements ofour road building and utilitycustomers. The recycled aggregateused in the mix is produced inaccordance with the QualityProtocol published by WRAP.

RequirementEcoBlend™ is tested to thespecification for Highways Works,Volume 1 Series 800 Clause 803Type 1 Unbound Mixtures. Testresults are available on request.

Benefits• Can reduce material costwhen compared with 100%primary aggregate.

• Offers a sustainable productwhich uses recycled material.

• Fully compliant tospecification.

• Robust product whichperforms well in a range ofapplications including trenchworkings and sports pitches.

• Effective use of waste.

DesignEcoBlend™ should beincorporated in a constructiondesign in the same way asprimary aggregate. Arecommended specification is…..the Type 1 sub-base shouldcomply with SHW Type 1 Clause803 (Nov 2009), which mayinclude EcoBlend™ Type 1produced in accordance with theQuality Protocol published byWRAP and available from DayAggregates (Tel: 0845 0654 655).

Grading forEcoBlend™

Type 1 Sub-base

Sieve size % Passing Each Sieve

63mm 100%

31.5mm 96%

16mm 74%

8mm 41%

4mm 26%

2mm 17%

1mm 12%

0.063mm 3%

SiteworkThe use of EcoBlend™ Type 1does not present any hazards tohuman health over and abovethose of more traditionalproducts (COSHH assessmentsare available on request).

It is important that any ‘Type 1’product including EcoBlend™should be laid with a suitablemoisture content andcompacted in accordance withthe Specification for HighwaysWorks.

Delivery to site can be loose orin bags.

SustainabilityThe use of EcoBlend™ Type 1rather than primary (quarried)aggregate will help designersand contractors address issues ofsustainability and resourcemanagement.

• The raw material forEcoBlend™ contains recycledconstruction and demolitionwaste. This reduces theenvironmental impact of theraw materials used on aproject.

• Proximity is applied to thelocal sourcing of the rawmaterials recycled content.

• The material is supplied as aproduct, not a waste.

Current Users ofEcoBlend™ Products• ClancyDocwra

• Smith Construction

Other ProductsThe other products which are

available in the EcoBlend™

range are:

• Sharp Washed Sand

• 0-20mm ballast

Case studies Please call or downloadfrom our website details ofrecent projects whereEcoBlend™ has been usedin the construction offootpaths, car parks, hardlandscaping or widening ofcarriageways.

www.daygroup.co.uk0845 0654 655

Transport Avenue, Brentford, Middlesex TW8 9HFTelephone: 020 8380 9600 Facsimile: 020 8380 9700

[email protected] www.daygroup.co.uk

Day Group supplies natural and recycled aggregatesto the construction and civil engineering industry

Issue 3 March 2012