DSS Valve

-

Upload

shankar-raj -

Category

Documents

-

view

106 -

download

1

description

Transcript of DSS Valve

DSS

DOUBLE SAFE SHUT VALVES

TECHNICAL MANUAL

RIZZIO SPA www.rizzio.it [email protected]

ITALY – 13018 Valduggia (VC) - via Circonvallazione, 37

Ph. 0039 0163 438 911 Fax +39 0163 48 181

DSS TECHNICAL MANUAL

RIZZIO Spa

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PAR-TY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. – VALDUGGIA (VC) – ITALY

G.M. P.M. DATE OF ISSUE LAST REVISION DATE OF LAST REV. PAGES

Masso Paolo 28/05/09 04 2 / 8

Contents

Page

1. GENERAL DESCRIPTION 3

2. DSS - MAIN FEATURES 3

3. LINE BLIND AND DOUBLE SAFE SHUT COMPARISON 4

4. ATTACHED DOCUMENTS 4

DSS TECHNICAL MANUAL

RIZZIO Spa

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PAR-TY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. – VALDUGGIA (VC) – ITALY

G.M. P.M. DATE OF ISSUE LAST REVISION DATE OF LAST REV. PAGES

Masso Paolo 28/05/09 04 3 / 8

1. GENERAL DESCRIPTION DSS valves satisfy IBC code par. 1.3.24 and solve the uncertainty leaking risks and all the very complex and delicate tightening procedures typical of the Line Blind valves.

2. DSS - MAIN FEATURES Auto emptying and very sturdy body, bonnet and cover entirely bolted to protect the trim, to grant internal discs movement on specific guides and to reduce any type of maintenance. DSS can be used in any possible position. Double, independent, symmetrical, bi-directional and no floating blinded discs with a central no floating cast wedge that segregates pipelines in two independent isolate parts. The discs are realized from flat stainless steel to prevent any possible passing leakage from the parts. Capacity to segregate two different fluids at difference pressures. Tightness recovering having pipelines in pressure. Double primary metallic seat on the discs also for propylene oxide. Double secondary dynamic and energized PTFE seat for bubble tightness. Rising shaft for a distant visual indication of the valve position. Lockable hand wheel or lockable hydraulic actuator. Lateral inspection door for ambient air communication with the internal body and maintenance procedure inspections. No dismantling procedures are required to segregate the valves and so very low operating costs. One or two option draining valves will make possible the recovering of the internal mixing of cargo product on a return tank. Moreover DSS valves can be used according to the “DEMO C 2002_05 rev 0” drawing and so with only one butterfly valve on condition that it is provided with the additional metal seat according to Fire Safe Design. The segregation can be identified from the group valves composed by one DSS and one 2D Butterfly. The two draining valves can be used to check the two independent chambers and to control any possible leak between them. The segregation is grant from several factors : the DSS is protected in order to avoid any big loss leakage. Also in case of damaged seat the valve will never allow the passage of big flow but only of few drops; anyway there will be 2 + 2 seats to protect. The opposite side on butterfly valve will have moreover 2 seats, which avoids the fluid contact towards the DSS valve. The chambers can be inspected in differential mode, in order to verify any possible leakage and its location. Also in case of two non-miscible fluids in pressure one against the other there will be the possibility to collect them from the two draining valves in two independent lines.

DSS TECHNICAL MANUAL

RIZZIO Spa

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PAR-TY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. – VALDUGGIA (VC) – ITALY

G.M. P.M. DATE OF ISSUE LAST REVISION DATE OF LAST REV. PAGES

Masso Paolo 28/05/09 04 4 / 8

3. LINE BLIND AND DOUBLE SAFE SHUT COMPARISON LINE BLIND FLANGE VALVES DSS - Double Safe Shut ValvesValve location For safety reason, it’s correct to never

locate a Blind valve under a cargo tank column like a tunnel or in the pump room. The only safe place is the deck on the cargo product column.

DSS valves can be placed in any location also under a cargo tank.

Overflow risk Independently from the location, in case that a seat leakage is bigger then the drain plug capacity, the cargo product will be poured out of the valve with all the possible risks. This is due to the absence of the cover that cannot be placed when the discs are inside of the body.

There are no possibilities of overflow because the conical metallic seats are self-cleaning during the valve closing and so able to reduce any leak also in case of dirtiness. The valve body is only one piece and it is entirely close so no external overflow is possible.

Water hammer In case of water hammer the disc and body structure will never grant any sure protection when the valve is closed. The too thin shaft is not able to contrast any lateral water hammer. Mostly on our competitor valves where bodies and discs are welding constructions.

The cast body is so sturdy that it cannot be affected by water hammer problems. We have built over 500 cargo ships with such body type with-out any problem.

Positioning Blind valve can be placed only in ver-tical position.

DSS can be placed in all posi-tions. These must be decided in advance for the drain plugs posi-tioning in the bottom place.

Preventive Air test procedure

For a safe segregation procedure, af-ter the discs introduction and their closing in the body, it would be correct a tightness air test in order to avoid cargo products losses in case of seat leakage. This preventive action is rarely done because too long and complex.

All the closing procedures are to-tally safe. This is because the tightness is done simply operat-ing by a hand wheel or in a re-mote way by an actuator. No spanners are required and no preventive actions are to be taken to tight the valves.

Tightness re-covering when lines are in pressure

The tightness recovering is never possible. The internal screw is not able to tight the discs under pressure due to a high torque request. 10 bar of pressure corresponds to a force of 1767 Kg on DN 150, of 3142 Kg on DN 200 and of 4909 Kg on DN 250.

One big advantage of DSS is that the recovering of the tight-ness is always possible.

DSS TECHNICAL MANUAL

RIZZIO Spa

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PAR-TY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. – VALDUGGIA (VC) – ITALY

G.M. P.M. DATE OF ISSUE LAST REVISION DATE OF LAST REV. PAGES

Masso Paolo 28/05/09 04 5 / 8

Preventive me-tallic body seats inspec-tion.

When the Blind has to be closed it’s necessary to inspect carefully the me-tallic body seat surfaces. They have to be like mirrors. Scratches, sedi-ments or any form of scale will never give a perfect disc support or o-ring grip. In case of damages it’s neces-sary to dismount the body from the flanges and to grind it on a machine.

No preventive actions to control the seats are foreseen. The internal wedge is moving in internal body tracks that do not allow any contact between the components.

Preventive me-tallic disc seats inspection.

In the same way the two metallic disc seat surfaces have to be inspected. In case of damages it’s necessary to dismount them from the flanges and to grind them on a machine.

For the same reasons the inter-nal discs can’t be damaged dur-ing their stroke and so no inspect actions are required.

Preventive disc soft seats in-spection.

The two soft o-rings must be checked, simply passing a finger on them to verify the scratches absence. It's preferable to change them at any closing operation.

The two soft seats are totally protected in their stroke. The in-spection door will leave the pos-sibility to inspect them during the periodical but very rare mainte-nance procedures.

Soft seat de-formations

The competitor’s valves without me-tallic seats are provided with only flat gaskets that, working statically, suffer of permanent deformations. The main gaskets have to be changed at any closing operation.

DSS are built to have a primary metallic seat for each side plus additional soft rings for bubble tightness. The two soft seats have to be changed only during the programmed and very rare maintenance procedures.

External disc fixing

The two discs, when are not used, are to be placed in vertical, safety and fixed position on a special support in order to avoid any collision or drag-ging with other external elements.

No components are to be placed out of the valve.

Disc introduc-tion

The two discs have to be introduced carefully, avoiding any metallic con-tact with the internal body. A contact can create permanent damage on the machined surfaces.

Vertical and guided movement protects all the mechanical con-tact.

Help of a crane In the biggest sizes is necessary to use a crane in order to avoid big ef-forts that would increase all the possi-ble mechanical contact of the parts.

Not required.

DSS TECHNICAL MANUAL

RIZZIO Spa

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PAR-TY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. – VALDUGGIA (VC) – ITALY

G.M. P.M. DATE OF ISSUE LAST REVISION DATE OF LAST REV. PAGES

Masso Paolo 28/05/09 04 6 / 8

Closing proce-dure, hesita-tion and exter-nal tools.

The valve has to be closed, rotating the internal tightening screw by means of a spanner in a very reduced rotation angle. An extra force has to be applied when the discs are in con-tact against the body seats applying a resolute and constant force in only one step in the last degrees rotation. Any hesitation of this will not assure the reaching of the tightness end po-sition and it will require to repeat this procedure after the pressure test.

The shaft and yoke threaded, the dimensioning of the hand wheel plus a perfect respect of the conical angle of body and disc seats, by means of CNC machin-ing centre, will grant a very sim-ple closing operations where the use of two arms is enough to tight the valve. No spanners or special tools are required.

Cover and his gasket inspec-tion

In the same way the cover and the top cover o-ring have to be inspected in advance.

We have only a lateral inspection doors corresponding to the clos-ing of a small flange.

Cover gasket In case of competitor valve the top cover seal is a flat gasket that, work-ing statically, suffers of permanent de-formation. It has to be changed during all closing operations. In our valves the gasket is dimensioned for a dy-namic tightness and it grants a capac-ity to adapt itself to the external profile of the groove when the pressure will move it against it. This requires very rare replacement.

Please see the previous item.

Cover closing procedure

The cover must be positioned and tight in a perfect parallel way to the top valve body. The two nuts have to be screwed down simultaneously, op-erating with a correspondent number of turns and torque for every nut. A wrong closing procedure of the cover will surely involve external fluid losses. So it’s once more preferable to test the line with air before the pipe-line is in use with cargo products.

Please see the previous item.

Cargo gas The opening of cover and disc risk to have external pouring of cargo gas product surely hazardous for the op-erator.

DSS let you open the discs when the valve body is closed. The in-ternal gas can be drained out by its valve and recovering pipe. No risks for the operators.

DSS TECHNICAL MANUAL

RIZZIO Spa

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PAR-TY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. – VALDUGGIA (VC) – ITALY

G.M. P.M. DATE OF ISSUE LAST REVISION DATE OF LAST REV. PAGES

Masso Paolo 28/05/09 04 7 / 8

4. ATTACHED DOCUMENTS

• RINA Approval

MAC/FSC/36060 date 6/7/2005

• DSS Segregation functionality

P24100-00010-Functional Views

• Segregation with one DSS valve and one 2D Butterfly valve

DEMO C 2002_05 rev.0

• DSS – dimensional drawing

P24100 5 DSS ISO 5752 S3 Manual Operated 02 P24100 7 DSS ISO 5752 S3 with LDD Actuator 02 P24200 5 DSS ISO 5752 S15 Manual Operated 02 P24200 7 DSS ISO 5752 S15 with LDD Actuator 02

DSS TECHNICAL MANUAL

RIZZIO Spa

THE COPYRIGHT / OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZZATION OR BROUGHT TO THE KNOWLEDGE OF A THIRD PAR-TY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO S.P.A. – VALDUGGIA (VC) – ITALY

G.M. P.M. DATE OF ISSUE LAST REVISION DATE OF LAST REV. PAGES

Masso Paolo 28/05/09 04 8 / 8

5. REVISIONS HISTORY

Author Date Revision Comments PM 28/05/2009 04

PM 03/05/2009 02 Renamed file, annexed and dwg update

GM 23/10/2007 01 New format

`0.100`0.100LENGHT :

DIAMETER :

GENERAL TOLERANCES

SPECIFIC INDICATION

ONLY FOR QUOTA WITHOUT

ANGLE : `0.25°

FILE

TITLE

--

REVISION DESCRIPTION

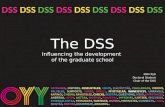

P24100-00010-Functional Views r 01

DOUBLE SAFE SHUT VALVE 2103 OS&Y HAND OPERATED ISO 5752 S3

--

DWG

Ph. +39 0163 47 107 - Fax +39 0163 48 181

P24100-00010

--

--

03 --

DATE

FUNCTIONAL VIEWSRIZZIO Valvole spa

OR BROUGHT TO THE KNOWLEDGE OF A THIRD PARTY. CONTRAVENTION WILL BE PROSECUTED. RIZZIO VALVOLE S.p.A. VALDUGGIA (VC) ITALY

--

REV.

02

01

G S

--

--

DESIGNER

www.rizziovalvole.com THE COPYRIGHT/OWNERSHIP OF THIS DOCUMENT IS AND WILL REMAIN OURS. THE DOCUMENT MUST NOT BE USED WITHOUT OUR AUTHORIZATION

--

00 09/09/2004

--

Via Circonvallazione, 37 - 13018 Valduggia (VC) ITALY

FLUID 1 FLUID 2

FLUID 2VALVE CLOSED

VALVE OPEN

FOR INTERNAL USE ONLY

FLUID 1

INTERNAL SEGREGATION AIR

BLIND DISC Nr.1 BLIND DISC Nr 2

EXPANSION WEDGEOPTIONAL DRAINING VALVE