DRAWER SLIDES

-

Upload

kiayada-blanchard -

Category

Documents

-

view

67 -

download

0

description

Transcript of DRAWER SLIDES

KPL CHINA SOURCING CO., LTD.

Mail: [email protected]

Website: www.kplchinasourcing.com

DRAWER SLIDES

INTRODUCTION QUALITY STANDARD PRODUCTION

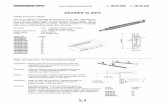

Drawer Slides Classification

The type of slides is determined by the design of the running elements.1. Guide rails: plastic rails act as gliding surfaces that support the weight of

drawers and their contents.2. Roller-guided drawer slides: the running elements are rollers. The type of roller

varies from friction bearing mounted nylon rollers to ball bearing mounted nylon rollers, ball bearing mounted nylon-coated steel rollers and silent moving rollers.

3. Ball guided runners: steel or plastic balls in ball cages are used as the running elements.

4. Concealed dynamic runners: rollers in running gear are used as the running elements.

Drawer slides classification rules

Drawer Slides Terminology

Drawer slides terminology

1. Load bearing capacity ( 1LB = 0.45kg ) The maximum load per slide pair. It’s a function of dimensions, rail thickness,

length, running elements material . Using a 18”(450mm) drawer slide to define rated load bearing capacity.2. Drawer slide length The longest dimension of a fully closed slide. 3. Half extension: slide opens partially, approximately ¾ slide length4. Full extension: slide opens the same length as the slide length5. Over travel: provide an extra extension beyond the normal extension of a full

extension length6. Self-closing: drawer automatically closed approximately 50mm out from the front

as it is being closed

1. Fixing hole center to the front edge of side panel distance: 37mm2. Fixing hole spacing pattern is: 32mm system3. Side panel drilling hole: Ø5mm

32mm System Drawer Slides

Furniture Hardware World Famous Brand

Hafele www.hafele.com

Blum www.blum.com

Hettich www.hettich.com

FGV www.fgv.it

Salice www.salice.com

Drawer Slide Quality Standard and Test

DIN EN 15338-2007: Hardware for furniture - Strength and durability of extension elements and their components

Drawer slide product standard

Test parameters

Test procedures and requirementsThree sets of extensions shall be used

First set shall be used for Overload test

Second set shall be used for Functional test

Third set shall be used for Corrosion test

1. Overload testDuring test, the extension element shall be loaded according to the load bearing capacity

1.1 Vertical downwards static overload

F=load bearing capacity but not higher than the maximum force specified in test parameter

Carry out 10 times

Drawer Slide Quality Standard and Test

1.2 Horizontal sideways static overload

1.3 Outwards static overload

F=50% load bearing capacity but not higher than the maximum force specified in test parameter

Carry out 5 times each direction

F=200N

Drawer Slide Quality Standard and Test

1.4 Slam-shut/open

Velocity=1.0/1.3 m/s

10 times for shut and open

2. Functional test

During test, the extension element shall be loaded according to the load bearing capacity

2.1 Operating force

When the load bearing capacity is less than 40kg, the open and closing force shall not exceed 50N

When the load bearing capacity is >= 40kg, the open and closing force shall not exceed 12.5% of load bearing capacity

Drawer Slide Quality Standard and Test

2.2 1st Vertical downwards static overload

F= 25% load bearing capacity but not higher than the maximum force specificed in test parameter

Carry out 5 times each direction

2.3 1st Horizontal sideways static overload

F=50% load bearing capacity but not higher than the maximum force specificed in test parameter

Carry out 5 times

Drawer Slide Quality Standard and Test

2.4 Durability

Grade 1: 20,000 cycles

Grade 2: 50,000 cycles

Grade 3: 80,000 cycles (if loading capacity is >15kg: 60,000 cycles

Premium grade: 100,000 cycles

2.5 Deflection of front

The deflection shall not exceed 4% of the extension length

Drawer Slide Quality Standard and Test

2.6 2nd Vertical downwards static overload

F= 25% load bearing capacity but not higher than the maximum force specificed in test parameter

Carry out 5 times each direction

2.7 2nd Horizontal sideways static overload

F=50% load bearing capacity but not higher than the maximum force specificed in test parameter

Carry out 5 times

Drawer Slide Quality Standard and Test

2.8 Operating force

When the load bearing capacity is less than 40kg, the open and closing force shall not exceed 50N

When the load bearing capacity is >= 40kg, the open and closing force shall not exceed 12.5% of load bearing capacity

2.9 Slam-shut/open

Velocity=1.0/1.3 m/s

10 times for shut and open

Drawer Slide Quality Standard and Test

3. Corrosion testEN ISO 6720-2: Paints and varnishes - Determination of resistance to humidity - Part 2: Procedure for exposing test specimens in condensation-water atmospheres

Requirement: 3 cycles AHT

EN ISO 9227: Corrosion tests in artificial atmospheres —Salt spray tests

Requirements: 24 hrs (general products) Ra/Rp=7/9

48 hrs (premium products) Ra/Rp=7/9

4. Other requirements( not included in DIN EN 15338-2007)

1. Surface requirements: surface dent mark, scratch, burrs etc. should be in a certain limit

2. Smoothly open and close, don’t have big noise

3. Extension length accuracy

4. Gaps between case, drawer member should be in a certain limit

5. Package: retail package or bulk package

retail package: 1 pair in one polybag or in one box, include accessories

bulk package: 20-30 pairs in one carton box, include or don’t include accessories

6. Product logo and printing: according to customer requirements

Drawer Slide Quality Standard and Test

Drawer Runner Production and Quality Control Plan

1. Raw materials

2. Rolling

3. Punching

1. Cold rolled carbon steel

2. Steel ball, package material, accessories etc.

3. Incoming quality control, inspection plan, inspection report

1. Rail section dimension, tolerance:

2. Rolling surface quality

3. In process quality control, inspection plan etc.

1. Punching dimensions, tolerance:

2. Punching surface quality;

3. In process quality control, inspection plan etc.

4. Powder coating / plating

5. Assembly

6. Final inspection and package

1. Epoxy coating or zinc plating

2. Coating layer quality, thickness, color

3. In process quality control, inspection plan etc.

1. Assembly methods, machine, effectiveness

2. Function test

3. In process quality control, inspection plan etc.

1. Package methods, according to customer requirement

2. 100% inspection before package

Drawer Runner Production and Quality Control Plan

Package Method

Retail PackagingThis retail packaging is required for certain markets. A specialized example of such a package would be product for the DIY store or online B2B store. This package contains a single pair of slides ( L hand & right hand ) along with a pack of screws, mounting brackets and quick installation instruction in one color box, then put 15 boxes in one carton box.

Distribution packagingThe wholesale distributors need this kind of package for his cabinet shop customers. A typical example would be: 15 pairs of drawer slides, each pair in its own poly bag, packed together in a strong carton box on which with company logo or barcode.

Industry PackagingIndustry package also called factory package is large scale package method upon on customers’ requirement.This package world typically have all right-hand slide members in one carton box and all left-hand slide members in another carton box.

Bulk packagingThis package is for high-volume customers. Slides are typically packed more than 250 pieces per box. These large box can be made out of wood or super heavy-loading corrugated cardboard, depending on product weight and customer requirements.

Package Method

The End

The End !