Early reinforced concrete - case study of a water tower in Karlowice, Wroclaw

-

Upload

anna-wojtun -

Category

Documents

-

view

217 -

download

2

description

Transcript of Early reinforced concrete - case study of a water tower in Karlowice, Wroclaw

Anna Wojtun s1262587

AC5 Conservation Technologysupervisor: Dr Dimitris Theodossopoulos

April 2013EARLY REINFORCED CONCRETE -CASE STUDY OF A WATER TOWER IN WROCLAW.

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

2 3

TABLE OF CONTENTS:

Abstract

1. Summary of the topic1.1 Development of early reinforced concrete in Europe.1.2 Overview of historic water towers.

2. Case study 2.1 Limitations of study2.2 Historical background2.3 Urban setting2.4 Construction2.4.1 The company 2.4.2 Structural design2.5 Decay: symptoms 2.5.1 Exterior2.5.2 Interior2.6 Decay: causes2.6.1 Exterior2.6.2 Interior

3. Statement of significance 4. Repair philosophy

Conclusion

Appendix

4

556

7778999

151519232325

2626

30

31

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

4 5

ABSTRACT

This paper will seek to investigate the material of early reinforced concrete, its history and pathology through the analysis of a 1914 water tower located in the Karlowice district of Wroclaw, Poland (until 1945 - German Breslau). First, the short history of the material’s development and historical role as well as present uses of early water towers will be discussed. Subsequently, the case study of the Wroclaw water tower will follow.

The water tower in Wroclaw stopped serving its original purpose in 1960s, it was listed for its industrial heritage in 1979 and is currently for sale, having been redundant since 2004. The immediate appearance of the water tower gives the impression of a fair condition, however a closer inspection reveals some degradation. This will be investigated so as to provide a detailed analysis of the specific decay mechanisms. The report will argue for both the ubiquity and individual uniqueness of water towers as specimens for conservation issues. Water towers are both functional and make a very obvious aesthetic mark on the landscape. This report will seek to describe aspects of conservation that surround these buildings’ changing roles and suggest that they present a microcosm of repair issues due to the stresses of their functional origins.

1. SUMMARY OF THE TOPIC

1.2 Development of Early Reinforced Concrete in Europe.

Concrete, originally developed in Egypt, Greece and Rome and mastered from the 18th century onwards, had little tensile strength when compared to its compressive strength. It was not until the 19th century that a compound material capable of taking the tensile stresses was investigated. The first concept of reinforced concrete (RC) was published in 1830 in a publication entitled Encyclopedia of cottage, farm and village architecture. It proposed a lattice of iron to be incorporated into a concrete mixture in order to form a roof.1 In 1854 William Wilkinson received a patent for his developments in studying reinforced concrete, but little evidence remains to show the extent to which his material was ever used.2 The first practical application of reinforced concrete is linked to Joan-Louis Lambot, whose concrete ship built in 1848 was presented during the 1855 International Exhibition held in Paris. In 1850’s Francois Coignet developed a technique for embedding a wrought-iron framework in concrete and in 1853 built the first ever erected reinforced concrete structure - a four storey house at 72 Rue Charles Michels. Simultaneously, in 1867 a French gardener Joseph Monier produced reinforced concrete flower pots and obtained a patent for iron reinforced concrete tubes, followed by patents for tanks, bridges and stairways.

In 1879 a German contractor, Gustav Adolf Wayss, purchased the rights to Monier’s patent. He was the first engineer who launched an extensive experimental program which employed renowned experts and produced theoretical texts, formulas and methods for design.3 Under his supervision numerous loads tests were carried and the corrosion behaviour of iron encased in cement studied.4 He precedented a scientific method of calculating reinforcement and concrete structures ratio. In 1887 Das System Monier (Eisengerippe met Cementumhulling) in seiner Anwendung aug das gesammte Bauwesen [The Monier system (iron skeleton with cement sheath) in its application to the entire building] was published and soon after widely applied in civil engineering, mainly in construction of arched bridges in Germany, Austria and France.5

In Belgium Francois Hannebique experimented with reinforced concrete, and patented his system in 1892. His idea was based on combining a frame with infill floor slabs and external cladding in various materials, including concrete. He published his own house magazine Le beton arme and one of his engineers, Paul Christopher, a first book on reinforced concrete: Le beton arme et ses applications. Since then many other patents were registered, differing mainly by the geometry of the systems and type of reinforcement, a few were however developed into the 20th century. most recognition was given to the works of Hannebique and Coignet responsible for the first widespread use of Portland cement.

Fig. 1A Karlowice roofscape with the water tower centre-

right.source: www.dolny-slask.org.pl

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

6 7

1.2. Overview of historic water towers.

Water towers became popular during the Industrial Revolution as growing communities recognized their value in sanitizing the daily living. Some of them were erected in immediate neighbourhood to train stations, especially during the time of steam engines, when large amounts of water were essential. At that time such combinations were often called “water stops”. The development of water towers was not sequential: whilst some engineers were still building in brick, others preferred to use concrete. According to their setting and role they can be divided into four categories: communal (domestic), railroad, industrial and park related. Domestic water towers often acted also as reservoirs during peak water or water shortages. They vary greatly in both material, shapes and appearance.

Early reservoirs and tanks were covered by brick vaulting or by brick jack-arching.6 Reinforced concrete was used from about 1900, however the scarcity of documentation from that time makes it impossible to discuss them in much detail.7 In some reports the designers of the reinforcement were anonymous, whilst in others only partially introduced. Early concrete tanks were not without problems, they often cracked at the wall/floor joint due to the expansion of the steel roof joints.

The earliest water towers were erected in brick, stone or were casted fully in metal, with tanks made of iron.8 The first reinforced concrete water tower was designed by Joseph Monier in 1868 in Maisons-Alfort, France. In Germany the first concrete tower was commissioned in 1894, in Sayda (Saxony) and consisted of a brick base and a 5.2m concrete tank.9 In 1900 Louis Gustav Mouchel designed the first British water tower in reinforced concrete.10 It was used for green watering at Meyrick Park golf course in Bournemouth. Since then the number of concrete water towers increased steadily. In Germany they were often based on the Intze Principle and since 1908 were popularized by Dyckerhoff & Widmann with headquarters in Munich. As experience with concrete grew, its use quickly became more ubiquitous.

Early design of concrete water towers followed three patterns: tanks on solid shafts of numerous cross-sectional arrangements mirroring earlier brick constructions; plain tanks, sometimes on brittle legs and tanks on central shafts supported by a ring of columns, some of them with a domed floor.11 12 The concrete tanks were often lined as a method of precaution. European water towers were often positioned in central points of urban areas, thus since the 1850‘s in Germany their outer form was regulated by building norms which at that time mandated monumentalism.13 As water towers made a distinct mark on any urban landscape, it became almost regulatory to apply historicist detailing to their outer surfaces. These were often copied from medieval military towers, as seen in 1877 Berlin-Neukoln structure based on the design of the Spandau Citadel. The sculptural finish was inevitably related to the setting - the most elaborate were the towers located in parks and recreational areas, whilst the remote towers by train stations were often ascetically simple. The final shape of any water tower was always a resultant of technical and economic circumstances.

2. CASE STUDY

2.1 Limitations of study

A condition survey of the water tower in Karlowice was conducted on two separate occasions in January and March of 2013. A non-invasive visual and tactile examination of the tower’s interior and exterior was undertaken. It was not possible to inspect the highest storeys as access to those levels was limited. The observed symptoms of decay were thoroughly and systematically photographed. There was no advanced surveying devices (such as humidity measuring devices, thermal cameras and radiography-based equipment) available, restricting the amount of gathered data. There is a great need for further specialist assessment in order to determine material specification, test the strength of concrete and reinforcement as well as to conduct a geotechnical survey.14 Additionally specialist advice to establish a course of further repairs would be recommended to be obtained from tinsmiths (with regard to the roof) and concrete conservation specialists.

The original documentation is archived and made available by The Architectural Archives of the City of Wroclaw, yet not much survived the post-war political shifts as encountered by Germany and Poland. A brief listing text from 1994 and a short description of maintenance to date is available on request at the Municipal Conservation Office. There is almost no available Polish literature discussing the topic of water towers and the only example found refers mainly to German resources. In English language literature the issue has been discussed to some extent, however there still remains a need for further academic studies, and the eclectic collection of sources referred to in this report are representative of this.

2.2 Historical background

The Breslau water tower was built in 1914 as a part of a local water supply system for a German village called Carlowitz. Three years earlier, in 1911, architects Paul Schmitthenner and Erich Grau began to implement a village redevelopment plan based on the idea of a city-garden (Gardenstadt Carlowitz), shaping the urban character of the area.15 This comprehensive plan resulted in the re-invention of what was the former market square and a new water tower being commissioned. In 1928 Carlowitz was absorbed by the city of Breslau and in the 1930s the water tower was incorporated into to the city’s main water supply system serving as an end reservoir for its 423km long network. In August 1945, following the provisions of the Potsdam Agreement, Breslau was incorporated within Polish borders. The water tower has been managed since by Wroclaw City Council and its executive, the Municipal Water and Sewer Enterprise (Miejskie Przedsiebiorstwo Wodociagow i Kanalizacji). The water tower stopped serving its original purpose in the 1960’ when the whole water supply system was redesigned and largely replaced by pumping devices. Following its decommissioning, the tower was recognized as part of Wroclaw industrial heritage and listed in

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

8 9

1979.16 Until 1985 the tower was still utilised as an emergency compensation tank and between 1994 and 2004 leased as an indoor artificial climbing wall. It now partly serves as a transformer station and is currently on sale, having been left redundant since 2004.17,18

2.3 Urban setting

The 46m high structure is set in the centre of the small square formed by the junction of the main street of Karlowice, and three other adjoining avenues. It is the most distinct visual landmark for the area and a crucial element of its urban layout. Its strong appearance, emphasized by use of concrete, sets itself apart from the nearby 19th century brick heritage as represented by a former Ursulines monastery and school (currently a children’s hospital) and a Franciscan church erected in a gothic revival manner. It also differs from the low rise buildings of mainly residential character erected as part of the 20th century redevelopment of Carlowitz, plastered and crowned with traditional, red tiled pitched roofs. The most immediate surroundings are shaped by rows of 3-storey houses encircling the tower and its adherent plot of land. The Karlowice area, in contrast to Wroclaw central and Western parts, did not suffer severe damage during the wars and is valued for its well preserved, well integrated and architecturally consistent built environment. The dominant silhouette of the water tower constitutes an inherent component of this urban locale.

2.4 Construction

2.4.1 The company

The structural design of the water tower was developed by a German company Lolat-Eisenbeton with headquarters in Breslau.19 The company was founded by Gustav Lolat from Dusseldorf, and Hans Bechtel from Mannheim.20 Their unique combination of experience, ranging from reinforced concrete buildings to military constructions, contributed towards a head and firm start in May 1904 under a name Baugesellschaft für Lolat-Eisenbeton GmbH [lit. Construction Company for Lolat-Reinforced Concrete GmbH]. They specialized in large industrial projects developed in, at that time, relatively new material, having branches in cities of Berlin, Halle, Hanover, Nuremberg and Szczecin. They also grew in the building materials industry, and soon acquired a concrete construction company run by Adolf Gustav Wayss, Wayss GA, at that time located in Vienna after Wayss’ withdrawal from the office in Berlin.21

Lolat-Eisenbeton was an internationally oriented company, operating on Monier’s patent. Their improved and redeveloped techniques were largely popular in Germany, Austria and France and known as Monier-Wayss systems. The company erected also a numerous power stations, cement factories and dams in Russia. Its later name, Huta Hoch- und Tiefbau AG [Huta Construction- and Civil Engineering AG] was given in 1916. In the post-war period the company was involved in reconstruction of destroyed cities and sustained its strong position until 1950’s, operating mainly from Hanover. In 1967 it merged with Huta Hegerfeld AG in Essen, but soon after, in 1985, it was forced to announce bankruptcy.

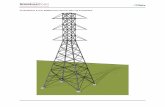

2.4.2 Structural design

The company’s extensive experience in industrial buildings engineering ensured high structural stability of the water tower for many years to come. According to the typology of water towers developed in Polish literature, the water tower of Karlowice is a “two-modules column” of a 10m radius and an octagonal footprint. It is a 46 m, 3-storey high structure with a domed concrete pavilion holding a steel water tank. The tower sits on a concrete continuous footing, its load bearing structure consists of 8 reinforced concrete columns with reinforced concrete girders supporting reinforced concrete ceiling’s slabs formed in-situ. It is crowned with galvanized steel dome laid on wooden laths. The walls are also casted in-situ, their wooden shuttering marks are visible from the interior.

The architectural detailing of the tower, applied to the external face, is sculpted solely in concrete. It incorporates low-relief panels (lesenes), stepped cornices and engaged columns at the pavilion level. The ratio of concrete mixture originally used was most likely to be one part of Portland Cement, three parts of sand (river sand and fine gravel) to three parts of aggregate, according to the existing

Fig. 3Around 1930, the tower seen from

Przybyszewskiego Street.source: www.dolny-slask.org.pl

Fig. 2The water tower under construction, 1914

source: www.dolny-slask.org.pl

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

10 11

archival documentation.22 This has resulted in quite rough and porous concrete. The tower is equipped with a steel, 7.5 m high, Intze-type water tank.23 According to the Intze Principle the water tank would usually be placed on a brick shaft, its base would be fixed with a ring anchor so that only vertical forces are transmitted to the tower,24 here however it sits on a concrete slab. As the horizontal forces are significantly reduced, the tower shaft did not require a very powerfully built structure. The water tank is covered with wooden planks and is surrounded by a concrete working platform.

The majority of interior fittings is made of steel and consists of steel window framing, steel red-painted fixed windows, and steel spiral staircase with steel balustrades. The 100cm-wide staircase runs alongside internal walls of the water tower and narrows to 50cm at the top storey level, where it is positioned centrally. Originally there was a wooden doorway at the main entrance, which has been replaced by a generic steel example in more recent times. The ground level accommodates a small brick storage with separate entrance from the outside.

Fig. 4 Intze type water tanks.Karlowice Water Tower is equipped with

Intze 1 Tank source: www.wikipedia.org

Fig.5 (page 11)Structural design archive with cross-sections

Fig. 6 (page 12)Structural design archive with tank support detail

Fig. 7 (page 13)Structural design archive with ceiling slab cross-

section

source: The Architectural Archives of City of Wroclaw

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

12 13

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

14 15

2.5 Decay: symptoms

The tower’s water-related function and its exposed setting are the main determining factors for the mechanisms of decay occurring in this structure. Their effects are visible internally and externally and are of different levels of significance. The areas of their occurence are indicated according to the drawing on page 14.

2.5.1 Exterior

Observable symptom: Spalling [Fig. 8]Cause: Atmospheric and climate (carbonation)Where: A1 - A8, above B1; various degrees. Occurs in places of inadequate reinforcement concrete cover.25 Normally, reinforcement corrosion is prevented by the alkali content of concrete mixture. During hydration calcium, potassium and sodium hydroxides are formed, by dissolving in the pore water of concrete they create a very alkaline environment (pH12-13.5). It is at this point that reinforcing steel creates a self-sustaining, thin and protective passive layer, which will maintain itself as long as the alkalinity stays above pH11. The alkalinity in concrete can be neutralized by atmospheric CO2 reacting with pore water resulting in the formation of carbonic acid.26 It is a slow process progressing from the outer surface inward, breaking through the passive layer of reinforcement bars. Subsequently, the steel reinforcement close to the surface of concrete rusts, which then causes its volume to expand and break the surface of the concrete. If not stopped, this may lead to structural damage.

Fig. 9Spalling external surface of the water tower [A3

section].

Fig. 8Survey drawing indicating the refrence grid used in this document [author’s own].

A1 A8A7A6A5A4A3A2

B1

B2

B3

B4

C1

C2

C3

1:250 A - vertical divisionsB - horizontal divisions (exterior)C - horizontal divisions (interior)2.5m 5m 7.5m 10m

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

16 17

Observable symptom: Rust stains from external steel elements [Fig. 10]Cause: Atmospheric and climateWhere: A2; A6; A7 Ferrous metals will corrode when exposed to water and oxygen in the process of electrochemical oxidation, known as rusting.27 As steel components of a building deteriorate they may visibly stain concrete surfaces.

Observable symptom: Black crust [Fig. 11]Cause: Atmospheric and climateWhere: B1; B4 (below the cornices) Weathering layers (the so-called ‘black crust’) are formed by deposition and accumulation of multi-pollutants and products of chemical reactions occurring in material surfaces. They most likely to occur in areas not subject to regular rainwater washing. The formation of the black damage layer compromise aesthetic qualities (blackening) of the building facade and may also cause material loss. The weathering layers are a record of environmental changes occurring over time, their chemical composition reflects the atmospheric combustion sources. Over time, these accumulating layers build up to form a historic record of air pollutants present during each layers’ formation.28

Observable symptom: Stalactites [Fig. 12]Cause: Atmospheric and climate Where: B4 (below) Stalactites can form in areas susceptible to slow leaks. In concrete they form due to the presence of calcium oxide, which reacts with any rainwater minerals that penetrates the concrete producing calcium hydroxide. Over time the calcium hydroxide reaches the edge of concrete and, if the concrete element is suspended in the air, it will drip down from the edge. By doing so it comes into contact with air. The reaction with CO2 results in precipitating calcium carbonate, particles of which drop down forming, over time, into a stalactite.

Observable symptom: Surface Damage [Fig. 13]Cause: Mechanical (human hazards + original design)Where: A6 Mechanical surface damage can occur in exposed places, such as protruding corners or edge. It may also be caused by fixing external elements to the surface of the concrete.

Fig. 10Rust stains on the concrete surface [A6]

Fig. 11Black crust on the cornice and beside the window.

Fig. 12Stalactites below top pavilion cornice.

Fig. 13Damaged exterior wall caused by initially weak bonding between outlet pipe and surrounding concrete.

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

18 19

Observable symptom: Graffiti [Fig. 14-15]Cause: Mechanical (human hazards)Where: A2; A3 Any structure localized in an urban environment and easily accessible is potentially susceptible to vandalism and graffiti. Stains and graffiti can greatly impair the appearance of the building and discolor the exterior walls.29

2.5.2 Interior

Observable symptom: Cracks [Fig. 16-17]Cause: Excessive moisture; Atmospheric and climaticWhere: C1; C2There are number of reasons for cracks to occur, including structural failure, thermally-induced movement, corrosion of steel reinforcement or poorly mixed or set concrete.30 It is crucial to correctly diagnose the reason for which the concrete is cracking as it determines subsequent course of repairs. In the case of water tower the cracks are most likely to be caused by excessive humidity and some design solutions in its interior, and can be identified as transverse or longitudinal. They normally form after the concrete has hardened and may occur as fine flexural cracks, their appearance is determined by the line of reinforcement.

Fig. 15As seen on the picture below, graffiti can signifi-cantly impair the visual appearance of concrete.

Fig. 14Graffiti.

Fig. 17Cracks in first floor level ceiling slab

Fig. 16Cracks in ground floor level ceil-ing slab.

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

20 21

Observable symptom: Corrosion process by decalcification [Fig. 18]Cause: Excessive moistureWhere: C1; C2; C3Decalcification of cement is closely linked to various types of concrete deterioration. It is triggered by material exposure to flowing soft water or condensation (including evaporating rain water), which washes out calcium from the mixture.31 The soft water leaches out the calcium and other dissolvable substances causing weakening and reduced tightness of the concrete. Leaching is a very slow process, which may reach the reinforcement bars and cause them to corrode. It appears as a white-rusty mark and may be following the lines of cracks.32

Observable symptom: Corrosion of reinforcement [Fig. 18]Cause: Excessive moisture; Inadequate use (change of use / climbing wall fixing)Where: C1; C2; C3Steel elements may be exposed to moisture and oxygen as a result of human intervention. As described in the Exterior section, corrosion of reinforcement appears when the thin passive layer of reinforcement is broken and its Ph level decreases to below 11. Subsequently, corroded reinforcement increases in volume and causes concrete cover to break, stimulating further damage.

Observable symptom: Leaching [Fig. 19]Cause: Excessive moisture; Atmospheric and climaticWhere: A1 - A8 (below sills)Leaching is caused by water migrating through cracks or voids present in concrete, dissolving various minerals present in the hardened cement paste or in the aggregates. As it washes out lime from the concrete, it reduces its alkalinity and strength. Dissolved ions are transported, and may be sediment and deposit at the concrete outer surface.

Observable symptom: Effloresence [Fig. 20]Cause: Excessive moisture; Atmospheric and climaticWhere: C1; C2 (below sills)It occurs in humid environments and may be caused by water run-off or water migrating through concrete. As cements are the greatest source of soluble materials, when solvent evaporates the salts will tend to concentrate on the surface areas, forming white deposits.33

Fig. 18Decalcified and weakend concrete slab with visible corrosion marks, evidence of inadequately treated

concrete with repair patches.

Fig. 19Leaching marks caused by water migrating through windows with poor insulation.

Fig. 20Effloresence on the ceiling slab.

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

22 23

Observable symptom: Scaling and Frost damage [Fig. ]Cause: Excessive moisture; Atmospheric and climatic (freeze - thaw action)Where: A1 - A8 (ground level); Various Frost damage occurs when water accumulates in cracks, voids or pores of the concrete, and expands when freezing, subsequently causing sections of concrete to break and fall from the surface. Porous concrete is particularly susceptible to frost damage.34 Over a number of freeze/thaw cycles it can cause a fatal damage of concrete. 35

Observable symptom: Green moulds [Fig. ]Cause: Biological actionWhere: A4 - A6 (ground level) Moulds germinate on damp internal surfaces, rich in organic material which would sustain their growth. They may appear as stains or spots on affected surfaces.36

2.6 Decay: causes

2.6.1 Exterior

The tower sits at the intersection of four streets, it marks the centre of an open and unsheltered square area and rises above the low-rise residential houses located in its immediate surrounding. It is, and has been, exposed to an array of environmental conditions and experienced the consequences of economic changes that have occurred during its hundred year existence. These environmental causes are the main reason for the tower’s decay, as indicated in the previous section.

The city of Wroclaw lies inland, in a lowland area propitious to long-lasting suspension of fly ash generated during combustion [Fig. 25]. Furthermore, it is a city of metal foundries and power stations which were developed extensively after World War II, located to the West of the neighbouring Upper Silesia area, a region known as the Upper Silesian Coal Basin. Pollution from industries located both proximally and further afield have contributed to the deterioration of the water tower’s material, which has been subjected to the action of air pollutants such as sulphur dioxide (SO2) and nitrogen dioxide (NO2). These are among the most important elements of anthropogenic origin present in the damaged, blackened layers of monuments located in urban areas.37 Thick formations of the black crust can be particularly observed in places unavailable for rain run-off, such as below the cornices and in window slots. The link between concrete decay and air pollution has been investigated and proven in relation to the high profile Centennial Hall, located minutes away from the water tower.38

Fig. 25A map indicating the level of airborne fly ash across Poland. Source: www.gios.gov.pl

Fig. 21 and Fig. 22 (left hand side)Frost damage penetrating deep into the concrete block.

Fig. 23Biological growth on the ground floor wall.Fig. 24Scaling on wall at ground level.

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

24 25

Moreover, the exhaust fumes emitted by cars’ engines and industries produce large amounts of carbon dioxide which accelerates carbonation processes and causes the tower’s external surface to spall. As this occurs only above the ground level, from which point the tower’s shape narrows notably, it is assumed that the issue of inadequate cover of reinforcement plays a vital role in this process. Further factors are the height of surrounding buildings acting as shelters, as well as the very nature of air-pollution which floats up and concentrates mainly at the higher levels. Additionally, Wroclaw’s climate, characterized by high seasonal and annual amplitudes, as well as having its highest annual rainfall during summer period, causes the wet/dry cycles to be more rapid, intensifying the effects of carbonation. [Fig. 26] The water tower being exposed also triggers another kind of problem: vandalism and graffiti. Despite the deep attachment of local residents to the tower, it has not been left without this generational mark presenting certain challenges with respect to cleaning and maintenance.

2.6.2 Interior

The interior of the tower is subject to conditions differing from those impacting its external surface. The most significant factor causing the internal spaces of water tower to deteriorate is water ingress and a high level of humidity. Historically, the main source of this was the top-storey water tank and pipes transporting the pressurized water. With time, as the water tower became redundant, the pipes started to rust and loosen. As the water was no longer being transported under high pressure, the groundwater level has since gradually increased. Furthermore, Wroclaw itself is characterized by an above average level of groundwater as it lies along the Odra river and within its multiple inlets. Hence, the groundwater, as well as the precipitation, have became a main major source of humid conditions prevailing inside the tower. Both can be categorized as soft water of slightly acidic qualities.

The ways in which the water manifests itself in the tower’s concrete decay processes are twofold. The rain water affects mainly horizontal surfaces, and its course of action can be described as “top down”, whilst the groundwater impacts vertical slabs interacting mainly through condensation processes. The ground level slab has visible wet staining, raising on the walls. Stains of similar nature can be observed on both first and a second-storey ceilings. The areas of imperfection, such as moulding joints, are most affected by evaporating water which penetrates along their lines, slowly dissolving calcium from cement and stimulating the corrosion of reinforcement. Similarly, the fine cracks on the second-storey slab (caused most likely by the diagonal arrangement of pipes leading through the ceiling) are suffering the same damage. Corrosion and decalcification also affects elements of reinforcement left exposed as a result of former interventions, such as circular marks in places where the climbing wall would have been previously fixed. Flat and even slab areas are shielded by salt deposits, which sedimented through evaporating water.

A different kind of deterioration is caused by rain water as it drips down through the cracks between the window sills and imperfectly fitted glazing. By doing so, it transports dust and dirt from the external surfaces, pigeons droppings, rust from the steel glazing, as well as leached calcium. These deposit on the outer surface of concrete, forming distinct bleeding marks underneath each of the window openings. Another damaging effect of water links to severe heating/cooling conditions, as the tower is subject to the environment of very high seasonal temperature differences, ranging from 39°C in summer to -30°C in winter period.[Fig. 26] Freezing water expands within the pores of concrete and, with the repetition of freeze/thaw cycle, causes its surface to scale, in some places penetrating deep into the block of concrete resulting in more severe damage. Additionally, the dampness within the tower’s interior has attracted a growth of green moulds, which may be compromising the integrity of concrete outer surface.

Fig. 26Annual weather pattern for Wroclaw.

source: www.stat.gov.pl

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

26 27

3. Statement of significance

The water tower was recognized as part of Polish industrial heritage and listed as early as 1979. Its historic significance is demonstrated by its central location which testifies to the tower being an inextricable element of the original urban layout of Gardenstadt Carlowitz. Such monumental treatment of an industrial structure can be observed in only one other place in Wroclaw and is emphasized by the low-rise surrounding shaped by residential buildings. Despite its prominent location the tower appears as an architectural statement on its function and role resembling the social and architectural desires of its time. This is highlighted by the choice of material and is unique in comparison with other such structures, often heavily decorated in a historicist fashion.

The 100-year-old water tower is preserved in fairly good condition due to its original structural design drawn by a company of vast engineering experience, examined and appraised on a European scale. It is a testimony to studies on reinforced concrete at the beginning of the twentieth century and an evidence of their successful application and development. It also links to the internationally renowned Centennial Hall, listed by Unesco World Heritage in 2006, where the responsibility for structural design of ambulatory was, likewise, handled by Lolat-Eisenbeton AG. To the significance of the water tower on social level best testifies a vocal protest raised by local residents against alleged rumors of its demolition spread in 2010. Various individuals, organisations and housing-cooperatives stood firmly in defense of its survival, making their appearance in local newspapers and TV. Most recently, the tower has attracted attention of fine arts student who envisaged possibilities of its future existence.[Fig. 27]

4. Repair philosophy

Following the changes in water supply systems and reaching towards more efficient water delivery, numerous towers have become redundant. The only viable solution aimed at saving these structures from decay, deterioration and subsequent inevitable demolition is their adaptive reuse. A number of brick and stone water towers have already been converted for various purposes, such as houses, restaurants, museums etc., and most recently interest has been shown in conversion of reinforced concrete structures.[Fig. 28] As with any reused buildings, water towers present a set of structure-specific problems, however, a changing function means more flexible repair philosophy with respect to the original, purpose-tailored design.

The greatest challenges of adaptive reuse of water towers is a risk of impairing their visual appearance whilst removing the water tank as well as providing access to the building.39[Fig. 29] The water tower of Karlowice makes an obvious mark on the landscape and this feature should be above all preserved. Hence, it is crucial to maintain its ascetic, modern appearance through appropriately chosen treatment accounted for resembling the qualities of detailing, texture and colouring. Greater authenticity can be achieved through leaving small losses and washouts of the

concrete in areas where this would not impair the structural strength and avoidance of glossy and artificially smooth surfaces. Due to a succession of different uses, the ubiquity and adverse effects of deteriorated steel fittings, the removal of the internal staircase, pipes, water tank, doors and windows would be beneficial. Sample windows and the water tank, if found underrepresented, may be considered as a donation to an industrial history museum. Finding the best and most adequate use for the tower, respectful to its past and sensitive to its individual nuance, is a challenge waiting for a creative, yet considerate conservation architect.

Fig. 27Student visualazation of proposed adaptation for

a club and conference centre.

source: http://neogen.carbonmade.com/pro-

jects/24109

Fig. 28 (bottom left)Water tower in Soest,

Netherlands / Zecc Architects

source: http://www.zecc.nl

Fig. 29 (bottom right)Removing a water tank

from the its tower in Sufolk, England

source: www.bwtas.blogs-pot.com

.

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

28 29

Repair priority: Immediate Decay type: - Spalling Decay cause: Carbonation, inadequate concrete cover

Recommended repair:Carbonated concrete offers little protection to encased reinforcement stimulating corrosion, which, in turn, causes the surface to spall, allowing further carbonation to take place. These appear to be the most pressing issues since it affects great surface areas of the water tower. If not stopped, it may lead to compromised structural stability of the tower. To measure the depth of carbonation phenolphthalein can be used, which, sprayed onto freshly broken concrete turns pink in places where the alkalinity has not yet been broken.40 It is possible to reinstitute the passivity of the damaged layers and re-alkalise the reinforcement bars with carbonate electrolyte,41 however corrosion inhibitors, such as phosphoric or tannic acid and the so-called “migrating inhibitors”, may also be used.42 A thorough cleaning and cutting away all the loose and deteriorated concrete must precede any treatments. Once the alkalinity of the affected area has been reinstated, the surface can be restored either by using formwork (in smaller areas) or a technique known as “gunite”.43 Subsequently, an application of an adequate anti-carbonation coating would be recommended.44 In order to obtain the color of concrete resembling its original shade it is possible to use special glazed coats, applied as final layers.45

Repair priority: Urgent Decay type: - Corrosion- Scaling and frost damage- Efflorescence- Stalactites- Leaching- Surface damage and cracksDecay cause: Water ingress, increased humidity, human intervention

Recommended repair:Increasing the watertightness and reducing the amount of ingress entering the tower is the second most urgent action needed to be undertaken in order to prevent further damage. After the removal of corroded internal steel fittings, I would recommend the tower to be rigorously dried and any cracks sealed. Cracks where the corrosion is manifested should be first cleared from any loose concrete and rust, and appropriately coated to prevent further damage. Likewise, when repairing cracks leaking the rainwater, mechanical cleaning of the leaching marks should precede the crack repair. Filling the dormant cracks won’t perform a structural role and may be conducted through enlarging the cracks along the external face and sealing them with a suitable joint sealer.46 Various

materials can be used to perform the task, including epoxies, urethanes, silicones and polymer mortars, therefore a further specialist diagnosis determining the right choice of material is required. Efflorescence marks can be removed with a dry brushing and will not occur again if the humidity and evaporation are controlled.47

Repair priority: Necessary Decay type: localized staining- Black crust- Graffiti- Green moulds- Rust stains Decay cause: Various

Recommended repair: Black crust from atmospheric pollution can adhere very strongly to the concrete and appropriate care should be given when cleaning to avoid damage. Various techniques can be used to clean the polluted surface areas, such as water washing and stiff brushing (however the effect of hard brushes can be harmful to the concrete and must to be carried very sensitively), high-pressure water lances (although due to high pressure jets can cause substantial damage to the finishes and any exposed aggregate) as well as chemical cleaning (this technique, however, may cause an unnaturally “over-cleaned”, bleached effect and further contaminate the building).48

Due to the disadvantages of all the above mentioned solutions, the safest cleaning method may be steam as it carries low risks of impairing the surface integrity and visual appearance. Any areas affected by green mould can be cleaned in a similar manner. In such cases a subsequent application of a biocide may be used to stop the growths from returning. In places requiring more powerful treatment abrasive cleaning may be most appropriate. The greatest challenge of cleaning any localised stains (eg. rust stains and graffiti) is to avoid leaving an overly cleaned marks. Chemical solvents and abrasive cleaning may be most effective in removing graffiti stains. When cleaning the rust stains it is vital not to compromise the bond between the embedded steel elements and the concrete.

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

30 31

CONCLUSION

The water tower in Karlowice is representative of an array of problems and issues arising around the maintenance and repairs specific to any RC water-retaining structures in Europe. These structures are threatened, yet represent truly fascinating heritage, often landmarking our urban and rural landscapes. In order to protect water towers nowadays, further academic study is pressingly required. Furthermore, a structured knowledge of the nature of historic concrete, its treatment and repair would advance the state of conservation expertise and allowed a wider appreciation of this often disregarded and neglected material.

APPENDIX

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

32 33

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

34 35

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

36 37

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

38 39

(Endnotes)1 Christopher C. Stanley, Highlights in the History of Concrete (Slough: Cement and Concrete Association, 1979), 18.2 Ibid., 193 “Engineer’s Standpoint,” http://engineerstandpoint.blogspot.co.uk/2010/09/services.html (accessed April 21, 2013).4 “Wayss and Freytag AG,” http://www.wf-ingbau.de/unternehmen/historie.html (accessed April 21, 2013).5 Peter Collins, Concrete: The Vision of a New Architecture (Montreal: McGill-Queen’s Press, 2004), 616 Michael Gould, “Water-retaining structures in Britain before 1920.,” in Historic Concrete: The Background to Appraisal, ed. James Sutherland, Dawn Humm, and Mike Chrimes (London: thomas Telford, 2001), 326,http://www.icevirtuallibrary.com/content/book/100475 (accessed April 21, 2013).7 Ibid., 3288 Janusz Dobesz, “Zabytkowe obiekty techniki wodociagowej z terenu wojewodztwa wroclawskiego,” in Zabytki Techniki Wodociagowej Polski [Polish Waterworks Heritage], ed. Stanislaw Januszewski (Wroclaw: KOZT RW NOT, 1989), 118.9 “Archiv Deutscher Wasserturme,” http://www.wassertuerme.com/wtneuUeberWtBeton.html (accessed April 21, 2013).10 “Engineering Timelines,” http://www.engineering-timelines.com/scripts/engineeringItem.asp?id=216 (accessed April 21, 2013).11 Michael Gould, “Water-retaining structures...”, 33012 Bernd Becher and Hilla Becher, Water Towers (New York: MoMa, 1988), passim13 Janusz Dobesz, “Zabytkowe ...”, 118.14 David S. Watt, Building..., 170-17715 Antoni Dudek, Wroclaw Karlowice 1699-1999 (Wroclaw: Wydawnictwo Sw. Antoniego, 1999), 1-48.16 A brief listing text was written in 1994 by an engineer Stanislaw Januszewski and is available on request in Wroclaw Municipal Conservation Office (no folder number)17 Jerzy Skarbek, Gminny Program Opieki Nad Zabytkami Na Lata 2009-2013 [Municipal Programme for Heritage Protection For 2009-2013](Biuletyn Informacji Publicznej, 2009), 44, http://bip.biuletyn.info.pl/php/pobierz.php3?bip=bip_popie&id_dzi=3&id_zal=2462&id_dok=993 (accessed April 14, 2013).18 “MPWiK. Ogloszenie o Przetargu.”[MPWiK ITT Notice] http://www.mpwik.wroc.pl/sub.php?613 (accessed April 14, 2013).19 Such name appears on the existing archival documentation of the water tower.20 “Huta Hoch- Und Tiefbau,” http://de.wikipedia.org/wiki/Huta_Hoch-_und_Tiefbau (accessed April 28, 2013).21 See section: Early reinforced concrete in Europe.22 Wasserturm Carlowitz, 1914, The Architectural Archives of the City of Wroclaw, folder AB72750-5423 Janusz Dobesz, “Zabytkowe...”, 118.24 “Bauformen Und Wasserhochbehaltern,” http://www.zagermann.de/proj/waturm/baufrmn.html (accessed April 28, 2013).25 Patrick Loughran, Failed Stone. Problems and Solutions with Concrete Masonry (Basel: Birkhauser, 2007), 5526 Susan Macdonald, ed., Concrete. Building Pathology (Oxford: Blackwell, 2003), 14227 Patrick Loughran, Failed Stone..., 9628 Izabela Joanna Ozga, “Multi Pollutants Impact On Modern Cement Built Heritage” (diss., University of Bologna, 2009), 18-21., http://amsdottorato.cib.unibo.it/2264/1/ozga_izabela_tesi.pdf (accessed April 28, 2013).29 Patrick Loughran, Failed Stone..., 8630 David Odgers, ed., English Heritage. Practical Building Conservation: Concrete (Surrey: Ashgate, 2013), 7831 Jeffrey Thomas et al., “Effects of Decalcification On the Microstructure and Surface Area of Cement and Tricalcium Silicate Pastes,” Cement and Concrete Research 34 (2004): 2297., www.sciencedirect.com.32 “Concrete Deterioration in Industrial Buildings,” http://www.drizoro-polska.pl/?site=uszkodzenia_betonu_3 (accessed April 28, 2013).33 David S. Watt, Building Pathology, 2nd ed. (Oxford: Blackwell, 2007), 12934 Geoff Myass, ed., Durability of Concrete Structures: Investigation, Repair, Protection (London: E & FN Spon, 1992), 7.35 Patrick Loughran, Failed Stone..., 5536 David S. Watt, Building..., 13237 Izabela Joanna Ozga, “Multi Pollutants...”,1838 Ibid., 45-6639 Michael Gould, “The Reuse of Water Towers,” Journal of Architectural Conservation 8, no. 1 (2002): 23-37.40 Susan Macdonald, ed., Concrete..., 15541 Ibid., 17742 R. T. L. Allen, The Repair of Concrete Structures, 3d ed. (1980: Cement and Concrete Association, Slough), 743 Ibid., 1344 Susan Macdonald, ed., Concrete..., 221

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

40 41

45 Leszek Konarzewski, “Renovation of the Façade of Centennial Hall in Wroclaw – Design Versus Its Accomplishment,” Conservation News 26 (2009): 374.,https://suw.biblos.pk.edu.pl/resources/i4/i9/i9/i2/r4992/KonarzewskiL_RenowacjaElewacji.pdf (accessed April 28, 2013).46 Susan Macdonald, ed., Concrete..., 17947 Patrick Loughran, Failed Stone..., 7648 Susan Macdonald, ed., Concrete..., 203-205

List of illustrations:Fig. 1A Karlowice roofscape with the water tower centre-right.[source: www.dolny-slask.org.pl]Fig. 2The water tower under construction, 1914 [source: www.dolny-slask.org.pl]Fig. 4 Intze type water tanks. Karlowice Water Tower is equipped with Intze 1 Tank [source: wikipedia.org]Fig.5Structural design archive with cross-sections [source: The Architectural Archives of City of Wroclaw]Fig. 6Structural design archive with tank support detail [source: The Architectural Archives of City of Wroclaw]Fig. 7Structural design archive with ceiling slab cross-section [source: The Architectural Archives of City of Wro-claw]Fig. 8Survey drawing indicating the refrence grid used in this document [author’s own].Fig. 9Spalling external surface of the water tower [A3 section].Fig. 10Rust stains on the concrete surface [A6]Fig. 11Black crust on the cornice and beside the window.Fig. 12Stalactites below top pavilion cornice.Fig. 13Damaged exterior wall caused by initially weak bonding between outlet pipe and surrounding concrete.Fig. 14Graffiti.Fig. 15As seen on the picture below, graffiti can significantly impair the visual appearance of concrete.Fig. 16Cracks in ground floor level ceiling slab.Fig. 17Cracks in first floor level ceiling slab.Fig. 18Decalcified and weakend concrete slab with visible corrosion marks, evidence of inadequately treated concrete with repair patches.Fig. 19Leaching marks caused by water migrating through windows with poor insulation. Fig. 20Effloresence on the ceiling slab.Fig. 21 and Fig. 22 Frost damage penetrating deep into the concrete block.Fig. 23Biological growth on the ground floor wall.Fig. 24Scaling on wall at ground level.Fig. 25A map indicating the level of airborne fly ash across Poland. [Source: www.gios.gov.pl]Fig. 26Annual weather pattern for Wroclaw. [source: www.gios.gov.pl]Fig. 27Student visualazation of proposed adaptation for a club and conference centre.source: http://neogen.carbonmade.com/projects/24109Fig. 28Water tower in Soest, Netherlands / Zecc Architects [source: http://www.zecc.nl]Fig. 29Removing a water tank from the its tower in Sufolk, England.

Early reinforced concrete - case study of a water tower in Wroclaw. Early reinforced concrete - case study of a water tower in Wroclaw.

42 43

Loughran, Patrick. Failed Stone. Problems and Solutions with Concrete Masonry. Basel: Birkhauser, 2007.

Macdonald, Susan, ed. Concrete. Building Pathology. Oxford: Blackwell, 2003.

Myass, Geoff, ed. Durability of Concrete Structures: Investigation, Repair, Protection. London: E & FN Spon, 1992.

Odgers, David, ed. English Heritage. Practical Building Conservation: Concrete. Surrey: Ashgate, 2013.

Skarbek, Jerzy. Gminny Program Opieki Nad Zabytkami Na Lata 2009-2013: [muniicipal Programme for Heritage Protection For. Biuletyn Informacji Publicznej, 2009.http://bip.biuletyn.info.pl/php/pobierz.php3?bip=bip_popie&id_dzi=3&id_zal=2462&id_dok=993 (accessed April 14, 2013).

Stanley, Christopher C. Highlights in the History of Concrete. Slough: Cement and Concrete Association, 1979.

Stroud Foster, Jack, and Raymond Harington. Mitchell’s Structure and Fabric Part 2. 6th ed. London: Pearson Education, 2000.

Thomas, Jeffrey, Jeffrey Chen, Andrew Allen, and Hamlin Jennings. “Effects of Decalcification On the Microstructure and Surface Area of Cement and Tricalcium Silicate Pastes.” Cement and Concrete Research 34 (2004): page nr. www.sciencedirect.com.

Watt, David S. Building Pathology. 2nd ed. Oxford: Blackwell, 2007.

Yeomans, David T. Construction Since 1900: Materials. London: BT Batsford Ltd., 1997.

Bibliography:

“Archiv Deutscher Wasserturme..” http://www.wassertuerme.com/wtneuUeberWtBeton.html(accessed April 21, 2013).

“Bauformen Und Wasserhochbehaltern..” http://www.zagermann.de/proj/waturm/baufrmn.html(accessed April 28, 2013).

“Concrete Deterioration in Industrial Buildings..” http://www.drizoro-polska.pl/?site=uszkodzenia_betonu_3 (accessed April 28, 2013).

“Engineer’s Standpoint..” http://engineerstandpoint.blogspot.co.uk/2010/09/services.html (accessed April 21, 2013).

“Engineering Timelines..” http://www.engineering-timelines.com/scripts/engineeringItem.asp?id=216 (accessed April 21, 2013).

“Huta Hoch- Und Tiefbau..” http://de.wikipedia.org/wiki/Huta_Hoch-_und_Tiefbau (accessed April 28, 2013).

“MPWiK. Ogloszenie o Przetargu..” http://www.mpwik.wroc.pl/sub.php?613 (accessed April 14, 2013).

Allen, R. T. L. The Repair of Concrete Structures. 3d ed. 1980: Cement and Concrete Association, Slough.

Becher, Bernd, and Hilla Becher. Water Towers. New York: MoMa, 1988.

Collins, Peter. Concrete: The Vision of a New Architecture. Montreal: McGill-Queen’s University Press, 2004.

Dobesz, Janusz. “Zabytkowe obiekty techniki wodociagowej z terenu wojewodztwa wroclawskiego.” In Zabytki Techniki Wodociagowej Polski [Polish Waterworks Heritage], edited by Stanislaw Januszewski, 118. Wroclaw: KOZT RW NOT, 1989.

Dudek, Antoni. Wroclaw Karlowice 1699-1999. Wroclaw: Wydawnictwo Sw. Antoniego, 1999.

Gould, Michael. “The Reuse of Water Towers.” Journal of Architectural Conservation 8, no. 1 (2002): 23-37.

________. “Water-retaining structures in Britain before 1920.” In Historic Concrete: The Background to Appraisal, edited by James Sutherland, Dawn Humm, and Mike Chrimes, 326. London: thomas Telford, 2001. http://www.icevirtuallibrary.com/content/book/100475(accessed April 21, 2013).

Hawes, Frank. The Weathering of Concrete Buildings. 1986: Cement and Concrete Association, Slough.

Konarzewski, Leszek. “Renovation of the Façade of Centennial Hall in Wroclaw – Design Versus Its Accomplishment.” Conservation News 26 (2009): page nr.https://suw.biblos.pk.edu.pl/resources/i4/i9/i9/i2/r4992/KonarzewskiL_RenowacjaElewacji.pdf(accessed April 28, 2013).

![[Wroclaw #2] iOS Security - 101](https://static.fdocuments.us/doc/165x107/587cfa441a28ab1e7e8b4abd/wroclaw-2-ios-security-101.jpg)