Dt magazine 04

-

Upload

radical-communications -

Category

Documents

-

view

229 -

download

0

description

Transcript of Dt magazine 04

8122024

inside How timber is transported to tHe stores40 years and top trimmedFinland polisHes it’s diamondsdt QUiZ: win Cake witH yoUr CoFFee

issue 4 · WINTER 2008/9

4read page

Central and Eastern Europe

now also in

thanks to

poland

C z e C h R e p u b l i C

Slovak ia

Hungary

Romania

Stores in five countries in Eastern Europe have joined us since the last issue, bring-ing with them 458 new col-leagues. The name of the new division is Woodcote, which is based in Prague in the Czech Republic. We profile the com-pany, and inside the magazine you can read why being incor-porated into the DT family is almost like returning home for Woodcote.

DT Group now has stores in 10 countries, and there is one thing at least which they are all noticing at the mo-ment. Nowhere has it been possible to avoid hearing about the financial crisis, and nowhere will it be possible to avoid feeling its conse-quences.

However, there is no need to panic, according to our President & CEO Steen Weirsøe, who goes into more detail inside the magazine. Implementing savings is not the only way of surviving a downturn. We provide a cou-ple of specific and useful tips for how to boost sales.

If you have any good ideas or comments, you are always welcome to call or send me an email.

enjoy!Charlotte Gullach, [email protected]

12

ed

itor-in

-chie

f: Ch

arlo

tte G

ulla

ch (D

T G

rou

p). C

on

cep

t an

d p

rod

uctio

n: R

ad

ical C

om

mu

nica

tion

s, Pa

t Ma

y. article

s: Co

ng

o H

use

t, Ib K

eld

Jen

sen

. g

rap

hic d

esig

n: A

pp

etize

r.dk, S

imo

n Jo

hn

sen

. ph

oto

s: Fle

mm

ing

Sch

iller. t

ran

slatio

n: L

an

gu

ag

eW

ire. p

rint: Trykb

ure

au

et.

Content

DT Group +45 39559700Wolseley +44 118 929 8700Starkki +358 3 850 900Stark +45 89343434Beijer +46 752411000Neumann +47 55549800Silvan +45 87308730Cheapy +46 431443540DT Trade +45 39559700

UseFUl nUmbers:

40 years and top trimmed

18a matter

of strength

Cement produ-cts are hard to

distinguish, but there can be

differences in strength – and

price.

welcome to 458 new colleagues

en

welcome to woodcote

Hardtalk

7 generals for stark

keep an eye on the warning lamp

Finland polishes its diamonds

make sure you tick up-sales

dt Quiz

4

6

8

16

20

22

24

Magazine2

new store with two entrances

Neumann’s new 5,000 sq m store in Hauge-sund on the west coast

of Norway has one entrance for private consumers and one for trade customers.

Private consumers and trade customers are kept apart in the newly built Neumann store. The store has two separate entranc-es and car parks to keep the two customer groups separated. How-ever, this segregation is not part of a new strategy.

“No, it definitely isn’t. We have a similar, combined store in Tromsø. On the other hand, there is a par-ticularly strong focus on interiors,” says Neumann’s Managing Direc-tor Per-Erik Pedersen.

The newly constructed store

is the result of two acquisitions: Røthing in 2006 and Sandvold in 2007. The two stores each had their respective fortes within building products and interiors, and the former employees, who are now working for Neumann, have brought with them consider-able expertise.

The store is the thirteenth Neu-mann and there are plans to open more.

“But it won’t be this year,” says Per-Erik Pedersen.

B2B logistiCs sHoP

news: NEumaNN

B2B logistiCs sHoP

pleasUre in one’s work is . . .

. . . looking aFter oneselF

established:

Head office in:

total stores:

part of the dt group since:

managing director:

neUmann FaCts:

1859

bergen

13

1997

per-erik pedersen

I’ll let the truck do the work

for me

3Magazine

poland

C z e C h R e p u b l i C

Slovak ia

Hungary

Romania

sweden

norway

DeNMARK

f inland

greenland

woodCote

Magazine4

A warm welcome also to Neville Parry, the man who is almost

synonymous with the Woodcote brand. Even though Parry was not present when it all started, he is responsible for Woodcote as we know it today.

It all started back in 1992. A UK construction company oper-ating in Central and Eastern Eu-rope became frustrated at the

fact that it was unable to ob-tain good, solid building materi-als. At least, not of the quality it was used to in the UK. Conse-quently, the company decided to start its own builders’ mer-chant business and opened the first Woodcote store in 1992 with the ambition of establish-ing a chain across several coun-tries in Central and Eastern Eu-rope.

Now also in Central and Eastern Europe, thanks to

Please join us in welcoming 458 new colleagues from Central and Eastern Europe. You will find them in the Czech Republic, Slovakia, Poland, Hungary, Romania and Croatia, working at and supporting over 45 stores.

B2B logistiCs sHoP

Interior systemsInsulationFloors, walls and doorsWood products and timberBuilding chemistryRoofing and façade systemsDecorative productsExternal insulation systemsGeneral building productsOther materials

123456789

10

1992

1995

19961997199819992000

20062008

Woodcote product categories: Milestones:

ContinUed on page 11

Founded in the Czech RepublicNeville Parry becomes managing directorFirst store in SlovakiaFirst store in PolandFirst store in HungaryFirst store in RomaniaFirst store in Croatia (closed in early 2008)Wolseley acquires Woodcote Woodcote becomes a member of DT Group

5Magazine

How can we be sure that the products which we sell in the stores are manufactured according to our own ethical code?

First and foremost, it is impor-tant to remember that 90 per cent of what we sell comes from Nordic suppliers.

As with everything else, it is expected that the individual em-ployee lives up to the set guide-lines. That said, we can never be certain.

We check our sub-suppliers and require that they sign a dec-laration stating they will comply with our ethical code, and that their sub-suppliers do likewise, and we follow up on this by mak-ing unannounced visits.

However, at the end of the day it is a question of trust, and we choose our suppliers accord-ingly.

How high are ethical codes on the priority list when the market is experiencing a downturn?

It is nonsense to suggest that ethical codes are dependent on earnings. An ethical code is

about having a well-run business both during the good times and the bad.

And this is also true for our sub-suppliers. We have seen ex-amples of children and adults working barefoot in quarries, and this is not just unethical, it is al-so highly inefficient and has no place in a streamlined organisa-tion.

what will incorporating the east european wood-cote chain mean for the dt group?

In my view, not that much. But hopefully it will mean a lot for Woodcote. Like the DT Group, Woodcote primarily sells to the construction sector – that side of the business which we call ‘heavy side’. Wolseley, on the other hand, mainly sells plumb-ing, ventilation and heating prod-ucts – what we term ‘light side’. Woodcote is therefore better off with us, and I have a feeling that they feel like they have returned home. In any case, I was given an incredibly warm reception when I visited them the first time.

Our ambition with Woodcote is, of course, to make it a lead-

Hardtalkwith Steen Weirsøe

Hardtalk

Magazine6

ing player in the five countries, and there is huge potential down there. I am in no doubt that, in the longer term, we will develop a shop structure with considerably larger units, similar to what we have seen in Scandinavia.

what are the implications of the new constellation in the executive manage-ment?

We will have a more specialised and con-structive manage-ment team, and it will be excit-ing to take on board a new approach and a dif-ferent cul-ture. If you want to take the lead, you can’t do the same as all the rest. I think everyone is look-ing forward to wel-coming Neville Parry, Woodcote’s new man-aging director, as part of group management.

in an enterprise with more than 7,700 employees, the distance to the top management may seem long. with Hardtalk, it becomes shorter, because here we put you in contact with dt group’s most senior manager. steen weirsøe answers your and your colleagues questions, however searching they are.

what would you like to ask steen? send your question to [email protected] don’t mince your words as you may remain totally anonymous.

7Magazine

distribUtion

How timber is transported to the stores:

7 generals for stark

This corresponds to 10,000 cubic metres of timber or almost seven times the world’s biggest tree, the American Giant Sequoia ‘General Sherman’, which stands in California, USA. This tree has a diameter of 32 metres, is 85 metres tall and is 1,500 cubic metres in volume.

Timber for Stark’s stores in Den-mark is transported via two routes. Either directly from the warehouse in Årstorp in Sweden across the Sound. Or from Stark’s warehouses in Hedensted (whitewood) or Hors-ens (pressure-treated wood).

First, a section manager, for exam-ple, telephones the call centre in Aarhus and orders the timber.

The call centre processes the or-der, passing it on to the warehouse in Åstorp; however, if it is an urgent order or an order for a more special-

ist type of wood, it is sent to the warehouses in either Horsens or Hedensted.

In Åstorp, a truck is loaded with tim-ber which follows a fixed route, de-livering the timber which has been ordered to the respective stores. It normally takes three to five days before the timber arrives.

However, timber can also be sup-plied from the warehouses in Hor-sens and Hedensted, which does not take as long if the wood is in stock. Sometimes within 24 hours.

in denmark, stark holds about 4,000 packs of timber in stock

Magazine8

B2B logistiCs sHoP

Linus Benjamin An-dresen, the warehouse foreman, can either be

found in his office or seated in a truck at the Stark warehouse near the small town of Hedensted in Jut-land. In fact, only two employees are working at the warehouse to receive and unload the eight truck-loads a day of whitewood and to pack just as many trucks and send them off with goods for Stark’s Danish stores.

“The challenge is to load the trucks in the best possible way. Ide-ally they should be completely full when they leave the warehouse,” says Linus Benjamin Andresen.

Even though the trucks, from DSV and the haulage firm Michael Sørensen, have a 90-cubic-metre capacity, Linus Benjamin is happy if he can load a truck with 60 cubic

metres of timber. It is the pack size and the pack composition which determines how much a truck can hold.

“But we also send trucks off with single packs of timber if, for example, it has been ordered for Sønderborg and there is nothing else to deliver in that direction – we don’t hold back the order. Ide-ally, we like to deliver the timber no later than the day after it has been ordered.”

The timber comes primarily from Sweden, but also from the Baltic States and Finland. However, in the past, unsold goods sometimes ac-cumulated, but this is no longer a problem.

“It doesn’t occur as often as it used to, but I can’t take the cred-it. It’s the buyers who look after that.”

linus loads eight trucks a day on average

9Magazine

At the Stark call cen-tre in Aarhus, Den-mark’s second-largest

city, Dorte Christensen receives orders from the stores. Dorte’s speciality is primarily pressure-treated wood from Sweden and Siberian larch, and this means that she always knows what is in stock.

“If I hear from the suppliers that they are running short of pressure-treated planks for ve-randas, when they call from the stores to place orders, I can sug-gest they order an extra pack to avoid the risk of running out,” says Dorte Christensen.

She is an important element in the break with the old builders’ merchant culture, where each builders’ merchant negotiated timber prices with individual sup-pliers.

“But it just doesn’t pay. The buyers have secured an attrac-tive price, and I can get hold of timber in 10 minutes instead of spending several hours out in each store.”

She refers to the large ware-house belonging to the major supplier Rörvik, which is located in Åstorp in southern Sweden and close to the Sound, as ‘our ware-house’.

B2B logistiCs sHoP

distribUtion

dorte manages the deliveries

Magazine10

However, it didn’t quite turn out that way. After the first three years, the ambitious plan was still in its early start-up phase with only a single store and less than impressive sales: EUR 0.75 million.

This called for immediate ac-tion. As a result, a new manag-ing director arrived in Prague in late 1995 – Neville Parry. He quickly assessed the situa-tion and started to implement a turnaround. Parry engaged in-vestors to develop Woodcote both geographically but also in terms of its product range.

From 1995 to 2000, Woodcote opened new stores in Slova-kia (1996), Poland (1997), Hun-gary (1998), Romania (1999) and Croatia (2000). In 2002, sev-en years after Parry took over, turnover had grown to EUR 30 million. Or forty times what it

B2B logistiCs sHoP

woodCote

what division would you say is most similar to woodcote?“It’s always difficult to make comparisons since Woodcote was developed to focus on a totally different market, but if I have to I would say Stark in Denmark is my best bet. Not in terms of size though. The smallest Stark store is the same size as the largest Woodcote store.”

what is your strategy?“At present the market is slowing down so we are con-solidating in order to reap the full benefit when the market starts to pick up again.”

How will woodcote benefit from dt group?“First of all from having a

similar mentality since you understand our business. Secondly, you have a good range of private label prod-ucts. And we can certainly use your experience, prod-uct portfolio and, for exam-ple, the Chinese sourcing.”

How will dt group benefit?Romania and Poland. More-over, we have a private label called Extherm, which is a high-quality, modern exter-nal facade insulation sys-tem – and which is probably interesting for DT Group. But realistically we will ben-efit far more from being a part of DT Group than vice versa. Probably 95 per cent vs 5 per cent.”

FoUr CHallenging QUestions For

managing director of woodcote

Neville Parry

ContinUed From page 5

ContinUed on page 15

11Magazine

silvan’s History

a n d t o p t r i m m e dyears

Year

Branches

Staff

Revenue in mio. DKK

Geographies opened

1970 198068 69 71 72 73 74 75 76 77 78 79 81 82

1 1 2 4 4 4 5 5 7 8 9 9 9 9 9

Sla

gel

se

Årh

us

Ålb

org

, Ra

nder

s

Gre

nå

Ma

rib

o, H

olb

æk

Græ

sted

Fre

der

icia

sales catalogue from 1977life broadcast from silvans’ branche in slagelse

erik kofoed, silvans’ forst branche manager

Magazine12

B2B logistiCs sHoP

The first store opens in Slagelse on Zealand with warehouse staff wearing white working coats. The store is named Silvan after the Latin for wood, silva.

Silvan becomes an independent chain. Until then, the stores have not had any significant joint purchasing.

Takes over Superbyg’s stores in Valby and Glostrup

Silvan takes over 4K’s five stores

The first Swedish Silvan store opens in Jönköping, and a few days later one in Stockholm

Highlights1968 1982 1989 1990 1997

a n d t o p t r i m m e d

8483 85 86 87 88 91 93 95 97 9989 92 94 96 98

1110 12 13 14 15 24 24 26 31 33 3518 24 24 24 27 32

1990 2000

Ho

rsen

s

Nyk

øb

ing

F

Od

ense

Fre

der

iksh

avn

Nyb

org

Esb

jerg

Hill

erø

d, V

alb

y,

Glo

stru

p

Sve

ndb

org

, Ro

skild

e,

Ba

lleru

p, A

lber

tslu

nd,

Gla

dsa

xe, R

ibe

Silk

ebo

rg,

Nø

rreb

ro

Bir

kerø

d

Ske

jby,

Hel

sing

ør,

Jönk

öp

ing

, Sto

ckho

lm

Fre

der

ikss

und

Vej

le

Fis

keto

rvet

, G

öte

bo

rg

1730

silvans first lorry

interior in the seventies

13Magazine

silvan launches its e-shop

silvan now also in malmø

B2B logistiCs sHoP

silvan’s History

against today’s yardstick

and based on what we know about Silvan, there was not the same degree of systematisation and organisation in Silvan’s early years.

For example, efforts to systematise historical data did not really start until 1989, which explains why the elements in the timeline do not

always go right back to the joyful opening days in 1968.

a n d t o p t r i m m e dyears

Year

Branches

Staff

Revenue in mio. DKK

Geographies opened

200801 02 03 04 05 06 07

42

2104

46 46

2343

1646 1727 1872 1890

46 47

2685

48 50 51

2794

Ha

der

slev

, Tå

rnb

y,

Nyk

øb

ing

S,

Vä

ster

ås,

B

orå

s,

Esk

ilstu

na,

Sun

dsv

all

Vib

org

, Ha

lmst

ad

, Lu

nd, Ö

reb

ro

Ma

lmö

Va

nlø

se

Ko

ldin

g, G

reve

Sø

nder

bo

rg

Magazine14

was when Parry took the helm in 1993. This impressive growth in turnover is due to extending the product range, novel stores and a steadily increasing sales force in all countries.

In 2006 Wolseley decided to acquire Woodcote. And in ear-ly summer 2008, Woodcote be-came a part of the DT Group. What about Parry? Well, he is still in the driving seat. And per-forming well too – turnover for 2008 is expected to exceed the EUR 100 million mark.

new productsMarcel Simko has been working at Woodcote for three years. He is a sales director in Slova-kia and is happy to share his expectations for the future af-

ter joining DT Group. “I feel great about the latest devel-opments and I am happy to be a part of DT. I think Woodcote can benefit from DT Group’s ex-periences. I also hope it means that we see a range of new products in our assortment, for example PVC products within waterproofing and thermal in-sulation.”

woodcote in a nutshellWoodcote’s core business is supplying interior systems, in-sulation and external insulation systems. Today, this represents approximately 50 per cent of Woodcote’s sales. Woodcote sells a wide range of specialist and general building materials to the construction industry.

B2B logistiCs sHoP

woodCote

Founded: 1992

total number of employees: 458

total number of stores: 45

location and number of employees in head office: Prague, Czech Republic, 5 employees

slogan: Strength in partnership

mission: Woodcote supplies a complete assortment of high-quality building materi-als

Customers: Professionals, mainly interior specialists and installation contractors

Woodcote facts:

Czech republic

slovakia

Hungary

romania

poland

Country

138

80

17

80

124

Employees

9

10

4

9

13

Stores

Prague

Bratislava

Budapest

Cluj

Warsaw

Head office

ContinUed From page 11

15Magazine

Crisis management

If the red light on a car’s dashboard comes on, you have to pull

over quickly to find out what is causing the problem.

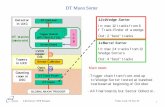

Plan 45 for DT Group compa-nies functions in just the same way. If staff costs exceed 45 per cent of gross profits, you have to take stock in the stores, establish what is wrong and then tailor the costs as quickly as possible.

This offers a simple recipe for how DT Group can survive the fi-nancial crisis. President & CEO Steen Weirsøe denies that head office has plans to fire staff.

“It is up to the local managers to react. There is no need to im-plement cutbacks in Svendborg

The financial crisis is also impacting DT Group companies, but there is no need to panic accord-ing to President & CEO Steen Weirsøe, who is impressed by the staff manning the stores.

if it’s going badly in Elsinore,” he says, adding that these two loca-tions have been chosen at ran-dom.

However, Steen Weirsøe does say that if DT’s stores have few-er customers, it will not be nec-essary to have as many staff to serve them.

“The first task is to attract the right customers and the right or-ders. Construction work hasn’t come to a complete standstill. There are still cars on the road – the customers are there.”

Steen Weirsøe says that DT Group has 10 per cent of the Nor-dic market.

“This means that 90 per cent are buying elsewhere, and so it

keep an eye on the warning lamp

Magazine16

B2B logistiCs sHoP

keep an eye on the warning lamp

is also a question of looking at the possibility of winning market share rather than just focusing on cutbacks.”

And there is a lot which the individual employee can do. One example: If a customer comes in to buy paint, he will also look at which brushes he might need. Some customers shop around. By identifying with the customer and understanding his or her needs, it might be possible to ensure that they buy everything in our stores.

“It is not just about selling products at attractive prices – but sometimes also about provid-ing logistical help, such as making sure the floorboards are not deliv-ered before the roofing beams.”

Steen Weirsøe reckons that DT is well prepared for the downturn.

“I am very impressed by our shop staff. Even though some businesses have gone bust, gen-erally speaking we have not suf-fered any losses.”

Last year DT Group returned the best result in the entire Wolseley Group with a profit of DKK 1.4 billion on a turnover of DKK 22 billion.

But now it is a new finan-cial year, and it is time to tighten one’s belt. Consequently, the ex-ecutive management has decided

to replace some of the monthly meetings between the division-al managers with telephone con-ferences to cut travel costs and boost efficiency.

dt trade wound upAt the end of September, DT Trade was wound up as an in-dependent division and the indi-vidual units were transferred to existing chains in the respective countries.

It means that Starkii in Fin-land, Beijer in Sweden, Neumann in Norway, Stark and DT Group HQ in Denmark have been joined by a number of new colleagues.

Steen Weirsøe explains the reason for the decision:

“DT Trade has presented many plans for how it was possible to generate satisfactory earnings. After its failure to do so last year, which was, after all, a fantastic year for the business, I found it difficult to see how it could suc-ceed when the market is declin-ing.”

But, with the exception of 4a in Denmark, he does not expect the individual employees in the vari-ous units to notice the decision.

However, the DT Trade secre-tariat, which had ten employees, has been closed.

17Magazine

strength

top tools

Most people would not give it a thought, but cement is nothing

more than a binding agent. On its own, cement is not that useful, but if you mix the grey powder with sand, stones and water and possibly a few chemical addi-tives, your end result is concrete.

And that is something durable.“Really, there is very little dif-

ference between one cement product and the next. For ex-ample, our own private label ce-ment RAW is the same top qual-ity as that from Aalborg Portland. In other words, the two cements are almost identical,” says Pur-chasing Manager Søren Lyse-mose from Danish Stark.

Up until two and a half years ago, Aalborg Portland enjoyed a cement monopoly at Stark, but in collaboration with the German company Zementwerk Berlin, Stark developed its RAW cement

Cement products are hard to distinguish, but there can be differ-ences in strength – and price.

a matter of

Magazine18

B2B logistiCs sHoP

which now has a market share of 12-14 per cent. RAW is 9 per cent cheaper than the rival product from Aalborg.

The cement is divided into the following strength classes: 32,5 MPa, 42,5 MPa and 52,5 MPa, which is the final compressive strength 28 days after laying.

Which cement to choose de-pends on the job: Stark has two types of cement in its RAW

range:1. raw portland

cement, which is fast drying with a fi-nal strength of ap-prox. 58 MPa, mak-ing it suitable for all normal con-

struction work.2. raw Universal cement

sand-lime cement, which was de-veloped by Zementwerk Berlin to

satisfy Danish building traditions.

By comparison, Silvan sells a cheap-er sand-lime cement which, in terms of strength, cannot match the RAW

products.Regardless, cement is not a

product that is easily moved, not in terms of product devel-opment either, and according to people in the business there is

not exactly a lot of product de-velopment taking place.

The explanation for this is that the cement industry is a conservative sector where the rapid development of a new product can have unforeseen consequences.

How can you dry a newly laid cement floor as quick-ly as possible?

The water needs to come out of the concrete, and this is a process that takes time. Some people in-stall a dehumidifier, but it is impor-tant to be careful if you do, and also if you use a fan heater. If the cement dries too quickly, there is a risk of cracks forming. It is very important to follow the instruc-tions which are supplied, other-wise serious problems may arise.

is it possible to use cement to repair dental cavities?This is probably not a good idea. There are chemicals in the ce-ment which are best kept out of your mouth. Also, cement does not taste good, and it is grey in colour.

Can you make your own parasol stand from cement?Of course, but it is probably a good idea to first mix it with something. Cement is just a bind-ing agent. Try using RAW universal concrete.

... is a grey powder used for making concrete and certain types of mortar. Cement mortar is a mix of cement, water and sand.Cement is made from three quarters lime and one quarter clay. the lime and clay are mixed together and heated to produce clinker. the clinker is then ground to

a powder, which is the finished cement.when the cement is mixed with water, it be-gins to harden. Hardening involves a chemical proc-ess which produces heat. if the cement mix is un-derwater or is constant-ly sprayed, the cement takes longer to set. this can be used to achieve a stronger final result.

... is an artificially produced con-struction materi-al which consists of sand, stone, water and ce-ment and possi-bly chemical ad-ditives.

CeMent ConCrete

19Magazine

staFF

Five days a week, 56-year-old Juha Pyykkönen spends

an hour walking. He does so be-cause he wants to lose weight, reduce his blood pressure and to boost his energy levels. And, of course, because he has contract-ed to do so.

Juha Pyykkönen is one of four-teen Starkki employees over the age of 50 who are participating in an ambitious mental and physi-cal training programme which is designed to encourage its senior employees to stay on at Starkki while also giving them the oppor-tunity for personal development.

The promise which Juha Pyykkönen has given is part of the personal development plan which is drawn up for each par-ticipant. For example, the prod-uct manager from the head of-fice in Lahti has, after 33 years

diamonds

with Starkki, acquired a wealth of knowledge about sub-suppliers, which he is now making a point of passing on to younger col-leagues.

“It is immensely satisfy-ing being able to pass on what you know. Even though I might not have trained as much as I wanted, I am definitely in bet-ter shape, which gives me more energy at work,” says Juha Pyykkönen.

Mauri Ivonen, a buyer, has just finished his year-long participa-tion in ‘Under the diamond’, the name given to the project. For him, the most important aspect of participating was discovering that he was not alone in experi-encing the problems he faced.

“And it is the same wherev-er you work in Finland,” says the 58-year-old buyer, who works at Starkki in Lahti. He has appreci-

Finland polishes it’s

Juha pyykkönen

Magazine20

B2B logistiCs sHoP

diamonds

is to ensure Starkki has happy, satisfied and well-rounded em-ployees.

“We want to show that old-er people, too, can continue to develop by setting themselves goals and pursuing them,” says Juha Porkka, a consultant with Mercuri International, which is managing the programme.

The aims might also include pulling your weight more in re-lation to your family, organis-ing your work more efficiently or looking after younger colleagues.

The experience so far shows that most participants are in bet-ter shape at the end of the year. In one instance, a female employ-ee lost more than 20 kilograms.

“At the same time, partici-pants understand that Starkki values them as employees and really wants to hold on to them,” says Juha Porkka in conclusion.

ated being able to discuss solu-tions to joint problems and val-ues in general.

“I think that Starkki will be-nefit from the fact that those of us who participated will continue to be good and stable employ-ees, and that we are aware of the need to share our experience with our younger colleagues, which is very important,” says Mauri Iivonen, who has been at Starkki for 36 years.

The programme runs over one year, with participants coming together several times for two and three-day meetings. This in-cludes being physically tested at the same place as the proud Finnish ice hockey team.

However, physical form is only part of the programme. The par-ticipants’ mental wellbeing and way of life are assessed and pre-sented for closer study. The aim

Starkki will retain it’s older employees through offering physical and mental training programmes to those who most need it.

mauri iivonen

21Magazine

Cross-sales:Selling a supplemen-tary product or serv-

ice to an existing customer. For example, brushes and masking tape to a customer who is buy-ing paint.

three useful tips:

1 Allow things to take their course. Many opportunities

for cross-sales arise of them-selves.

2 Stick to the point. If you drown the customer in too

many cross-sale suggestions, you risk spoiling everything.

3 Expert assessments are one way of supporting

There will be a battle for customers in a declining market. Two sales techniques, which are quite similar, can help secure additional sales from customers who have already walked in through the door. Here are a couple of tricks.

tick up-sales

cross-sales. Make special claims about the product and mention what professionals, experts and other customers have said in the same situation.

Up-selling:To encourage customers to pur-chase more expensive items in an attempt to generate more profit on the transaction. For ex-ample, selling a more expensive, more advanced machine than the one which the customer ini-tially showed an interest in.

effective up-selling strategy:

1 You need to assume that the customer wants the

product which you want to sell.

ask tHe gUrU

Magazine22

2 Start the up-sell by briefly describing the product’s

features. Then, if possible, men-tion something completely unique about the product you are selling.

3 Then ask the customer’s permission to describe the

product. This way you avoid seeming too forceful.

specific examples:Imagine that you are a waiter and you have to sell a dessert. There is a right way and a wrong way:

the wrong way:Imagine a restaurant where a group of customers have just fin-ished eating a large main course.

B2B logistiCs sHoP

Name:

Address:

Zip and City:

Country:

Phone:

E-mail:

Employed at:

send this coupon to dt group, att.: Charlotte gullach, gladsaxe møllevej 5, dk-2860 søborg, denmark

1:2:3:4:5:6:

A B C

yoUr answers

You ask: “Would anyone like des-sert?”

In saying “yes”, a customer can feel that they look like a glutton, so many customers will opt to say no out of sheer politeness. Result: no sale.

the right way:The skilled salesperson/waiter does not ask whether any of the customers would like dessert. He assumes that they do.

He therefore takes the dessert menu card and passes it round, saying: “To round off your meal with something sweet (that is the benefit), please take a look at our dessert menu. Would you like to hear about our most popular des-serts? (Asks for permission.)

Now the customer has giv-en his permission. Avoid listing the desserts by saying, “This is a chocolate mousse.” Instead, try saying:

“If you like chocolate, you will love this dish. We have a choco-late mousse that simply melts on your tongue, and is really some-thing special.”

the biggest mistakes when up-selling:

No attempt to up-sell The salesperson seems over-bearing

The up-sell is not sufficiently convincing, so the customer automatically rejects the pro-posal

B2B logistiCs sHoP

QUiZ

527

YO

U M

US

T P

AY

TA

x O

N T

HE

PR

IZE

QUiZQUiZ

the winner of a branche party is sub-manager odd H. eriksen from neumann in tromsø, norway.

“We are planning a party for all 25 employees in the store. We did discuss having a barbecue, although we haven’t decided yet what to do, but we do know that it will definitely be fun.”

no less than employees par-ticipated in our bezzerwizzzer com-petition featured in dt magazine nr. 3

1 where does the name ‘silvan’ come from?

A After its founder (Jonathan Silvan)

B It is Latin for ‘wood’

C It is Old Norse for ‘construction’.

2 in which countries is woodcote repre-sented?

A Poland, Romania, Slovakia, the Czech Republic and Hungary

B Poland, Slovakia, the Czech Re-public, Hungary and Latvia

C Poland, Slovakia, the Czech Re-public, Hungary and Croatia

3 How many neu-mann stores are there in norway?

A 3B 13C 23

4 where can you find the world’s biggest tree?

A California (USA)B New South

Wales (Australia)C Chengdu (China)

5 what is the princi-ple behind ‘plan 45’?

A The number of employees at any one store must not exceed 45

B Staff costs must not exceed 45 per cent of gross profits

C 45 per cent of gross profits must come from timber

6 where and when did the first silvan store open its doors?

A 1968 i AarhusB 1968 i SlagelseC 1982 i Horsens

Use the coupon on the other side or send your answers by e-mail to: [email protected]

Cakewith your coffee

the prize for winning this issue’s dt Quiz is dKK 5,000 which is ear-marked for coffee and cake for you and your col-

leagues.

Whether you have a mas-sive cream cake once a month or Danish pastries every Friday is entirely up to you.

but first you must answer the following

questions:

– every

Friday!

send your answers before February 15th!

please flip the page for the response coupon