Drawer Slides

Transcript of Drawer Slides

Drawer Slides

Dra

wer

Slid

es

6

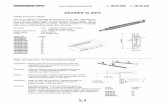

Side Mounting Drawer Slides

Special Features

! New smooth, silent roller system.

! Right side pair has lateral guiding.

! Left side pair has side gap adjustment.

! Tilt and remove of drawer.

! Stopper to prevent drawer from falling.

! New “Auto-Closing” feature of drawer.

! “System 32” compatible.

! Ribs provided for strength.

! Load capability - 20 kgs.

37.00

17.259.0

2.0

13.2

0

2.00

37.00Front Edgeof Cabinet

128.00 96.00 96.00 96.00 96.00

250

300

350

375400

450

500

525550

600

9.00

31.50 128.00 128.00 128.00 128.00 128.00

650

700

750

Drilling Diagram for Cabinet

Design Reg. No: 159024/87

7

Specifications

PowderCoatedBlack,BrownandIvory

Code Nos.

12.7(1/2”)

20

15.6(5/8”)

Length(mm)

Extension(mm)

Gap/Side(mm)

Max.LoadKgs.

Finish

SMDS 25 250 160

SMDS 30 300 210

SMDS 35 350 260

SMDS 37 375 285

SMDS 40 400 310

SMDS 45 450 360

SMDS 50 500 410

SMDS 52 525 435

SMDS 55 550 460

SMDS 60 600 510

* SMDS 65 650 560

* SMDS 70 700 610

* SMDS 75 750 660

For efficiency and durability.

1. Side gap of 12.7 mm (1/ 2”) and 15.6 mm (5/ 8”) per side is most important.

2. Fix slides parallel and at equal height.

Caution

SIDE VIEWFig. 2

25.4

mm

1"2.0

FIXED SLIDE

MOVING SLIDE

DRAWER

Top

Cle

aran

ce

CABINET

2.0

FRONT VIEWFig. 1

12.7

7.0

1/2"

1. Side gap of 12.7 mm (1/2”) per side required (Refer fig. 1).

2. Side gap of 15.6 mm (5/8”) per side is required for 650, 700 and 750 mm.

3. 25.4 mm (1”) clearance from top edge of drawer required to tilt and remove drawer

(Refer fig. 2).

4. Fixed and moving slide should be equally offset by 2 mm for Auto-Closing (Refer fig. 2).

5. Recess screw heads to avoid interference.

6. A set of slides must be fitted parallel and at same heights to each other.

Fitting Instructions

Fig. 3 Side Mounting D' Slide for Steel Furniture

12.7

1/2"

STEELCABINET

STEELDRAWER

WOODENDRAWER

12.7

1/2"

For Side Mounting Bottom Slide - EURO add 'E-' before the existing codes.* Not available in EURO series.For Side Mounting Bottom Slide - EURO add 'E-' before the existing codes.* Not available in EURO series.

! New smooth silent roller system.

! Right side pair has lateral guiding.

! Left side pair has side gap adjustment.

! Tilt and remove of drawer.

! Stopper to prevent drawer from falling.

! New ''Auto-Closing'' feature of drawer.

! ''System-32'' Compatible.

! Ribs provided for strength.

! Load capability - 20 Kgs.

37.00

17.259.0

2.0

13.2

0

2.00

37.00Front Edgeof Cabinet

128.00 96.00 96.00 96.00 96.00

250

300

350

375

400

450

500

525

550

600

9.00

Bottom Mounting Drawer Slides

Special Features

Drilling Diagram for Cabinet

SIDE VIEW

7.0

14.5

12.5

1/2’’

12.7

Fig. 1

8

Bottom Mounting D’ Slide for Steel Furniture

STEELCABINET

WOODENDRAWER

6.0

1/2’’

12.7

STEELCABINET

STEELDRAWER

6.0

1/2’’

12.7

1. Side gap of 12.7 mm (1/2”) per side required (Refer fig. 1).

2. 25.4 mm (1”) clearance from top edge of drawer required

to tilt and remove drawer (Refer fig. 2).

3. Fixed and moving slide should be equally offset by 2 mm

for Auto-Closing (Refer fig. 2).

4. Recess screw heads to avoid interference.

5. A set of slides must be fitted parallel and at same heights

to each other.

Fitting Instructions

For efficiency and durability.

1. Side gap of 12.7 mm (1/ 2”) per side is most important.

2. Fix slides parallel and at equal height.

Caution

Specifications

1"

2.0

FIXED SLIDEMOVING SLIDE

DRAWER

25.4

mm

Top

Cle

aran

ce

CABINET

2.0

SIDE VIEWFig. 2

Code Nos.Length(mm)

Extension(mm)

Euro Extension (mm)

For Bottom Mounting Bottom Slide - EURO add 'E-' before the existing codes.

PowderCoatedBlack,Brown,Ivoryand

Sliver

Gap/Side(mm)

Max.LoadKgs.

Finish

12.7(1/2”)

20

BMDS 30 300 225 210

BMDS 35 350 275 260

BMDS 37 375 300 285

BMDS 40 400 325 310

BMDS 45 450 375 360

BMDS 50 500 425 410

BMDS 52* 525 450 -

BMDS 55 550 475 460

BMDS 60 600 525 510

* Not available in EURO series.

9

12

Full Panel Drawer Slides

Lengthmm

Extensionmm

Height (mm)/Code Nos.

54 86 125

FPDS 54-30 FPDS 86-30 FPDS 125-30

FPDS 54-35 FPDS 86-35 FPDS 125-35

FPDS 54-40 FPDS 86-40 FPDS 125-40

FPDS 54-45 FPDS 86-45 FPDS 125-45

FPDS 54-50 FPDS 86-50 FPDS 125-50

FPDS 54-55 FPDS 86-55 FPDS 125-55

FPDS 54-60 FPDS 86-60 FPDS 125-60

PowderCoatedBlack,Brownand

Ivory.

Finish

300 225

350 275

400 325

450 375

500 425

550 475

600 525

Special Features

! Simplifies construction of drawer as it eliminates the sides of

drawer.

! Saves wood, labour, drawer space, time and cost, which

enhances bulk production.

! Tilt and remove capability with guiding.

! Auto closing of drawer.

! Front facia adjustment.

! Ribbed for strength.

! Precision rollers for smooth running.

! Load capability - 25 kgs.

! "System 32'' compatible.

! Stopper prevents drawer from falling.

! Also available with 6 mm bottom track easy to fit and helps in faster

assembly, as it does not require screwing the bottom, using 6 mm board in

place of 9 mm or 12 mm.

Drilling Diagram for Cabinet ( 6mm Bottom Track )

Front Edge of Cabinet

600

37.00

9.00128.00 96.00 96.00 96.00 96.00

2.00

550

525

500

450

400

375

350

300

Specifications

10

For efficiency and durability.

1. Strictly maintain side gap of 15.5 mm per side.

2. Fix slides parallel and at equal height.

3. Do not apply paint or polish.

Caution

1. Side gap of 15.5 mm per side is required and acts as side panel of

drawer. (Refer fig 1).

2. Clearance of 25mm from top edge of drawer required to tilt and

remove drawer. (Refer fig 2).

3. Fixed slide should be set by 2mm for auto-closing. (Refer fig 2).

4. Screws should be recessed to avoid fouling.

5. Fixed slides should be fitted parallel and at equal height to each other.

6. Front fascia is to be fitted into front brackets which have 2-way

adjustment for alignment.

Fitting Instructions

A B C D(mm) (mm) (mm) (mm)

54 71 52 32

86 103 84 64

125 142 123 96

150 167 148 96

SIDE VIEWFig.2

FRONT VIEWFig.1

8.5

15.5

17.01.3

A D CB

Wooden Shelf

Full Panel with 6mm Bottom Track

CABINETTop

Cle

aran

ce

25.4

(1")

Full PanelSlide

2 mm

Fixed Slide

Code Numbers / HeightLength

mmExtension

mmFinish

375

350 275

300 225

400

525

550

450

475

425

375

325

300

450

500

PowderCoatedBlack,Brownand

Ivory.

FULLPANEL BOTTOM TRACK

54 86 125 150

FPDS 54 30-6 FPDS 86 30-6 FPDS 125 30-6 FPDS 150 30-6

FPDS 54 35-6 FPDS 86 35-6 FPDS 125 35-6 FPDS 150 35-6

FPDS 54 37-6 FPDS 86 37-6 FPDS 125 37-6 FPDS 150 37-6

FPDS 54 40-6 FPDS 86 40-6 FPDS 125 40-6 FPDS 150 40-6

FPDS 54 45-6 FPDS 86 45-6 FPDS 125 45-6 FPDS 150 45-6

FPDS 54 50-6 FPDS 86 50-6 FPDS 125 50-6 FPDS 150 50-6

FPDS 54 52-6 FPDS 86 52-6 FPDS 125 52-6 FPDS 150 52-6

FPDS 54 55-6 FPDS 86 55-6 FPDS 125 55-6 FPDS 150 55-6

FOUR HEIGHTS

150mm125mm

86mm54mm

11

15.5

250.

0

64.0

64.0

64.0

248.

0

267.

0

15.0

Front View

Bottom GuideFig. 1

Side ViewFig. 2

CABINETTop

Cle

aran

ce25

.4 (1

")

2 mm

Full panelSlide

Fixed Slide

Special Features

Specifications

Power Coated

Black, Brown &

Ivory

Code No. Length(mm)

Extension(mm)

Finish

! Simplifies construction of drawer as it eliminates the sides of drawer.

! Saves Wood, Labour and Drawer space.

! Tilt & remove capacity with guiding.

! 'Auto-Closing' of drawer.

! Front facia adjustment.

! Ribbed fro strength.

! Precision rollers for smooth running.

! 25 Kgs. load capability.

! 'System 32' Compatible.

! Stopper prevents Drawer from falling.

! Available with 6 mm bottom track is easy to fit and helps in faster

assembly, as it does not require screwing the bottom, using 6 mm board in

place of 9 mm or 12 mm.

Fitting Instructions

1. Side gap of 15 mm is required and acts as side panel of drawer. (Fig. 1)

2. 25 mm clearance from top edge of drawer required to tilt and remove

drawer. (Fig. 2)

3. Fixed slide should be set by 2 mm for 'Auto-Closing.' (Fig. 2)

4. Screws should be recessed to avoid fouling.

5. Fixed slides should be fitted parallel and at equal heights to each other.

6. Front facia is to be fitted into front brackets which have 2 way adjustment

for alignment.

Caution :

For efficiency and durability.

1. Strictly maintain side gap of 15.5 per side.

2. Fix slides are parralel and equal height.

3. Do not apply pain or polish.

FPDS 250 40-6 400 325

FPDS 250 45-6 450 375

FPDS 250 50-6 500 425

Full Panel Drawer Slides 250

12

11

FinishLength

mmExtension

mm

Gap/Sidemm

Max.LoadKgs.

3015.5

Height (mm)/Code Nos.

54 86 125 150

FFDS 54-30 FFDS 86-30 FFDS 125-30 FFDS 150-30

FFDS 54-35 FFDS 86-35 FFDS 125-35 FFDS 150-35

FFDS 54-37 FFDS 86-37 FFDS 125-37 FFDS 150-37

FFDS 54-40 FFDS 86-40 FFDS 125-40 FFDS 150-40

FFDS 54-45 FFDS 86-45 FFDS 125-45 FFDS 150-45

FFDS 54-50 FFDS 86-50 FFDS 125-50 FFDS 150-50

FFDS 54-52 FFDS 86-52 FFDS 125-52 FFDS 150-52

FFDS 54-55 FFDS 86-55 FFDS 125-55 FFDS 150-55

FFDS 54-60 FFDS 86-60 FFDS 125-60 FFDS 150-60

PowderCoatedBlack,Brownand

Ivory.

300 335

350 385

375 410

400 435

450 485

500 535

525 560

550 585

600 635

! Simplifies construction of drawer as it eliminates the sides of drawers.

! Saves wood, labour, drawer space, time & cost.

! Full extension of drawer provided.

! Slide latches and wheel catches provided on both sides to prevent the

slides from getting disengaged while working.

! Auto-closing of drawer.

Special Features

Front Edge of Cabinet

600

550

500 & 525

450

400

350 & 375

300

64.00

64.00

64.00

96.0096.0096.0096.00128.0032.00

6.00

Drilling Diagram for Cabinet

Specifications

! Front fascia adjustment.

! Ribbed for strength.

! Ideal for filing drawers where full extension of drawer

is necessary.

! System-32 compatible.

! 25 kgs load capacity.

Full Panel Full Extension Drawer Slides

13

For efficiency and durability.

1. Side gap of 15.5 mm per side is most important.

2. Fix slides parallel and at equal height.

Caution

Fig.3

Fig.5

Fig.1 FRONT VIEW

A

8.5

D C B

15.5

1. To install Full Panel Full Extension Drawer Slide a 15.5mm gap per

side is required between cabinet and drawer. A total of 31 mm for

both sides (Refer fig.1).

2. Fit the outer slide onto the inside of the cabinet

(Refer fig.2). Leave 6mm from the front edge.

3. Assemble the intermediate slide with the outer slide and slide it

forward till it stops (Refer fig.3).

4. Complete the drawer by adding front, back and bottom panels to

the Full Panel. Make sure the slide latches (red color) is pulled

forward (Refer fig.4B).

5. Slide the full panel into the intermediate slide

(Refer fig.5). Move the slide latch backward to the locked position

(Refer fig.4A).

6. For removal of drawer, move slide latches (Red color) forward. The

drawer can now be tilted and removed. (Refer fig.4B).

7. Slides should be fitted parallel to each other and screws tightened

fully, to avoid gaps or interference with wheels.

Fitting Instructions

A B C D(mm) (mm) (mm) (mm)

54 90 79 32

86 122 111 64

125 161 150 96

150 186 175 128

Fig.4

SLIDE LATCH POSITION

FORWARDTO ASSEMBLEOR TO REMOVE

BACKWARDTO LOCK

Fig.2

6 0.

B A

14

11

Fullpanel Quick Fit

Design Reg. No: 202444

Special Features

Specifications

Fitting Instructions

! A unique new way to assemble a drawer by

clipping on a matching back panel.

! This not only improves the look of the drawer but

also saves valuable time during assembly and

brings down cost.

! Tilt and remove capability with guiding.

1. Side gap of 15.5mm is required and acts as side panel of drawer (Fig.1).

2. 25mm clearance from top edge of drawer required to tilt and remove drawer (Fig. 2).

3. Fixed slide should be set by 2mm for 'Auto-Closing’ (Fig. 2).

4. Screws should be recessed to avoid fouling.

5. Fixed slides should be fitted parallel and at equal heights to each other.

6. Insert the Rear panel onto the Side panels through the key slot provided in the side panels (Ref. Fig.3).

7. Place the bottom flap through the track provided in the Side panels and fix the front facia with the

Bracket and insert the unit onto Fixed slides which are fitted internal sides of cabinet (Ref. Fig.4).

Caution

1. Strictly maintain side gap of 15.5mm per side

2. Fix slides are parallel and at equal height.

3. Do not apply paint or polish.

! Autoclosing of drawer.

! Front facia adjustment.

! Precision rollers for smooth running.

! 'System 32' compatible.

For efficiency and durability:

Fig. 4 Fig. 3

Fig. 2 SIDE VIEW

Fig.1

15.5

FRONT VIEW

ABCD

CABINETTop

Cle

aran

ce

25.4

(1")

Fixed Slide

2 mm

Full PanelSlide

325

375

325

375

325

375

25

PowderCoatedBlack,Brown &Ivory.

FPQ 54-40-40 54 400 400

FPQ 54-40-45 54 400 450

FPQ 54-45-40 54 450 400

FPQ 54-45-45 54 450 450

FPQ 86-40-40 86 400 400

FPQ 86-40-45 86 400 450

FPQ 86-45-40 86 450 400

FPQ 86-45-45 86 450 450

FPQ 125-40-40 125 400 400

FPQ 125-40-45 125 400 450

FPQ 125-45-40 125 450 400

FPQ 125-45-45 125 450 450

Code Nos. Height Depth Width Extension MaxLoad kgs.

Finish

A B C D(mm) (mm) (mm) (mm)

54 71 52 32

86 103 84 64

125 142 123 96

15

Fullpanel Quick Fit File Drawer

Fig.7Fig.6

1 .51 5

152.

096

.0

'A'

10 deep8.0Ø

Special Features

! Special raised rear panel is ideal for filing cabinets.

! A unique new way to assemble a drawer by clipping on a

matching back panel.

! This not only improves the look of the drawer but also saves

valuable time during assembly and brings down cost.

! Tilt and remove capability with guiding.

! Autoclosing of drawer.

! Front facia adjustment.

! Precision rollers for smooth running.

! ‘System 32’ compatible.

1. Side gap of 15.5mm is required and acts as side panel of drawer (Fig. 1).

2. Fixed slide should be set by 2mm for ‘Auto-closing’ (Fig. 2).

3 Screws should be recessed to avoid fouling.

4. Fixed slides should be fitted parallel and at equal heights to each other.

5. Insert the raised rear panel on to the side panels through the key slot provided in the side panels

(Ref. Fig. 3).

6. Slide the 6mm bottom panel through the tracks provided in the side panels. (Ref. Fig. 4).

7. Connect the cross rods by using T-connectors as shown in diagram (Ref. Fig. 5).

8. Screw the front facia with side panels and insert the dowel in to the Ø8 hole made in front facia

screw the side rods in to dowels (Ref. Fig. 6). Push the other end of the rod in to the rubber

bushes fitted on the raised rear panel (Ref. Fig. 7).

Fitting Instructions

Fig.1 FRONT VIEW

15.5

125.

0

96.0

123.

0

142.

0

Fig.3SIDE VIEW

Fig.2

CABINET

2mm

Fixed Slide

Full PanelSlide

Specifications

325

375

FPQ 125-40-40 F 125 400 400

FPQ 125-40-40 FG1 125 400 400

FPQ 125-40-45 F 125 400 450

FPQ 125-40-45 FG2 125 400 450

FPQ 125-45-40 F 125 450 400

FPQ 125-45-40 FG3 125 450 400

FPQ 125-45-45 F 125 450 450

FPQ 125-45-45 FG4 125 450 450

25

PowderCoatedBlack,Brown &Ivory.

* With Gallery fitting set.

Code Nos. Height Depth Width Extension MaxLoad kgs.

Finish

Design Reg. No: 207641

Fig.4

Fig.5

16

Full Panel Quick Fit Full Extension

Special Features

Fitting Instructions

1. To install Full Panel Full Extension Drawer Slide a 15.5mm gap per side is required between cabinet and drawer. A total of 31 mm for both sides. (Refer Fig.1)

2. Insert the Rear panel onto the Side panels through the key slot provided in the side panels. (Ref. Fig.2)

3. Place the bottom flap through the track provided in the Side panels and fix the front facia with the Bracket.(Ref. Fig.3)

4. Fit the outer slide onto the inside of the cabinet. Leave 6 mm from the front edge. (Refer Fig.4)

5. Assemble the intermediate slide with the outer slide and slide it forward till it stops. (Refer Fig. 5)

6. Complete the drawer by adding front, back and bottom panels to the Full Panel, Make sure the slide latches (red color) is pulled forward. (Refer Fig. 6B)

7. Slide the Full panel into the intermediate slide. Refer Fig.7. Move the slide latch backward to the locked position. (Ref. Fig.6A)

8. For removal of drawer, move slide latches(Red color) forward. The drawer can now be tilted and removed. (Ref. Fig.6B)

9. Slides should be fitted parallel to each other and screws tightened fully, to avoid gaps or interference with wheels.

! A unique new way to assemble a drawer by clipping on a matching back panel.

! This not only improves the look of the drawer but also saves valuable time

during assembly and brings down cost.

! Tilt and remove capability with guiding.

! Full extension of drawer provided.

! Slide latches and wheel catches provided on both sides to prevent the slides

from getting disengaged while working.

! 'Auto-Closing' of drawer.

! Front facia adjustment.

! Ribbed for strength.

! 'System 32' Compatible.

! 25 Kgs. of load capacity.

Specifications

Code Nos. Height Depth Extension Max. LoadKgs.

Finish

FFQ 125-40-40 125 400 400

FFQ 125-40-45 125 400 450

FFQ 125-45-40 125 450 400

FFQ 125-45-45 125 450 450

Width

485

435

25

PowderCoatedBlack,Brown

&Ivory

Fig. 1

161.

0

15.5

150.

0

96.0

125.

0

8.5

17.0

17

Fig. 3Fig. 2

Fig. 5Fig. 4

Fig. 7Fig. 6

6.0

SLIDE LATCH POSITION

B A

FORWARDTO ASSEMBLEOR TO REMOVE

BACKWARDTO LOCK

18

19

Special Features

Full Panel Quick Fit Full Extension File Drawer

! Special Raised rear panel is ideal for filing cabinets.

! A unique new way to assemble a drawer by clipping on a matching back panel.

! This not only improves the look of the drawer but also saves valuable time during

assembly and brings down cost.

! Full extension of drawer provided.

! Tilt and remove capability with guiding.

! Autoclosing of drawer.

! Front facia adjustment.

! Precision rollers for smooth running.

! System 32 compatible.

1. To install Full Panel Full Extension Drawer Slide a 15.5 mm gap per side is required between

cabinet and drawer. A total of 31 mm for both sides. (Ref. Fig.1)

2. Insert the Raised Rear panel onto the side panels through the key slot provided in the side

panels. (Ref. Fig.2)

3. Slide the 6 mm bottom panel through the tracks provided in the side panels.( Ref. Fig.3)

4. Connect the cross rods by using T- connectors as shown in diagram.(Ref.Fig.4)

5. Fix the front facia with side panels by using the clip-on mechanism and lock it by rotating the

lever as shown in diagram and insert the dowel into the Ø8 mm hole made in front facia and

screw the rods in it. (Ref. Fig. 5). Push the other end of the rod into the plastic sleeves fitted on

the Raised rear panel. (Ref. Fig.6)

6. Fit the fixed slide onto the inside of the cabinet. Leave 6 mm from the front edge. (Ref. Fig.7)

7. Assemble the intermediate slide with the fixed slide and slide it forward till it stops. (Ref. Fig. 8)

8. Slide the File drawer assembly into the intermediate slide. (Ref. Fig.10). Make sure that the

slide latches(red colour) are pulled forward.(Ref.Fig.9B) After engaging the drawer assembly

into the intermediate slide move the slide latches backward to the locked position. (Ref.Fig.9A)

9. For removal of drawer, move slide latches(Red color) forward. The drawer can now be tilted

and removed. (Ref. Fig. 9B)

10. Slides should be fitted parallel to each other and screws tightened fully, to avoid gaps or

interference with wheels.

Fitting Instructions

125.

0 161.

0

150.

096

.0

8.5

17.0Fig. 1

15.5

Fig. 2

Specifications

Code No. Height Depth Width ‘A’ Extn. Max. LoadKgs.

Finish

FFQ 125-40-40 F 125 400 400 340

*FFQ 125-40-40 FG1 125 400 400 340

FFQ 125-40-45 F 125 400 450 390

*FFQ 125-40-45 FG2 125 400 450 390

FFQ 125-45-40 F 125 450 400 340

*FFQ 125-45-40 FG3 125 450 400 340

FFQ 125-45-45 F 125 450 450 390

*FFQ 125-45-45 FG4 125 450 450 390

435

485

25

Powder CoatedBlack, Brown &Ivory

*with gallery fitting set

Design Reg. No. 207640

20

Fig. 3 Fig. 4

Fig. 5

Ø8.0

10 de pe

Ø8.0 x 12.0 Min.

32.0

T E ER

ROTA E L V O OCK

T L

Fig. 6

Fig. 8Fig. 7

6.0

Fig. 10Fig. 9

SLIDE LATCH POSITION

FORWARDTO ASSEMBLEOR TO REMOVE

BACKWARDTO LOCK

B A

189.

0

2.5A' '

Full Extension Drawer Slides

Design Reg. No: 181904/00

FEDS 30 300 335

FEDS 35 350 385

FEDS 37 375 410

FEDS 40 400 435

FEDS 45 450 485

FEDS 50 500 535

FEDS 52 525 560

FEDS 55 550 585

FEDS 60 600 635

Code Nos.

Powdercoated-Black,Brown,Ivoryand

Silver.

Length(mm)

Extension(mm)

Gap/Side(mm)

Max.Load(Kgs.)

Finish

12.7(1/2”)

30

! Full extension of drawer provided.

! Slide latches and wheel catches provided on both

sides to prevent the slides from getting disengaged

while working.

! Inner Slide has Bottom Mounting.

Special Features

Front Edge of Cabinet

600

550

500 & 525

450

400

350 & 375

300

64.00

64.00

64.00

96.0096.0096.0096.00128.0032.00

6.00

Drilling Diagram for Cabinet

Specifications

! Screw holes as per System 32.

! Lateral guiding provided.

! 25 kgs load capacity.

! Ideal for kitchen baskets where full extension of drawer

is necessary.

21

22

1. To install Full Extension Drawer Slide a 12.7mm (1/2")

gap per side is required between cabinet and drawer. A

total of 25.4mm ( 1") for both sides (Refer fig. 1).

2. Fit the outer slide onto the inside of the cabinet (Refer

Fig.2).

3. Assemble the intermediate slide with the outer slide and

slide it forward till it stops (Refer fig. 3).

4. Fit the inner slide onto the drawer. Make sure the slide

latches (red color) is pulled forward (Refer fig. 4B).

5. Slide the inner slide with the drawer into the intermediate

slide (Refer fig. 5). Move the slide latch backward to the

locked position (Refer fig 4A).

6. For removal of drawer, move slide latches (Red color)

forward. The drawer can now be tilted and removed.

7. Slides should be fitted parallel to each other and screws

tightened fully, to avoid gaps or interference with wheels.

Fitting Instructions

Fig.5

Fig.3

Fig.1 FRONT VIEW

7.0

60.0

50.0

1/2"12.7

Drawer

Cab

inet

Fig.2

6.0

Caution

For efficiency and durability.

1. Side gap of 12.7 mm (1/2") per side is most important.

2. Fix slides parallel and at equal height.

3. Do not remove Red Latch.

Fig.4

SLIDE LATCH POSITION

FORWARDTO ASSEMBLEOR TO REMOVE

BACKWARDTO LOCK

BA

23

Fascia Swivel Bottom Mounting Drawer Slides

Special Features

! Specially designed fascia swivel is ideal for

locking computer keyboards when not in use.

! Right side with lateral guiding.

! Tilt and remove of drawer.

! New ‘auto-closing’ feature.

! ’System 32’ compatible.

Specifications

Code No.Extension

(mm)Max. Load

Kgs.Gap/Side

(mm)

Fitting Instructions

1. Side gap of 12.7mm (1/2”) per side required (Ref. Fig. 1)

2. 25.4mm (1”) clearance from top edge of drawer required to tilt and remove

drawer (Ref. Fig. 2)

3. Fixed and moving slide should be equally offset by 4mm for “Auto-closing”

(Ref. Fig. 2)

4. Recess screw heads to avoid interference.

5. Screw front facia bracket to the facia panel (Ref. Fig. 3.)

6. Front facia can be lifted and tilted in 90° (Ref. Fig.4)

7. While closing the drawer, rotate the front facia and lock the facia bracket in

slot provided in the slide (Ref. Fig. 5)

FRONT VIEWFig. 1

SIDE VIEWFig. 2

Fig. 4 Fig. 5

1/2’’

12.7

FIXED SLIDEMOVING SLIDE

DRAWER

25.4

mm

Top

Cle

aran

ce

CABINET

2.0

1 "

BMDS 35 FS 350 260

BMDS 40 FS 400 310 12.7

BMDS 45 FS 450 360 (1/2”) 20

BMDS 50 FS 500 410

Fig. 3

Length(mm)

24

Sleek Telescopic Drawer Slide (I)

Special Features

Drilling Diagram for Cabinet

! Precision ball bearing.

! Full extension of drawer.

! Load capacity 35 Kgs.

! Direct fitting from front.

! Removable drawer with Latch

! System 32 installation.

250

300

350

400

450

500

550

600

750

900

32.0 32.0 32.0

32.0 32.0

32.0 32.0

64.0 32.0 32.0

32.0 32.0

64.0 32.0 32.0

64.0 64.0 32.0

64.0 32.0 32.0

32.0 32.0

32.064.064.064.096.096.096.096.064.064.064.032.032.0

Front Edgeof Cabinet

DRILLING DIAGRAM FOR CABINET

.2Ø4

25

Specifications

Fitting Instructions

1. To install sleek telescopic drawer slide 12.7 to13.0mm side gap per

side is required between cabinet and drawer. (Refer Fig. 1)

2. Depress latch and remove the inner slide. (Refer Fig. 2)

3. Fit outer (fixed) slide onto the inside of the cabinet, access to holes can

be got through slots in intermediate slide

4. Slides should be fitted parallel and screws tightened fully to avoid gaps.

5. Fit inner slide onto the outside of the drawer.

6. Now slide the drawer with inner slide fluted on to the intermediate slides

on the cabinet till the latch will automatically engage.

Code No. Length(mm)

Extension(mm)

Max. LoadKgs.

Gap/Side(mm)

Finish

White,Black, MG GrayZinc Plated

STDS 25 (I) 250 260

STDS 30 (I) 300 310

STDS 35 (I) 350 360

STDS 40 (I) 400 410

STDS 45 (I) 450 460 12.7

STDS 50 (I) 500 510 to 35

STDS 55 (I) 550 560 13.0

STDS 60 (I) 600 610

STDS 75 (I) 750 760

STDS 90 (I) 900 910

CautionFor efficiency and durability:

1. Strictly maintain 12.7 to 13.Omm side gap.

2. Fit slides parallel and at equal heights.

3. Do not apply paint or polish.

4. Do not let saw dust enter into the slides.

13.0

12.7

13.045

.0

CAB

INET

12.7

3.2

1/8"CABINET

DRAWERMinimumBottomClearance

Fig. 1

Fig. 2

Depress Latchto Remove Inner Slide

26

Sleek Telescopic Drawer Slides-Auto Closing (I)

! New Auto closing feature.

! Precision ball bearing.

! Full extension of drawer.

! Load capacity 35 Kgs.

! Direct fitting from front.

! Removable drawer with latch.

! System 32 installation.

Fitting Instructions

1. To install sleek telescopic drawer slide 12.7 to13.0mm side gap per

side is required between cabinet and drawer. (Refer Fig. 1)

2. Depress latch and remove the inner slide. (Refer Fig. 2)

3. Fit outer (fixed) slide onto the inside of the cabinet, access to holes can

be got through slots in intermediate slide

4. Slides should be fitted parallel and screws tightened fully to avoid gaps.

5. Fit inner slide onto the outside of the drawer.

6. Now slide the drawer with inner slide fitted on to the intermediate slides

on the cabinet till the latch will automatically engage.

Special Features

CautionFor efficiency and durability:

1. Strictly maintain 12.7 to 13.Omm side gap.

2. Fit slides parallel and at equal heights.

3. Do not apply paint or polish.

4. Do not let saw dust enter into the slides.

Specifications

Code No. Length(mm)

Extension(mm)

Max. LoadKgs.

Gap/Side(mm)

Finish

White,Black, MG GrayZinc Plated

STDS 25-AC(I) 250 245

STDS 30-AC(I) 300 295

STDS 35-AC(I) 350 345

STDS 40-AC(I) 400 395

STDS 45-AC(I) 450 445 12.7

STDS 50-AC(I) 500 495 to 35

STDS 55-AC(I) 550 545 13.0

STDS 60-AC(I) 600 595

STDS 75-AC(I) 750 745

12.713.0

45.0

DRAWERMinimumBottomClearance

CABINET

CAB

INET

3.2

1/8"

Fig. 1

Fig. 2

Depress Latchto Remove Inner Slide

27

Special Features

Mini Drawer Slide H-17

1. Lateral play is virtually eliminated when the

groove mounting method is employed.

2. This slide is small, elegant and space saving.

3. Accessible from both sides.

4. 32mm hole pattern.

5. Max. load capability - 10kg/set.

Specifications

MDS 21 214-341 214 214 70

MDS 31 310-506 310 310 94

MDS 37 374-616 374 374 104

MDS 43 438-726 438 438 122

Drawer Depthmm

Length of drawerslide ‘L1’ mm

Item CodeLength of cabinet

slide ‘L2’ mmExtension loss of drawer ‘A’ mm

Fitting Instructions

1. Side gap required is 10.0mm per side including

the groove (Ref. Fig. 1).

2. Make a groove in the drawer as per given

dimensions (Ref. Fig. 1).

3. Fix the cabinet slide to the cabinet (Ref. Fig. 2).

4. Fix the drawer slide to the drawer with the M4

screws provided (Ref. Fig. 2).

±0.210.0

±0.

225

.5

Caution

1. Side gap required is 10.0mm per side is

most important.

2. Fix slides parallel and at equal height.

3. Do not apply paint or polish.

4. Do not let saw dust enter in to the slides.

L1

A

8.0

8.0

L2

M4 x 2 Nos

1.0

27.044.0

32.0

Drawer Depth

Fig.2

±0.210.0

-017

.0

7.5Side Gap

M4

+0.

2

Gro

ove

DRAWER

CABINET

Fig.1

28

Mini Telescopic Drawer Slides H- 36

Special Features

1. Easy to pullout, pull release for disconnect.

2. Ball retainer detent for drawer easy re-install.

3. Hold-in detent.

4. Side space adjustable tabs and non-handed.

5. 32mm hole pattern.

Fitting Instructions

1. Side gap required is 12.7mm (½”) per side (Ref. Fig. 1).

2. Fix the outer (fixed) slides to the cabinet. Access to holes can be got

through slots in intermediate slide (Ref. Fig. 1).

3. Press latch and remove the inner slide (Ref. Fig. 2).

4. Slides should be fitted parallel and screws tightened fully to avoid gaps.

5. Fit inner slide onto the outside of the drawer. (Ref. Fig. 1).

6. Now, slide the drawer with inner slide fitted onto the intermediate slides

on the cabinet.

Caution

1. Side gap required is 12.7mm per side is most important.

2. Fix slides parallel and at equal height.

3. Do not apply paint or polish.

4. Do not let saw dust enter in to the slides.

±0.3

12.7

DRAWER

CABINET

±0.

336

.0

Specifications

Slide Length mm

Item Code Extension mm

Max. Load Kgs.

Gap/Slide mm

Finish

12.7 25Bright Zinc

Plated

MTDS 35 350 350

MTDS 40 400 400

MTDS 45 450 450

MTDS 50 500 500

Fig.2

Fig.1

29

Basket Slides - 12.7mm

Special Features

! Precision Ball Bearing.

! Full extension of drawer.

! Special clamp arrangement for baskets.

! Basket can be removed by depressing latch.

! Max. Load capacity 35 kg.

Drilling Diagram for Cabinet

400

450

500

550

600

Front Edgeof cabinet

31.0 96.0 64.0 295.0 32.0 32.0 53.0

32.032.0

32.0 32.0

32.0 32.0

64.0145.0

95.0

195.0

245.0

30

Specifications

Fitting Instructions

1. Basket slides require 12.7 to 13 mm gap per side.

(Ref. Fig.1)

2. Inner slide can be removed by depressing latch.

(Ref. Fig.2)

4. Baskets are clamped onto the slides where two

clamps are provided.

Code No. Length(mm)

Extension(mm)

Max. LoadKgs.

Gap/Side(mm)

Finish

KBTS-40 (I) 400 410

KBTS-45 (I) 450 460 12,7

KBTS-50 (I) 500 510 to 35

KBTS-55 (I) 550 560 13.0

KBTS-60 (I) 600 610

WhiteBlack, Zn Plated

12.7

13.0

45.0

Fig. 1

12.7

13.0

Fig. 2

Depress latchto remove tray.

31

Special Features

! Full extension of drawer available.

! Direct front installation without De-assembly.

! Precision ball bearing for smooth movement.

! Hole 'System-32' compatible.

Front Edge of Cabinet

750

35.00 128.00 96.00 96.00 96.00 96.00 64.00 96.00

700

650

600

550

500

450

400

Drilling Diagram for Cabinet

Heavy Duty Telescopic Drawer Slides

Design Reg. No: 162398/90

32

For efficiency and durability.

1. Side gap of 25 mm (1”) per side is most important.

2. Fit slides parallel and at equal height.

3. Do not apply paint or polish.

4. Do not let saw dust enter into the slides.

Caution

Zinc Plated

60

50

25.0

Lengthmm

Extensionmm

Gap/Sidemm

Max. LoadKgs.

FinishCode Nos.

HTDS 40 400 412

HTDS 45 450 462

HTDS 50 500 512

HTDS 55 550 562

HTDS 60 600 612

HTDS 65 650 662

HTDS 70 700 712

HTDS 75 750 762

1. To install, gap per side required is 25mm. (Refer fig. 1)

2. Screw holes are accessible through slots in inner slides.

3. Slides must be fitted parallel and at equal height.

4. Screw outer slides on drawer and inside of cabinet

maintaining parallelism.

Fitting Instructions

Fig.1

DRAWER

MinimumBottom Clearance

3.2

1/8”

CABINET

34.0

25.0

SIDE MOUNTING

Specifications

33

! Smooth quiet movement with ball bearings.

! Set comes with left and right hand slides.

! Removable drawer with depressible latch.

! Adjustable height on Mounting Brackets.

! Direct front installation.

! Pressure Latch prevents play.

! Slides can be fitted top hung or bottom hung.

For efficiency and durability.

1. Side gap of 20 mm per side is most important

2. Fix slides parallel and at equal height.

3. Do not apply paint or polish.

4. Do not interchange right and left inner slides.

Special Features

CKDS 35 350 200

CKDS 45 450 250

Code Nos.Length(mm)

Extension(mm)

Gap/Side(mm)

Max.LoadKgs.

Black, Whiteand

zinc plated.

Finish

Specifications

1. Fit Mounting brackets with outer side in 80 mm

from the front edge of the table. ( Ref. Fig.1 )

2. Slides can be fitted top hung or bottom hung.

Caution

MountingBrackets

80.0

Front Edgeof TableFig.1

Fitting InstructionsVariable Height Mounting

Brackets are also reversible.

Key Board TrayAttached to moving slide

New Pressure Latch prevents play &movement of Keyboard when pulled out.

Tray can be completely removed bydepressing Latch.

Fig.2

Depress latchto removetray.

20 35

Fig.3

Hei

ght

Adju

stm

ent

36.0

Computer Keyboard Slides

Design Reg. No: 172578/96

34

Computer Keyboard Slide - Eco

Special Features

! Basic and economic option.

! Having all steel construction with ball cages for long life.

! Has a built in end stop. (Ref. Fig. 1)

Code Nos. CKSE 37

Specifications

Fig.1

42 1.0

Latch

76.0

Special Features

! Basic and economic option.

! Having all steel construction with ball cages for long life.

Specifications :

Code No.

CKSE 35 (I)

CKSE 45 (I)

Slide

Length

mm

350

450

Extension

mm

250

350

Finish

Zinc

Plated

Max. Load

Kgs.

12

Fig. 1

2 4.02

32.0

Fig. 2 Height Adjustment

62.0

Min

. 95.0

Max

.

36.0

Front View

Computer Keyboard Slide - Eco (I)

35

Two Way Slides

! Slim design requires only 10mm side gap.

! Can be used with bigger drawers as slides are reversible.

! No deassembly required.

! "System 32" compatible.

! Precision ball bearing for smooth movement.

! Load capacity - 12kgs.

Code Nos.Length(mm)

Extension Loss (mm)

Drawer Length‘A’ mm

Gap/Side(mm)

10

Max.LoadKgs.

12Zinc

plated.

Finish

TWDS 200-325 194 58.0 200-325

TWDS 300-485 290 88.0 300-485

TWDS 375-625 374 118.0 375-625

TWDS 420-710 418 118.0 420-710

Special Features

Specifications

Front Edge of Cabinet

420

375

300

200

27.00 32.00 64.00 172.00 64.00 32.00

32.00

32.00

32.0076.00

64.00128.00

172.00

Drilling Diagram for Cabinet

36

Minimum BottomClearance

3.2m

m1/

8”

10.0

6.7

13.5

27.0

CABINET

DRAWER

Fig.2

10.0

27.0

Minimum BottomClearance

1/8”CABINET

DRAWER

3.2m

m

Fig.1

CABINET

DRAWER

Minimum Cabinet Depth =

Drawer Length + 1 mm

Drawer Length ‘A’

Extension Loss

Fig.3

1. 10mm side gap required per side. (Refer fig. 1)

2. Can be recessed fitted in a 27mm slot to reduce side gap. (Refer fig. 2)

3. Slide must be parallel and at equal height.

Fitting Instructions

For efficiency and durability.

1. Strictly maintain side gap given in diagrams.

2. Fit slides parallel and at equal heights.

Caution

Quadrail Slides

! This new drawer slide system has a unique design with chrome

steel ball bearings and rollers for long life, smooth working and

two dimensional guiding.

! Easy to fit by just pushing the drawer in and come with a special

Release Clip with built-in Fascia Adjuster.

Special Features

! Has a spring loaded auto-closing feature.

! System 32 compatible

! Saves space due to reduced side gap.

Front Edge of Cabinet

600

550500450

400350300

250

5.00 96.00

160.00160.00

224.00

224.00

288.00

288.00

352.0016.00

16.00

16.00

16.0040.00 32.00 32.00

33.00

Drilling Diagram for Cabinet

Specifications

QSDS 25 255 134 250 265

QSDS 30 305 184 300 315

QSDS 35 355 234 350 365

QSDS 40 405 284 400 415

QSDS 45 455 334 450 465

QSDS 50 505 384 500 515

QSDS 55 555 434 550 565

QSDS 60 605 484 600 615

4.0 30Zinc

plated.

Code Nos. Slide Length(mm)

Extension (mm)

Drawer Length(L) mm

Min Cabinetdepth mm

Gap/Side(mm)

Max.LoadKgs.

Finish

37

38

1. Side wall thickness of drawer should not exceed 16mm Max.

and bottom extension of side should not exceed 10mm max.

(Refer fig. 1).

2. Drill hole Ø6mm required at the rear of drawer to anchor the

rear end of slides (Refer fig. 2).

3. Release clips to be fitted the drawer in front of the fascia.

(Refer fig. 3)

4. Mounting brackets of slide to be fitted parallel and at equal

height inside the cabinet leaving 5mm from the front edge

(Refer fig. 4).

5. Push Drawer onto slide and automatically locks onto the

slides. (Refer fig. 5).

6. Fascia can be adjusted by sliding the adjuster.

Fitting Instructions

DRAWER

Fig.1

7.0

16.0 Max.

Ø6.0CABINET

10.0

Max

.

20.0

11.0

28.5

18.0 20.0

Fig.2

Ø6.0

11.0

10.0

18.0

'L'

Fig.3 BOTTOM VIEW OF DRAWER

13.0 64.0 13.064.0

Fig.4

DRAWER CABINET

5.0

Fig.5

Facia adjuster toadjust the levelof drawer

Press toremove thedrawer

39

Side Hinged Door Slide

SHUTTER WOODSTRIP

CABINET

Fig.2SHUTTER

45.0

12.0

Dee

p

Ø35

.0

10.0

37.0

FRONT VIEW

SLIDE

WOOD STRIP

BRIDGE

SHUTTER

HINGE

CORNERROLLER

CABINET

Fig.1

Specifications

Code Nos.

WhiteZinc

Plated

Length(mm)

Min. Widthof shutter (mm)

Max. weightof shutter (kgs)

Thickness ofshutter (mm)

Finish

SHDS 30 300 175

SHDS 35 350 225

SHDS 40 400 275

SHDS 45 450 325 16 to 19 5.5

SHDS 50 500 375

SHDS 55 550 425

SHDS 60 600 475

Special Features

! Cabinet shutter opens 90° and can slide inside the cabinet on each side.

! Channels are mounted inside the cabinet on the side.

! Precision ball bearings with European type cup hinges.

! Support rollers reduce sag of door.

! L-shaped bridge provided to fit wood strip to prevent jamming.

! Adjustable hinges with auto-closing.

! Corner roller for door protection. Ideal for TV cabinet.

1. Fit the slides onto inside of cabinet as in Fig.1.

2. Slides should be parallel to each other or they will get damaged.

3. Bridges must face each other and a wooden strip must be fixed to join them.

4. Shutter thickness must not be less than 16 mm and not more than 19 mm.

5. To fit Hinge in shutter use Ø35 mm round cutter 12 mm deep. Do not use

chisel. Round cavity should be 10 mm from edge (Refer fig.2).

Fitting Instructions

40

Top Hinged Door Slide

! Shutter opens upwards and slides on top of the cabinet. Ideal for

T.V., Bar and filing cabinets.

! Precision ball bearing movement with roller to protect shutter.

! Special cranked hinge.

Special Features

For efficiency and durability.

1. Fit slides parallel and at equal height.

2. Do not apply paint or polish.

Caution

Specifications

Code Nos.Length(mm)

Min. Height of shutter (mm)

Movementof slide (mm)

Min. thicknessof shutter (mm)

Finish

THDS 30 300 320 175

THDS 35 350 370 225

THDS 40 400 420 275

THDS 45 450 470 325 16

THDS 50 500 520 375

THDS 55 550 570 425

THDS 60 600 620 475

WhiteZinc

Plated

Fig.1

Hinge

SlideSHUTTER

CABINET

10.0

10.0

Fig.3

Recessed Slot in Shutter

35.0

8.6

Fig.4

Top front edge of Cabinet

10.0

50.0

1.6

Fig.2

SHUTTER

2.5

1.6

CABINET1. Slide fits vertically on inside of shutter in closed condition and

hinge on inside top front edge of cabinet. (Refer Fig. 1).

2. When opened upwards to horizontal position, shutter can slide

backwards on top of the cabinet. (Ref. Fig. 2).

3. Slide must be recessed into 35mm wide and 8.6mm deep slots

inside the shutter. (Refer Fig. 3).

4. Hinge must be recessed into the top front edge of cabinet 50mm

wide and 10mm deep. (Refer Fig. 4).

5. Opening angle : 90°.

Fitting Instructions

41

Premium Sleek Telescopic Slides - Auto Close

Special Features

! Full extension

! 30 mm stroke of Auto - Closing

! Pull force 2.5 kg.

! Non-handed Disconnect Release.

! 45 kg / 100 lbs. loading at 18".

! Electro-Zinc plated with clear, yellow or black chromate,

or Cr-Free galvanized steel.

Specifications

300

350

400

450

500

550

600

8.59.0

21.334.3

27.0 128.0 96.0 128.0

Ø.46 Ø6.4

64.0

160.0

21.69.0

front Edge Cabinet

DRILLING DIAGRAM FOR CABINET

Code Nos.Size(mm)

Length(mm)

Extension (mm)

Max. Load(kgs)

P-STDS-30-AC 300 300 305 25

P-STDS-35-AC 350 350 356 35

P-STDS-40-AC 400 400 406 40

P-STDS-45-AC 450 450 457 45

P-STDS-50-AC 500 500 508 45

P-STDS-55-AC 550 550 559 40

P-STDS-60-AC 600 600 610 40

42

Fitting Instructions

1. To install Ball bearing slide, 13.0 to 13.6 mm side gap per side is

required between cabinet and drawer. (Refer Fig. 1)

2. Fit outer (fixed) slide onto the inside of the cabinet, access to holes can be

got through slots in intermediate slide

3. Slides should be fitted parallel and screws tightened fully to avoid gaps.

4. Fit inner slide onto the outside of the drawer.

5. Now slide the drawer with inner slide fitted on to the intermediate slides

on the cabinet till the latch will automatically engage.

Caution

For efficiency and durability :

1. Strictly maintain 13.0 to 13.6 mm side gap.

2. Fit slides parallel and at equal heights.

3. Do not apply paint or polish.

4. Do not let saw dust enter into the slides.

+0.6-0

13.0

Fig. 1

+0.2-0

12.8

±0.

345

.5

30 mm stroke of Auto-Closing

+0.5-0

8.5+0.5-0

35

9

flush

43

300

350

400

450

500

550

600

Front Edge Cabinet DRILLING DIAGRAM FOR CABINET

128.0

80.0

128.0

176.0

21.69.0

8.5

9.0

27.0 128.0 96.0 128.0

21.634.3

Premium Sleek Telescopic Slides - Soft close

Special Features

! 30 mm stroke of Soft - Closing

! Pull force 3.2 - 3.5 kg

! Soft-closing function built in slide, easy for installation.

! Non-handed Disconnect Release.

! 45 kg / 100 lbs. loading at 20".

! Electro-Zinc plated with clear, yellow or black chromate, or Cr-Free galvanized steel.

Specifications

Code Nos.Size(mm)

Length(mm)

Extension (mm)

Extension Loss (mm)

Max. Load(kgs)

P-STDS-30-SC 300 300 238 -62 20

P-STDS-35-SC 350 35 305 -45 25

P-STDS-40-SC 400 400 378 -22 35

P-STDS-45-SC 450 450 430 -20 40

P-STDS-50-SC 500 500 482 -18 45

P-STDS-55-SC 550 550 533 -17 40

P-STDS-60-SC 600 600 584 -16 35

44

Fitting Instructions

1. To install Ball bearing slide, 13.0 to 13.8 mm side gap per side is

required between cabinet and drawer. (Refer Fig. 1)

2. Fit outer (fixed) slide onto the inside of the cabinet, access to holes can be

got through slots in intermediate slide

3. Slides should be fitted parallel and screws tightened fully to avoid gaps.

4. Fit inner slide onto the outside of the drawer.

5. Now slide the drawer with inner slide fitted on to the intermediate slides

on the cabinet till the latch will automatically engage.

Caution

For efficiency and durability :

1. Strictly maintain 13.0 to 13.8 mm side gap.

2. Fit slides parallel and at equal heights.

3. Do not apply paint or polish.

4. Do not let saw dust enter into the slides.

Fig. 1

+0.8-0

13.0

+0.2-0

12.8

±0.

345

.5

30 mm stroke of Soft-Closing

+0.5-0

8.5+0.5-0

35

9

flush

45

Premium Sleek Telescopic Slides - Push Open

Fitting Instructions

1. To install Ball bearing slide, 13.0 to 13.8 mm side gap per side is

required between cabinet and drawer. (Refer Fig. 1)

2. Fit outer (fixed) slide onto the inside of the cabinet, access to holes can be

got through slots in intermediate slide.

3. Slides should be fitted parallel and screws tightened fully to avoid gaps.

4. Fit inner slide onto the outside of the drawer.

5. Now slide the drawer with inner slide fitted on to the intermediate slides

on the cabinet till the latch automatically engages.

Caution

For efficiency and durability :

1. Strictly maintain 13.0 to 13.8 mm side gap.

2. Fit slides parallel and at equal heights.

3. Do not apply paint or polish.

4. Do not let saw dust enter into the slides.

Special Features

! Full extension

! Push-rebound function built in slide, easy for installation.

! Non-handed Disconnect Release.

! 45 kg / 100 lbs. loading at 18".

! Rebound 2" - 5" when drawer is pushed.

! Electro-Zinc plated with clear, yellow or black chromate,

or Cr-Free galvanized steel.

Specifications

Code No.Sizemm

Lengthmm

Extensionmm

Max. Loadkgs

400

450

500

Front Edge Cabinet DRILLING DIAGRAM FOR CABINET

Ø.64

Ø64.

160.0

21.69.0

8.59.0

21.634.3

27.0 128.0 96.0 128.0

P-STDS-40-PO

P-STDS-45-PO

P-STDS-50-PO

400

450

500

400

450

500

406

457

508

40

45

45

46

Fig. 1

+0.8-0

13.0

+0.2-0

12.8

±0.

345

.5

+0.8-0

13.0

+0.8-0

13.0Max. drawer width

PUSH AREA

400

450

500

400

450

500

600

650

700

Sizemm

SlideLength

Max. drawerwidth Suggested

Without Gasket

GAP 3±0.5 mm

PUSH 2 mm

6±0.5 35

flush 9

48.654.6±0.5

Under horizontal installation,drawer will rebound 2"-5"

when pushing

2"-5" For Overlay Drawer

58.0 + t

t

PUSH 2 mm

9.0 + t35

flush 9

2"-5"

Under horizontal installation,drawer will rebound 2"-5"

when pushing

For Inset Drawer

With Gasket (Anti insect)

t= Gaskett= thickness of gasket max. 8mmpressed amount of gasket min. 2.5mm

Side PanelGasket

(Anti insect)

Front Panel of Drawert APUSH

Min

2.5

mm

Top View (View from 'X')

'X'

flush

54.6-A935

47

Premium Quadrail - Auto Close

Special Features

! Full extension

! Suited to wooden drawer.

! With Easy - Release Catch.

! 45 kg / 100 lbs. loading at 18".

! 45mm stroke of Auto-Closing.

! Ball bearing slide offers strong structure and avoids sway

Fitting Instructions

1. Install the slides as per given diagrams.

300

350

400

450

500

550

600

Front Edgeof Cabinet

288247

224128

32+1-0

37

DRILLING DIAGRAM FOR CABINET

+1-0

3732+1-0

4

9 9 9 9

1226±0.

5

Ø6.3

min. internal carcase depthDrawer length

37 32

4

X

10

37 32

Inner Drawer length = Drawer length + XDrawer length

Inner Drawer

22 10

internal drawer width = internal carcase width-41 mm

+10-1

internal carcase width

internal drawer width

max 16

12-1

4

7

28.5

20.520.5

11

±0.

526 ±

0.5

38

Specifications

Code No.Sizemm

NormalRunnerLength

DrawerLength

LoadCapacity

Kgs.

OverTravel

Min. internal cabinetDepth for Standard

Drawer

Overlay Inset

P-CDS-30

P-CDS-35

P-CDS-40

P-CDS-45

P-CDS-50

P-CDS-55

P-CDS-60

300

350

400

450

500

550

600

300

350

400

450

500

550

600

290

340

390

440

490

540

590

25

30

35

40

35

35

30

310

360

410

460

510

560

610

328

378

428

478

528

578

628

10

10

10

10

10

10

10

48

4-sided-drawer

3-sided-drawer

Inset-drawer

25.8 20

14.8 42

8.6

117

Ø6X10 Depth

Height Adju ment= 3.5mm

st

rovides up ard

P

w

ad u ment only

j st

90º

+0-0.5

20.5

max 16

Ø6X107

max

14

1226

±0.

5

28.5

±0.

511

49

Premium Quadrail - Soft Close

Special Features! Full extension

! Suited to wooden drawer.

! With Easy - Release Catch.

! 45 kg / 100 lbs. loading at 18".

! 45mm stroke of Soft Closing.

! Ball bearing slide offers strong structure and avoids sway

Specifications

Fitting Instructions

1. Install the slides as per given diagrams.

300

350

400

450

500

550

600

Front Edgeof Cabinet

288247

224128

32+1-0

37

DRILLING DIAGRAM FOR CABINET

+1-0

3732+1-0

4

9 9 9 9

1226±0.

5

Ø6.3

min. internal carcase depthDrawer length

37 32

4

X

10

37 32

Inner Drawer length = Drawer length + XDrawer length

Inner Drawer

22 10

internal drawer width = internal carcase width-41 mm

+10-1

internal carcase width

internal drawer width

max 16

12-1

4

7

28.5

20.520.5

11

±0.

526 ±

0.5

38

Code No.Sizemm

NormalRunnerLength

DrawerLength

LoadCapacity

Kgs.

OverTravel

Min. internal cabinetDepth for Standard

Drawer

Overlay Inset

P-CDS-30-SC

P-CDS-35-SC

P-CDS-40-SC

P-CDS-45-SC

P-CDS-50-SC

P-CDS-55-SC

P-CDS-60-SC

300

350

400

450

500

550

600

300

350

400

450

500

550

600

290

340

390

440

490

540

590

25

30

35

40

35

35

30

310

360

410

460

510

560

610

328

378

428

478

528

578

628

10

10

10

10

10

10

10

50

4-sided-drawer

3-sided-drawer

Inset-drawer

25.8 20

14.8 42

8.6

117

Ø6X10 Depth

Height Adju ment= 3.5mm

st

rovides up ard

P

w

ad u ment only

j st

90º

+0-0.5

20.5

max 16

Ø6X107

max

14

1226

±0.

5

28.5

±0.

511

51

Premium Quadrail - Push Open

Special Features

! Push-rebound function built in slide, easy for installation

! Full extension

! Suited to wooden drawer.

! With Easy - Release Catch.

! 40 kg / 90 lbs. loading at 18".

! Ball bearing slide offers strong structure and avoids sway

! Fully push in (2 mm) for open or close

Under horizontal installation, drawer will redound 5" - 8"

when pushing

! Cr-free galvanized steel.

Fitting Instructions

1. Install the slides as per given diagrams.

Specifications

Code No.Sizemm

NormalRunnerLength

DrawerLength

+0-1.5

LoadRatingkg/pr

P-CDS-50-PO 500 500 490 35

Min. internal CarcaseDepth for Drawer

510

OverTravel

10

Max.DrawerWidth

700

500

Front Edgeof Cabinet

247

224

12832 37

+1-0

DRILLING DIAGRAM FOR CABINET

+0-0.5

20.5

max 16

max

14

12

7

11

26±

0.5

28.5

±0.

5

610

ØX

52

+1-0

32 37

+1-0

4

9 9 9 9

1226±

0.5

Ø63.

25.8

8.6

20

4214.8

dHeight A justment= +3.5mm

Pro ides upwa d

v

r

ad ustmn only

je t

90º

Ø6X10 Depth117

min. carcase depth GAP 4-5 mm

Drawer length -1.5+0

+0-1

37

PUSH2 mm

Under horizontal installation,drawer will rebound 5" - 8" when pushing 5 - 8"

Internal drawer width=internal carcase -41 mm

+0-1

Internal carcase width

max. drawer width

internal drawer width

PUSH

PUSH