Eaton - Internormen Wind Power Solutions

-

Upload

eaton-filtration -

Category

Documents

-

view

55 -

download

0

description

Transcript of Eaton - Internormen Wind Power Solutions

Lubrication Systems, Filter Systems, and Accessories for Wind Power Gears

Wind Power SolutionsInternormen Product Line

The Importance of Cleanliness• Providesmaximumefficientproductivity

• Improvescontrolofsparepartsthroughpreventivemaintenanceandmonitoring

• Reducesequipmentdowntimethroughscheduledinspections

• Minimizessafetyhazardsandpreventscontamination-relatedfailure

• Increasesthelifeexpectancyofsystemcomponents,whichbothincreasesoperatingprofitabilityanddecreasesmaintenancecosts

• Reducesrepaircostsandsystemdowntime

Occurrence of ContaminationTherearethreeprincipalmeanswherecontaminationcanoccurinatypicalhydraulicsystem:

• Incorporatedduringsystemassembly

• Generatedduringsystemoperation

• Ingestedbythesystemduringoperation

Hydraulic Filtration Product Families:

• Hydraulic & Lubrication Systems

• Hydraulic & Lubrication Filters

• Condition Monitoring

• Hydraulic Filter Accessories

Eaton Filtration Services • State-of-the-arttestinglabfacilities

• Equipmentrentals

• Fieldservice—inspections,fieldtrials,start-up,repair,replacement,andmaintenance

• Extensivenetworkofsalesandservicerepresentatives

• Worldwidetechnicalsupport

• Productspecialistsdedicatedtoprovidingapplicationengineering

Eaton combines sales, engineering, manufacturing, customer service, and technical sales support into one focused business objective: Provide customers with optimum filtration solutions.

Eaton’s Filtration business is a leader in manufacturing filtration products and solutions that include measurement, diagnostic and analysis technology.

Following a path of continuous improvement, Eaton has maintained quality as a fundamental corporate strategy and a hallmark of all products and services. Eaton’s Internormen Product Line currently includes more than 4,000 hydraulic filter elements and corresponding filter housings.

Hydraulic System CleanlinessCleanlinessisthemeasureofsolidandliquidcontaminationfoundinhydraulicsystems.Contaminationisdefinedasanysubstancenotpartofahydraulicsystem’sworkingfluid.

Eaton Sustainability CommitmentEaton is unwavering in our commitment to being sustainable by design—in the way we operate, through the design of our products, and through the energy and climate saving benefits our products deliver. Eaton issues a Sustainability Report as part of its Annual Report, available on www.eaton.com.

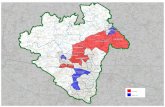

Lubrication System Diagram

Windpowerisnotonlythefastestgrowingenergyproductionplatformintheworld,itisalsooneofthecleanestrenewablepowersourcesonEarth.Asturbinesaregettinglargerandoffshoresystemsbecomemorecommon,thepossibilitytobuildwindpowerplantsalmostanywheremakestheirgrowthinevitable.

Effectiveandconsistentlubricationofcomponentscansometimesbeachallengeinwindturbines.Contaminants,likesolidparticlesormoisturecanenterthegearboxduringmanufacturingandassembly,orintheinitialrun-inprocess,orduringroutinemaintenance.Contaminantsalsocanbeingestedthroughsealsandbreathers,orinternallygeneratedduringregularoperations.

Properoilmaintenance,monitoring,andfiltrationareessentialpartsofpreventive,structuredmaintenanceprograms.

Expertsrecommendequippingwindpowersystemswith:

• Additionalfiltrationsystems

• Metalparticlemonitoringsystems

• Solidcontaminationmonitoringsystems

• Water-in-oilmonitoringsystems

• Waterremovalsystems

• Highqualitydesiccantbreathers

• Heatingsystemsforcoldenvironments

• Coolingsystems

Twinfil Filter Systems

Legendp1: Pressure filter ONp2: Pressure filter OFFp4: Pressure hose ONp5: Bypass ONp6: Pressure cooler ONp7: Pressure cooler OFFp8: Pressure flow junctionTB: Temperature casingT1: Temperature filter ONT6: Temperature cooler ONT7: Temperature cooler OFFVM: Flow measuring deviceK: CoolerQ: Oil flow pumpQ1: Oil main flow filterQ2: Oil parallel flow filterQ3: Oil flow to the gearQ5: Deaeration flowQK: Oil flow coolerQB: Oil flow bypassE1: Permanent deaerationVD1: Valve with filter element 51 psi (3.5 bar)VD2: Valve to cooler 7.3 psi (0.5 bar)VD3: Valve to bypass 87 to 174 psi (6 to 12 bar)

It is particularly important that wind turbine lubricants provide appropriate protection of gearboxes against corrosion, wear and tear. Most lubrication and hydraulic systems failures are caused by oil contamination. That is why proper oil maintenance, monitoring, and filtration are an essential part of preventive, structured maintenance programs.

Lubrication Systems, Filter Systems, and Accessories for Wind Power Gears

MPS Metal Particle Sensor

T7 °F (°C)

59 (15) —

50 (10) —

41 (5) —

32 (0) —

23 (-5) —

14 (-10) —

5(-15) —

-4 (-20) —2 10

Trial Start 1VD3 174 psi (12 bar)Δ pk min = 55 psi (3.8 bar)OK > 4 gal/min (15 l/min)

↑

Trial Start 2VD3 87 psi (6 bar)Δ pk min = 55 psi (3.8 bar)OK > 4 gal/min (15 l/min)

[min]

Filter, Valve, and Cooling System Function from Cold Start to Normal Operating Temperature

Performance TestsEaton’sInternormenproductspecialistscoordinatedwithcustomersandotherpartnerstotesttheTWFsystem’sfunctionality.Theysimulatedcoldstartconditions(downto-22°F(-30°C)operatingand-40°F(-40°C)survivaltemperatures)andusedspecialgearoils.

Theyfoundthatallsystemcomponents—includingthepump,filter,valves,andtubesystem—workedproperlyfromcoldstarttothe158°F(70°C)maximumoperatingtemperaturewithoutanynegativeeffectontheoverallgear-oilsupply.

TwinfilFilterSystemsFeatures

• Speciallydesignedgearlubricationsystems

• Reliablysuppliesallgearlubricationpointsasitfiltersanddeaeratesthesystem

• Lownoiseemission

• Indicatesoiloperatingcondition

• Prolongslubricantservicelife

• Simpletoservice

• Operatesincoldweatherconditionswithanadditionalpump-assistedheatingsystem

Available OptionsCondition Monitoring Systems

• Metalparticlesensors(MPS)

• Watersensors(WSPS)

• Multifunctionoilconditionsensors(IVS01)

Clogging Indicators

• Electric,electronic,orvisualpressuredifferentialindicatorstomonitorfilteroperatingconditions.Theymaybeconnectedtothefilterwithoutanytubes.

Water Removal Filter Elements

• Useforparticleretentionandabsorptionoffreeandemulsifiedwaterfromoil

• Reduceoilaginganddeadditivationoffluids

Twinfil Filter System

Start Trial ResultsTestsundersimulatedcoldstartconditions—downto-22°F(-30°C)operatingand-40°F(-40°C)survivaltemperaturesandwithaspecialgearoil—yieldedthefollowingresults:

• Oilflowthroughtheair-oilcoolercouldbeattainedaftertwominutes

• Theadjustablepressuredifferentialvalve(VD3)appearedtoinfluencehowlongittooktoseeatemperatureincrease(T7)atthecooleroutlet.Basedontheoilflow(QK20%ofthetotalflowQ),andatpressuresfrom87to174psi(6to12bar),thetimesrangedfrom10to2minutes

• Allsystemcomponentsworkedproperlyfromcoldstartuptomaximumtemperature.Whenevermeasured,oilviscositieswere<4635SUS(1000mm²/s),andtheoilflowwas100%filteredthroughthemainelement(filterfineness10µm,fiberglassfleece)

TWF 1001 Technical Data Operating pressure: 232 psi (16 bar) maximum

Flow rate: 31.7 gal/min (120 l/min)

Operating temperature: -22 °F (-30 °C) minimum

Survival temperature: -40 °F (-40 °C) minimum

E-motor - rotary current: 400/690 V, 50 Hz/60 Hz

E-motor - protection class: IP 65

TWF 1001 with MPS

TWF 1950

TWF 4000

TWF 6000

TWF 1950 Technical Data Operating pressure: 232 psi (16 bar) maximum

Flow rate: 52.8 gal/min (200 l/min)

Operating temperature: -22 °F (-30 °C) minimum

Survival temperature: -40 °F (-40 °C) minimum

E-motor - rotary current: 400/690 V, 50 Hz/60 Hz

E-motor - protection class: IP 65

TWF 4000 Technical Data Operating pressure: 232 psi (16 bar) maximum

Flow rate: 66 gal/min (250 l/min)

Operating temperature: -22 °F (-30 °C) minimum

Survival temperature: -40 °F (-40 °C) minimum

E-motor - rotary current: 400/690 V, 50 Hz/60 Hz

E-motor - protection classes: IP 65

TWF 6000 Technical Data Operating pressure: 232 psi (16 bar) maximum

Flow rate: 105.7 gal/min (400 l/min)

Operating temperature: -22 °F (-30 °C) minimum

Survival temperature: -40 °F (-40 °C) minimum

E-motor - rotary current: 400/690 V, 50 Hz/60 Hz

E-motor - protection classes: IP 65

Twinfil Filter Systems

Technical Data: Dimensions: 20.5 x 14 x 28.7 in (520 x 355 x 730 mm)

Weight: 26.5 lb (12 kg)

Barrel capacity: 16.85 gal (60 l)

Flow rates: 1.3 to 4 gal/min (5 to 15 l/min)

Viscosity: 18,540 SUS (4000 mm²/s)

Suction/pressure hose: 59 in (1.5 m)

Connection: G 1/2“ threaded

Power supply: 230 V

WGR 60 - Maintenance Unit• Inexpensivemaintenanceunitmeantforquick,cleanchangeoffilterelementwithoutoilloss

• Oilispumpedoutofthefilterhousingintoanappropriatereservoirandpumpedbackintothesystemafterthefilterhasbeenchanged

• Especiallysuitableforapplicationinwindpowerplants

TWF 1950 with WGR 60

Technical Data: Voltage supply: 230 V, 50 Hz / 110 V, 60 Hz

Pressure operating range: -2.9 to 2.9 psi (-0.4 to 0.5 bar)

Viscosity: 92.7 to 4635 SUS (20 to 1000 mm2/s)

Max. oil temperature: 32 to 158 °F (0 to 70 °C)

Ambient temperature: 32 to 122 °F (0 to 50 °C)

Protection class: IP 54

Output signals: Two alarm signals; limit values programmable RS232 / RS485 output, USB, Ethernet Alarm through e-mail via Internet Measurement results displayed on monitor Printing function with optional thermal printer

Operation: On touch-screen

Measuring Parameters: Particle counting: Contamination classes - acc. to ISO 4406:99

Water saturation: 0 to 100%

Temperature: 32 to 158 °F (0 to 70 °C)

Dynamic viscosity: 9 to 900 mPas

Relative dielectric constant: 1 to 10

Weight: 72.8 lbs (33 kg) approximately

CSM 02 - Contamination Sensor Monitor

Applications

In-lineparticlecountinginthewindturbinegearboxoilcanquicklypresentthefollowingchallenges:

• Highviscosityoilsandvariationsinoutdoortemperaturescansignificantlyaffectmeasurementsystems

• Foamedoilsmakeparticlecountinginwindpowerplantsadditionallydifficult

Features

• Useasastationaryormobileoilconditionmonitoringsystem

• Operatesoff-line,independentofthesystembeingmeasured

• Analyzestheamountandsizeofsolidcontaminationinhydraulicandlubricationfluids

• Easilyupgradedwithadditionalsensormodulestomeasureotherimportantfluidparameters

• Measuresfoamedoilsaccurately

• Effectiveforearlydetectionofchangesinfluidcleanlinessandoilcompositionaswellascontaminationincreases

• Usefulforqualitycontrol,maintenance,andduringinitialoperations

• SoftwareupdatablethroughSDcard

• RemotecontrolviaInternetorIntranet

• Graphicdisplayofstoredmeasurements

• Storagecapacity8x100measurementresults

• EnglishandGermanlanguagesavailable

CSM 02

US 22TheUS22stationaryfilterunitsareintendedforoilmaintenanceinhydraulicsystems,applicationsinclude:

• Secondaryflowfiltrationinadditiontoanexistingoperatingfilter

• Secondaryflowfiltrationwithoutanoperatingfilter

• Filtrationwhenfillingtheoilreservoir

TheUS22unitshouldnotbeusedtopumpcontaminatedhydraulicfluidsandisthereforedesignedwithoutaswitch-overfittingtoby-passthefilter.Featureslikehighreliabilityandsmalldimensionsareguaranteedbyitscompactstructuraldesignonabaseplatewithoutapipe.ThedeviceisequippedwithagearpumpdrivenbyanE-motor.Easytoreplacefilterelementsareavailableindifferentfineness.

Technical Data: Filter fineness: 4.5 μm(c), 7 μm(c), or 10 μm(c)

Weight: 77.1 lbs (35 kg) (approx.)

Operating medium: Hydraulic oil based on mineral oil from 46.4 SUS (10 mm²/s). Other media on request.

Metal Particle SensorsAdditionally,theUS22canbeequippedwithanMPS-MetalParticleSensorhavingthefollowingfeatures:

• Detectionofmetalparticles

• Designedasaninexpensivein-linemonitoringsolutionforstationaryandpermanentoperations

• Suitableforinstallationinneworexistingsystems

• Operatingwithinductivemeasuringconceptforhydraulicandlubricatingfluids

• Varioustypes:MPS01.2,MPS02.1,MPS03.1

US 10TheUS10stationaryfilterunitsaredesignedforservicingoilatgearswithlubricantsofhighviscosity.Theunitsperformoff-linefiltration,andareconstructedonabaseplatewithoutatube,whichguaranteessmalldimensionsandhighreliability.Thestationaryfilterunitcanoperateunattended.Theelectricsecurityandswitchelementsofthefilterunitperformthefollowingfunctions:

•MotorprotectiveswitchturnsE-motoroffwhenoverloaded

•Thermostatswitchesonthepumpdependingontherespectivegeartemperature

•Pressureswitch(cloggingindicationE5.5)actsasprotectionagainstpermanentoverload(>72.5psi,5bar)

•TimelagrelaybridgesthecoldstartofE5.5

Theconduction,deaeration,anddiversionconnectionsaremarkedcorrespondingtotheirfunction.Diversionisnecessaryforthe

purificationofthefilterunitandappropriatereplacementofthefilterelementaswellasforchangingthefluidtobefiltered.

Technical Data:

Flow rate: 3 gpm (11.3 l/min) at 700 rpm

E-motor: 0.37 KW, about 700 rpm

Power supply: 230/400 V, 50 Hz

Max. Pressure: 116 psi (8 bar)

Filter fineness: 5 μm(c), 7 μm(c), 10 μm(c), 15 μm(c), or 20 μm(c)

Weight: 77.1 lbs (35 kg) (approx.)

Medium : Hydraulic oil based on mineral oil, 46.4 to 13,905 SUS (10 to 3000 mm²/s)

US 10 with Control Unit

US 10

RetrofitFilterSystems

US 22 with Metal Particle Sensor

Wind Energy in Cold Climates Takeadvantageofwindpowereveninthecoldestregionsoftheworld.Coldclimateandsevereoutdoorconditionshaveparticularlyundesirableeffectsonwindturbines,primarilyaffectingplasticandsteelcomponentsandlubricants.

Atlowtemperatures,theviscosityoflubricantsandhydraulicoilsincreases,causingtheoiltostiffen,leavingitunabletosufficientlylubricatethegearboxandbearings.

Iftheoilistoothicktofreelycirculate,damagetothegearswilloccuralmostimmediately.Anincreaseininternalfrictionwillreducethepowertransmissioncapacityofthegearbox.Itisalsoimportanttoaccountforservicingandmonitoringthesystemunderdifficultcoldweatherconditions.Increasedmaintenancecostsandextendedturbinedowntimeneedtobeconsidered.

Tosignificantlyimprovethedependabilityandextendtheservicelifeofwindturbinesundercold,unpredictablewinterconditions,EatonoffersavarietyofInternormenproductsolutions.

TwinfilFilterSystems with Additional Pump- assisted Heating System

Technical Data Operating pressure: 217.5 psi (15 bar) maximum

Operating temperature: -22 °F (-30 °C) minimum

Survival temperature: -40 °F (-40 °C) minimum

Pump heating: 4 x 100 W, 230 V

E-motor: Customer-specific

Heating elements

HSH – Oil Pre-heater for Suction Hoses

Features

• SuctionhoseheaterplacedinsidetheEatonInternormenDN60suctionhose

• Additional59”(1.5m)heaterconnectionlineandinlet

• Excellentcoldstartperformanceofthegearpump

Benefits

• Highpower(350W/m)ensuresexceptionallyquickheat-uptime:from-22to40°F(-30to+5°C)in20minutes

• Overheatcontrolpreventsoilcombustion

• Outersheath,madeofstainlesssteelwavetube,isleak-proofandcompatiblewithdifferentmedia

• Temperaturecontrolatthesurfaceofthestainlesssteelwavetube(uptoamaximumof140°F(60°C))

• Hosetoheaterissealedwithoutcompressionglands

• Varioushoselengthsavailable(standard:59”(1.5m))

Technical Data Tube length: 59” (1.5 m) (other lengths available on request)

Connections: 2 x SAE 2“ (other connections available on request)

Nominal diameter: DN 60

Power supply: 230 V~ (other supply voltages available on request)

Power: 350 W/m

Operating temperature: -22 °F (-30 °C) minimum

Survival temperature: -40 °F (-40 °C) minimum

HS – Heating Systems

HS 10 Technical Data Operating pressure: 116 or 174 psi (8 or 12 bar) maximum

Operating fluid: Poly-alpha-olefin or mineral oil-based gear oils

Starting viscosity: 741,600 SUS (160,000 mm²/s) maximum

Operating temperature: -22 °F (-30 °C) minimum, 86 °F (30 °C) maximum

Survival temperature: -40 °F (-40 °C) minimum, 176 °F (80 °C) maximum

Operatingvoltage: 400/460VΔAC(othervoltagesuponrequest)

Frequency: 50/60 Hz

Hydraulic thermal output: 1000 W (maximum)

Electric thermal output: H1: 2 x 100 W, 230 V AC H2: 2 x 160 W, 230 V AC H3: 3 x 2500 W, 400 V AC

Geared pump: 80 cm³/rev, 13.74 gal/min (52 l/min) at 750 rpm, 16.38 gal/min (62 l/min) at 500 rpm

Electric motor: 3.0 kW

HS 16 Technical Data Operating pressure: 116 or 174 psi (8 or 12 bar) (maximum)

Operating fluid: Poly-alpha-olefin or mineral oil-based gear oils

Starting viscosity: 741,600 SUS (160,000 mm²/s) maximum

Operating temperature: -22 °F (-30 °C) minimum, 86 °F (30 °C) maximum

Survival temperature: -40 °F (-40 °C) minimum, 176 °F (80 °C) maximum

Operatingvoltage: 400/460VΔAC(othervoltagesuponrequest)

Frequency: 50/60 Hz

Hydraulic thermal output: 1500 W (maximum)

Electric thermal output: H1: 2 x 100 W, 400 V AC H2: 2 x 250 W, 400 V AC H3: 6 x 2500 W, 400 V AC

Geared pump: 80 cm³/rev, 13.74 gal/min (52 l/min) at 750 rpm, 16.38 gal/min (62 l/min) at 500 rpm

Electric motor: 3.0 kW

Features• Providesquickadditionalgearoilheatingwhenextremelylowtemperatureconditionspushoilviscosityupto741,6000SUS(160,000cSt(mm²/s))

• Twotypesavailable-HS10andHS16-eachoperatesat116or174psi(8or12bars)maximumpressure

• Fittedforsurvivaltemperaturesfrom-40to176°F(-40to80°C)

• Systemsaremaintenance-freeandequippedwithamonitoringdevicetopreventoiloverheating H3

H2H1

Wind Power Coolers

High performance oil coolersHighorincreasedoiltemperaturesleadtooildeterioration,whichleadstodecreasedefficiency,wearandtear,andreducedservicelifeofequipmentandcomponents.

Topreventhighoperatingandmaintenancecostsandprolongthelifeexpectancyofasystem,oilhastobecooledandthusenabledtoperformtrouble-freelubricating,sealing,corrosionprotection,orcooling.

Designed and dimensioned to suit your needs and requirementsEatonoffersawiderangeofhigh-qualitystandardandcustomdesignedoilcoolerswithexcellentcoolingcapacitiesdesignedtowithstandhardestoperatingconditions.

Efficientcoolingbeginswithoptimaldimensioningandextensiveproducttesting.Eatonconsidersvariousfactors,suchastheapplicationarea,theenvironment,orthecoolingmedium,andcanoffertherightcoolersizeortypetosuityourspecificrequirements.

Advantages of Eaton’s Internormen Coolers:•Compactdesign

•Highcoolingperformance

•Lownoiselevel(essentialforindoorinstallations)

•Varioussizes

•Varioustypes(e.g.,platecoolers)

•Customer-specificsolutions

•Widerangeofaccessories(e.g.,adapters)

CI 71 Technical Data Operating pressure: 290 psi (20 bar)

Weight: 201 lbs (91 kg)

Noise level: 80 dB, +/- 3 dB

Working temperature: -22 to 131° F (-30 to +55°C)

Survival temperature: -40 °F (-40 °C)

Cooling capacity: 45 KW

Motor: 1.1 kW 690 V, 50 H 905 rpm, 6-pin

CI 61 Technical Data Operating pressure: 290 psi (20 bar)

Weight: 108 lbs (49 kg)

Noise level: 82 dB, +/- 3 dB

Working temperature: -22 to 131 °F (-30 to +55 °C)

Survival temperature: -40 °F (-40 °C)

Motor: 1.1 kW 400 - 690 V, 50 Hz 1450 rpm, 4-pin

CI 61

CI 71

CI 71

EatonInternormencoolersareflushedwithlowviscosityfluidaccordingtoISO4406contaminationclass16/14/11

Cl 91 Technical Data Operating pressure: 290 psi (20 bar)

Weight: 302 lbs (137 kg)

Noise level: 83 dB, +/- 3 dB

Working temperature: -22 to 131 °F (-30 to +55 °C)

Survival temperature: -40°F (-40°C)

Motor: 2.2 kW 690 V, 50 Hz 905 rpm, 6-pin

Cl 101 Technical Data Maximum operating pressure: 290 psi (20 bar)

Test pressure: 435 psi (30 bar)

Weight: 346 lbs (157 kg)

Noise level: 83 dB, +/- 3 dB

Cooling capacity: 60 KW

Motor: 2.2 kW 3 x 690 V, 50 Hz 6-pin

CI 81 Technical Data Operating pressure: 290 psi (20 bar)

Weight: 245 lbs (111 kg)

Noise level: 82 dB, +/- 3 dB

Working temperature: -22 to 131 °F (-30 to +55 °C)

Survival temperature: -40 °F (-40 °C)

Cooling capacity: 51 KW

Motor: 1.1 kW 690 V, 50 Hz 905 rpm, 6-pin

CI 101

PlateCoolerWO-CI 95

CI 81

Filter Systems

Twinfil

Lubrication and Filter Systems for Gears

—TWF 1001

—TWF 1950

—TWF 4000

—TWF 6000

Filter Units

Stationary

— US 10

— US 22 with MPS 01.2

Lubrication Systems

For Main Bearings of Wind Turbine Gears

Supplementary Products

— WGR 60 maintenance unit for filter change

—Filter Elements

Contamination Monitoring Systems

Sensors

Metal Particles

— MPS 01.2

— MPS 02.1

— MPS 03.1

Water Contamination

— WSPS 01 - 05

Oil Condition

— IVS 01

In-line Measuring Systems

Particle Counter

— CSM 02

— MPM 01 - Set

Water Contamination

— WSTM 01 - Set

Oil Condition

— IVS 01

On-line/Off-line Measuring Systems

Multi-analysis Systems

— OCM 01

Water Contamination

— WSH 01

Heating and Cooling Systems

Heating Systems

—HS 10

—HS 16

—HSH - Heated Suction Hose

Cooling Systems

— CI 71

— CI 81

— CI 91

— CI 101

Plate Cooler

— WO - CI 95

For more information, please e-mail us at [email protected] Visit us online at eaton.com/filtration for a complete list of Eaton’s filtration products

©2012 Eaton Corporation. All Rights Reserved.All trademarks and registered trademarks are the property of their respective owners. Litho USA.

Europe/Africa/Middle East Friedensstraße 41 D-68804 Altlussheim, GermanyVoice: +49 6205 2094-0

Auf der Heide 2 53947 Nettersheim, GermanyVoice: +49 2486 809-0

An den Nahewiesen 24 55450 Langenlonsheim, GermanyVoice: +49 6704 204-0

BrazilAv. Julia Gaioli, 474 – Bonsucesso 07251-500 – Guarulhos, BrazilVoice: +55 (11) 2465-8822

North America — HQ70 Wood Ave., South, 2nd Floor Iselin, NJ 08830Toll Free: (800) 656-3344 (North America Only) Voice: (732) 767-4200

ChinaNo. 3, Lane 280, Linhong Road Changning District, 200335 Shanghai, P.R. ChinaVoice: +86-21-5200-0099

Singapore4 Loyang Lane #04-01/02 Singapore 508914Voice: +65-6825-1668

All information and recommendations appearing in this brochure concerning the use of products described herein are based on tests believed to be reliable. However, it is the user’s responsibility to determine the suitability for his own use of such products. Since the actual use by others is beyond our control, no guarantee, expressed or implied, is made by Eaton as to the effects of such use or the results to be obtained. Eaton assumes no liability arising out of the use by others of such products. Nor is the information herein to be construed as absolutely complete, since additional information may be necessary or desirable when particular or exceptional conditions or circumstances exist or because of applicable laws or government regulations.

EFINWPR 6-12

8

Lubrication Systems, Filter Systems, and Accessories for Wind Power Gears