Draft · 2019. 12. 4. · Draft Liquefaction and Post-liquefaction Assessment of Lightly Cemented...

Transcript of Draft · 2019. 12. 4. · Draft Liquefaction and Post-liquefaction Assessment of Lightly Cemented...

-

Draft

Liquefaction and Post-liquefaction Assessment of Lightly Cemented Sands

Journal: Canadian Geotechnical Journal

Manuscript ID cgj-2018-0833.R1

Manuscript Type: Article

Date Submitted by the Author: 11-Feb-2019

Complete List of Authors: Rasouli, Habib; University of Technology SydneyFatahi, Behzad; University of Technology Sydney, Nimbalkar, Sanjay; University of Technology Sydney, School of Civil & Environmental Engineering

Keyword: lightly cemented sand, Multi-stage soil element tests, Post-liquefaction behaviour, Liquefaction

Is the invited manuscript for consideration in a Special

Issue? :Not applicable (regular submission)

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

Liquefaction and Post-liquefaction Assessment of Lightly

Cemented Sands

Habib Rasouli 1, Behzad Fatahi 2* and Sanjay Shrawan Nimbalkar 3

1 PhD Candidate (BEng, MEng), School of Civil and Environmental Engineering, University of

Technology Sydney (UTS), Sydney, Australia. Email: [email protected]

2 Associate Professor of Geotechnical Engineering (PhD, CPEng, FIEAust), Centre for Built

Infrastructure Research (CBIR), School of Civil and Environmental Engineering, University of

Technology Sydney (UTS), Sydney, Australia. Email: [email protected]

3 Lecturer of Geotechnical Engineering (PhD, MTech, BEng), Centre for Built Infrastructure Research

(CBIR), School of Civil and Environmental Engineering, University of Technology Sydney (UTS),

Sydney, Australia. Email: [email protected]

*Corresponding Author, School of Civil and Environmental Engineering

Faculty of Engineering and Information Technology

University of Technology, Sydney (UTS)

City Campus PO Box 123 Broadway NSW 2007

T (+61) (2) 9514 7883 F (+61) (2) 9514 2633 M 0413573481

Email: [email protected]

Page 1 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

1 Liquefaction and Post-liquefaction Assessment of Lightly Cemented Sands

2 ABSTRACT

3 Post-liquefaction response of lightly cemented sands during an earthquake may alter and become

4 similar to uncemented sands due to bonding breakage. In the current study, the effect of degree of

5 cementation on liquefaction and post-liquefaction behaviour of lightly cemented sands was studied

6 through a series of cyclic and monotonic triaxial tests. Portland cement with high early strength and

7 Sydney sand were used to reconstitute the lightly cemented specimens with unconfined compression

8 strength ranging from 25 to 220 kPa. A series of multi-stage soil element tests including stress-

9 controlled cyclic loading events with different amplitudes and post-cyclic undrained monotonic

10 shearing tests were carried out on both uncemented and cemented specimens. Furthermore, a series of

11 undrained monotonic shearing tests without cyclic loading history on different types of specimens

12 were conducted to investigate the effect of cyclic loading history on the post-cyclic response of the

13 specimens. The results show that residual excess pore water pressure is correlated to the cyclic

14 degradation of lightly cemented sands during cyclic loading. In addition, optical microstructure

15 images of the cemented specimens after liquefaction showed that a major proportion of cementation

16 bonds remained unbroken which resulted in a superior post-liquefaction response with respect to

17 initial stiffness and shear modulus in comparison to the uncemented sand.

18 Keywords: Liquefaction; Post-liquefaction behaviour; lightly cemented sand; Multi-stage

19 soil element tests

Page 2 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

3

20 Introduction

21 In nature, soils are commonly found with some sort of cementation, or binding agents may be

22 added to improve soil response under static or cyclic loading. The degree of cementation can

23 vary ranging from very lightly cemented soils to strongly cemented soils where the

24 interparticle voids are filled with a cementing agent. Over the past few decades, liquefaction

25 response of cemented soils has attained extensive attention while the post-liquefaction

26 behaviour of cemented soils has not been studied comprehensively.

27 Post-liquefaction behaviour of uncemented soils

28 Among different types of soils, the post-liquefaction behaviour of clean sands has been

29 studied by many researchers (Ashour et al. 2009; Dash and Sitharam 2016; Sitharam et al.

30 2009; Toyota and Takada 2016; Vaid and Thomas 1995). Vaid and Thomas (1995) using

31 cyclic triaxial apparatus studied the post-liquefaction behaviour of loose to medium dense

32 clean sand under different confining pressure ranging from 100 to 1200 kPa. They showed

33 that the initial strength of liquefied clean sand was negligible, while by increasing the axial

34 strain beyond a certain value, the soil showed a dilative behaviour in which the excess pore

35 water pressure gradually decreased, and thus both shear strength and stiffness increased. They

36 also revealed that the recovery rate of the post-cyclic shear strength of the liquefied clean

37 sand would increase by increasing the initial relative density and decreasing the cyclic double

38 shear strain. In a similar research attempt adopting a series of multi-stage soil element tests

39 using cyclic triaxial, Rouholamin et al. (2017) showed that a bi-linear curve could present the

40 post-liquefaction stress-strain behaviour of sand with three parameters based on the initial

41 relative density of the specimen.

42 The effect of other parameters such as fines content, type of fines content, post-cyclic

43 reconsolidation effects on the post-liquefaction behaviour of sandy soils have been studied

Page 3 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

4

44 using laboratory tests (Ashour et al. 2009; Noorzad and Shakeri 2017; Rouholamin et al.

45 2017; Sitharam et al. 2013; Soroush and Soltani-Jigheh 2009; Wijewickreme and Sanin 2010;

46 Zhuang et al. 2018). Sitharam et al. (2013) through an experimental study using cyclic

47 triaxial setup investigated the effect of fines content, density, amplitude of cyclic shear stress

48 for a given confining pressure of 100 kPa on the post-liquefaction behaviour of sand-silt

49 mixture at the constant void ratios of 0.44 and 0.54 with and without dissipation of excess

50 pore water pressure built during liquefaction. The results showed that by increasing fines

51 content up to a specific value, liquefaction resistance and post-liquefaction shear strength

52 decreased. However, by increasing the fines content beyond a specific value, both

53 liquefaction and post-liquefaction resistances increased. This response was due to the

54 variation of relative density of silt-sand mixture to keep the void ratio constant, resulting in

55 the relative density decrease until a specific point (where silt particles occupied the voids

56 between sand particles) while beyond which the density increased. Similar results were

57 reported by Noorzad and Shakeri (2017) on the post-cyclic behaviour of silty sand. The

58 predations showed that the pore space between sand particles could be occupied by the fines

59 content in which rearrangement of soil particle during cyclic loading could result in

60 increasing or decreasing interlocking of the particles. Soroush and Soltani-Jigheh (2009)

61 using cyclic triaxial test studied liquefaction resistance of clay-sand and gravel-clay mixtures

62 with strain controlled cyclic loading tests. They also investigated the post-liquefaction shear

63 strength of liquefied soils in compression with monotonic shearing without cyclic loading

64 history. The results highlighted that adding granular material beyond a threshold resulted in

65 increasing shear strength and secant Young’s modulus during monotonic shearing.

66 Additionally, excess pore water pressure generation during cyclic loading increased with

67 increasing granular material content. Soroush and Soltani-Jigheh (2009) also showed that

Page 4 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

5

68 cyclic loading history considerably reduced the undrained shear strength and secant

69 deformation modulus.

70 Similar to sandy soils, the liquefaction resistance and post-liquefaction behaviour of silty

71 soils have been studied intensely (Erken and Ulker 2007; Kim et al. 2015; Wang et al. 2013;

72 Wang et al. 2015a; Wang et al. 2015b; Yasuhara et al. 2003). Erken and Ulker (2007), using

73 cyclic torsional tests, studied the cyclic and post-cyclic behaviour of fine-grained soils

74 including silts and silty clays using undisturbed and reconstituted specimens with plasticity

75 index ranging from 2 to 33%. The results showed that the post cyclic undrained shear

76 strength of the undisturbed and reconstituted specimens could significantly decrease

77 depending on the level of cyclic shear strain and number of cycles of loading at the specific

78 cyclic stress ratio.

79 Yasuhara et al. (2003) investigated post-cyclic behaviour of normally and overconsolidated

80 low plasticity silts ranging from 1 to 10% using cyclic triaxial tests. The obtained results

81 showed that stiffness degradation was more predominant than shear strength degradation and

82 by increasing the overconsolidation ratio, the ratio of stiffness to strength degradation

83 increased. Wang et al. (2015a) assessed the effect of clay content on the cyclic and post-

84 cyclic behaviour of low-plasticity silts using a series of cyclic triaxial tests. The results

85 showed that adding clay would alter the cyclic and post-cyclic behaviour of soil as the

86 Plasticity Index (PI) of silty clay increased. Indeed, they showed that the cyclic shear

87 behaviour of silty clays with PI < 6% was similar to clean sand, while when the Plasticity

88 Index was beyond 6%, both post-cyclic undrained shear strength and stiffness of liquefied

89 specimens increased. Wang et al. (2013) in similar research on Mississippi River Valley silt,

90 addressed the effect of limited liquefaction (i.e. ru < 1; where ru is the ratio of excess pore

91 water pressure over initial confining pressure) on post-cyclic shear strength and stiffness after

92 full and no excess pore water pressure dissipation. The obtained results revealed that when ru

Page 5 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

6

93 > 0.7, both volumetric strain and shear strength significantly increased when the excess pore

94 water pressure dissipation was allowed, while the initial stiffness and ultimate shear strength

95 considerably decreased in the case that the excess pore water pressure was not allowed to

96 dissipate. Zand et al. (2009) using cyclic triaxial tests studied the liquefaction resistance and

97 post-liquefaction strength after reconsolidation of impounded fly ash by considering the

98 variation of density, effective confining pressure and cyclic stress ratio. The results showed a

99 general trend of increasing post-cyclic shear strength of fly ash after being reconsolidated.

100 Effect of cementation on the dynamic behaviour of soils

101 To date, most researchers have been studying the effect of cementation on liquefaction

102 resistance and dynamic response of cemented soils, while no investigation is available on the

103 post-liquefaction behaviour of lightly cemented sands. According to the available studies in

104 the literature, increasing degree of cementation also significantly increases the liquefaction

105 resistance of soils (Clough et al. 1989; Diaz-Rodriguez et al. 2008; Porcino et al. 2012, 2015;

106 Saxena et al. 1988; Suazo et al. 2016). Clough et al. (1989) using an experimental study

107 showed that lightly cemented sands with an unconfined compression strength lower than 100

108 kPa are susceptible to liquefaction under the common earthquakes, while soils with the

109 unconfined compressive strength above 100 kPa are unlikely to undergo liquefaction

110 exclusively for very large earthquakes. In a similar research study using direct simple shear

111 tests on cemented backfill material, Suazo et al. (2016) showed that cemented soils with an

112 unconfined compression strength of 70 kPa could avoid liquefaction under cyclic loading

113 induced by an earthquake with the maximum ground acceleration of 0.3g. Diaz-Rodriguez et

114 al. (2008) found similar results for non-plastic silty sands improved with colloidal silica

115 grout, and they observed that adding colloidal silica grout to silty sand significantly decreased

116 generation of excess pore water pressure during cyclic loading. Porcino et al. (2012) using

117 experimental investigation with cyclic simple shear tests, drained triaxial tests and bender

Page 6 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

7

118 element tests studied the behaviour of lightly cemented silicate-grouted sand under both static

119 and dynamic loadings. The results showed that even a small amount of cementation increased

120 the initial stiffness and cyclic shear strength in comparison to clean sand.

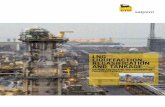

121 Figure 1 schematically shows the response of uncemented sand and lightly cemented sand

122 during an earthquake event. Referring to Figures 1a and b, an element of uncemented sand

123 during an earthquake, due to the increase of excess pore water pressure, liquefies. The

124 liquefied soil element as shown in Figure 1c indicates almost zero axial stiffness until a

125 significant settlement occurs. Generally, an even small degree of cementation increases the

126 liquefaction resistance of sands, however, there is a chance that during an earthquake, cyclic

127 shearing or excess pore water pressure would break the weak cementitious bonds between the

128 particles down so that after earthquake, the ground undergoes a significant deformation

129 similar to loose uncemented sand as shown in Figure 1d-e.

130 This research aims to assess the liquefaction and post-liquefaction resistance of lightly

131 cemented sands by considering the level of cementation and magnitude of cyclic loading. In

132 the present study, high early strength (Type III) Portland cement was used to constitute the

133 cemented sands. This type of cement was chosen since it results in a rapid increase of

134 strength allowing sample preparation and curing in seven days. To achieve these goals, a

135 series of multi-stage soil element tests including stress-controlled undrained cyclic loading at

136 a frequency of 1 Hz followed up by post-cyclic strain-controlled undrained monotonic

137 shearing were conducted for different soil compositions by considering the degree of

138 cementation ranging from uncemented to lightly cemented sands. In addition, a series of

139 strain-controlled monotonic undrained shearing tests without cyclic loading history for

140 different degrees of cementation were conducted to show the effect of cyclic loading events

141 on the monotonic shear strength of soils.

Page 7 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

8

142 Material and experimental method

143 Testing material

144 In the present study, Sydney sand was used to reconstitute four types of soil elements with

145 different degrees of cementation. The grain size distribution and index properties including

146 the mean diameter, coefficients of uniformity ( and curvature ( ), fines content ( , 𝐶𝑢) 𝐶𝑐 𝐹𝑐)

147 minimum and maximum unit weight ( , ) of Sydney sand was measured according to 𝛾𝑚𝑖𝑛 𝛾𝑚𝑎𝑥

148 Australian Standard AS 1289.5.5.1 (1998) and AS 1289.3.6.1 (2009) and results are

149 summarised in Figure 2 and Table 1. Similar to ASTM methods for determining maximum

150 and minimum dry density of cohesionless soil (ASTM D 4253-16 and ASTM D 4254-00),

151 the Australian Standard also adopts the minimum void ratio concept determined by pouring

152 oven dried material from a fixed height while the maximum density is achieved by pouring

153 the saturated cohesionless material into the mould and vibrating until the soil is completely

154 densified. The only differences between the relevant Australian standard and ASTM are

155 related to the mould size and surcharge load used to determine the density. Sydney sand with

156 the particle shape shown in Figure 2b, is classified as a uniform fine sand with a negligible

157 amount of fines content which is highly susceptible to liquefaction as indicated in Figure 2a

158 (PHRI. 1997).

159 In this study, Portland cement of high early strength type HE according to AS 3972 (2006)

160 was used to reconstitute the cemented sand specimens. Three types of cemented sands with

161 cement contents of 0.5, 1, and 2% (on the basis of dry weight of sand) was considered to

162 investigate the effect of degree of cementation on the cyclic and post-cyclic behaviour of

163 lightly cemented sands. In addition, a series of undrained monotonic shearing tests without

164 cyclic loading history for uncemented and cemented sands were conducted to evaluate the

165 effect of cyclic loading history on the post-liquefaction behaviour of cemented soils.

Page 8 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

9

166 A preliminary study based on unconfined compressive strength (UCS) was conducted to

167 evaluate the effect of cement content on sample strength. All unconfined compression tests

168 were conducted with a strain rate of 0.5 mm/min after seven days of curing. As Figure 3

169 shows, the unconfined compressive strength of cemented specimen with CC=2.0% was 218

170 kPa at the axial strain of 0.4%, while the corresponding unconfined compressive strength and

171 axial strain at peak strength for CC=1.0% were 76.4 kPa and 0.62%, respectively. Referring

172 to Figure 3, the obtained peak strength for the cemented specimen with CC=0.5% was 26.7

173 kPa with the corresponding axial strain of 0.74%, which is more than the other two samples

174 with higher cement content as expected.

175 Specimen preparation

176 Specimen preparation procedure has a significant effect on the dynamic behaviour of soil,

177 and the appropriate soil preparation method could lead to more consistent and accurate

178 results. In this series of tests, soil specimens were prepared using the under-compaction

179 method proposed by Ladd (1978). In the first step, the desired oven dried soil, water and

180 cement were weighted. In the next step, water and the soil were mixed with a weight ratio of

181 (where is the weight of water and is the weight of oven dried sand) in 𝑊𝑤 𝑊𝑆 = 5% 𝑊𝑤 𝑊𝑆

182 an electronic mixer until a homogeneous wet soil was attained. At the same time, cement and

183 water were mixed in a separate container with water: cement ratio of 1:1 (i.e. 𝑊𝑤 𝑊𝑐 = 1

184 where and are the weights of water and cement, respectively). Then the provided 𝑊𝑤 𝑊𝑐

185 grout was mixed with wet sand in the electric mixer until a uniform paste was attained. The

186 specimens were then statically compacted in five sublayers at a cylindrical split mould of 50

187 mm in diameter and 100 mm in high. Each sublayer was poured into the mold and compacted

188 to the desired level. Before placing the next layer, the top surface of each layer was coarsely

189 scratched to provide an appropriate bonding between sublayers. The entire procedure from

Page 9 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

10

190 mixing to compaction was done in less than 20 minutes, to ensure the initial setting of the

191 adopted high early strength cement was not impacted. All specimens were demolded after 24

192 hours and then cured for the next six days in a humidity chamber with a humidity level of

193 95% and a constant temperature of 25°. In the laboratory investigation, the most common

194 method for sample saturation is adopting high back pressure after supplemental percolation of

195 carbon dioxide through the sample in order to replace the air in the specimen with carbon

196 dioxide which is more solvable in water. Full saturation of cemented specimens through this

197 method usually requires a very high back pressure and depending on the degree of

198 cementation a high B value may not be attained as stated by Rad and Clough (1984).

199 However, in this study, to reach high level of saturation, the sample saturation using vacuum

200 procedure described by Rad et al. (1984) was used. Initially, a negative pressure (vacuum) of

201 about -10kPa was applied to the top of the sample in the triaxial setup to remove the air. In

202 the next step, the water was percolated to the specimen from the bottom line under a low

203 pressure of +7kPa, until no air bubbles were observed in the top line while still under

204 vacuum. Subsequently, the back pressure technique was used to reach the full saturation (i.e.

205 B-value of 0.95 or higher was deemed sufficient). Then, all specimens were isotropically

206 consolidated to the effective confining stress of 50 kPa.

207 Testing procedure

208 The liquefaction and post-liquefaction resistance assessment of all specimens were conducted

209 using cyclic triaxial apparatus available at the University of Technology Sydney as shown in

210 Figure 4. The multi-stage tests procedure in the current study is conceptually illustrated in

211 Figure 5. In this series of tests, as shown in Figure 5 with the solid line, the specimens were

212 first cyclically sheared with a stress-controlled condition at a constant frequency of 1 Hz

213 according to ASTM D5311M-13 (2013) until the excess pore water pressure ratio reached 1

214 (i.e. ratio of excess pore water pressure to initial effective confining pressure, as 𝑟𝑢 = 1

Page 10 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

11

215 shown in Figure 5a). The initial laboratory results obtained by the authors showed that

216 cemented specimens under a cyclic loading event with a very low cyclic stress ratio (CSR),

217 did not reach even subjected to 300 cycles of loading. However, in the range of CSRs 𝑟𝑢 = 1

218 chosen in this paper, all the specimens could reach . Hereafter, the applied cyclic 𝑟𝑢 = 1

219 deviator stress was expressed by using the cyclic stress ratio ( , where q and𝐶𝑆𝑅 = 𝑞 (2𝜎′0 3)

220 are the cyclic deviator stress and initial effective confining stress). All types of cemented 𝜎′0 3

221 and un-cemented specimens were liquefied at least under three different CSRs. As shown in

222 Figure 5a, after liquefaction (i.e. ), the specimens were monotonically sheared with 𝑟𝑢 = 1

223 undrained strain-controlled condition according to ASTM D4767-11 (2011). The strain rate

224 of 0.1 mm/min was applied to the specimens during monotonic shearing referring to ASTM

225 D4767-11 (2011) based on (i.e. the time for 50% primary consolidation) determined from 𝑡50

226 the consolidation phase.

227 In addition, corresponding samples with various cement contents (i.e. 0, 0.5, 1, and 2%) were

228 sheared monotonically without any prior cyclic loading, to explore the effect of cyclic

229 loading history and liquefaction on the post-cyclic response of the specimens. The summary

230 of tests conducted in this study is presented in Table 2.

231 Test results and analysis

232 Effect of degree of cementation on liquefaction resistance

233 Figure 6 shows a typical cyclic loading response of uncemented sand (i.e. clean sand) at a

234 cyclic stress ratio CSR=0.12. The stress path (i.e. where is the mean effective stress 𝑝′ ―𝑞 𝑝′

235 during cyclic loading and q is the cyclic deviator stress) presented for uncemented sand in

236 Figure 6a, shows that the mean effective stress during early loading cycles except the first 𝑝′

237 cycle decreased gradually, while in the last few loading cycles ( ) progressively 𝑁𝑐 = 12 to 15

238 decreased and finally, the specimen liquefied after 15 loading cycles. Similarly, in the few

Page 11 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

12

239 last cycles of loading, the axial strain and the excess pore water pressure ratio, 𝜀𝑎 𝑟𝑢 = 𝑢 𝜎′0 3

240 (where u is the excess pore water pressure during cyclic loading and is the initial 𝜎′0 3

241 effective confining stress) significantly increased as depicted in Figures 6b and 6c,

242 respectively. Figures 6b and c also show the residual axial strains and excess pore water

243 pressures. The residual pore water pressure is defined as the excess pore water pressure at the

244 end of each cycle of loading when the deviator stress is zero (i.e. ). The main focuse of 𝑞 = 0

245 this study is on the residual excess pore water pressure since it is induced by the progressive

246 collapse of the soil skeleton (Dobry et al. 1982; Polito et al. 2008).

247 Figure 7 shows a typical cyclic response of very lightly cemented sand with a cement content

248 of 0.5% at CSR=0.27. It is evidenced that even a small amount of cement (i.e. 𝐶𝐶 = 0.5%)

249 increased the liquefaction resistance of sand significantly. Referring to Figure 7a, similar to

250 the uncemented sand shown in Figure 6a, for a given number of loading cycles similar to the

251 one used for uncemented sand (i.e. 15 loading cycles ), the lightly cemented sand liquefied

252 however under a higher cyclic stress ratio of CSR=0.27 (note that the corresponding CSR for

253 uncemented sand was CSR=0.12). The excess pore water pressure of uncemented sand, at the

254 last few cycles of loading intensely increased when the excess pore water pressure ratio

255 reached as shown in Figure 6c, while the excess pore water pressure of the 𝑟𝑢 = 0.7

256 cemented sand with , from the early loading cycles gradually increased until the 𝐶𝐶 = 0.5%

257 specimen liquefied as evidenced in Figure 7c. This shows that the interparticles cementation

258 even under a high excess pore water pressure ratio (i.e. ) did not break down and 𝑟𝑢 > 0.7

259 contributed to the observed stiffness until the initial liquefaction was triggered (i.e. ).𝑟𝑢 = 1.0

260 Figure 8 indicates a typical response of cemented specimen with 1% cement content at

261 CSR=0.38. As shown in Figure 8a, the initial liquefaction triggered after 47 loading cycles. It

262 should be noted that the residual excess pore water pressure ratio (shown in red symbols) of

Page 12 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

13

263 cemented sand with a cement content of 1% at failure was less than one as shown in Figure

264 8c while the corresponding values for uncemented and cemented sands with 0.5% cement

265 content were equal one when the as shown in Figures 6c and 7c. This reduction of the 𝑟𝑢 = 1

266 residual excess pore water pressure ratio at failure (i.e. ) is due to a stronger 𝑟𝑢 = 1

267 cementitious bonds between particles.

268 Figure 9 shows the effect of cement content ranging from CC=0.5% to CC=2.0% on the

269 liquefaction resistance (i.e. ru=1) defined based on criterion proposed by Seed and Lee

270 (1966). The results demonstrate that the liquefaction resistance of uncemented sand

271 considerably increased with increasing cement content from 0.5 to 2%. For instance, for a

272 given number of loading cycles (i.e. 15 cycles), the required cyclic stress ratio to liquefy the

273 specimens with cement contents of 0.5, 1, and 2% were 2.25, 4.2, and 5.2 times higher than

274 the corresponding value for uncemented sand. It should also be noted that the liquefaction

275 resistance more significantly increased by increasing cement content from CC=0.5% to

276 CC=1.0% rather than CC=1.0% to CC=2.0%.

277 Pore water pressure generation during cyclic loading

278 In this section, the effect of degree of cementation on cyclic pore water pressure generation is

279 discussed in terms of the residual excess pore water pressure. The very first attempt to predict

280 pore water pressure generation during cyclic loading for clean sand was carried out by Seed

281 et al. (1975). Later on, Booker et al. (1976) simplified the proposed equation by Seed et al.

282 (1975) as follows:

283 (1)𝑅𝑢 ― 𝑟𝑒𝑠 =2𝜋𝑠𝑖𝑛

―1 [(𝑁𝑐𝑁𝑓)

12𝛼

]

284 where is the residual excess pore water pressure ratio at the end of each cycle of 𝑅𝑢 ― 𝑟𝑒𝑠

285 loading and is defined as a normalised cycle number which is the ratio of the number of 𝑁𝑐𝑁𝑓

Page 13 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

14

286 the applied loading cycles at the time of interest ( ) over the number of loading cycles 𝑁𝑐

287 required to trigger the liquefaction ( ) and the parameter is a fitting parameter which 𝑁𝑓 𝛼

288 depends on the soil composition. Figure 10 shows the residual excess pore water pressure of

289 clean sand under different CSR in comparison to the proposed model by Booker et al. (1976).

290 The residual excess pore water pressure of clean sand for different cyclic stress ratios were

291 well matched with the predictions of the model proposed by Booker et al. (1976) with

292 R2=0.99 adopting according to the recommendation of Seed et al. (1975) for clean 𝛼 = 0.7

293 sand. In contrast, the results of the residual excess pore water pressure of lightly cemented

294 sands with different cement contents reported in Figure 11 showed a significant discrepancy

295 to the predictions adopting the model proposed by Booker et al. (1976). Indeed, the

296 coefficients of determination of the model proposed by Booker et al. (1976) were 0.79 and

297 0.49, for cemented sands with CC=0.5%, and CC=1 and 2% respectively as shown in Figure

298 11.

299 Therefore, the correlation developed for uncemented sand is not reliable for cemented sands

300 as expressed by other researchers (Clough et al. 1989; Porcino et al. 2012, 2015). Porcino et

301 al. (2015) using cyclic simple shear tests on moderately grouted sands with an unconfined

302 compressive strength of 500 kPa proposed an empirical equation as follows:

303 (2)𝑅𝑢 ― 𝑟𝑒𝑠 = 𝑎.(𝑁𝑐𝑁𝑓)

𝑏.𝑐(𝑁𝑐/𝑁𝑓)

304 where a, b, and c are model parameters which are functions of soil type, the degree of

305 cementation and the initial density of uncemented sand, which can be obtained by fitting the

306 equation to the experimental data. To verify the validity of the proposed equation for

307 predicting the residual pore water pressure of very lightly cemented sand using cyclic triaxial,

308 the obtained results of cemented sands for different cement contents available in this study

309 were plotted in comparison to the equation proposed by Porcino et al. (2015). In this study,

310 the direct search method using a Downhill Simplex Algorithm also known as Nelder-Mead

Page 14 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

15

311 (Nelder and Mead 1965) was used to determine the model parameters in Equations (2) and

312 (4). This method uses the Simplex algorithm to adjust the parameter "simplex" until it

313 converges to a local minimum during the iterations. This method is one of the well-known

314 algorithms for multidimensional unconstrained optimisation which does not require any

315 derivative information, and it is widely used in different fields of science and technology for

316 parameter estimation.

317 Figure 11 shows the residual excess pore water pressure for cemented sands in compression

318 to the predictions adopting Booker et al. (1976) and Porcino et al. (2015) models. The

319 residual excess pore water pressure of very lightly cemented sand with a cement content of

320 reported in this study agreed well with predictions using the proposed model by 𝐶𝐶 = 0.5%

321 Porcino et al. (2015) with R2=0.99 and model parameters shown in Figure 11a. In addition,

322 the residual excess pore water pressure ratio of the very lightly cemented sands with

323 CC=0.5% varied by increasing the CSR in such way that under a low CSR (e.g. CSR=0.17)

324 showed a double curvature behaviour while by increasing the CSR, the second curvature tend

325 to alter to linear as shown in Figure 11a. However, Figure 11b indicates that by increasing the

326 cement content, the residual excess pore water pressure ratio showed a single curvature

327 behaviour. In addition, the proposed model fits very well with the residual excess pore water

328 pressure for the higher cement contents of 1 and 2% with the coefficient of determination of

329 R2=0.99 as evidenced in Figure 11b.

330 Residual pore water ratio model based on cyclic stiffness degradation index

331 The concept of cyclic stiffness degradation index ( ) was proposed by Idriss et al. (1978) as 𝛿

332 the ratio of secant shear modulus at the loading cycle N to the secant shear modulus at (𝐺𝑠𝑁)

333 the first cycle of loading as presented in Equation (3). (𝐺𝑠1)

334 (3)𝛿 =𝐺𝑠𝑁𝐺𝑠1

Page 15 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

16

335 Matasovic and Vucetic (1992, 1995) using cyclic simple shear tests proposed a model to

336 predict the residual pore water pressure of normally consolidated and overconsolidated

337 marine clays based on cyclic degradation. The proposed model was a function of cyclic

338 degradation, residual pore water pressure and the threshold shear strain beyond which

339 significant pore water pressure generates and degradation occurs.

340 In contrast to the pore water pressure generation model based on the normalised cycle

341 number (i.e. for cemented sands and uncemented sands, no attempt has been made so 𝑁𝐶 𝑁𝑓)

342 far to correlate cyclic stiffness degradation index and cyclic excess pore water (i.e. 𝛿)

343 pressure generation in lightly cemented sands. Since a majority of natural sand deposits

344 contain some degree of cementation (Arroyo et al. 2013; Jiang et al. 2017; Sharma and Fahey

345 2004; Toll and Rahman 2017) such correlation could lead to a better understanding of the

346 dynamic response of lightly cemented sands during an earthquake event.

347 Figure 12 illustrates the variation of the cyclic stiffness degradation index with the (𝛿)

348 normalised cycle number for different cement content. Figure 12a illustrates the (𝑁𝐶 𝑁𝑓)

349 variations of cyclic stiffness degradation index for very lightly cemented sand with 𝐶𝐶

350 in comparison to clean sand with no cementation. As evidenced in Figure 12a, the = 0.5%

351 value of for uncemented sand reduced rapidly with increasing number of loading cycles. 𝛿

352 However, very lightly cemented sand with a cement content of 0.5% showed a different

353 behaviour under cyclic loading in comparison to uncemented sand.

354 Referring to Figure 12a, it is evidenced that the cyclic stiffness degradation index of the very

355 lightly cemented sand with under a cyclic loading event with low cyclic stress 𝐶𝐶 = 0.5%

356 ratio (e.g. CSR=0.17), gradually decreased until normalised cycle number of 0.3, while

357 beyond which it behaved similar to the uncemented sand. It seems that by increasing cyclic

358 number some of the weak cementitious bonds broke down therefore soil behaved similar to

359 the uncemented sand. However, under a cyclic loading event with a higher cyclic stress ratio

Page 16 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

17

360 such as CSR=0.34, cyclic degradation behaviour was entirely similar to the uncemented sand,

361 and δ decreased rapidly from the early stages as shown in Figure 12a. This rapid reduction

362 might be due to this fact that the cyclic applied stress at the beginning was much higher than

363 the strength of bonds between the sand particles. Furthermore, cyclic stiffness degradation

364 index at the onset of failure/liquefaction (i.e. for both very lightly cemented sand 𝑟𝑢 = 1)

365 with and the uncemented sand were similar and well below 0.05.𝐶𝐶 = 0.5%

366 Lightly cemented sands with showed a different trend in which gradually 𝐶𝐶 = 1% and 2% δ

367 decreased by increasing normalised cycle number, while in contrast to uncemented sand and

368 very lightly cemented sand (i.e. ), cyclic stiffness degradation index at failure (i.e. 𝐶𝐶 = 0.5%

369 the initial liquefaction at was between 0.1 and 0.2, depending on the cyclic stress 𝑟𝑢 = 1)

370 ratio and cement content as shown in Figure 12b. In addition, by looking at the cyclic

371 stiffness degradation index for all uncemented and cemented specimens with different level

372 of cementation, by increasing cyclic stress ratio, the rate of degradation increased as observed

373 in Figure 12. A similar trend was also reported by Sharma and Fahey (2003) for artificially

374 cemented soil with calcareous.

375 The obtained results from cyclic stress-controlled tests on the uncemented sand and lightly

376 cemented sands with different cement content and cyclic stress ratios were used to correlate a

377 relationship between normalised residual excess pore water pressure and the cyclic stiffness

378 degradation index. The following empirical relationship is proposed for predicting the cyclic

379 residual excess pore water pressures based on cyclic stiffness degradation index:

380 (4)𝑅𝑢𝑐 ― 𝑟𝑒𝑠𝑅𝑢𝑓 ― 𝑟𝑒𝑠 = 𝑑 + 𝑒.𝛿

𝑓

381 where is cyclic stiffness degradation index of soil during cyclic loading defined in Equation 𝛿

382 (3), and are the residual excess pore water pressures at the end of each 𝑅𝑢𝑐 ― 𝑟𝑒𝑠 𝑅𝑢𝑓 ― 𝑟𝑒𝑠

383 loading cycles and the residual excess pure water pressure at failure where , 𝑟𝑢 = 1

384 respectively, d, e, and f are model parameters which mainly dependent on cyclic stress ratio

Page 17 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

18

385 and degree of cementation. It should be noted that the residual excess pore water pressure

386 ratio of uncemented and very lightly cemented sands with at failure was one as 𝐶𝐶 = 0.5%

387 shown in Figures 6c and 7c, while the corresponding value for cemented sands with 𝐶𝐶

388 was less than one as depicted in Figure 8c.= 1 and 2%

389 Figure 13 shows the variation of the normalised residual excess pore water pressures ratio

390 with the cyclic stiffness degradation index for samples with different cement contents.

391 Referring to Figure 13, the proposed Equation (4) with the calibrated model parameters

392 reported in the same figure, showed a good agreement with the experimental results.

393 Post-liquefaction results and analysis of specimens

394 The specimens with and without cement were first liquefied under stress-controlled cyclic

395 loading with different cyclic stress ratios at a frequency of 1 Hz, and then they were

396 monotonically sheared under undrained condition and strain controlled loading with a strain

397 rate of 0.1 mm/min. Figures 14 and 15 show the post-liquefaction monotonic undrained

398 shearing response of samples with different cement content in comparison to the monotonic

399 shearing response of the similar specimens without prior cyclic loading history (or

400 liquefaction).

401 As evidenced in Figure 14a, a liquefied uncemented sand under undrained monotonic

402 shearing showed a very low initial stiffness as stated by other researchers (i.e. nearly zero)

403 (Ashour et al. 2009; Rouholamin et al. 2017; Sitharam et al. 2009; Sitharam et al. 2013; Vaid

404 and Thomas 1995). However, by increasing axial strain to a certain level, the specimen

405 stiffness slowly increased due to soil particles rearrangement during undrained monotonic

406 shearing. Referring to Figure 14a, by further shearing the specimen (i.e. increasing the axial

407 strain) beyond a specific level (i.e. the axial strain of 2.5% in Figure 14a), the axial stiffness

408 increased significantly. A similar trend was also observed for the excess pore water pressure

Page 18 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

19

409 of uncemented sand during undrained post-cyclic monotonic shearing as shown in Figure

410 15a. The excess pore water pressure during monotonic shearing in Figure 15 was normalised

411 with the initial confining pressure. As shown in Figure 15a, the excess pore water pressure

412 ratio of uncemented sand at failure (i.e. , until the axial strain of 2.5% did not 𝑟𝑢 = 1)

413 decrease while beyond which it considerably decreased.

414 In contrast, the initial axial stiffness of cemented sands under different CSRs was

415 considerably higher than the corresponding values for uncemented sand and depended on the

416 degree of cementation and cyclic stress ratio as shown in Figures 14b-d. Referring to Figure

417 14b, it is evidenced that the initial stiffness of very lightly cemented sand with a cement

418 content of 0.5% was much higher than uncemented sand. The results showed that even a high

419 magnitude cyclic loading event and the induced excess pore water pressure could not break

420 all the weak cementation bonds down. In order to show this fact, the microstructure of the

421 cemented sands after liquefaction was analysed to show the circumstance of cementation

422 bonds after liquefaction. Figure 16 shows the microstructure of two cemented specimens with

423 cement contents of 0.5% and 1% after liquefaction under cyclic loading events with CSRs of

424 0.23 and 0.22 respectively. Many interparticle cementation bonds for both cement contents of

425 0.5% and 1% were remained unbroken after liquefaction as shown in Figure 16. The

426 unbroken bonds after liquefaction significantly improve the post-liquefaction response of

427 lightly cemented sands in comparison to uncemented sand. The uncemented sand and very

428 lightly cemented specimens with CC=0.5% showed a bulging-barrelling mode of failure

429 without a specific shear band observed either after experiencing liquefaction or without cyclic

430 loading histories. The failure mode after liquefaction for lightly cemented specimens with

431 CC=1% was a combination of the shear band forming and bulging-barrelling mode as shown

432 in Figure 17. However, the samples with CC=2% before cyclic loading events and after

433 liquefaction showed a full shear band formed as evidenced in Figure 17. In general, the

Page 19 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

20

434 cemented specimens with CC=0.5 and 1% seemed partially cemented after experiencing

435 liquefaction, while for higher cement content (i.e. CC=2%) after liquefaction the sample

436 looked generally cemented.

437 In addition, under a cyclic loading event, the initial stiffness of cemented sands increased

438 with the degree of cementation, while it significantly reduced under a cyclic loading event

439 with a higher amplitude (i.e. higher CSR) as shown in Figure 14b-d. Furthermore, following

440 the recommendation by Gu et al. (2014), to evaluate the effect of cyclic loading history with

441 different CSRs on secant shear modulus Gsec (the secant shear modulus at half of the peak

442 deviator stress), a secant shear modulus reduction factor can be defined as follows:

443 (5)𝑅𝑠𝑒𝑐 =𝐺′𝑠𝑒𝑐 ― 𝐺𝑠𝑒𝑐

𝐺𝑠𝑒𝑐

444 where and are the secant shear modulus corresponding to post-liquefaction 𝐺′𝑠𝑒𝑐 𝐺𝑠𝑒𝑐

445 undrained monotonic shearing of the liquefied specimens after cyclic loading and the

446 specimens without prior cyclic loading history, respectively. Figure 18 shows the effect of

447 cyclic loading history on shear modulus for samples with different cement content. It is

448 evidenced that the post-cyclic secant shear modulus under a cyclic loading history with a

449 higher cyclic stress ratio reduced more significantly. For instance, secant shear modulus of

450 cemented sand with 1% cement content, reduced 45.7% when it experienced a cyclic loading

451 event with CSR=0.38, while the corresponding reduction for CSR=0.42 was 65.2%. The

452 higher rate of secant modulus reduction under higher cyclic stress ratio could be due to this

453 fact that under a higher applied cyclic loading, more particles may exceed their cementitious

454 bond strength. Therefore, more interparticle bonding would break when cyclic loading event

455 with a higher CSR is applied. The results clearly show that under a cyclic loading event with

456 higher amplitude, more interparticle bonding would break subjected to cyclic loading event.

457 Summary and conclusions

Page 20 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

21

458 The liquefaction and post-liquefaction resistance of lightly cemented sands were studied

459 through a series of multi-stage tests on samples with different cement content using cyclic

460 triaxial apparatus. Furthermore, a series of undrained monotonic shear tests on similar

461 specimens without cyclic loading history was conducted. Portland cement Type III as a

462 cementing agent was used in this study. However, further research is necessary to be

463 undertaken in future to assess the impact of other cementing agents such as lime on the post-

464 liquefaction behaviour of lightly cemented soils. The post-liquefaction behaviour of lightly

465 cemented sands is of great importance since there is a chance that during cyclic loading due

466 to bonding breakage, lightly cemented soils similar to uncemented sand experience a

467 significant axial deformation. Specific conclusions of this study are:

468 1. The liquefaction resistance of the sand increased considerably with the additions of

469 cementing agents. Moreover, increasing degree of cementation altered the trend of residual

470 excess pore water pressure during cyclic loading in comparison to the proposed model by

471 Seed et al. (1975) for the prediction of residual excess pore water pressure based on the

472 normalised cycle number. The residual excess pore water pressure of lightly cemented

473 sands, irrespective of the cyclic stress ratio and degree of cementation, were in a good

474 agreement with the proposed model by Porcino et al. (2015) for predicting residual excess

475 pore water pressure based on the normalised cycle number.

476 2. An empirical equation was proposed to predict the residual excess pore water pressure of

477 lightly cemented sands as a function of the cyclic degradation. The proposed equation

478 showed satisfactory predictions for the residual pore water pressure for different degrees

479 of cementation and cyclic stress ratios.

480 3. While uncemented sand specimens after liquefaction almost showed zero initial stiffness,

481 an even small amount of cement improved the post-liquefaction initial stiffness of lightly

482 cemented sand considerably. The microstructure analysis of cemented specimens after

Page 21 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

22

483 liquefaction showed that even under large cyclic loading events, parts of cementation

484 bonds remained unbroken. Therefore, the post-liquefaction initial and secant shear

485 modulus of cemented sands were more than the corresponding values for the uncemented

486 sand.

487 4. A comparison between the stress-strain behaviour of lightly cemented sands after

488 experiencing liquefaction and the corresponding response of specimens without prior

489 liquefaction revealed that undrained shear strength, initial and secant shear modulus of

490 lightly cemented sands reduced significantly due to liquefaction. The reduction rate was a

491 function of the amplitude of cyclic deviator stress, number of loading cycles, and degree

492 of cementation.

Reference

ASTM D5311-13, 2013. Standard Test Method for Load Controlled Cyclic Triaxial Strength of Soil. ASTM International, West Conshohocken, PA, USA.

AS 3972, 2010. General Purpose and Blended Cements.

ASTM 4254–00, 2002. Standard test method for minimum index density and unit weight of soils and calculation of relative density. ASTM International, West Conshohocken, PA, USA. pp. 1-9.

AS 1289.5.5.1, 1998. Soil compaction and density tests - Determination of the minimum and maximum dry density of a cohesionless material - Standard method.

AS 1289.3.6.1, 2009. Soil classification tests - determination of the particle size distribution of a soil - standard method of analysis by sieving.

ASTM 4253-00, 2000. Standard Test Methods for Maximum Index Density and Unit Weight of Soils Using a Vibratory Table. ASTM International, West Conshohocken, PA, USA.

Arroyo, M., Amaral, M., Romero, E., and Viana da Fonseca, A. 2013. Isotropic yielding of unsaturated cemented silty sand. Canadian Geotechnical Journal, 50(8): 807-819.

Ashour, M., Norris, G., and Nguyen, T. 2009. Assessment of the undrained response of sands under limited and complete liquefaction. Journal of geotechnical and geoenvironmental engineering, 135(11): 1772-1776.

Booker, J.R., Rahman, M.S., and Seed, H.B. 1976. GADFLEA: a computer program for the analysis of pore pressure generation and dissipation during cyclic or earthquake loading.

Clough, G.W., Iwabuchi, J., Rad, N.S., and Kuppusamy, T. 1989. Influence of cementation on liquefaction of sands [Article]. Journal of Geotechnical Engineering, 115(8): 1102-1117. doi:10.1061/(ASCE)0733-9410(1989)115:8(1102).

Page 22 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

23

Dash, H., and Sitharam, T. 2016. Effect of frequency of cyclic loading on liquefaction and dynamic properties of saturated sand. International Journal of Geotechnical Engineering, 10(5): 487-492.

Diaz-Rodriguez, J., Antonio-Izarraras, V., Bandini, P., and López-Molina, J. 2008. Cyclic strength of a natural liquefiable sand stabilized with colloidal silica grout. Canadian Geotechnical Journal, 45(10): 1345-1355.

Dobry, R., Ladd, R., Yokel, F.Y., Chung, R.M., and Powell, D. 1982. Prediction of pore water pressure buildup and liquefaction of sands during earthquakes by the cyclic strain method. National Bureau of Standards Gaithersburg, MD.

Erken, A., and Ulker, B.C. 2007. Effect of cyclic loading on monotonic shear strength of fine-grained soils. Engineering Geology, 89(3): 243-257.

Gu, C., Wang, J., Cai, Y., and Guo, L. 2014. Influence of cyclic loading history on small strain shear modulus of saturated clays. Soil Dynamics and Earthquake Engineering, 66: 1-12. doi:https://doi.org/10.1016/j.soildyn.2014.06.027.

Idriss, I.M., Dobry, R., and Sing, R. 1978. Nonlinear behavior of soft clays during cyclic loading. Journal of geotechnical and geoenvironmental engineering, 104(ASCE 14265).

Jiang, M., Li, T., Cui, Y., and Zhu, H. 2017. Mechanical behavior of artificially cemented clay with open structure: Cell and physical model analyses [Article]. Engineering Geology, 221: 133-142. doi:10.1016/j.enggeo.2017.03.002.

Kim, J., Kawai, T., Kazama, M., and Mori, T. 2015. Density Index for Estimating the Postliquefaction Volumetric Strain of Silty Soils. International Journal of Geomechanics, 16(5): C4015005.

Ladd, R. 1978. Preparing test specimens using undercompaction. Geotechnical Testing Journal, 1(1): 16-23.

Nelder, J.A., and Mead, R. 1965. A Simplex Method for Function Minimization. The Computer Journal, 7(4): 308-313. doi:10.1093/comjnl/7.4.308.

Noorzad, R., and Shakeri, M. 2017. Effect of silt on post-cyclic shear strength of sand. Soil Dynamics and Earthquake Engineering, 97: 133-142.

PHRI. 1997. Handbook on liquefaction remediation of reclaimed land. Port and Harbor Research Institute Balkema, Rotterdam, Netherlands.

Polito, C.P., Green, R.A., and Lee, J. 2008. Pore pressure generation models for sands and silty soils subjected to cyclic loading. Journal of geotechnical and geoenvironmental engineering, 134(10): 1490-1500.

Porcino, D., Marcianò, V., and Granata, R. 2012. Static and dynamic properties of a lightly cemented silicate-grouted sand. Canadian Geotechnical Journal, 49(10): 1117-1133.

Porcino, D., Marcianò, V., and Granata, R. 2015. Cyclic liquefaction behaviour of a moderately cemented grouted sand under repeated loading. Soil Dynamics and Earthquake Engineering, 79: 36-46.

Rad, N.S., and Clough, G.W. 1984. New Procedure for Saturating Sand Specimens. Journal of Geotechnical Engineering, 110(9): 1205-1218. doi:doi:10.1061/(ASCE)0733-9410(1984)110:9(1205).

Page 23 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

24

Rouholamin, M., Bhattacharya, S., and Orense, R.P. 2017. Effect of initial relative density on the post-liquefaction behaviour of sand. Soil Dynamics and Earthquake Engineering, 97: 25-36.

Saxena, S.K., Reddy, K.R., and Avramidis, A.S. 1988. Liquefaction resistance of artificially cemented sand. Journal of Geotechnical Engineering, 114(12): 1395-1413.

Seed, H.B., Martin, P.P., and Lysmer, J. 1975. The generation and dissipation of pore water pressures during soil liquefaction.

Sharma, S.S., and Fahey, M. 2003. Degradation of stiffness of cemented calcareous soil in cyclic triaxial tests. Journal of geotechnical and geoenvironmental engineering, 129(7): 619-629.

Sharma, S.S., and Fahey, M. 2004. Deformation characteristics of two cemented calcareous soils. Canadian Geotechnical Journal, 41(6): 1139-1151.

Sitharam, T., Vinod, J., and Ravishankar, B. 2009. Post-liquefaction undrained monotonic behaviour of sands: experiments and DEM simulations. Géotechnique, 59(9): 739-749.

Sitharam, T., Dash, H., and Jakka, R.S. 2013. Postliquefaction undrained shear behavior of sand-silt mixtures at constant void ratio. International Journal of Geomechanics, 13(4): 421-429.

Soroush, A., and Soltani-Jigheh, H. 2009. Pre-and post-cyclic behavior of mixed clayey soils. Canadian Geotechnical Journal, 46(2): 115-128.

Suazo, G., Fourie, A., and Doherty, J. 2016. Cyclic Shear Response of Cemented Paste Backfill. Journal of geotechnical and geoenvironmental engineering, 143(1): 04016082.

Toll, D.G., and Rahman, Z.A. 2017. Critical state shear strength of an unsaturated artificially cemented sand [Article]. Géotechnique, 67(3): 208-215. doi:10.1680/jgeot.15.P.042.

Toyota, H., and Takada, S. 2016. Variation of Liquefaction Strength Induced by Monotonic and Cyclic Loading Histories. Journal of geotechnical and geoenvironmental engineering: 04016120.

Vaid, Y., and Thomas, J. 1995. Liquefaction and postliquefaction behavior of sand. Journal of Geotechnical Engineering, 121(2): 163-173.

Wang, S., Luna, R., and Yang, J. 2013. Postcyclic behavior of low-plasticity silt with limited excess pore pressures. Soil Dynamics and Earthquake Engineering, 54: 39-46.

Wang, S., Luna, R., and Zhao, H. 2015a. Cyclic and post-cyclic shear behavior of low-plasticity silt with varying clay content. Soil Dynamics and Earthquake Engineering, 75: 112-120.

Wang, S., Luna, R., and Onyejekwe, S. 2015b. Postliquefaction behavior of low-plasticity silt at various degrees of reconsolidation. Soil Dynamics and Earthquake Engineering, 75: 259-264.

Wijewickreme, D., and Sanin, M.V. 2010. Postcyclic reconsolidation strains in low-plastic Fraser River silt due to dissipation of excess pore-water pressures. Journal of geotechnical and geoenvironmental engineering, 136(10): 1347-1357.

Yasuhara, K., Murakami, S., Song, B.-W., Yokokawa, S., and Hyde, A.F.L. 2003. Postcyclic Degradation of Strength and Stiffness for Low Plasticity Silt. Journal of geotechnical and geoenvironmental engineering, 129(8): 756-769. doi:doi:10.1061/(ASCE)1090-0241(2003)129:8(756).

Page 24 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

25

Zand, B., Tu, W., Amaya, P.J., Wolfe, W.E., and Butalia, T.S. 2009. An experimental investigation on liquefaction potential and post-liquefaction shear strength of impounded fly ash. Fuel, 88(7): 1160-1166.

Zhuang, H., Wang, R., Chen, G., Miao, Y., and Zhao, K. 2018. Shear modulus reduction of saturated sand under large liquefaction-induced deformation in cyclic torsional shear tests. Engineering Geology, 240: 110-122. doi:https://doi.org/10.1016/j.enggeo.2018.04.018.

Page 25 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

26

List of symbols

PI Plasticity Indexru Excess pore water pressure ratio𝐶𝑢 Coefficient of uniformity𝐶𝑐 Coefficient of curvature𝐹𝑐 Fines content

𝛾𝑚𝑖𝑛 Minimum unit weight𝛾𝑚𝑎𝑥 Maximum unit weightGs Specific gravity

UCS Unconfined compressive strength𝑊𝑤 Weight of water𝑊𝑆 Weight of oven dried sand𝐶𝑆𝑅 Cyclic stress ratio

q Deviator stress𝜎′0 3 Initial effective confining stress𝑝′ Mean effective stress𝑢 Excess pore water pressure

𝑅𝑢 ― 𝑟𝑒𝑠 Residual excess pore water pressure ratio𝑁𝐶 𝑁𝑓 Normalised cycle number

𝑁𝑓 Number of loading cycles to trigger liquefaction𝑁𝑐 Applied loading cycles at the time of interest𝛼 Soil fitting parameter

a, b, and c Model fitting parameter𝐶𝐶 Cement content𝛿 Cyclic stiffness degradation index

𝐺𝑠𝑁 Secant shear modulus at the loading cycle N𝐺𝑠1 Secant shear modulus at the first cycle of loading

𝑅𝑢𝑐 ― 𝑟𝑒𝑠 Residual excess pore water pressures at the end of each loading cycles𝑅𝑢𝑓 ― 𝑟𝑒𝑠 Residual excess pore water pressure at failure

d, e, and f Model fitting parameters

GsecSecant shear modulus of undrained monotonic shearing without prior cyclic loading

𝐺′𝑠𝑒𝑐 Secant shear modulus of post-cyclic undrained monotonic shearing 𝑅𝑠𝑒𝑐 Secant shear modulus reduction factor

Page 26 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

1

Figure captions

Figure 1. Schematically representation of liquefaction and post-liquefaction resistance of uncemented sand in comparison to lightly cemented sand (a) uncemented sand before earthquake (b) liquefaction triggering due to earthquake (c) post-cyclic monotonic shearing; (d) cemented sand before the earthquake (e) bonding breakage during earthquake, (f) post-cyclic monotonic shearing

Figure 2. (a) Grain size distribution curve for Sydney sand in comparison to particle size distribution susceptible to liquefaction, (b) particle shape of Sydney sand

Figure 3. Unconfined compression strength of cemented sands with different cement contents including CC=0.5, 1.0, and 2.0%

Figure 4. (a) Schematic diagram of the experiment system and (b) cyclic triaxial equipment used in this study

Figure 5. Schematic representation of multi-stage tests (a) cyclic loading and post-cyclic monotonic shearing and (b) the corresponding stress path in the current study

Figure 6. Cyclic response of uncemented sand under CSR=0.12; variation of (a) mean effective stress with deviator stress; (b) axial strain with the number of cycles; (c) excess pore water pressure ratio with the number of cycles; (d) cyclic deviator stress with axial strain

Figure 7. Cyclic response of cemented sand with 0.5% cement content under CSR=0.27; variation of (a) mean effective stress with deviator stress; (b) axial strain with the number of cycles; (c) excess pore water pressure ratio with the number of cycles; (d) cyclic deviator stress with axial strain

Figure 8. Cyclic response of cemented sand with 1% cement content under CSR=0.38; variation of (a) mean effective stress with deviator stress; (b) axial strain with the number of cycles; (c) excess pore water pressure ratio with the number of cycles; (d) cyclic deviator stress with axial strain

Figure 9. Effect of degree of cementation on liquefaction resistance

Figure 10. Residual excess pore water pressure ratio of uncemented sand for different cyclic stress ratio

Figure 11. Residual excess pore water pressure ratio for cemented sand with (a) cement content

of 0.5% and (b) 1 and 2%

Figure 12. Cyclic stiffness degradation index of Sydney sand in comparison to cemented sand with cement content ratio of (a) and (b) with normalized cycle number 𝐶𝐶 = 0.5% 𝐶𝐶 = 1.0 and 2.0%

Figure 13. Normalised residual excess pore water pressure (a) for uncemented sand and cemented sand with cement contents of (b) 0.5% (c) 1 and 2% based on cyclic stiffness degradation index

Figure 14. Post-cyclic undrained shearing response of (a) uncemented sands; and cemented sands with (b), (c) , and (d) 𝐶𝐶 = 0.5% 𝐶𝐶 = 1.0% 𝐶𝐶 = 2.0%

Page 27 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

2

Figure 15. Post-liquefaction excess pore water pressure response of (a) uncemented sands, and cemented sands with (b) , (c) , and (d) 𝐶𝐶 = 0.5% 𝐶𝐶 = 1.0% 𝐶𝐶 = 2.0%

Figure 16. Microstructure of lightly cemented sands with cement content (a) , (b) 𝐶𝐶 = 0.5% 𝐶𝐶 = 1%after liquefaction under cyclic loading event with CSRs of 0.23 and 0.22 respectively

Figure 17. Post-monotonic shearing response of (a) uncemented sand in comparison to cemented sand with cement content of (b) CC=0.5%; (c) CC=1.0% and (d) CC=2.0%

Figure 18. Effect of cyclic loading history on secant shear modulus of uncemented sand and cemented sands

Page 28 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

3

(a) (b) (c)

Sand grains

Pore water

EarthquakeConstantvolume

Earthquake

No axial stiffness untilrearrangement of sandgrains

Constantvolume

Sand grainsseparation

Sand grains

Pore water

EarthquakeConstantvolume

Earthquake

No axial stiffness untilrearrangement of sandgrains

Constantvolume

Sand grainsseparation

Sand grains

Pore water

EarthquakeConstantvolume

Earthquake

No axial stiffness untilrearrangement of sandgrains

Constantvolume

Sand grainsseparation

(d) (e) (f)

Sand Grains

Cementationbonds Bondingbreakages

EarthquakeConstantvolume

Earthquake

Axial strainConstantvolume

Pore water

Sand Grains

Cementationbonds Bondingbreakages

EarthquakeConstantvolume

Earthquake

Axial strainConstantvolume

Pore water

Sand Grains

Cementationbonds Bondingbreakages

EarthquakeConstantvolume

Earthquake

Axial strainConstantvolume

Pore water

Figure 1. Schematically representation of liquefaction and post-liquefaction resistance of uncemented sand in comparison to lightly cemented sand (a) uncemented sand before earthquake (b) liquefaction triggering due to earthquake (c) post-cyclic monotonic shearing; (d) cemented sand before the earthquake (e) bonding breakage during earthquake, (f) post-cyclic monotonic shearing

Page 29 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

4

(a)

0.001 0.01 0.1 1 100

20

40

60

80

100

Liquefable

Pass

ing

(%)

Particle size (mm)

Sydney Sand

Highly liquefiable

PHRI. (1997)

(b)

Date: 18 Oct 2018Time: 10:12:17

128 mMag= 10.0 XWidth=1.6 mmUTS

Figure 2. (a) Grain size distribution curve for Sydney sand in comparison to particle size distribution susceptible to liquefaction, (b) particle shape of Sydney sand

Page 30 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

5

0.00 0.25 0.50 0.75 1.000

50

100

150

200

250

300

UCS=218 kPa

UCS=26.7 kPa

Axi

al s

tress

(kP

a)

Axial strain, a (%)

CC=2.0%CC=1.0%CC=0.5%

UCS=76.4 kPa

Cemented sand

Figure 3. Unconfined compressive strength of cemented sands with different cement contents including CC=0.5, 1.0, and 2.0%

Page 31 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

6

(a)

Dynamic control &data acquisition unit

Back pressure /Volume controller

Pneumatic controller/Air pressure

Negative pressureline

Vertical displacementtransducer & loading system

Cell

Cell pressure line

Soil specimen

Submerged load cell

Water level

Pressure transducerLower drainageUpper drainage

(b)

Dynamic control &data acquisition unit

Back pressure /Volume controller Pressure transducer Pneumatic controller

Water reservoirVertical displacement transducer and vertical loading system

Triaxial Cell

Figure 4. (a) Schematic diagram of the experiment system and (b) cyclic triaxial equipment used in this study

Page 32 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

7

(a)

q

Time

Isotropicallyconsolidatedat =50 kPa

Mon

otonic

shea

ring

witho

ut cy

clic l

oadin

g

Mon

otonic

shea

ring a

fter

lique

factio

n

0

max

Dev

iato

r stre

ss, q

(kPa

)

03

frequency of 1 Hzqmin Liquefaction

( i.e. r =1)u

(b)

Mean effective stress, p' (kPa)

Isotropicallyconsolidatedat =50 kPa

Mon

otonic

shea

ring w

ithou

t

cycli

c loa

ding h

istor

y

Mon

otonic

shea

ring a

fter

lique

factio

n

03

q

0

max

Dev

iato

r stre

ss, q

(kPa

)

qmin

Figure 5. Schematic representation of multi-stage tests (a) cyclic loading and post-cyclic monotonic shearing and (b) the corresponding stress path in the current study

Page 33 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

8

(a)

0 20 40 60-30

-20

-10

0

10

20

30D

evia

tor s

tress

, q (k

Pa)

Mean effective stress, p' (kPa)

Uncemented Sand, CSR=0.12(b)

0 4 8 12 16 20-0.6

-0.4

-0.2

0.0

0.2

0.4

Axia

l stra

in,

a(%

)

Number of cycles, Nc

Uncemented sand, CSR=0.12Residual strain

(c)

0 4 8 12 16 200.0

0.2

0.4

0.6

0.8

1.0

Exce

ss P

WP

ratio

, ru=

u/

' 0 3

Number of cycles, Nc

Uncemented Sand, CSR=0.12Residual EPWP

(d)

-0.6 -0.4 -0.2 0.0 0.2-30

-20

-10

0

10

20

30 Uncemented sand, CSR=0.12

Dev

iato

r stre

ss, q

(kPa

)

Axial strain, a (%)

Figure 6. Cyclic response of uncemented sand under CSR=0.12; variation of (a) mean effective stress with deviator stress; (b) axial strain with the number of cycles; (c) excess pore water pressure ratio with the number of cycles; (d) cyclic deviator stress with axial strain

Page 34 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

9

(a)

0 20 40 60-50

-25

0

25

50

Dev

iato

r stre

ss, q

(kPa

)

Mean effective stress, p' (kPa)

Cemented sand, CC=0.5%, CSR=0.27 (b)

0 5 10 15 200.50

0.25

0.00

-0.25

-0.50

-0.75

Axia

l stra

in,

a (%

)

Number of cycles, Nc

Cemented sand, CC=0.5%, CSR=0.27Residual strian

(c)

0 5 10 15 20

0.00

0.25

0.50

0.75

1.00

Exce

ss P

WP

ratio

, ru=

u/

' 0 3

Number of cyles, Nc

Cemented sand, CC=0.5%, CSR=0.27Residual EPWP

(d)

-0.75 -0.50 -0.25 0.00 0.25 0.50-50

-25

0

25

50 Cemented sand, CC=0.5%, CSR=0.27

Dev

iato

r stre

ss, q

(kP

a)

Axial strain, a (%)

Figure 7. Cyclic response of cemented sand with 0.5% cement content under CSR=0.27; variation of (a) mean effective stress with deviator stress; (b) axial strain with the number of cycles; (c) excess pore water pressure ratio with the number of cycles; (d) cyclic deviator stress with axial strain

Page 35 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

10

(a)

0 20 40 60 80

-50

0

50

Dev

iato

r stre

ss, q

(kPa

)

Mean effective stress, p' (kPa)

Cemented sand, CC=1%, CSR=0.38 (b)

0 10 20 30 40 50-0.75

-0.50

-0.25

0.00

0.25

Axia

l stra

in,

a (%

)

Number of cyles, Nc

Cemented sand, CC=1%, CSR=0.38Residual axial strain

(c)

0 10 20 30 40 50-0.5

0.0

0.5

1.0

Exce

ss P

WP

ratio

, ru=

u/'

3

Number of cyles, Nc

Cemented sand, CC=1%, CSR=0.38Residual EPWP

(d)

-0.75 -0.50 -0.25 0.00 0.25

-50

0

50

Cemented sand, CC=1%, CSR=0.38

Dev

iato

r stre

ss, q

(kPa

)

Axial strain, a (%)

Figure 8. Cyclic response of cemented sand with 1% cement content under CSR=0.38; variation of (a) mean effective stress with deviator stress; (b) axial strain with the number of cycles; (c) excess pore water pressure ratio with the number of cycles; (d) cyclic deviator stress with axial strain

Page 36 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

11

1 10 100 10000.00

0.25

0.50

0.75

1.00

Cyc

lic s

tress

ratio

, CS

R=q

' 0 3)

Number of cycles to trigger liquefaction, Nf

CC=2.0% Sydney sandCC=1.0%CC=0.5%

Cemented sand Uncemented sand

Figure 9. Effect of degree of cementation on liquefaction resistance

Page 37 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

12

0.0 0.2 0.4 0.6 0.8 1.00.0

0.2

0.4

0.6

0.8

1.0

Res

idua

l exc

ess

pore

wat

er p

ress

ure

ratio

, Ru-

res

Normalised cycle number, Nc/Nf

CSR=0.12 CSR=0.14CSR=0.15CSR=0.16

Uncemented sand

R2=0.99

Booker et al. (1976)

2 Nc

NfR

u-res = sin-1[( ) ]

Figure 10. Residual excess pore water pressure ratio of uncemented sand for different cyclic stress ratio

Page 38 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

13

(a)

0.0 0.2 0.4 0.6 0.8 1.00.0

0.2

0.4

0.6

0.8

1.0

R2=0.99

Booker et al. (1976)

NcNf

Res

idua

l exc

ess

pore

wat

er p

ress

ure

ratio

, Ru-

res

Normalised cycle number, Nc/Nf

CSR=0.17CSR=0.23CSR=0.27CSR=0.31CSR=0.34

Cemented sandCC=0.5%

Ru-res= a.( )b.c(Nc / Nf)

R2=0.79

Porcino et al. (2015)

2 Nc

NfR

u-res = sin-1[( ) ]

Model parametersa b c

0.44 0.34 2.3

(b)

0.0 0.2 0.4 0.6 0.8 1.00.0

0.2

0.4

0.6

0.8

1.0Cemented sand

Res

idua

l exc

ess

pore

wat

er p

ress

ure

ratio

, Ru-

res

Normalised cycle number, Nc/Nf

CSR=0.22 CSR=0.42CSR=0.38 CSR=0.50CSR=0.42 CSR=0.72CSR=0.48

Model parametersa b c

0.82 0.5 0.96

CC=1.0% CC=2.0%

R2=0.49

R2=0.98

NcNf

Ru-res= a.( )b.c(Nc / Nf)

Porcino et al. (2015)

Booker et al. (1976)

2 Nc

NfR

u-res = sin-1[( ) ]

Figure 11. Residual excess pore water pressure ratio for cemented sand with (a) cement content of 0.5% and (b) 1 and 2%

Page 39 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

14

(a)

0.01 0.1 10.0

0.2

0.4

0.6

0.8

1.0

Cemented sand,

CSR=0.17 CSR=0.12CSR=0.23 CSR=0.14CSR=0.27 CSR=0.15CSR=0.31 CSR=0.16CSR=0.34

Cyc

lic s

tiffn

ess

degr

adat

ion

inde

x,

=(G

sN /G

s1)

Normalised cycle number, Nc/Nf

Uncemented sand

Uncemented sandCC=0.5%

Increasing CSR

(b)

0.01 0.1 10.0

0.2

0.4

0.6

0.8

1.0

Cemented sand

CSR=0.22 CSR=0.42 CSR=0.38 CSR=0.50 CSR=0.42 CSR=0.72 CSR=0.48

Cyc

lic s

tiffn

ess

degr

adat

ion

inde

x,

=(G

sN /G

s1)

Normalised cycle number, Nc/Nf

CC=2.0%CC=1.0%

Uncemented sand

Figure 12. Cyclic stiffness degradation index of Sydney sand in comparison to cemented sand with cement content ratio of (a) and (b) with normalized cycle number 𝐶𝐶 = 0.5% 𝐶𝐶 = 1.0 and 2.0%

Page 40 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

15

(a)

1 0.1 0.010.01

0.1

1

= d + e. fRuf-res

Ruc

-res

/Ruf

-res

Cyclic stiffness degradation index, =(GsN / Gs1)

CSR=0.12CSR=0.14CSR=0.15CSR=0.16

Uncemented sand

Ruc-res

R2=0.98

Model parametersd e f

1.1 -0.95 0.72

(b)

1 0.1 0.010.01

0.1

1

Cemented sand

Ruc

-res/R

uf-re

s

Cyclic stiffness degradation index, =(GsN /Gs1)

CSR=0.17CSR=0.23CSR=0.27CSR=0.31CSR=0.34

Model parametersd e f

1.02 -0.92 0.99

CC=0.5%R2=0.98

= d + e. fRuf-res

Ruc-res

(c)

1 0.1 0.010.01

0.1

1

CC=2.0%

Ruc

-res

/Ruf

-res

Cyclic stiffness degradation index, =(GsN /Gs1)

CSR=0.22 CSR=0.42CSR=0.38 CSR=0.50CSR=0.42 CSR=0.72CSR=0.48

Cemented sandCC=1.0%

= d + e. fRuf-res

Ruc-res

Model parametersd e f

1.01 -0.89 1.46

R2=0.97

Figure 13. Normalised residual excess pore water pressure (a) for uncemented sand and cemented sand with cement contents of (b) 0.5% (c) 1 and 2% based on cyclic stiffness degradation index

Page 41 of 48

https://mc06.manuscriptcentral.com/cgj-pubs

Canadian Geotechnical Journal

-

Draft

16

(a)

0 5 10 15 20 250

500

1000

1500

Without cyclic loading Post-cyclic, CSR=0.14 Post-cyclic, CSR=0.15 Post-cyclic, CSR=0.16 Post-cyclic, CSR=0.12

Dev

iato

r Stre

ss, q

(kP

a)

Axial Strain, a (%)

Uncemented sand(b)

0 5 10 15 20 250

500

1000

1500

Without Cyclic loading Post-cyclic, CSR=0.17 Post-cyclic, CSR=0.27 Post-cyclic, CSR=0.34

Dev

iato

r Stre